Patents

Literature

62results about How to "Guaranteed normal extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

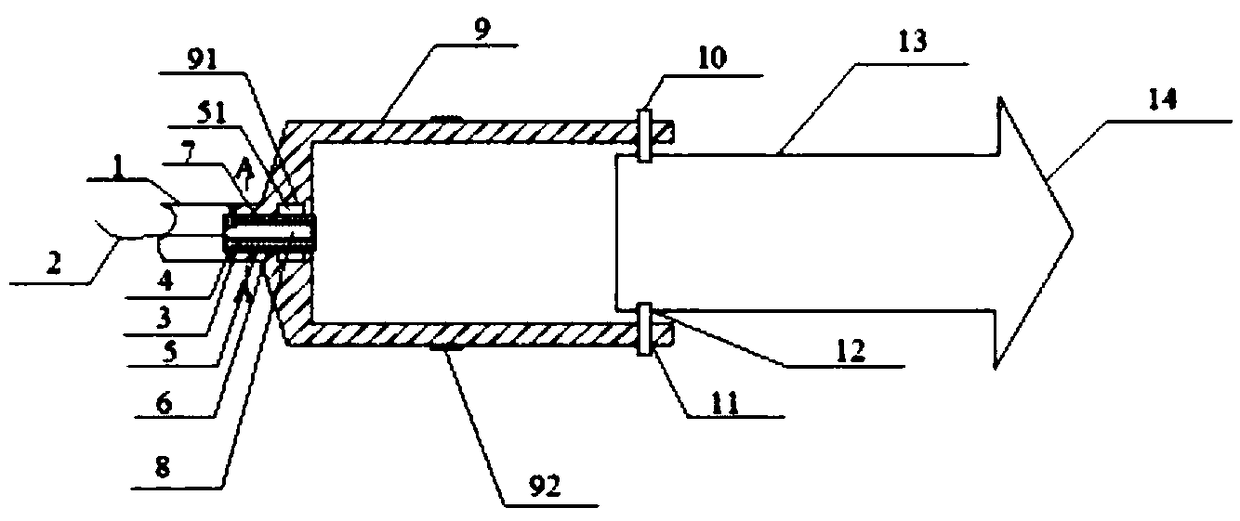

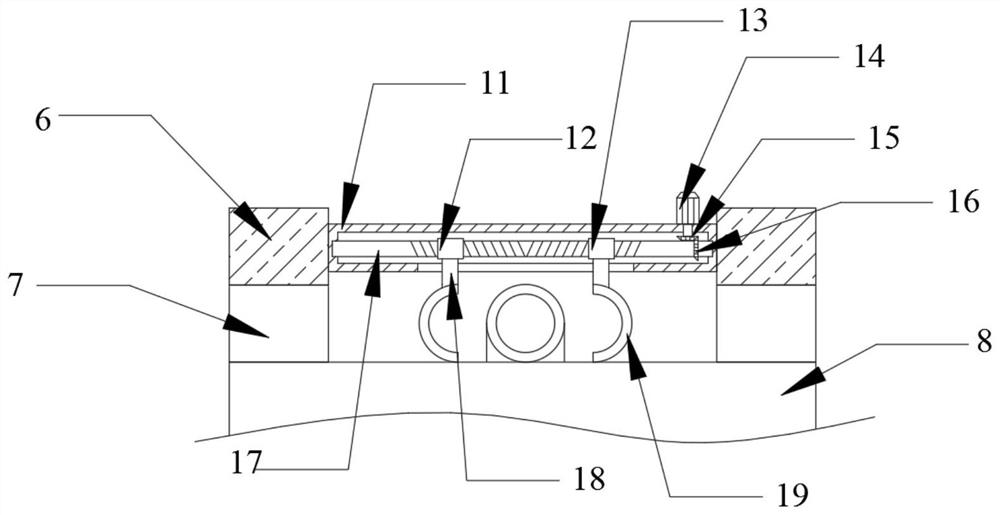

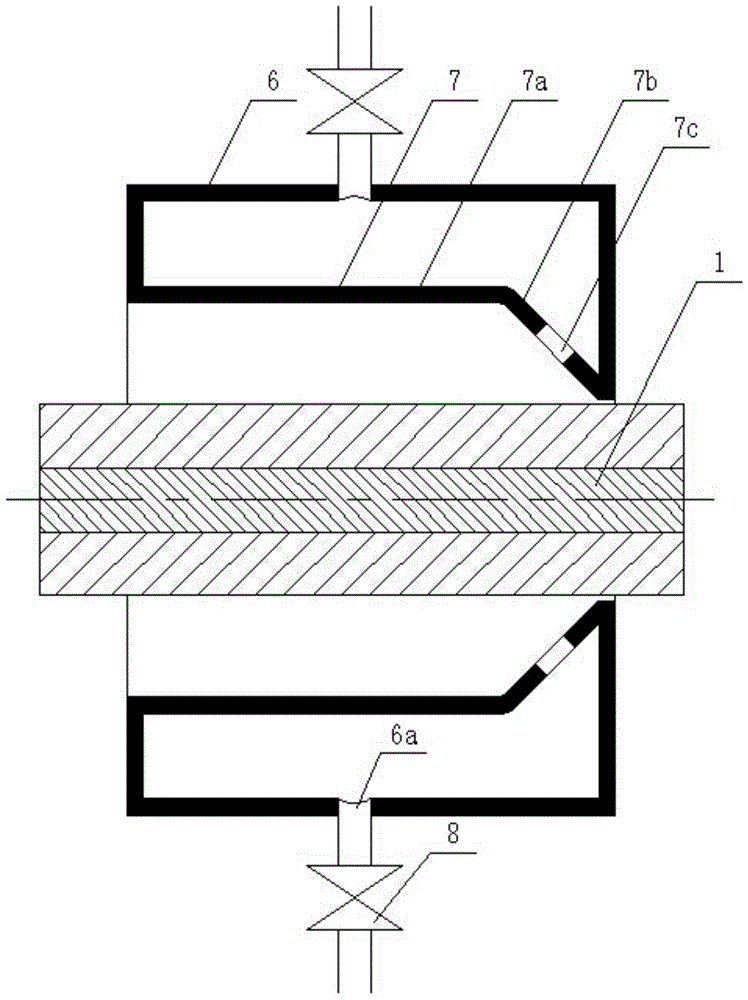

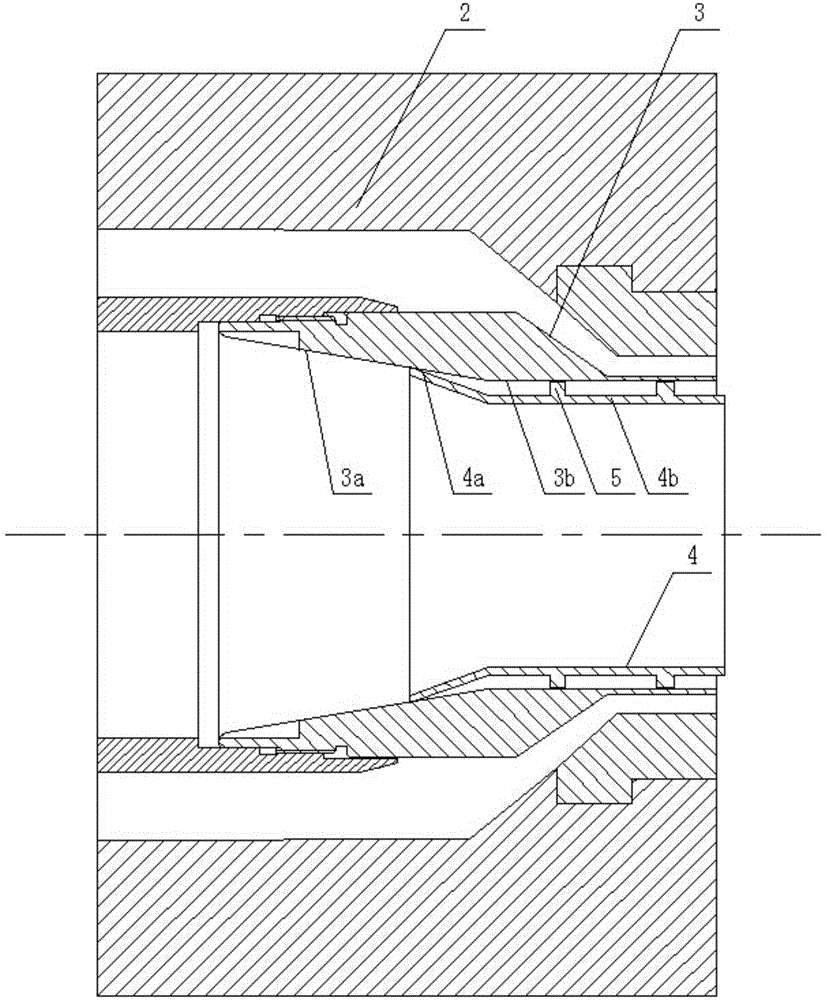

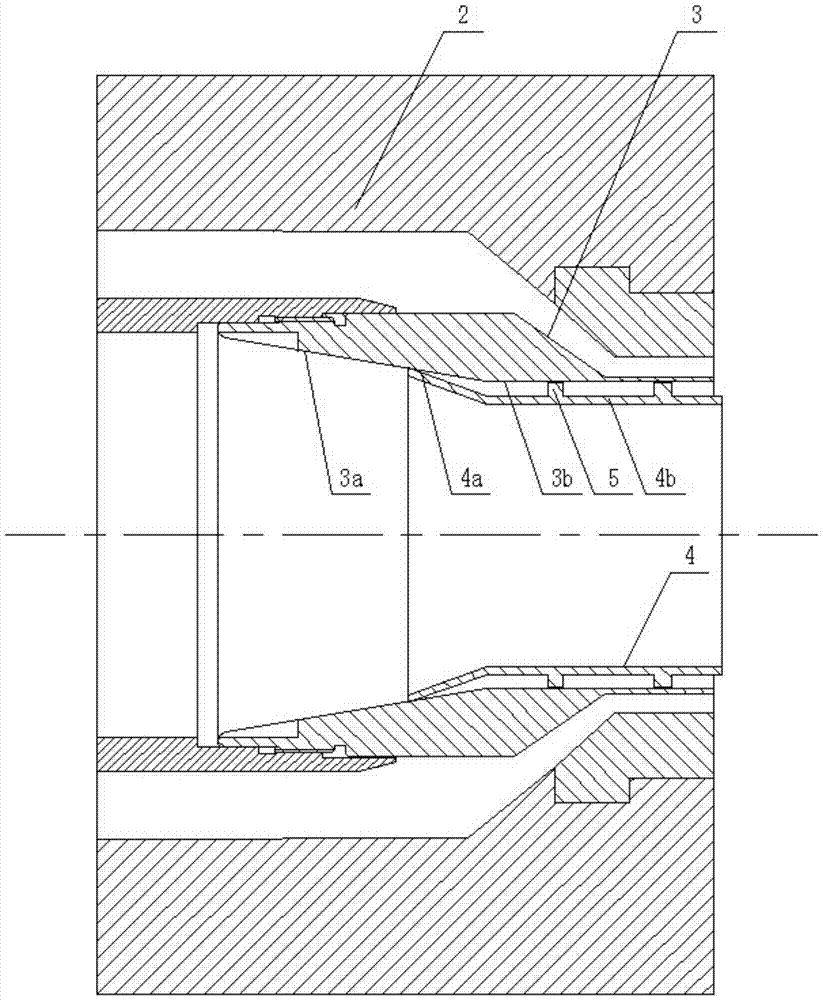

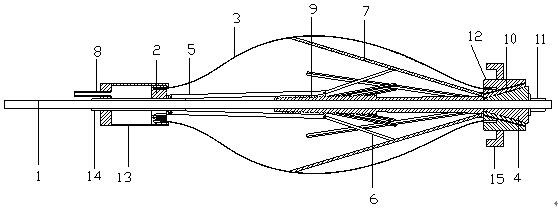

Dual-fluid synchronous slip casting and cleaning switching mechanism

InactiveCN101476469AAvoid cloggingAvoid clogged tubingUnderground chambersTunnel liningWater dischargeSlurry

The invention discloses a dual-liquid synchronous slurry injecting, cleaning and switching device, which comprises a slurry injection main pipeline, an outlet pipe, a switching valve core, a cleaning oil cylinder and a cleaning water pipe, wherein the slurry injection main pipeline comprises a mixing pipe used for supplying dual-slurry liquid and a plurality of slurry pipes which are connected with the mixing pipe; the heads and the tails of the slurry pipes are linked in sequence; the outlet pipe is an outlet of the slurry liquid, and the pipe wall is provided with through holes; the through holes are communicated with the outlet ends of the slurry pipes; the switching valve core is arranged in the pipe cavity of the outlet pipe in a way of sliding fit, and the pipe wall is provided with a plurality of water discharging holes; the water discharging holes can be blocked or communicated with the through holes of the outlet pipe through the axial slide of the switching valve core; the cleaning oil cylinder is connected with the switching valve core and drives the switching valve core to slide in the pipe cavity of the outlet pipe; and the cleaning water pipe is communicated with the water discharging holes of the switching valve core finally. The device realizes the automatic mixture of dual-slurry liquid, avoids the situation that the slurry liquid is solidified and blocks the pipelines, and can realize automatic switch to automatically clean the pipelines. The device is applicable to synchronous slurry injection construction in the shield method.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

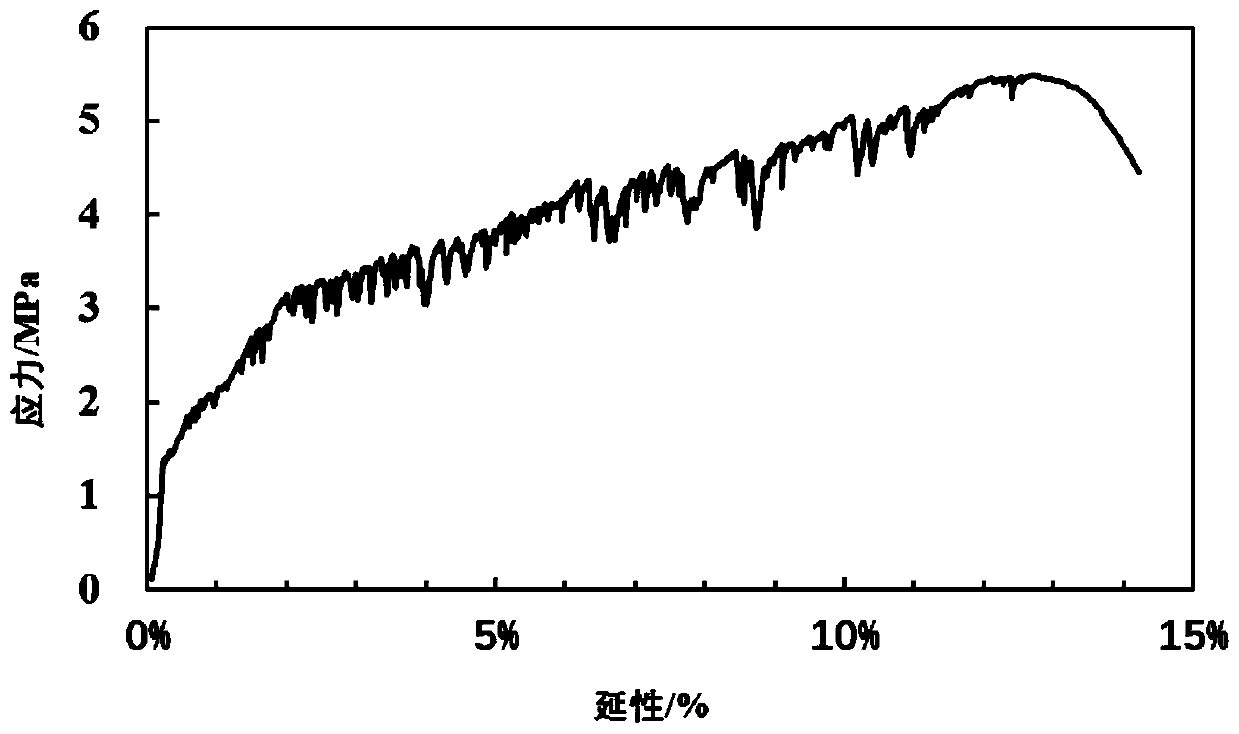

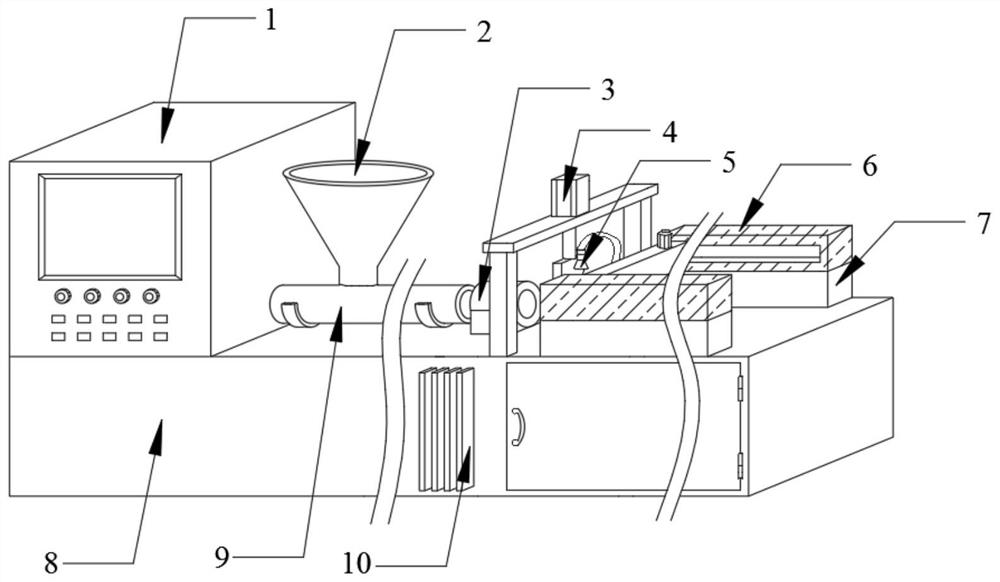

Fiber reinforced cement-based material for 3D printing, preparation, performance evaluation and application

