Isoepitaxial-growth gallium-nitride-base photocatalytic material and preparation method thereof

A photocatalytic material, gallium nitride-based technology, applied in the field of gallium nitride-based photocatalytic materials and its preparation, can solve the problems of substrate and GaN lattice mismatch, thermal expansion coefficient mismatch, etc., achieve excellent degradation activity, improve Effects of catalytic activity and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

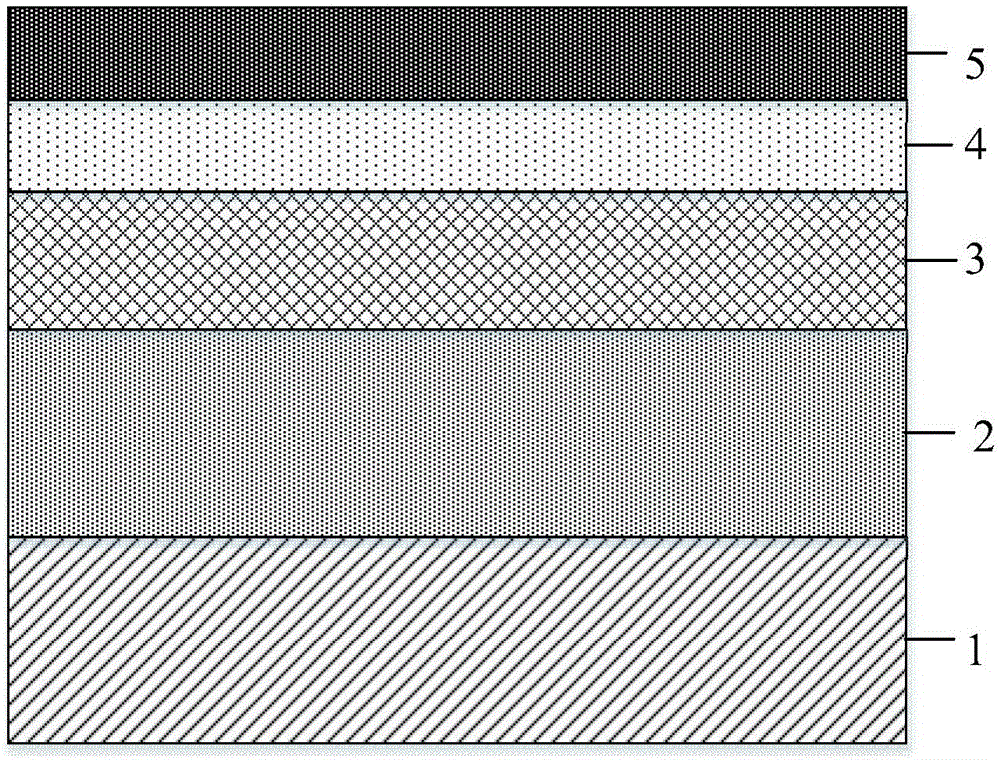

[0031] Such as figure 1 As shown, the homoepitaxially grown gallium nitride-based photocatalytic material of this embodiment includes from bottom to top: n-type gallium nitride-based substrate 1, n-GaN layer 2, multiple quantum well layer 3, p-GaN Layer 4 and metal layer 5.

[0032] The preparation method of the homoepitaxially grown gallium nitride-based photocatalytic material of this embodiment comprises the following steps:

[0033] 1) A Ge-doped n-type gallium nitride-based substrate 1 grown by hydride vapor phase epitaxy (HVPE), the substrate has a resistivity of less than 0.05Ω·cm at a temperature of 300K, a size of 10.0mm×10.5mm, and a thickness of 350± 25 μm, the crystal orientation is c-plane (0001) direction.

[0034]2) Using MOCVD growth system, using trimethylgallium TMGa, trimethylindium TMIn, trimethylaluminum TMAl as gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com