Slot turning process for stator coil and auxiliary tooling device thereof

A stator coil and groove turning technology, which is applied in the direction of prefabricated winding embedded in the motor, etc., can solve the problems of coil damage, unreliable coil insulation, difficult control of coil deformation, etc., and achieve the effect of improving reliability and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

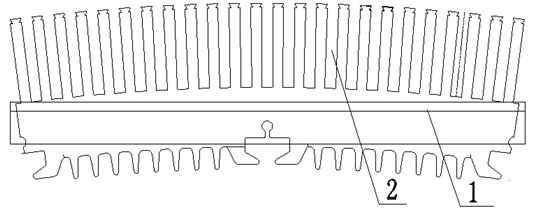

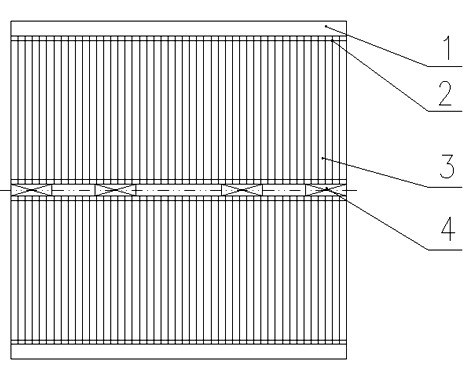

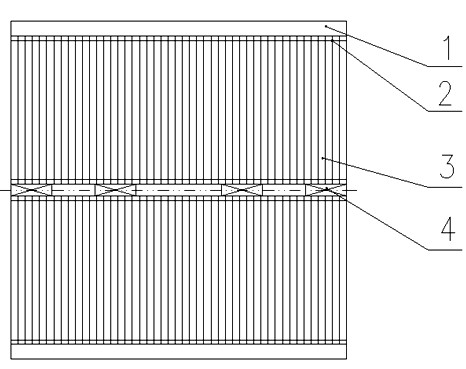

[0012] The invention is a stator coil groove turning process. The expanded coil is flat-wrapped once with a white cloth tape, and the wrapping is compact. The white cloth tape is not allowed to be overlapped on the straight line, and then preformed in the groove turning mold. Then use wire rods and slot wedges to press the lower side of the coil tightly in the groove turning mold, and adjust the tightness through the pad; the lower side must be pressed tightly, otherwise the lower side will be deformed during the groove turning process. Then lift the first coil out of the core to a certain height, and the other coils are higher than the previous one by a certain distance; in the process of lifting the upper edge, force is required to be perpendicular to the core surface to provide a guarantee for the subsequent smooth insertion of the wire. When each co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com