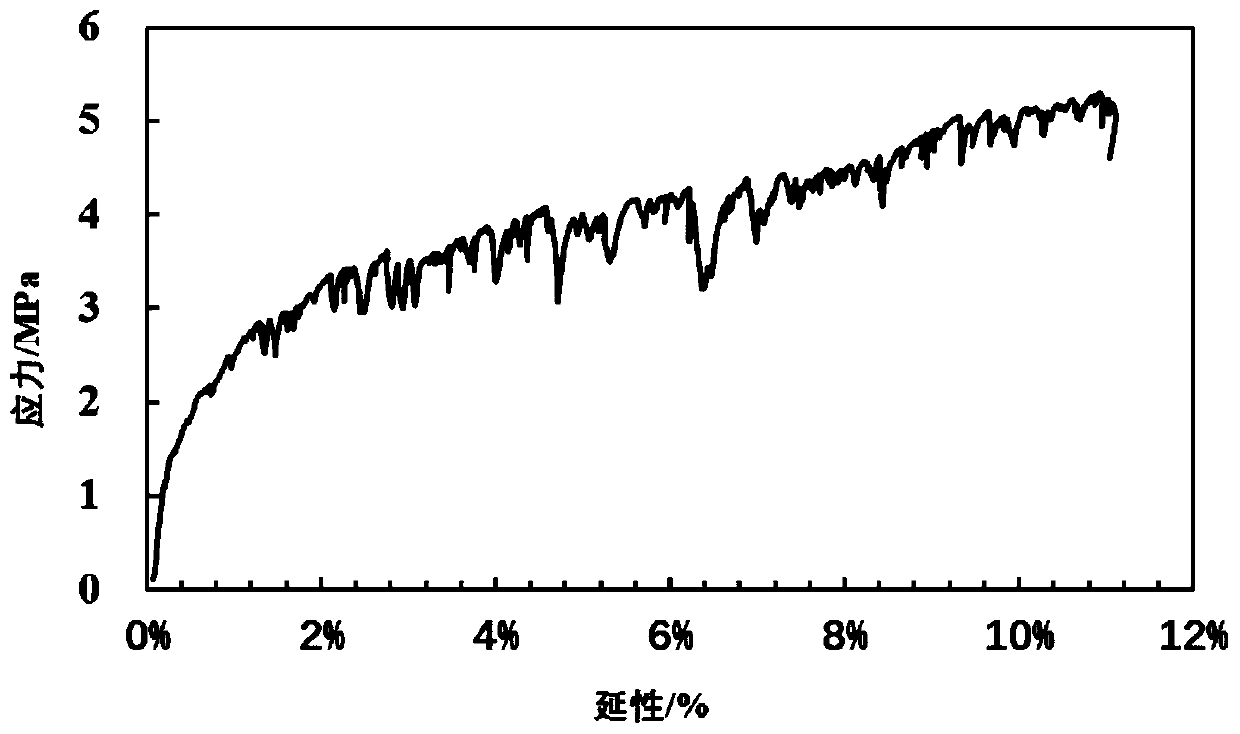

ActiveCN109942262AHigh tensile ductilityImprove bending strengthAdditive manufacturing apparatusFlow propertiesSocial benefitsHigh energy

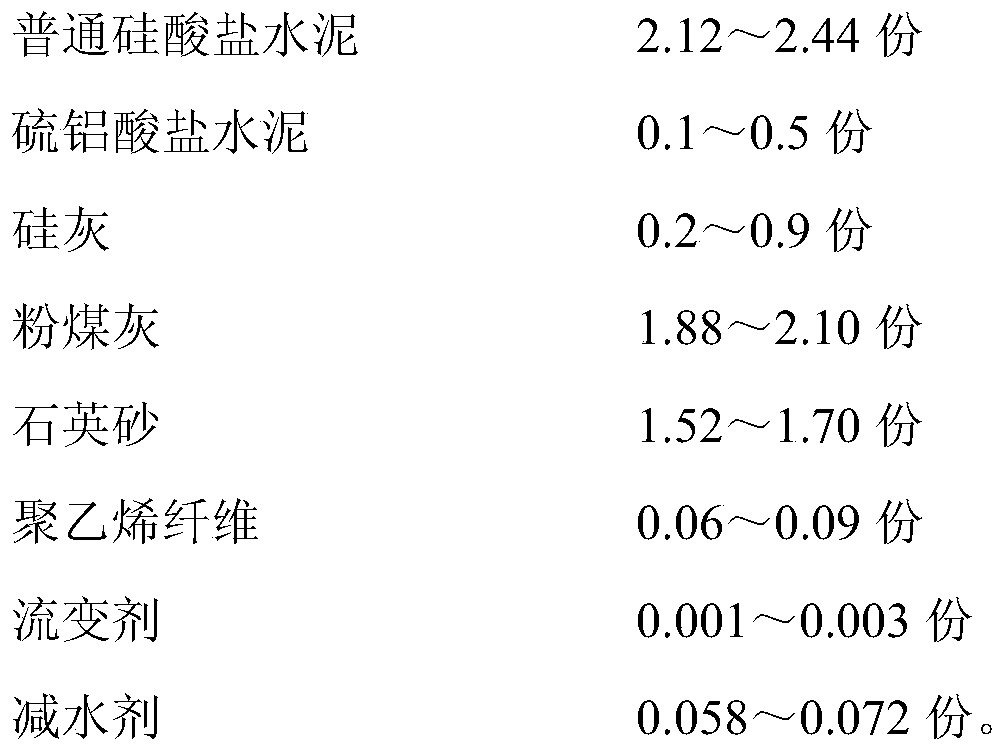

The invention discloses a fiber reinforced cement-based material (ECC) for 3D printing, preparation, performance evaluation and an application. The cement-based material is prepared by taking sulfatealuminum cement produced by industrial solid wastes fully as an early strength agent and doping polyethylene fiber relatively high in tensile strength and modulus. The cement-based material is introduced to 3D printing concrete and is applied to building 3D printing and a concrete structure or ribless construction of a member or pouring of the concrete structure, has the characteristics of strainstrengthening and multi-crack cracking under action of stretching and bending, has high ductility and high energy consumption, and solves the problem that a 3D printing concrete member is low in mechanical property. The fiber reinforced cement-based composite material is simple in preparation method, low in cost and low-carbon and environment-friendly, and has certain engineering demonstration meaning and social benefits. The invention also provides a 3D printing performance evaluation method of the material, including micro slump test, flowability test and rheological property test.

