Multifunctional hardware hammer

A multi-functional, hardware technology, applied in hand hammers, striking tools, hand-held tools, etc., can solve the problems of easy plugging, troublesome use, hidden dangers, etc., to achieve convenient control, ensure safety, and reduce impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

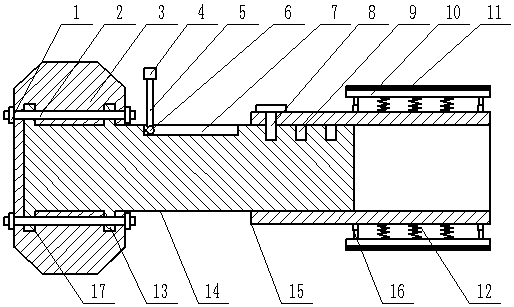

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

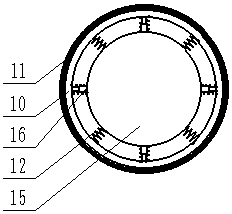

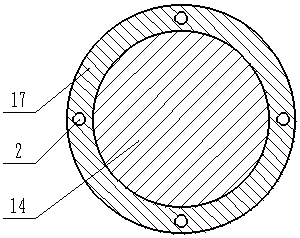

[0017] see Figure 1-3 , a multifunctional hardware hammer, comprising an inner sleeve 15, an outer sleeve 10, a hammer handle 14 and a hammer head 3, the outer side wall sliding sleeve of the hammer handle 14 is provided with an inner sleeve 15, and the hammer handle 14 is provided with a A plurality of threaded holes 9, the inner sleeve 15 is provided with bolts 8; the outer side of the inner sleeve 15 is provided with an outer sleeve 10, and the middle part between the outer sleeve 10 and the inner sleeve 15 passes through a plurality of The buffer spring 12 is fixedly connected; the two sides of the outer sleeve 10 and the inner sleeve 15 are evenly distributed with telescopic rods 16 in the circumferential direction, and the telescopic rods 16 include a sleeve and a sliding rod, and the sleeve is fixed to the outer wall of the inner sleeve 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com