Owner:SOUTHEAST UNIV +1

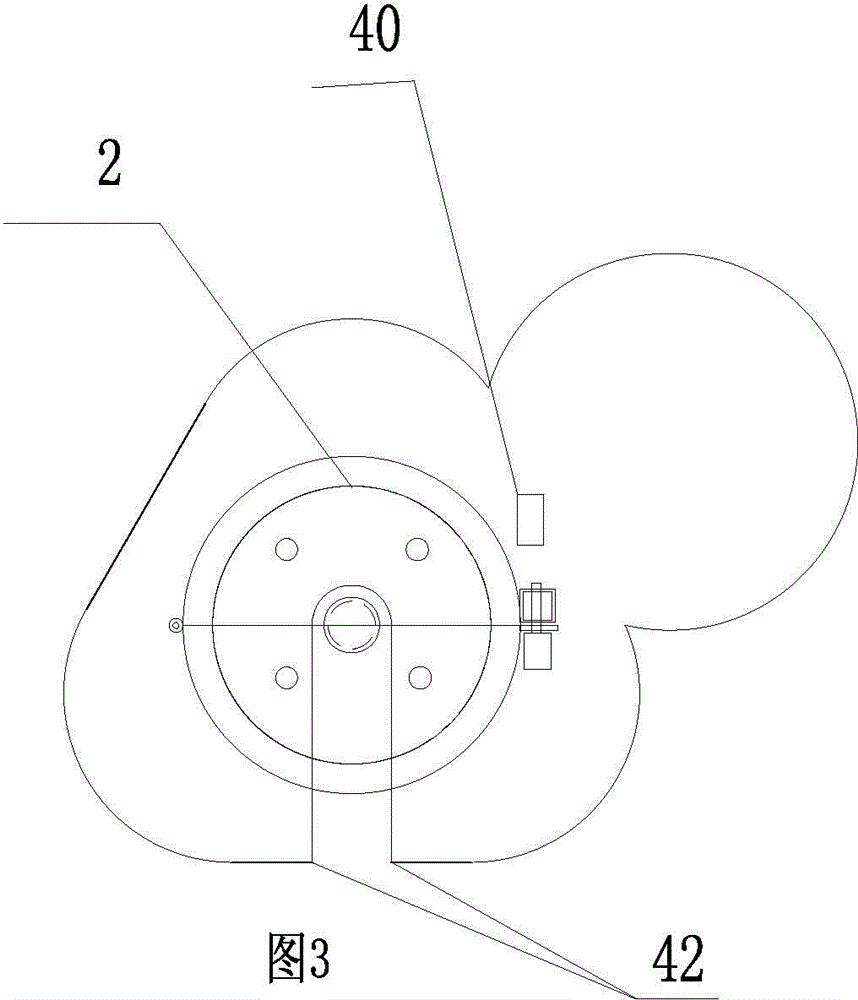

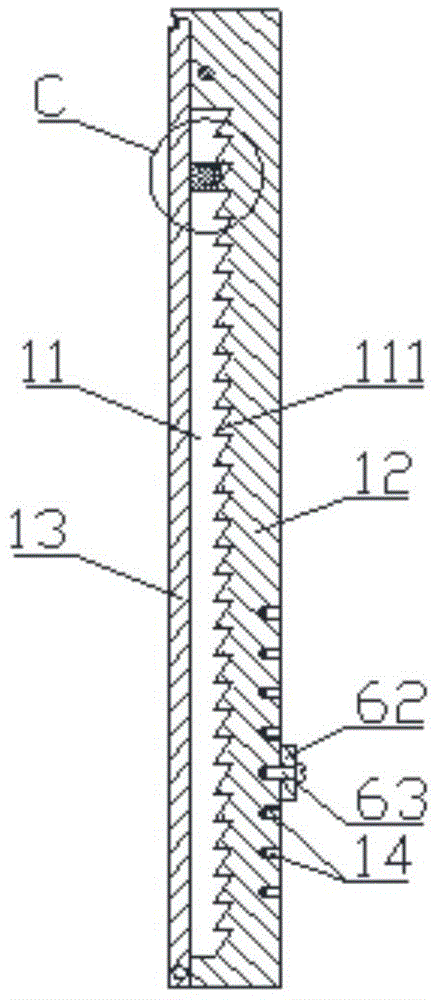

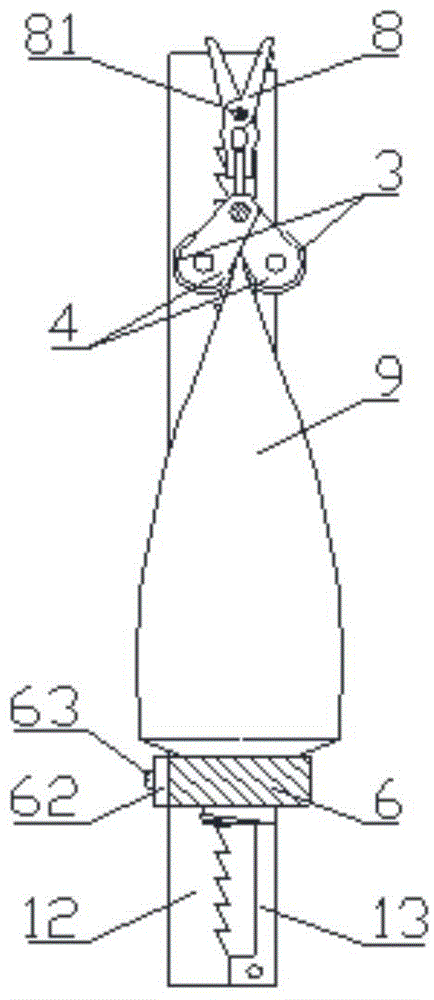

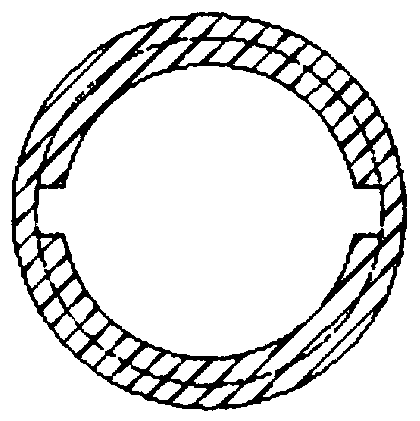

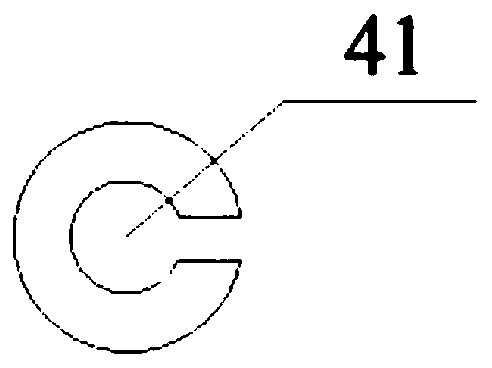

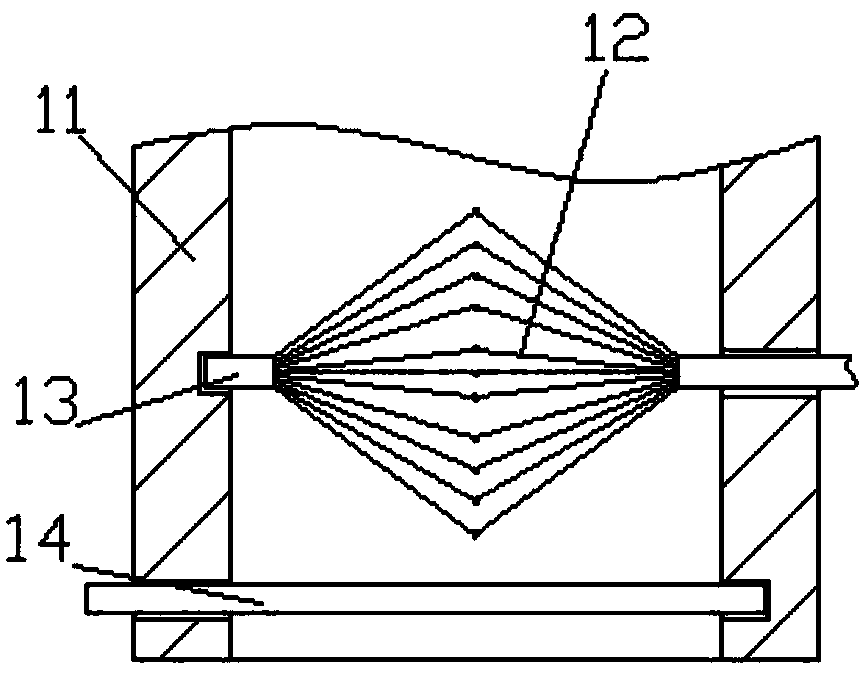

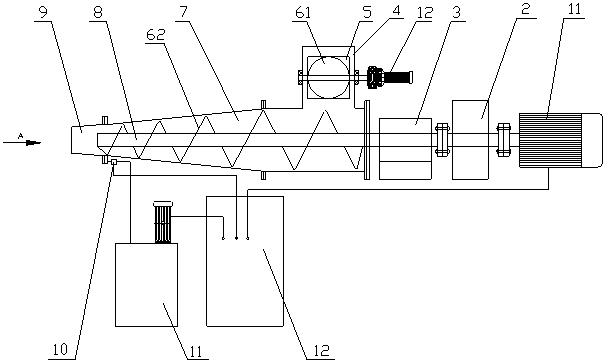

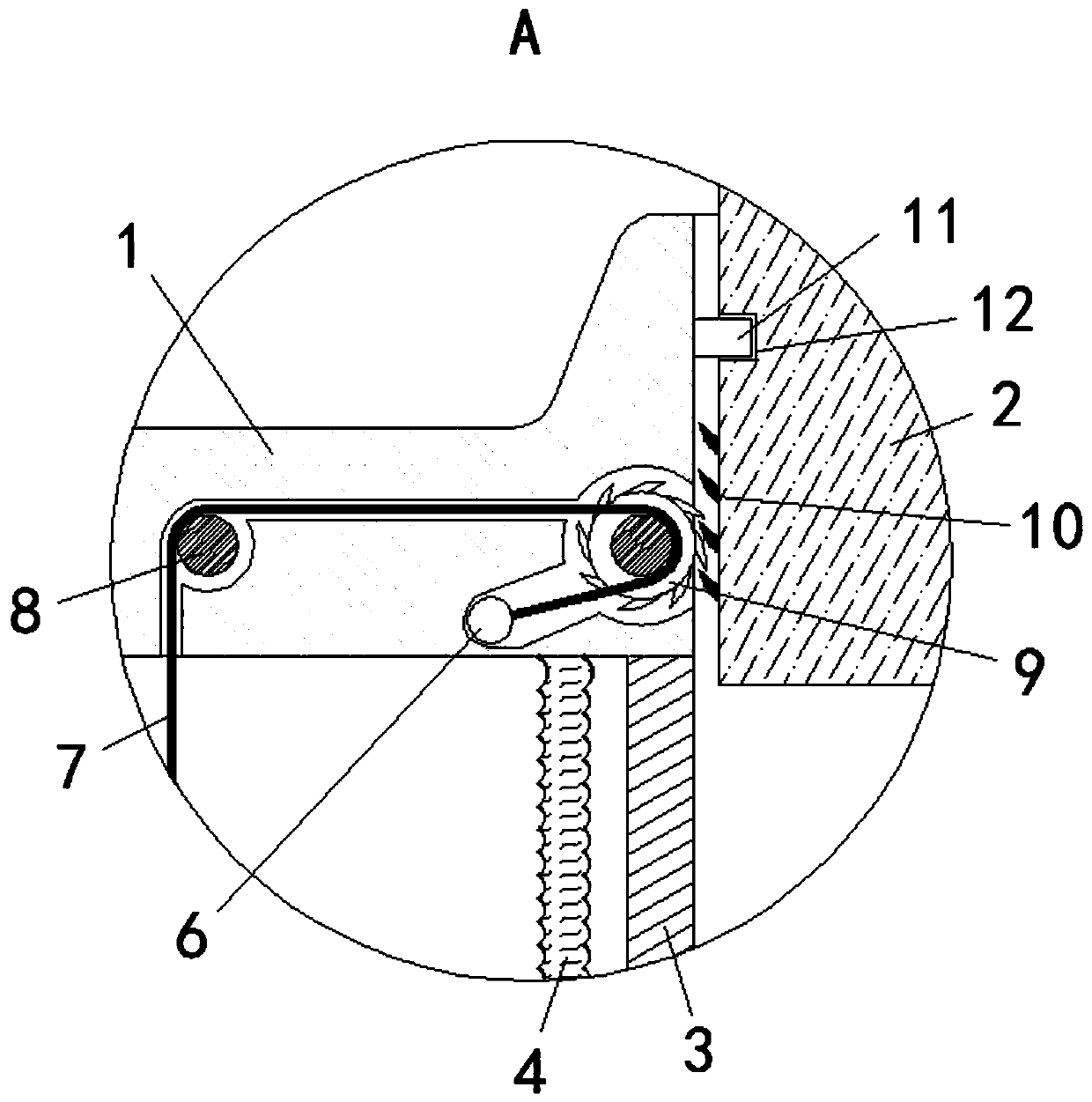

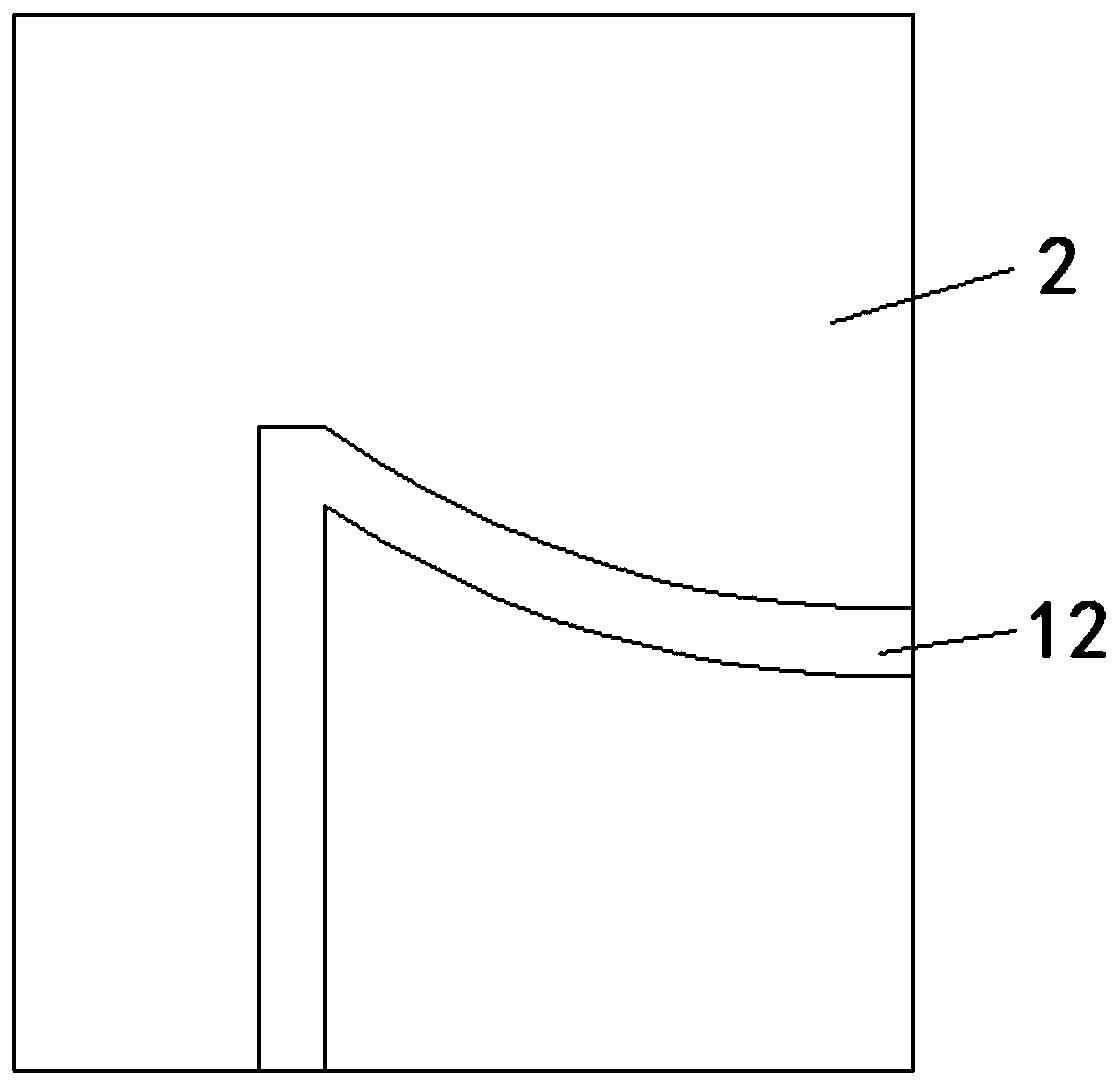

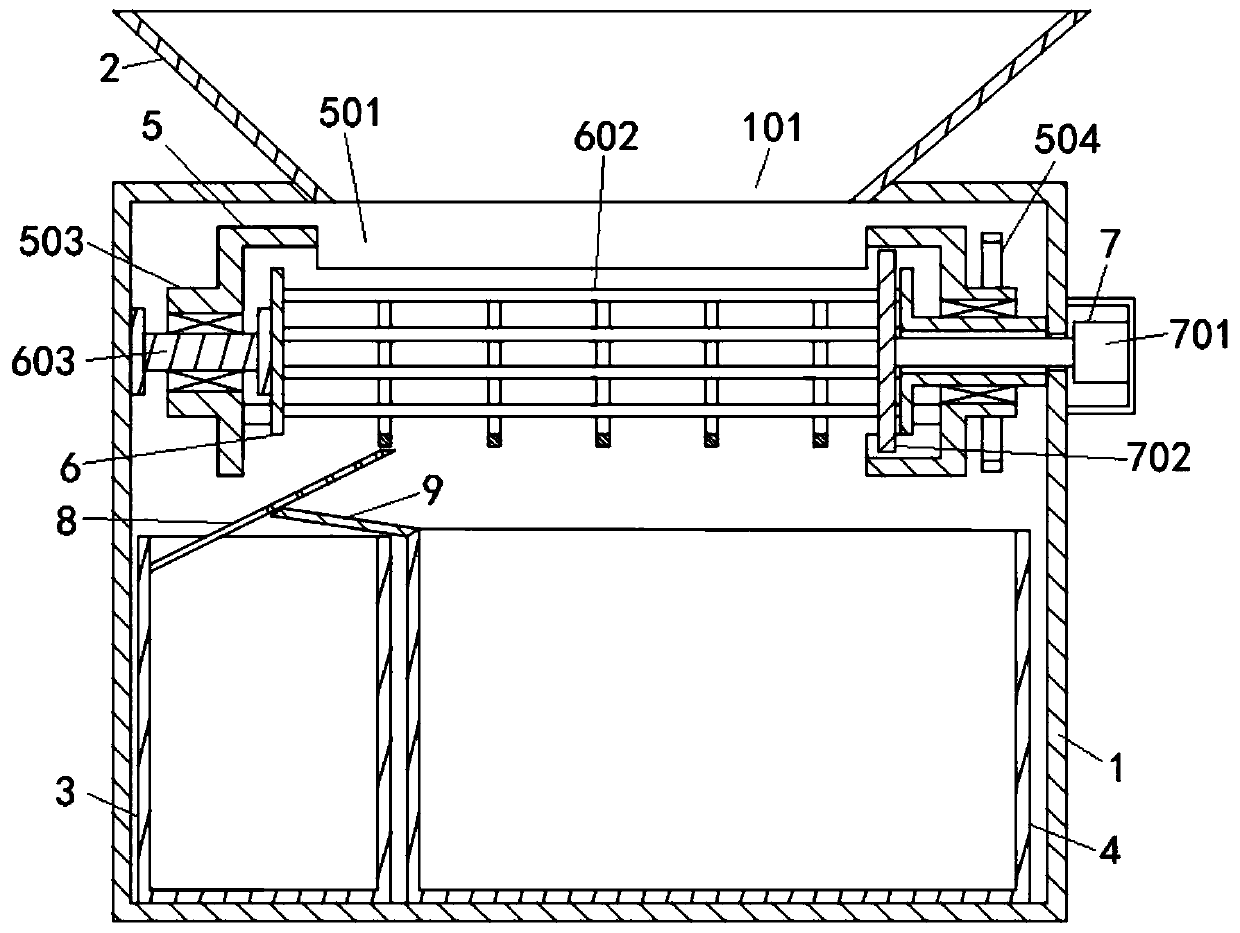

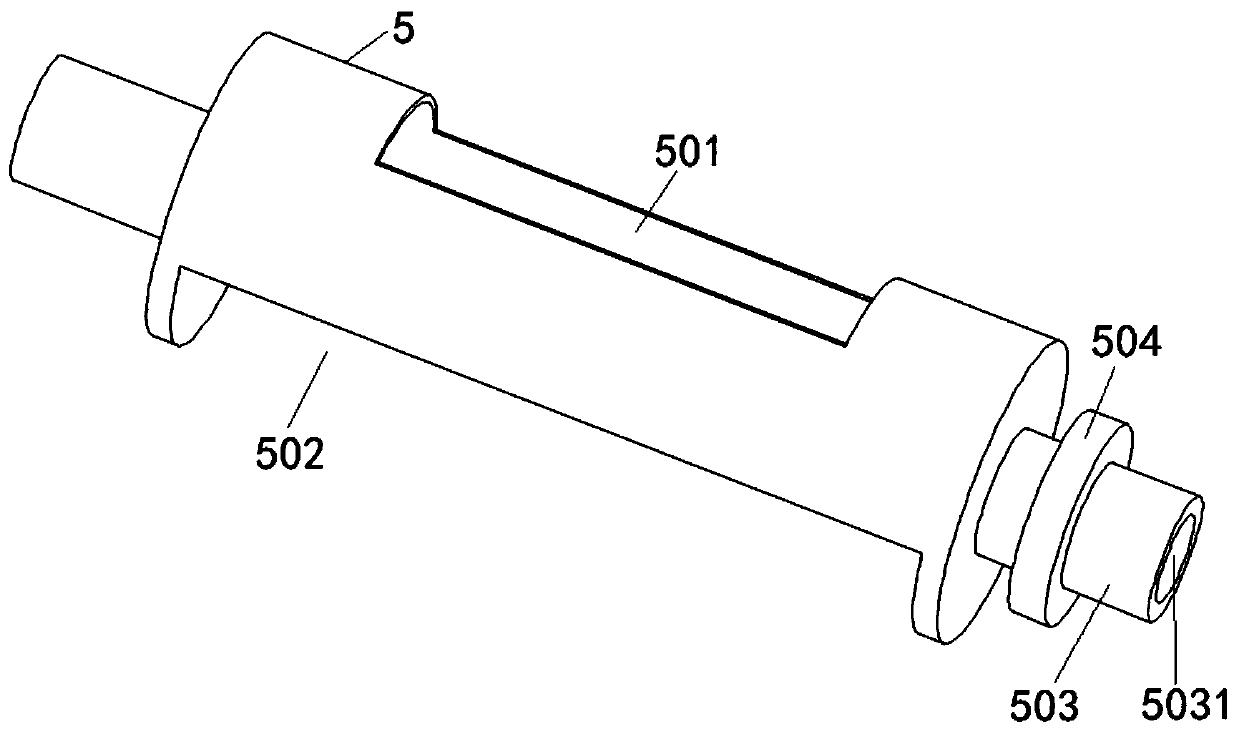

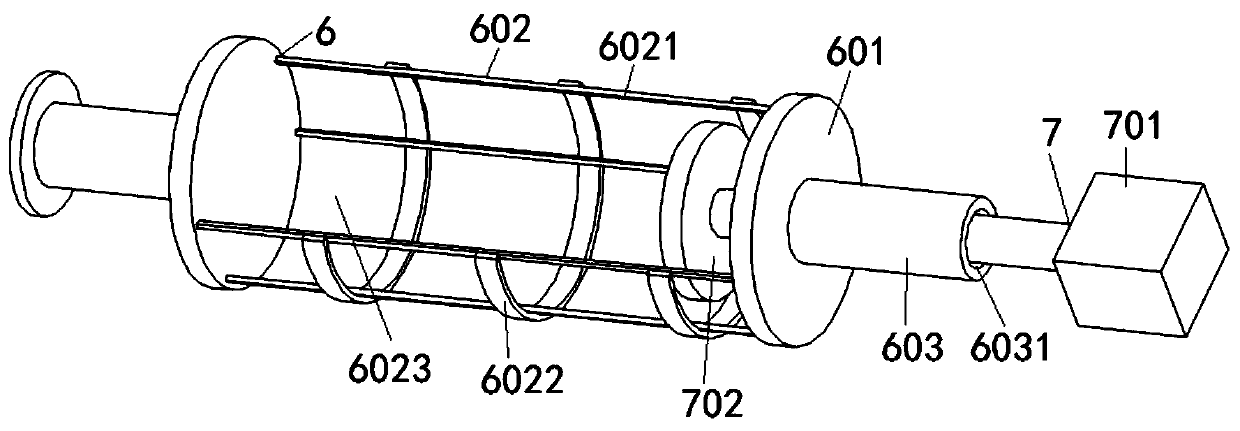

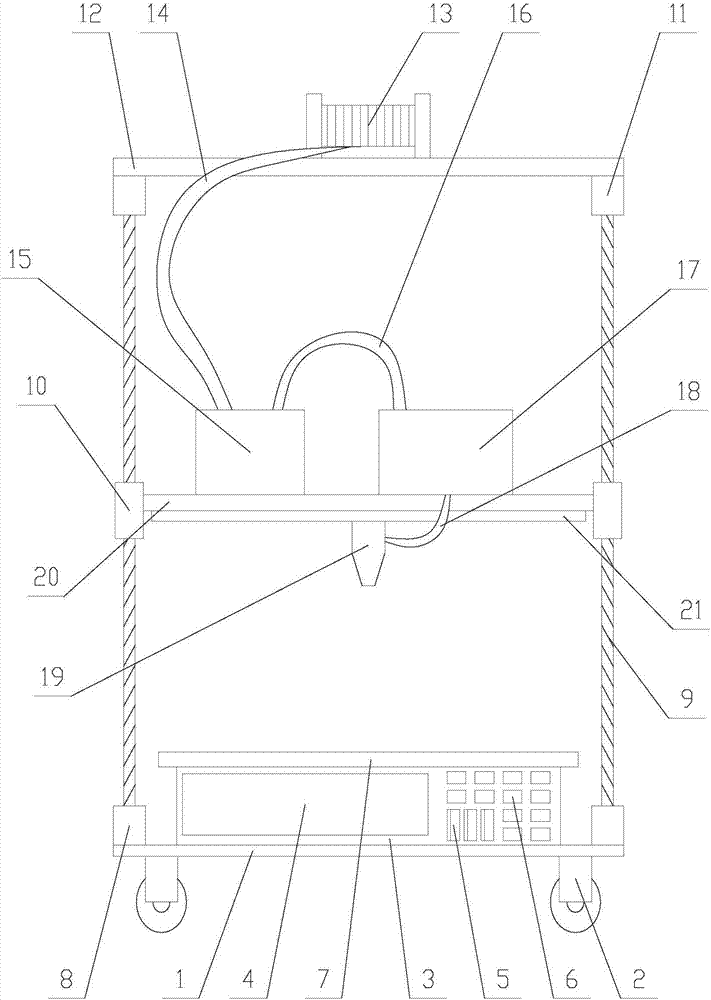

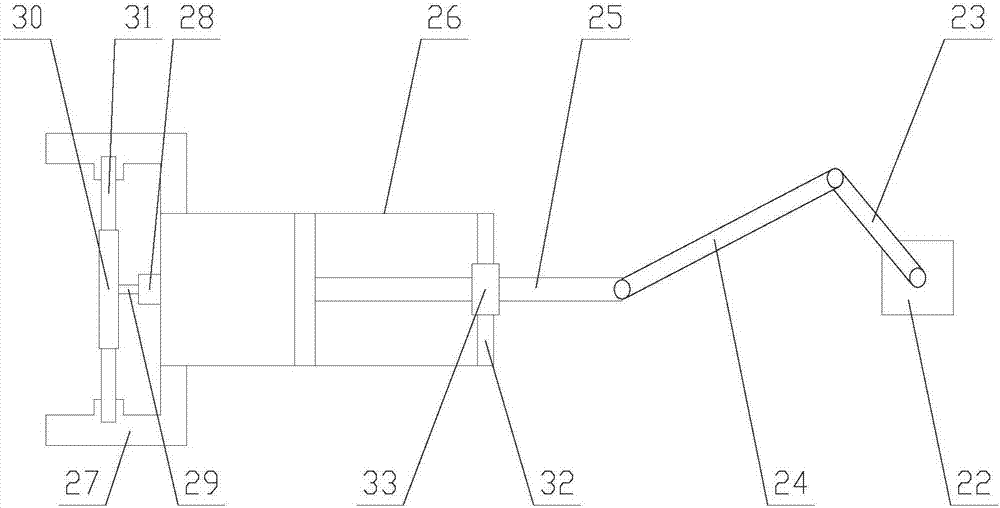

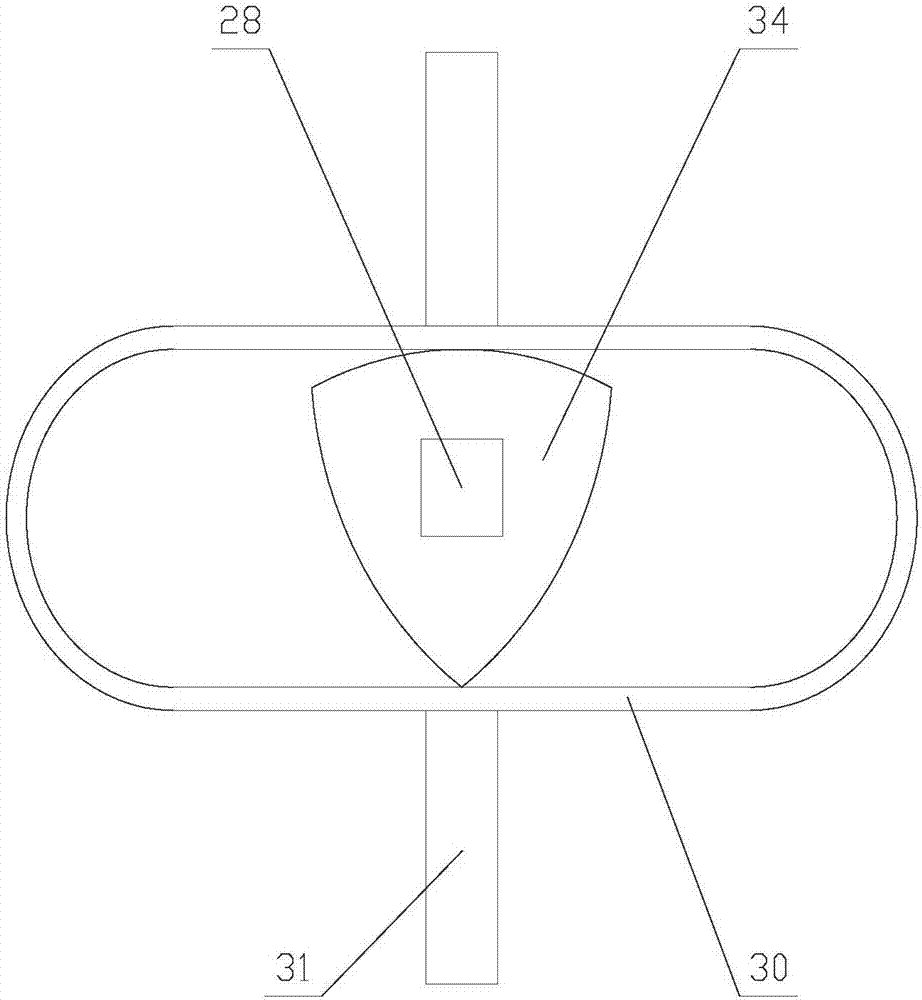

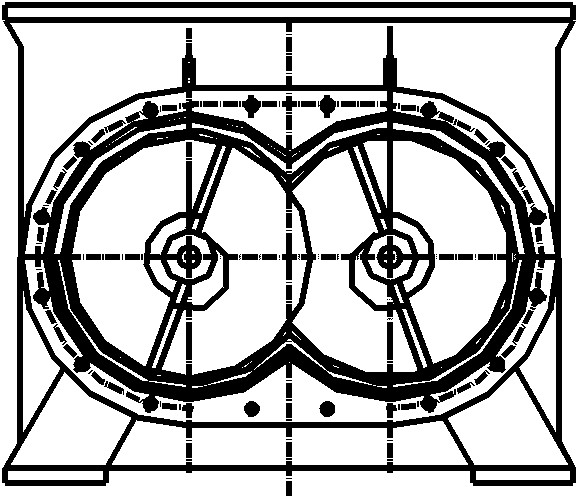

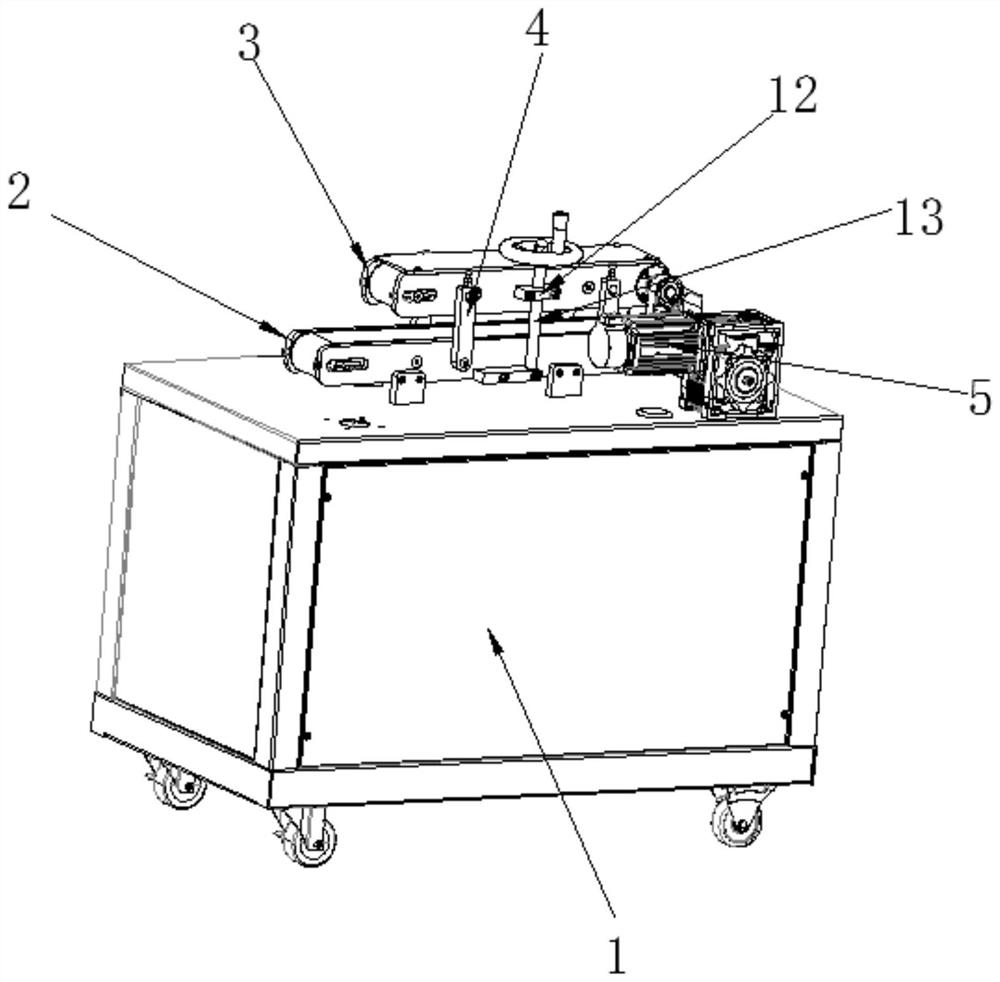

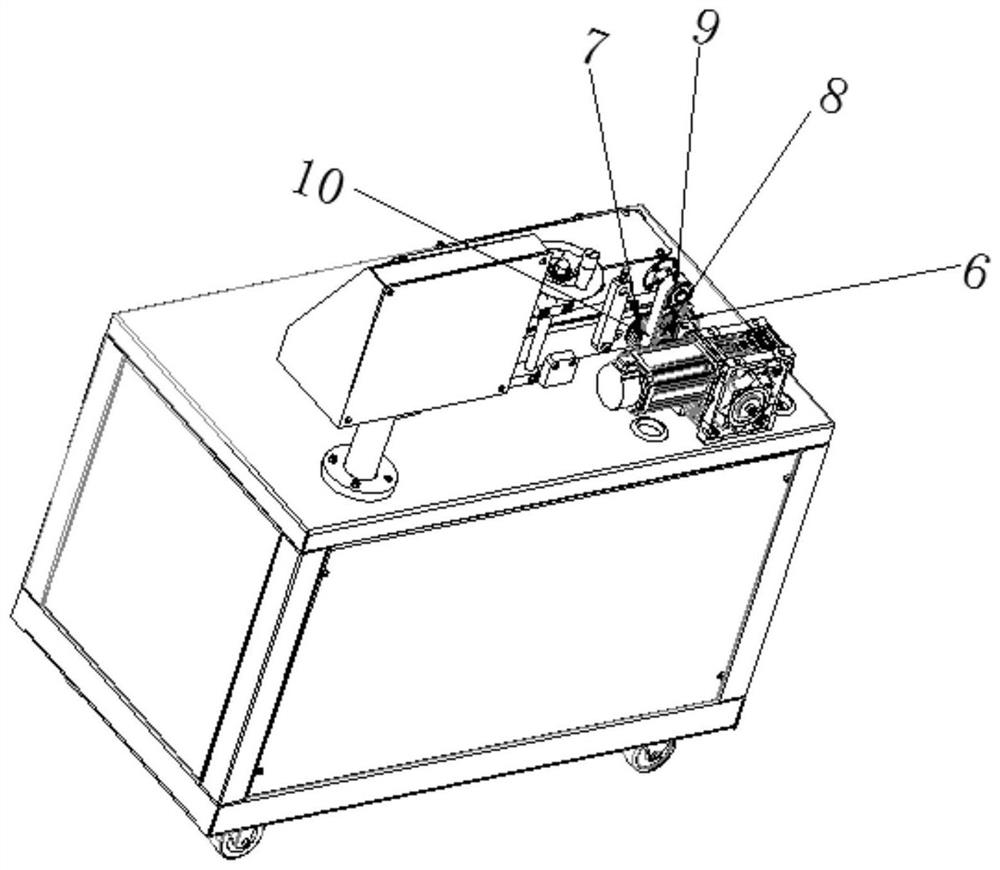

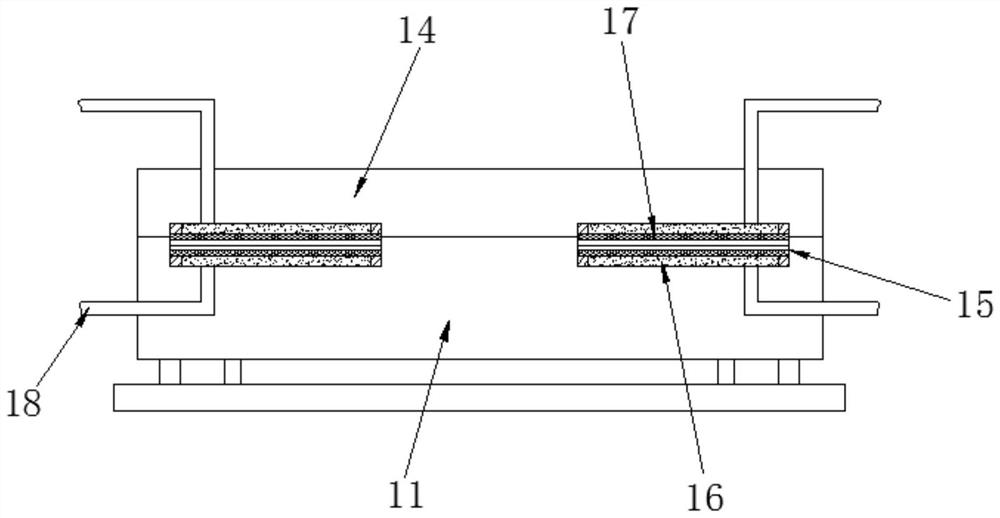

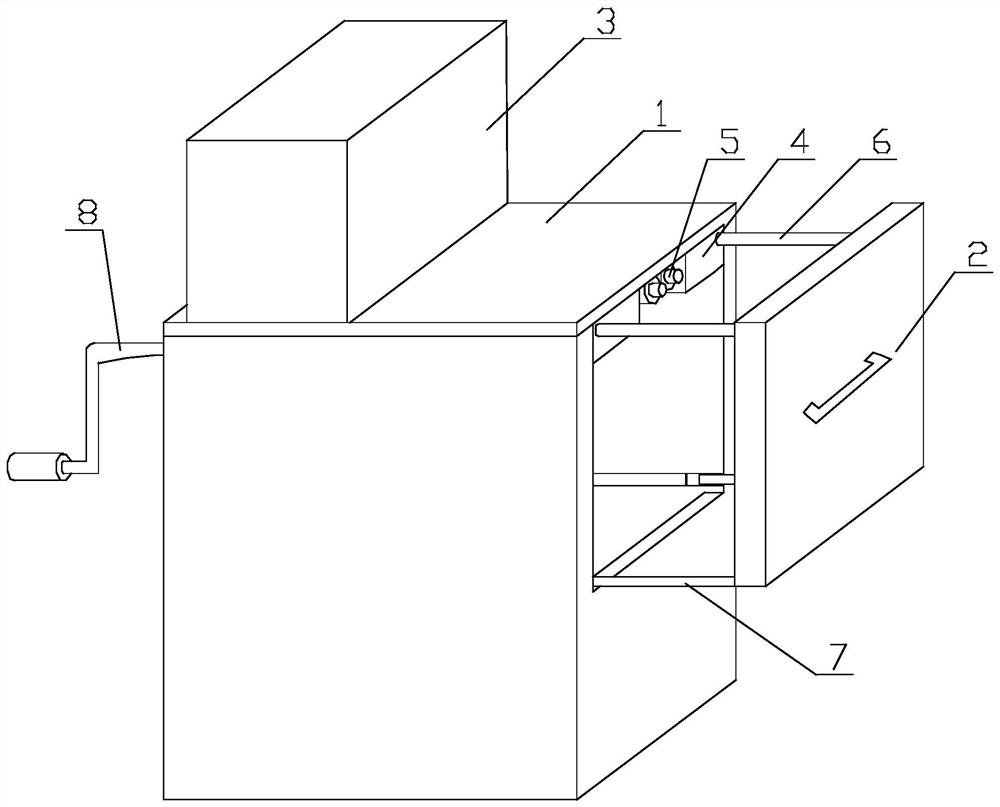

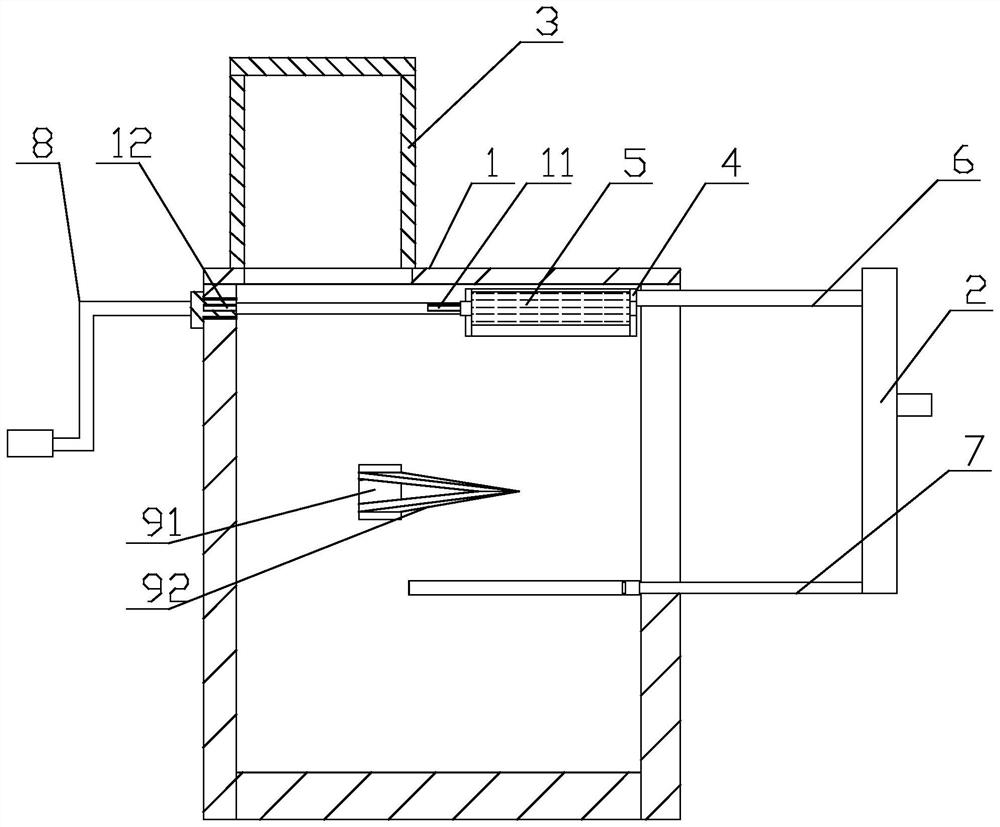

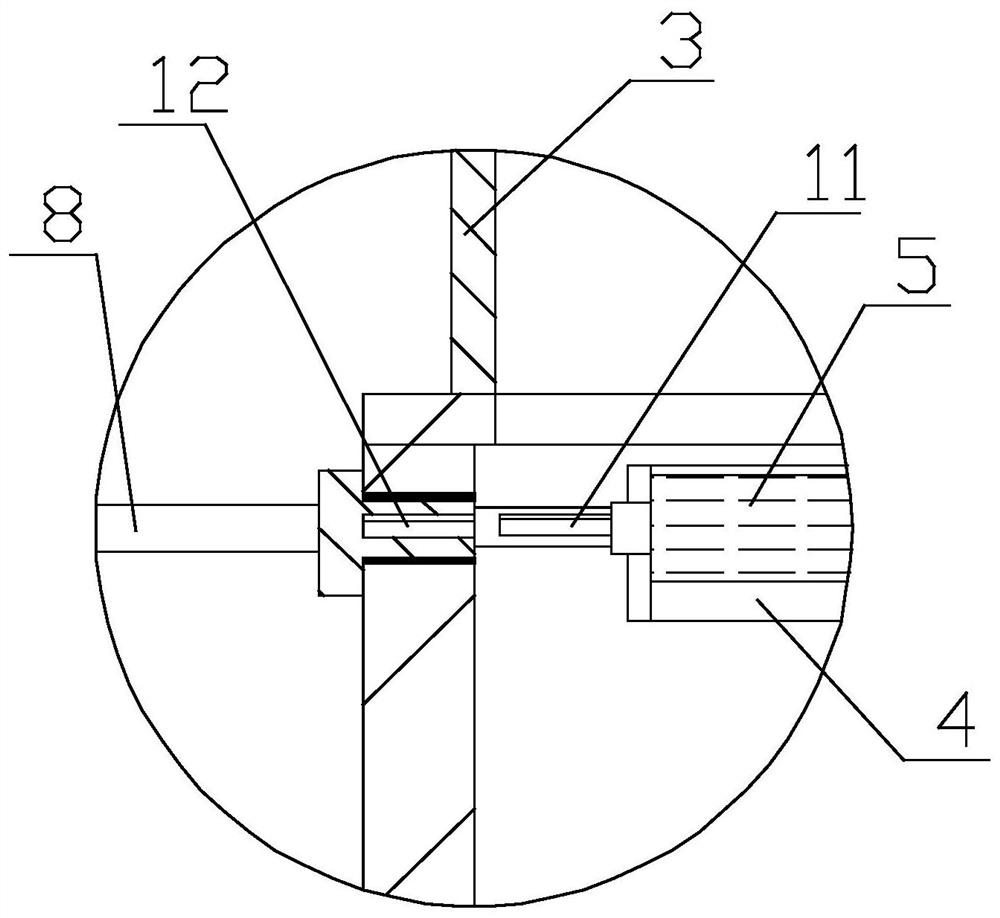

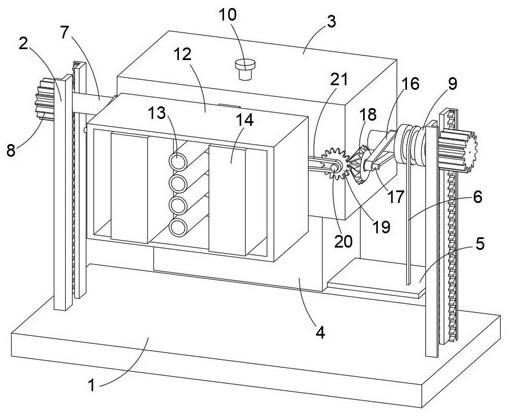

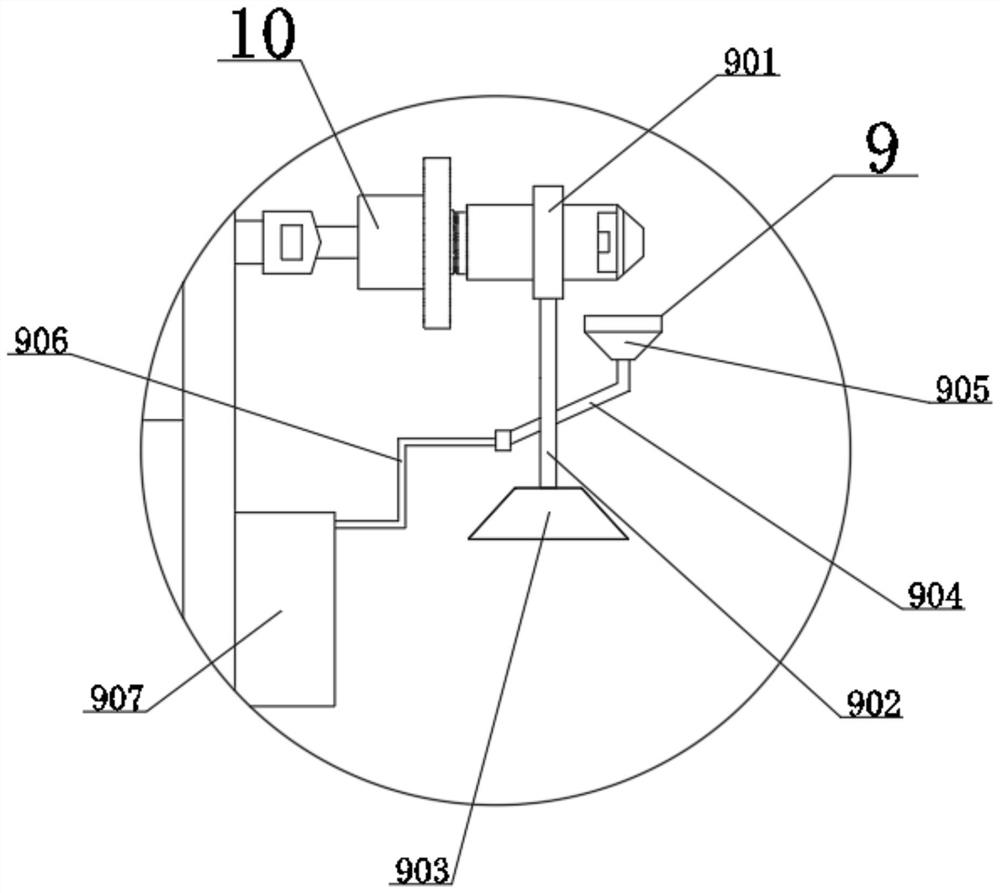

Steel wire rope dirt-removing oiling machine

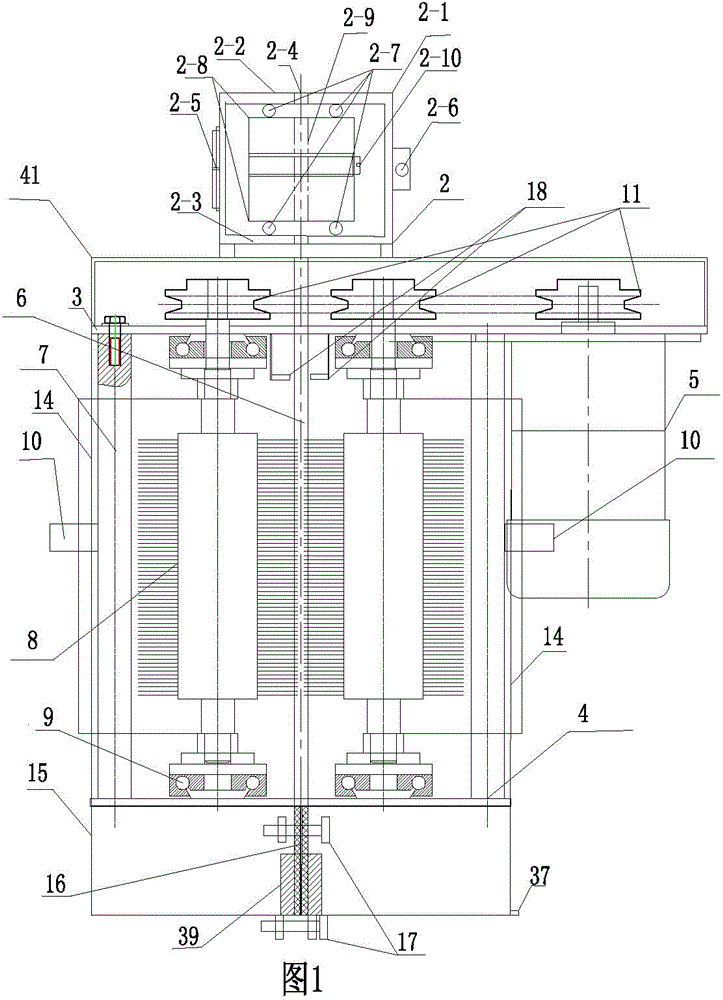

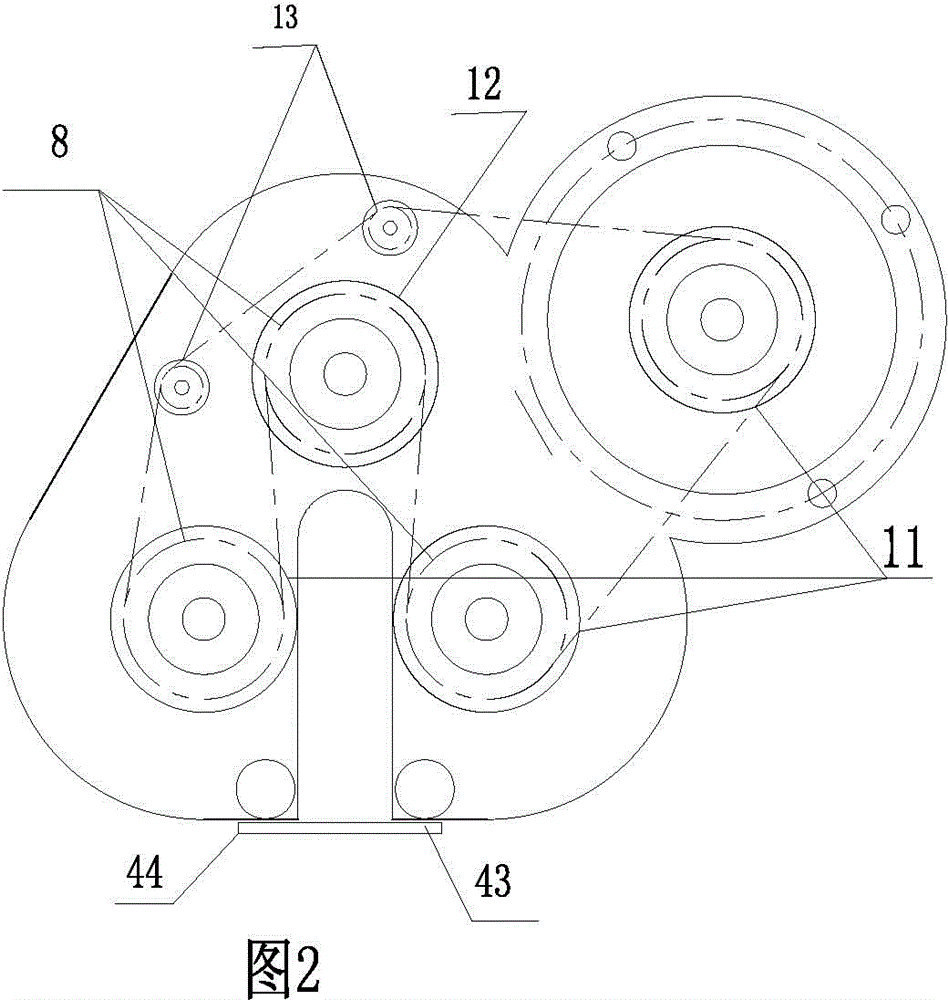

ActiveCN104307775AReduce frictionGuaranteed normal extrusionRope making machinesCleaning using toolsSEMI-CIRCLEReciprocating motion

The invention relates to the field of maintenance of a steel wire rope used in a water conservancy project, a bridge, mine hoisting, a crane ship, a cableway and the like. The steel wire rope 46 is loaded in a cylindrical polyurethane inner hole spiral mud dirt-removing component consisting of two semi-circles; polyurethane hole inner teeth and spiral pitches of steel wire rope strand ditches are tightly rubbed; a spiral mud dirt-removing device moves up and down to extrude mud dirt; three brush rollers 8 are annularly arranged at the inner periphery of a narrow slot opening 6 and are in contact with the steel wire rope 46; a spray type oil nozzle 18 points to the steel wire rope at the inner circle of the narrow slot opening 6; a grease filling device comprises a cylinder body consisting of two semi-circles and provided with a hollow cavity; two semi-circular rubber shaft sleeves are embedded in cylindrical holes; spirals are formed in the inner holes of the shaft sleeves and are matched with spirals of the steel wire rope. An oiling machine reciprocates, can clearly clean and is uniform in oil filling.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

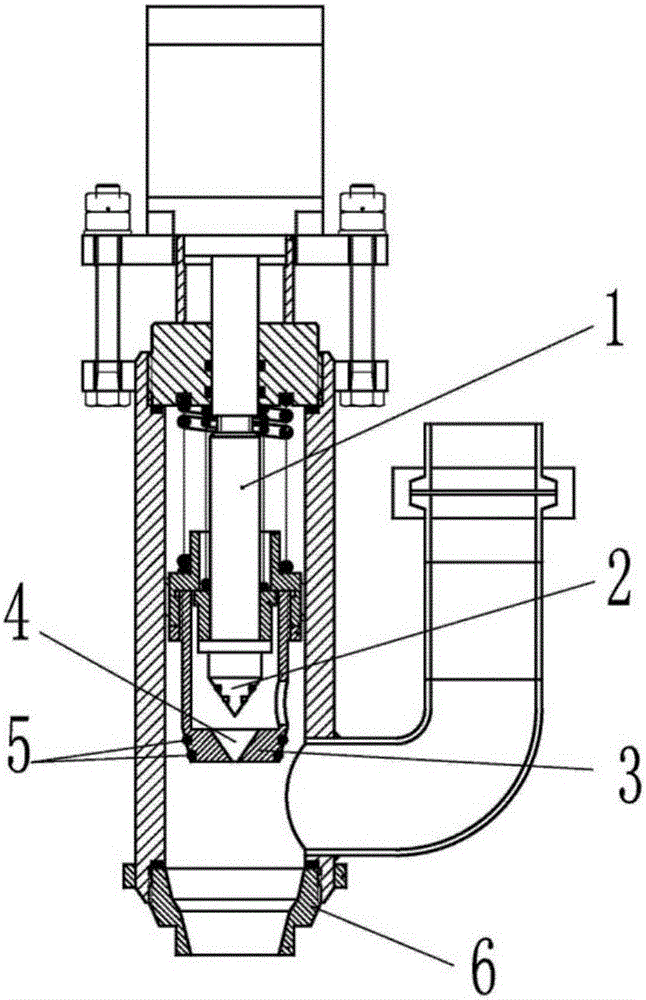

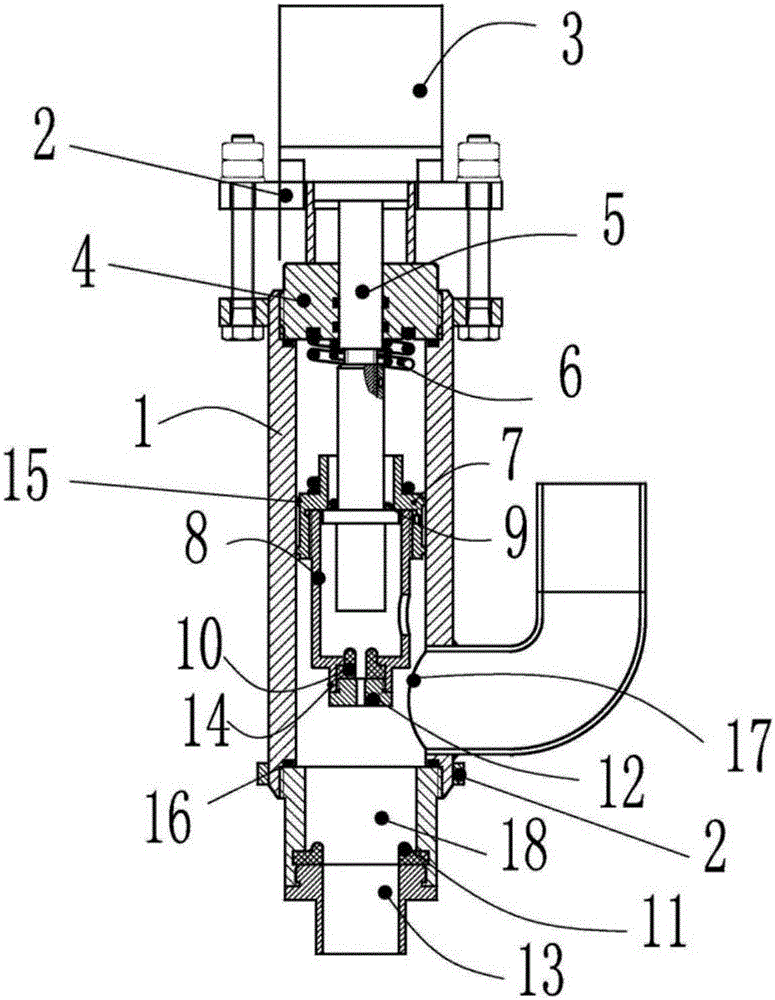

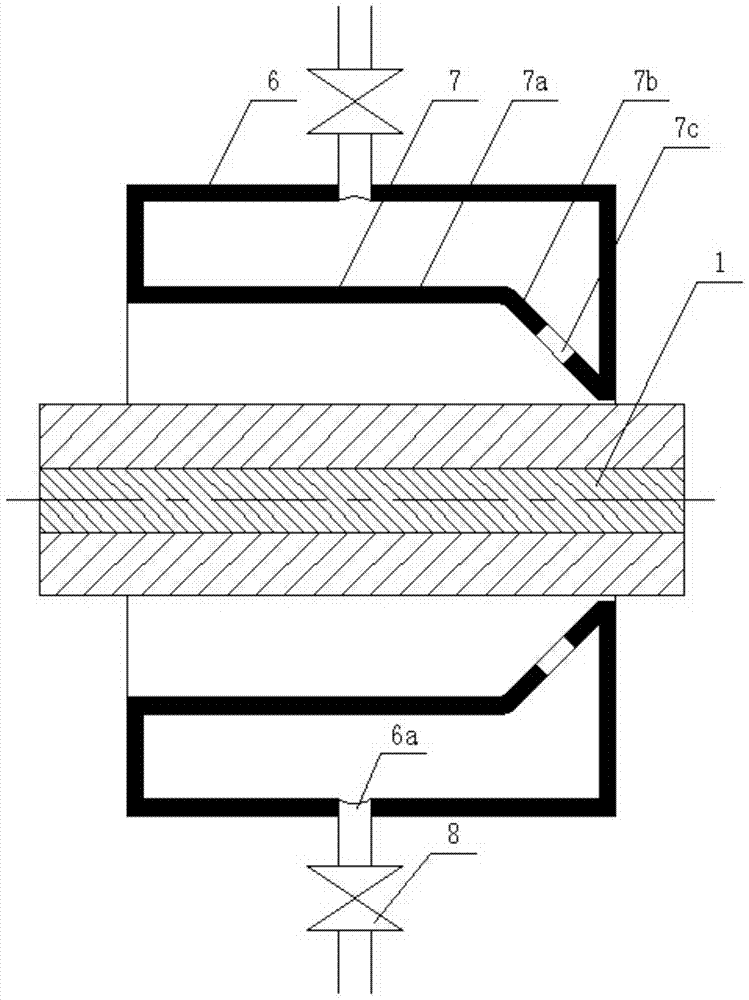

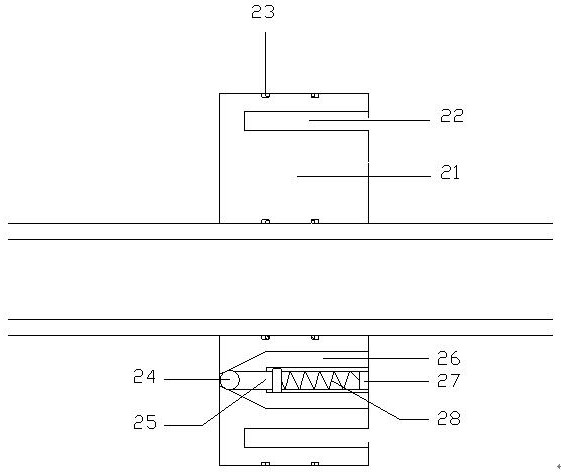

Anti-sputtering material distributing valve adjustable in flow

ActiveCN106402418APrevent splashSputtering will notOperating means/releasing devices for valvesSlide valveSputteringEngineering

The invention discloses an anti-sputtering material distributing valve adjustable in flow. The anti-sputtering material distributing valve comprises a valve core assembly and a power assembly. The valve core assembly comprises an upper valve body, a lower valve body, a valve core and a middle valve core. The upper valve body is connected with the upper end of the lower valve body and is of a hollow structure. The lower valve body is of a hollow structure, the side surface of the lower valve body is provided with a feeding inlet for allowing liquid to enter, and the lower end of the lower valve body is provided with a plurality of cylindrical holes serving as large flow openings of the material distributing valve. The valve core is sequentially inserted into the hollow structure of the upper valve body and the hollow structure of the lower valve body from the upper end of the upper valve body, and a small spring is arranged between the valve core and the upper valve body. The middle valve core is arranged between the valve core and the inner wall of the lower valve body and slidably matched with the valve core, a large spring is arranged between the middle valve core and the upper valve body, and the lower end of the middle valve core is provided with a through hole matched with the lower end of the valve core and a plurality of cylinders closely matched with the cylindrical holes in the lower valve body. The power assembly is connected with the upper end of the valve core and used for driving the valve core and the middle valve core to move up and down. The anti-sputtering material distributing valve adjustable in flow has the advantages of being capable of preventing sputtering and residues and adjusting the flow, high in preparation precision and the like.

Owner:WUHAN INTELLIGENT EQUIP IND INST CO LTD

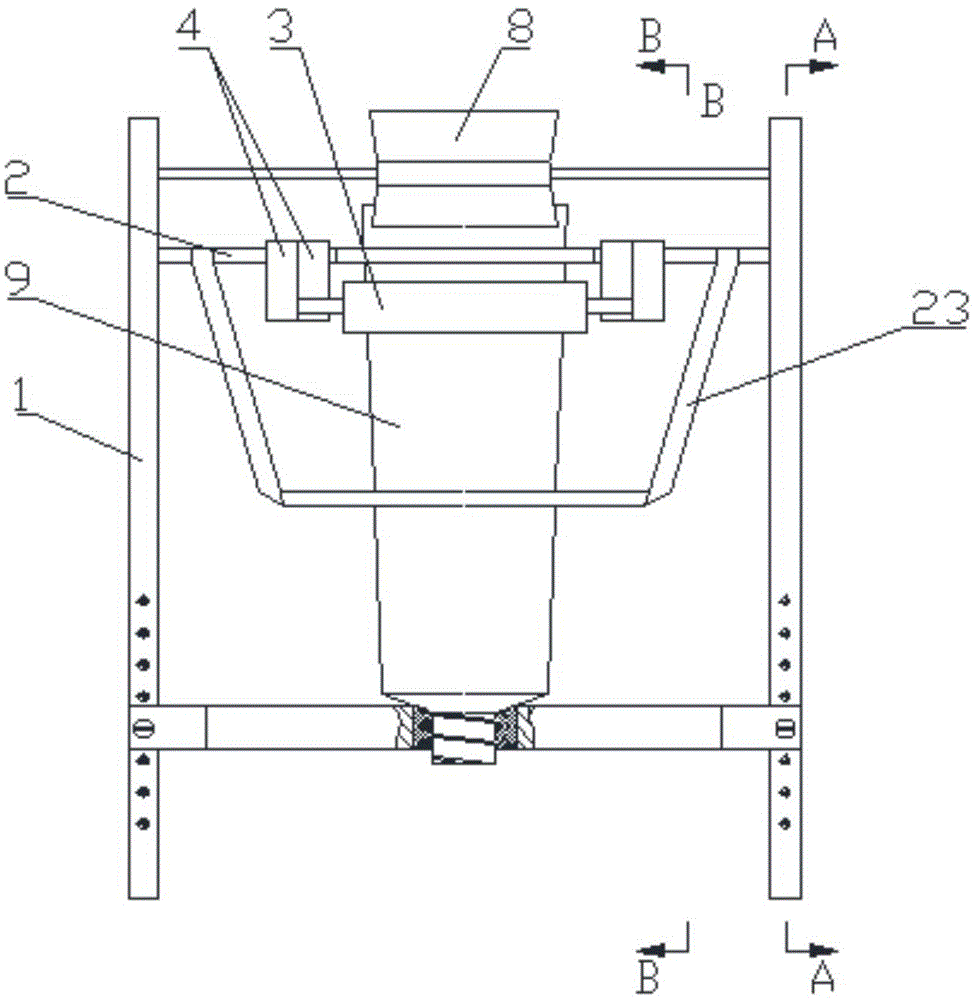

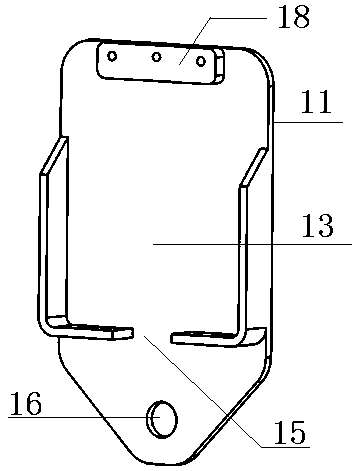

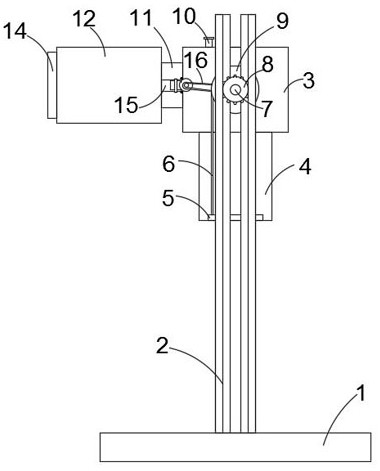

Toothpaste extruder

ActiveCN104150057AGuaranteed normal extrusionTake advantage ofArticle unpackingToothpasteEngineering

The invention discloses a toothpaste extruder. The toothpaste extruder comprises a support and an extruding component, wherein the support comprises vertical plates on two sides; a first fixing piece and a second fixing piece are arranged between the vertical plates on the two sides of the support; the first fixing piece is used for fixing the head of a toothpaste shell; the second fixing piece is used for fixing the tail of the toothpaste shell; the extruding component is arranged between the first fixing piece and the second fixing piece and comprises a connecting rod and extruding rolls; chutes are respectively formed in opposite side surfaces of the vertical plates on the two sides of the support; each chute extends from one end of the corresponding vertical plate to the other end of the corresponding vertical plate; two ends of each chute are closed; the connecting rod is arranged in the chutes and can slide along the chutes from the tail of the toothpaste shell to the head of the toothpaste shell; the extruding rolls are respectively arranged on the front surface and the reverse surface of the toothpaste shell and are parallel to each other; the axial direction of the toothpaste rolls is parallel to the axial direction of the connecting rod; and connecting pieces are respectively arranged at two ends of each extruding roll and are connected with the connecting rod.

Owner:菏泽建数智能科技有限公司

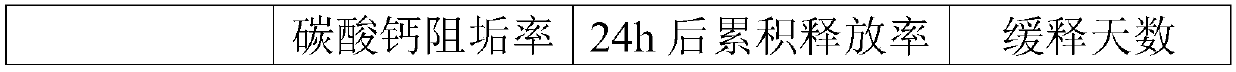

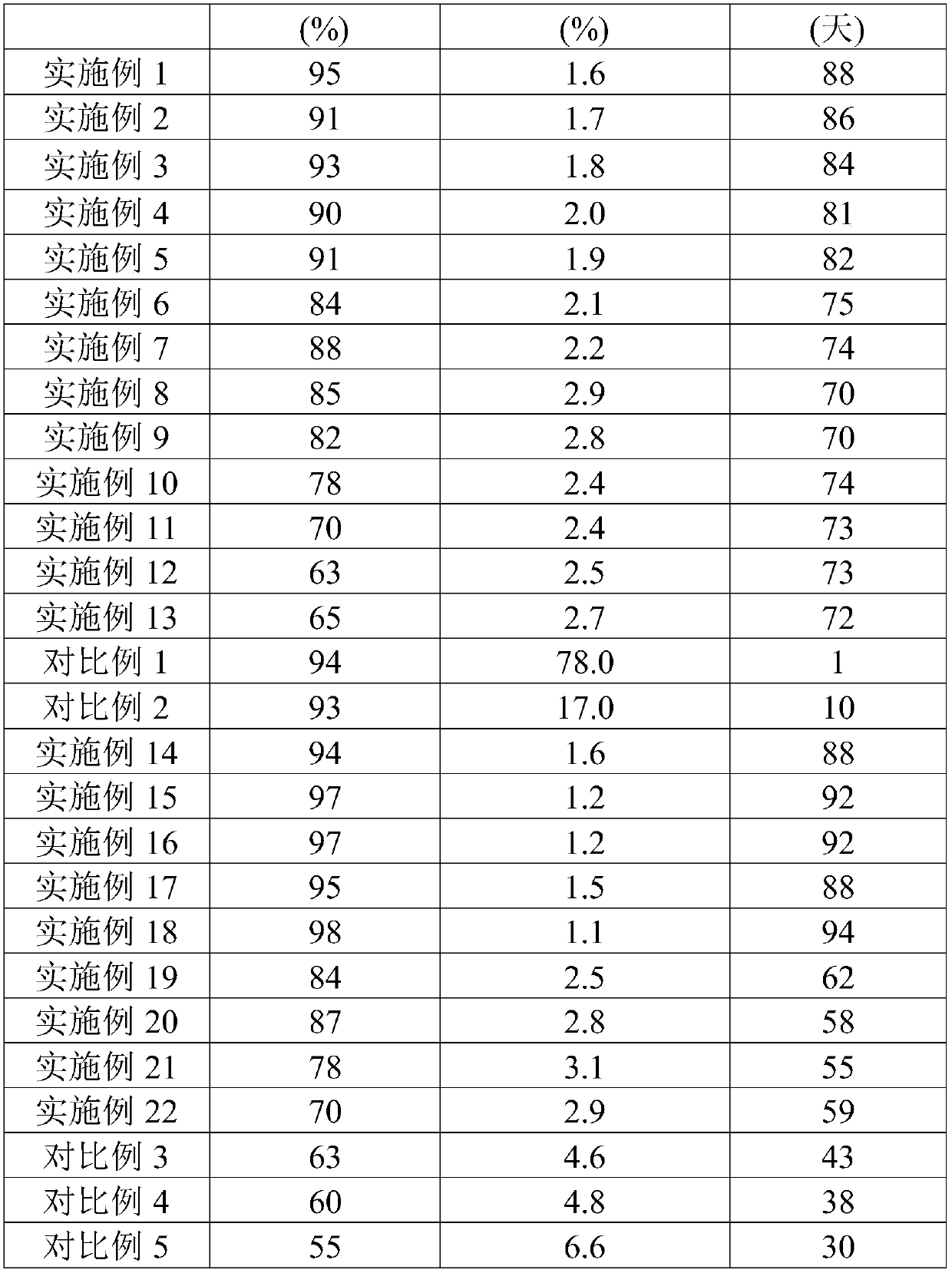

Scale inhibition particle as well as preparation method and application thereof

PendingCN111233176AGood sustained release effectAchieve long-term effectTreatment using complexing/solubilising chemicalsControl releasePhysical chemistry

The invention provides a scale inhibition particle as well as a preparation method and application thereof, the scale inhibition particle comprises scale inhibition powder, an adsorption material anda binder, and the binder is a combination of a water-soluble binder and a cured binder; the scale inhibition particle prepared by the invention has the advantages of strong descaling capability, longscale inhibition life, good water resistance, excellent water purification function, good slow release effect, controllable release rate, long action, simple preparation process and low cost, are usedfor water quality scale inhibition treatment, and are especially suitable for scale inhibition treatment of household water.

Owner:BEYCLEAN ENVIRONMENTAL PROTECTION TECH

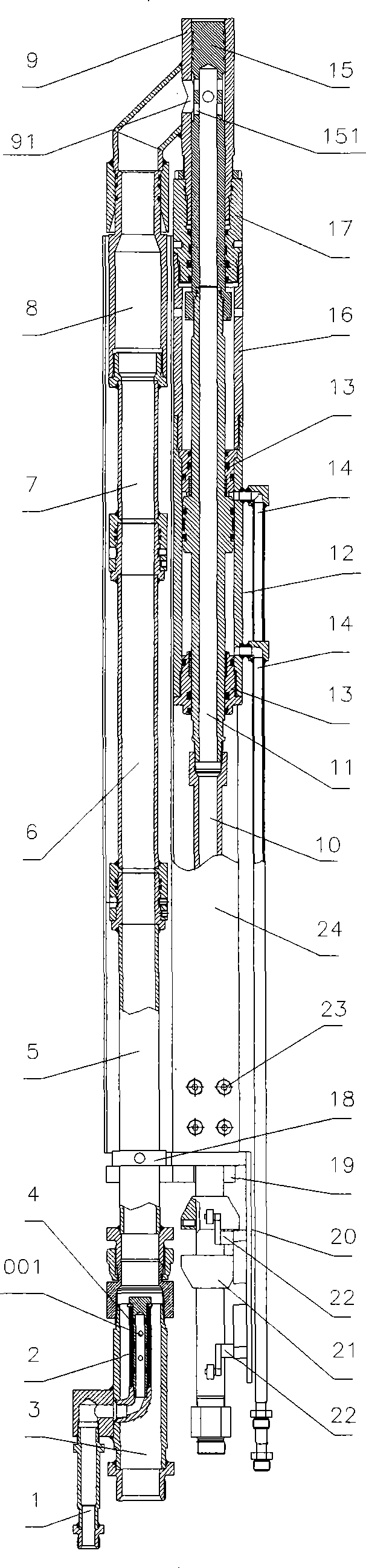

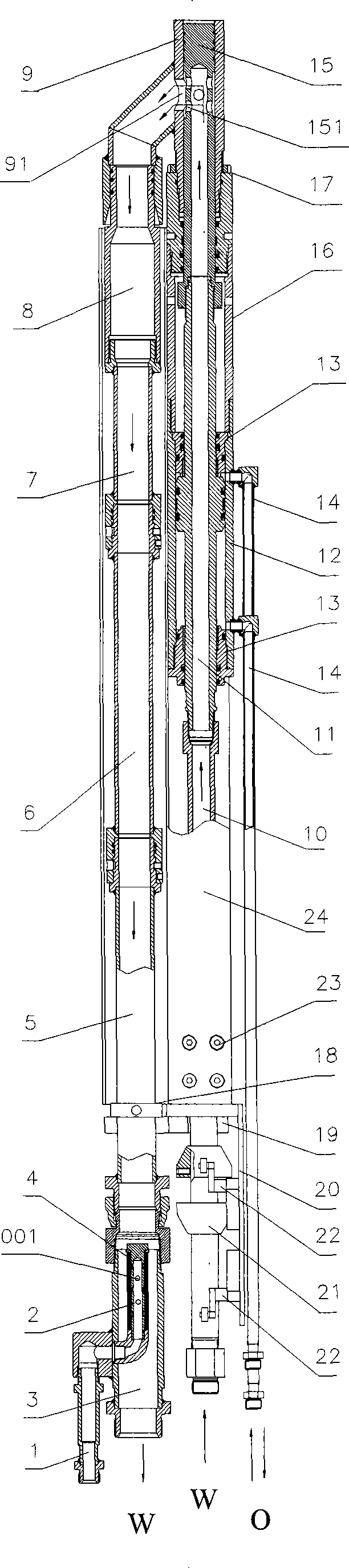

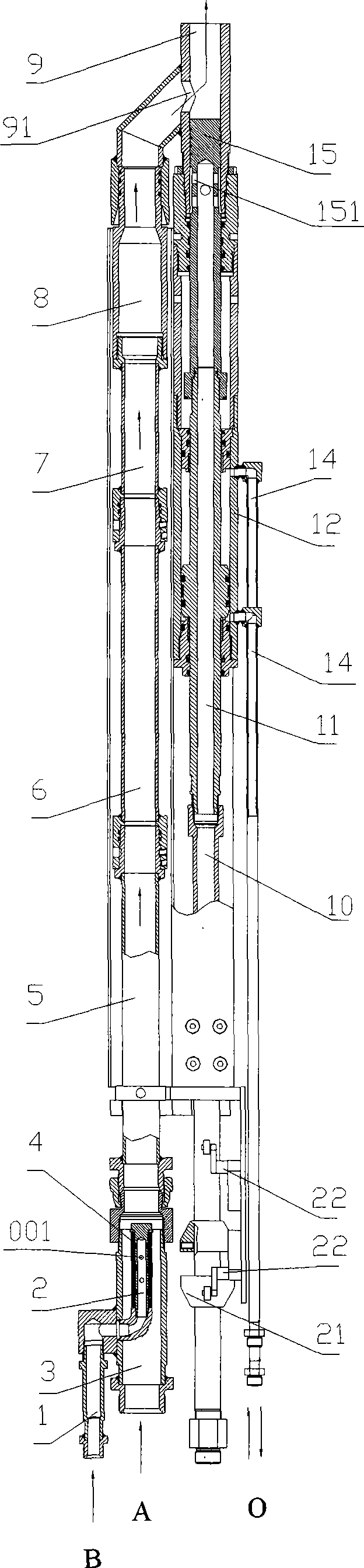

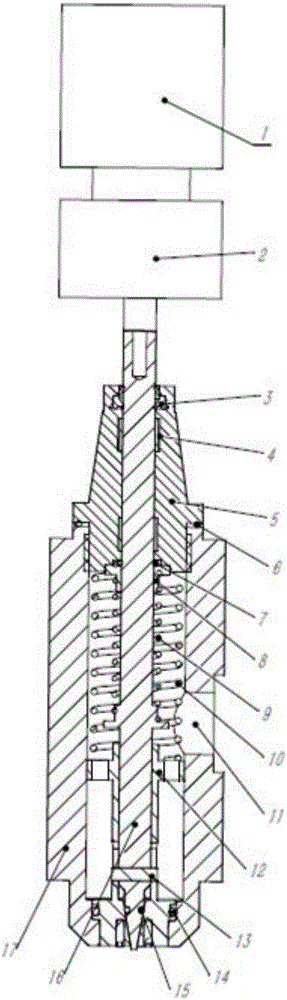

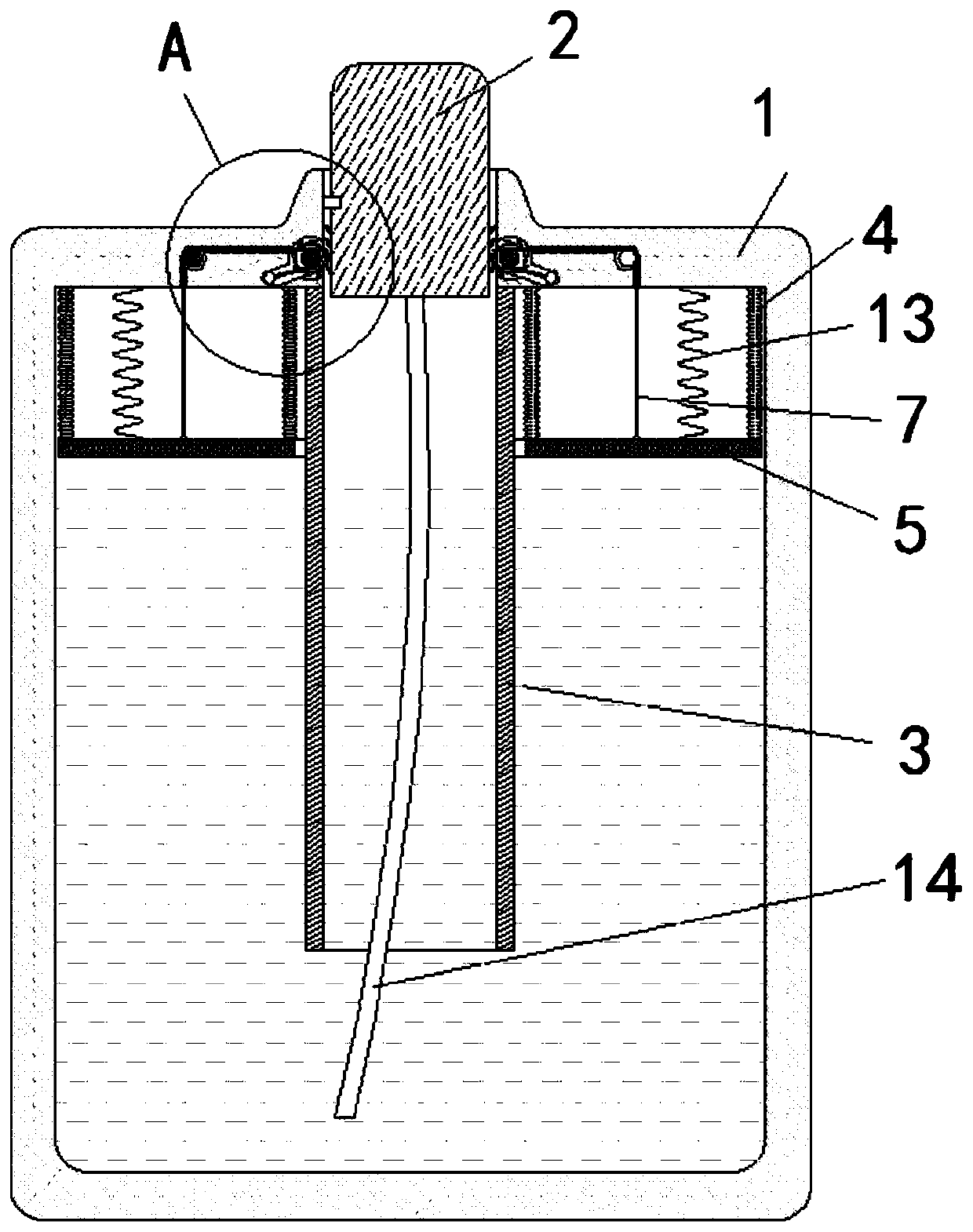

Hollow inclusion stressometer and measuring method

InactiveCN109211446AEasy to install and disassembleGuaranteed normal extrusionForce measurementEpoxyColloid

The invention discloses a stressometer for testing a crustal stress and particularly to a hollow inclusion stressometer for testing the crustal stress. The hollow inclusion stressometer comprises a monitoring module, an epoxy resin cylinder and a guide device. A detection device comprises a video camera placer and a video camera; the video camera placer comprises a hollow upper part and a base; four groups of strain rosettes are uniformly stuck at the periphery of the epoxy resin cylinder; three-dimensional crustal stress is measured through the strain rosettes; and the tapered guide head comprises an adjusting rod and a tapered guide head. As the detection device is arranged at the hollow inclusion stressometer, the flowing condition of colloid in the epoxy resin cylinder under the actionof a traction bar can be monitored in real time, and the colloid in the epoxy resin cylinder are ensured to be extruded completely; and the detection device is convenient to install and can be used for many times, so that the cost is saved.

Owner:ANHUI UNIV OF SCI & TECH

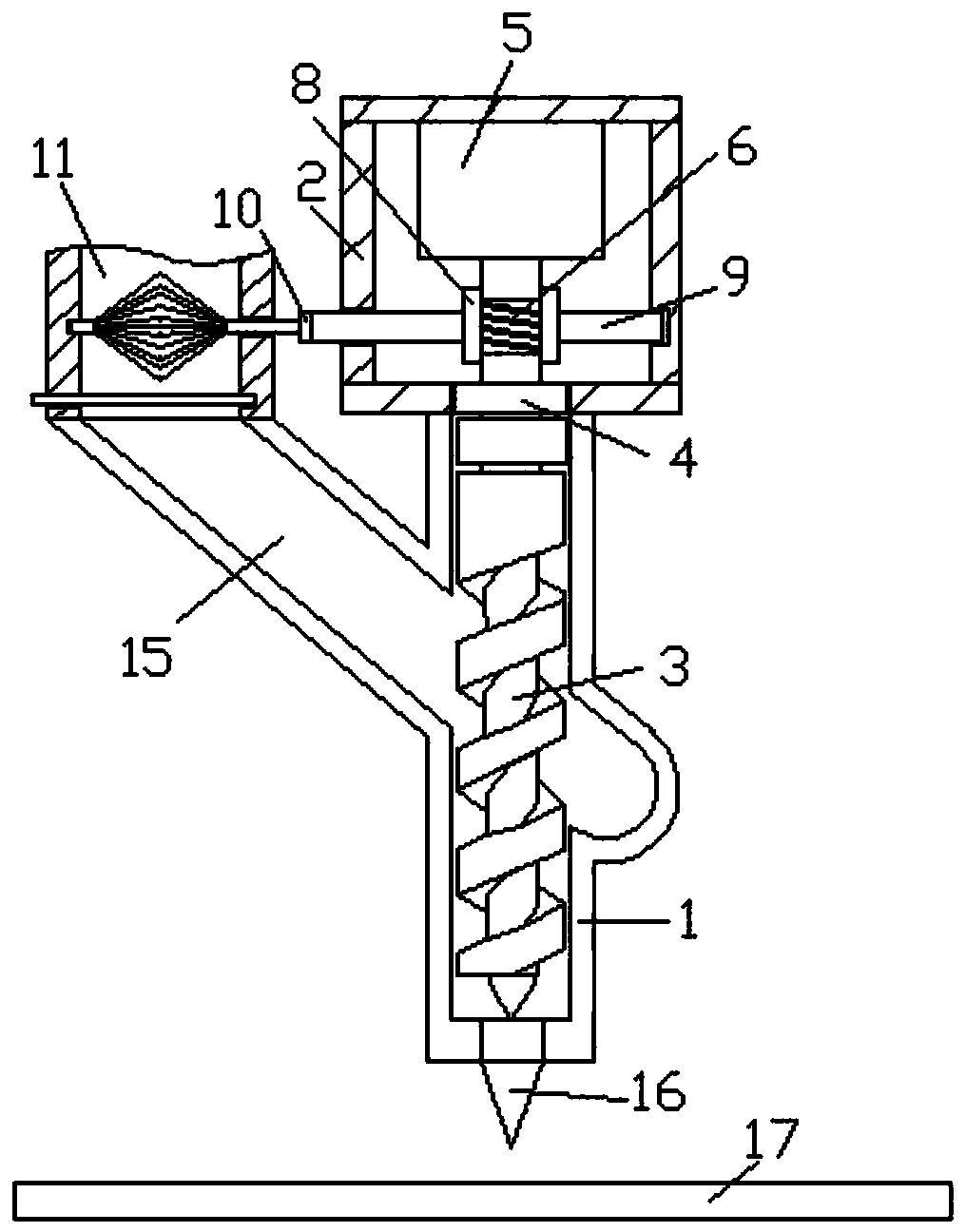

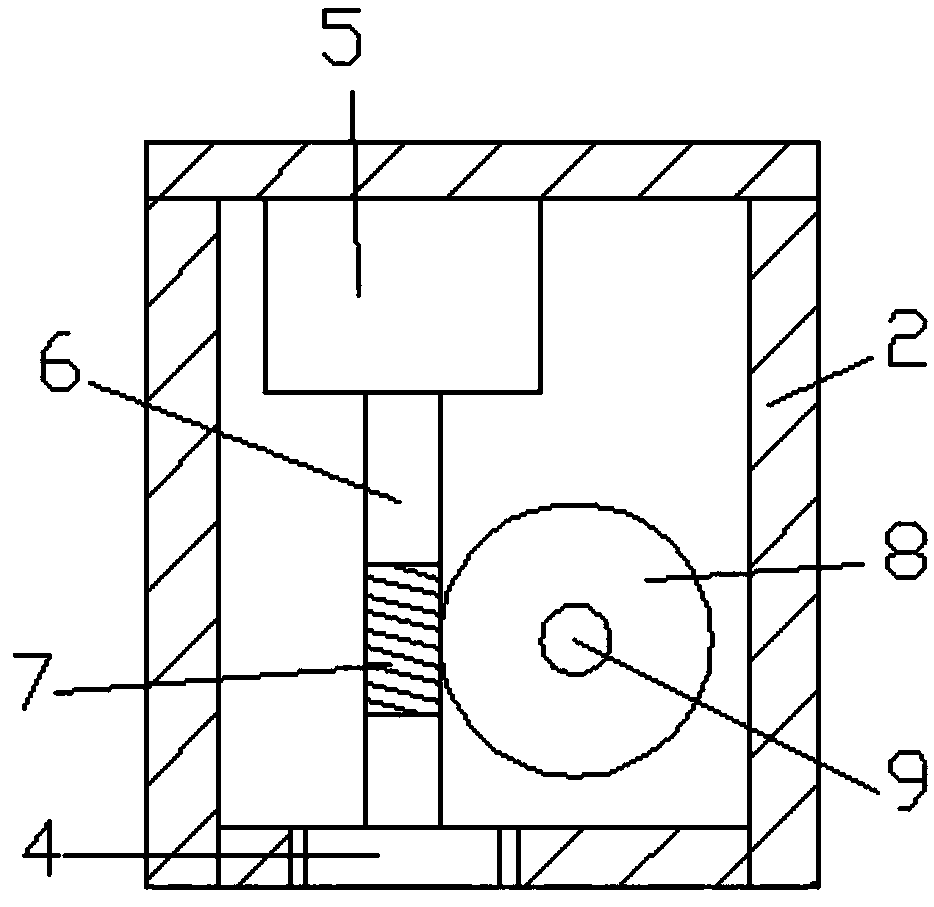

Ceramic 3D printing extruder

InactiveCN109435007AFreeze fastAvoid problemsAdditive manufacturing apparatusCeramic shaping apparatusEngineering3d printer

The invention discloses a ceramic 3D printing extruder, and relates to the technical field of 3D printing. The 3D printing extruder comprises a shell, wherein an extruding device is arranged in the middle of the shell, a power assembly is arranged at the upper part of the shell, and a bubble removing assembly is arranged on one side of the shell; the power assembly is connected with the extrudingdevice in a matched mode, the bubble removing assembly is connected with the power assembly in a matched mode, and the bubble removing assembly communicates with the shell; and a carrying table is arranged below the shell, and a heating gasket is arranged at the bottom of the carrying table. The problem that the extruding speed of the extruding device of a 3D printer is not controlled well, and thus an extruding part is easily scrapped is solved.

Owner:安徽恒利增材制造科技有限公司

Hand-rocking and vibrating combinational massager

ActiveCN106038166ARelax all musclesAvoid wastingDevices for pressing relfex pointsChiropractic devicesWhole bodyDrive shaft

The invention discloses a hand-rocking and vibrating combinational massager. The hand-rocking and vibrating combinational massager comprises a vertical type shell and a horizontal type shell, wherein the vertical type shell is fixed on the horizontal type shell; a hand-rocking crank is connected on each of the two sides of the horizontal type shell separately; the two hand-rocking cranks are connected through a first transmission shaft; a fourth transmission shaft is arranged on the horizontal type shell in an erection manner; the first transmission shaft is connected with the fourth transmission shaft through a transmission wheel system; two pedal apparatuses which are in mirror symmetry are arranged on the horizontal type shell; each pedal apparatus comprises a pedal, a pedal lifting part and an eccentric wheel; the pedals are hinged on the horizontal type shell; the pedal lifting parts are fixed on the lower surfaces of the corresponding pedals; the eccentric wheels are coaxially assembled on the fourth transmission shaft; and a bearing is clamped on the outer ring of each eccentric wheel. The hand-rocking and vibrating combinational massager adopts the two-part structure, including the vertical type shell and the horizontal type shell, so that the massager can be used by both hands and feet; the simultaneous movement of legs and the shoulders can be realized in the movement process, so that all the muscles on the body can be relaxed; and in addition, the massager specifically adopts a self-power-generation manner, so that the waste of energy is avoided.

Owner:SANHE GUIYUXING SPORTS GOODS

Novel light-weight high-strength low-density optical cable sheathing material and preparation method thereof

The invention relates to the technical field of optical cable sheathes, and particularly relates to an optical cable sheathing material and a preparation method thereof. The optical cable sheathing material is prepared from PE (Polyethylene), carbon black, thermal expansion microspheres or hollow glass microspheres, antioxidants and white oil. The preparation method comprises the steps of adding the raw materials to a mixing device according to an adding proportion, performing primary mixing and homogenization, then adding to an extruding machine, forming a homogeneous polymer / gas system by the thermal expansion microspheres or the hollow glass microspheres and PE polymers under the combined action of a shear mixing field and the processing temperature in a machine barrel, then conveying to a machine head, extruding, then cooling, dicing and drying, so as to obtain sheathing material granules of microcellular structures. By utilizing the characteristics of light weight, high strength and low density, the cost of a traditional optical cable sheathing material can be greatly reduced, obtained microcellular plastics have stable foaming properties and microcellular sizes, the process is simple, the manufacturing is easy, and industrial utilization is satisfied.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP

Heating component for plastic extruding machine

InactiveCN104943130AReduce wasteGuaranteed normal extrusionElectrical resistance and conductanceEngineering

The invention provides a heating component for a plastic extruding machine and belongs to the technical field of plastic extruding machines. The heating component comprises at least three heating devices installed outside a charging barrel in a sleeving ode and a shell installed outside the heating devices in a sleeving mode to protect the heating devices, wherein the heating devices are infrared heating devices or electromagnetic heating devices. The heating component is simple in structure, convenient to install, and capable of being used in cooperation with a charging barrel of the plastic extruding machine and a screw extruder quickly. Due to the fact that the infrared or electromagnetic heating devices are adopted to replace original resistance wires for heating, heating efficiency is improved, and energy waste is reduced.

Owner:天津煊生源高分子科技有限公司

Novel straw compression forming equipment

The invention provides novel straw compression forming equipment, and relates to a compression forming device of fiber materials. The novel straw compression forming equipment comprises a main driving mechanism, a precompression mechanism and a compression mechanism. The precompression mechanism comprises a second motor, a feeding box, a precompression packing auger and a forced feeding turnover plate, a reinforcing compression cavity is formed in the outlet end of a compression cavity, and is of a left-and-right buckling structure, the two sides of the reinforcing compression cavity are connected with connecting rod mechanisms respectively, the connecting rod mechanisms are connected with a hydraulic station, the hydraulic station is controlled by an electric drive travel switch, and the hydraulic station and the electric drive travel switch are in linkage and automatic control through a PLC control cabinet. Based on the working principle that main machine volume variable physical extrusion and auxiliary machine forced feeding extrusion are combined, the materials are conveyed, extruded and dehydrated, the equipment is especially suitable for compression forming of straw type biomass, and the compressed materials are low in water content and small in density.

Owner:河南天冠纤维乙醇有限公司

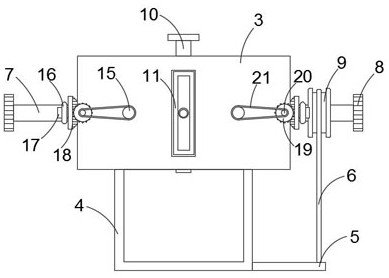

Constant-pressure cosmetic bottle guaranteeing liquid outlet amount

InactiveCN111449403AGuaranteed normal extrusionEasy to usePackaging toiletriesPackaging cosmeticsGear wheelEngineering

The invention relates to a constant-pressure cosmetic bottle guaranteeing the liquid outlet amount. The bottle comprises a bottle body, a guide ring is fixedly connected to the inner top wall of the bottle body and located on the outer side of a button, an air bag is installed on the inner top wall of the bottle body, a lifting ring is fixedly connected to the bottom of the air bag, ropes connected to the lifting ring are wound on reels, gears corresponding to the button are fixedly connected to the outer sides of roller shafts in a sleeving mode, racks are arranged on side walls of the button, and clamping columns inserted into the button are fixedly connected to the inner wall of the bottle body. When the button is pressed, liquid in the bottle body is reduced; meanwhile, when the buttonmoves upwards, the gears are driven to rotate through the racks, the ropes wound on the reels are released, the lifting ring moves downwards, the air bag stretches out, the blank caused by liquid reduction in the bottle body is filled through the lifting ring and the air bag, the pressure of the liquid in the bottle body is kept, and the problems that after long-time use, the pressure borne by the liquid becomes small, the liquid cannot be extruded out in time or the extrusion amount becomes small are solved.

Owner:杭州喙个科技有限公司

Special paint for evaporative pattern aluminum alloy and manufacturing method of special paint

InactiveCN103008532AReduce impact resistanceExclude smoothlyFoundry mouldsFoundry coresEmulsionHydroxyethyl cellulose

The invention relates to special paint for an evaporative pattern aluminum alloy and a manufacturing method of the special paint. The special paint comprises the following components: 40-70% of aluminosilicate, 5-25% of mica powder, 5-20% of talcum powder, 0.1-0.3% of industrial salt, 1.5-3% of emulsion powder, 1-1.5% of artificial starch, 1.5-3% of argil, 0.3-0.8% of hydroxyethyl cellulose, 1-2% of attapulgite, 0.2-0.8% of sodium carbonate, 0.2-0.5% of sodium benzoate and water with the weight accounting for 40-50% of the total weight of the other components. The paint is good in suspension property, and does not settle; and the thickness of a single coated coating is between 0.4mm and 0.5mm. The paint can maintain good air permeability, has higher liquid penetrating capacity, is remarkable in thermal insulation effect, and does not crack easily due to a high solid-to-solution ratio. A coating of a cast complicated thin-wall aluminum alloy casting is easy to clear.

Owner:安徽中兴华汉机械有限公司

Medical ointment tube

InactiveCN105456030AGuaranteed normal extrusionControl the amount of extrusionPharmaceutical containersMedical devicesGynecologyPackaging Tube

The invention discloses a medical ointment tube, comprising a tube body whose one end is sealed and the other end is provided with an opening. A cladding bag is arranged abutting against the inner wall of the tube in the tube body, and the cladding bag divides the tube body into an upper cavity and a lower cavity which are not communicated with each other. The cavity in the cladding bag is a placing cavity used to store contents. The cavity under the cladding bag is an air cavity. The air cavity is connected with an air bag used to inflate the air cavity. The air bag is on the outer side of the placing cavity and is close to a tube mouth. The air outlet end of the air bag is communicated with the air cavity through a pipe. The medical ointment tube solves a problem in the prior art that a thick content in the packing tube cannot be used up.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Extrusion molding mechanism for ultrahigh molecular weight polyethylene composite pipe

InactiveCN112721088AQuality assuranceAvoid bendingLighting and heating apparatusMetal working apparatusEngineeringWorkbench

The invention belongs to the technical field of polyethylene composite pipe production, particularly relates to an extrusion molding mechanism for an ultra-high molecular weight polyethylene composite pipe, and provides the following scheme aiming at solving the problem that discharged materials are easy to bend. The extrusion molding mechanism comprises a workbench and an extruder, and a water storage chamber and a dust storage chamber are correspondingly formed in the middle and one side in the workbench; a cooling lantern ring is installed at the top of the workbench, a water supply pipe is wound in the inner wall of the cooling lantern ring, a cooling circulation mechanism is arranged in the water storage chamber, electric sliding tables are installed at the two ends of one side of the top of the workbench, installation boxes are installed in the middles of the output ends of the two electric sliding tables, and fixing rings are arranged at the bottoms of the installation boxes; and synchronous moving mechanisms are arranged in the installation boxes, a cutting knife is arranged at the top of the workbench, and a dust suction nozzle is mounted on the side face of the cutting knife. The device ensures that the polyethylene composite pipe always keeps horizontal movement, avoids bending caused by deviation, has a cooling function, and avoids deformation of the polyethylene composite pipe due to incomplete cooling.

Owner:九江中科鑫星新材料有限公司

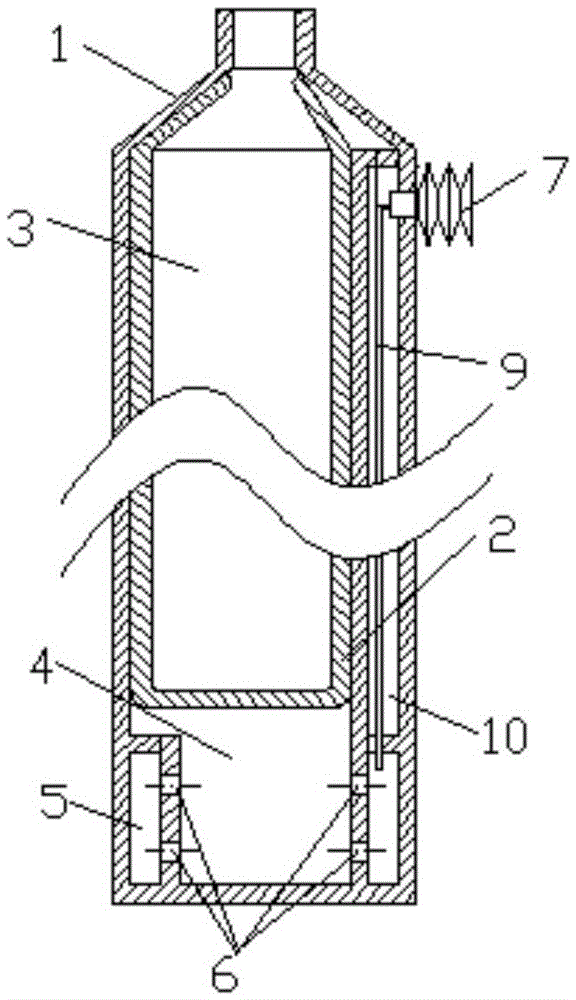

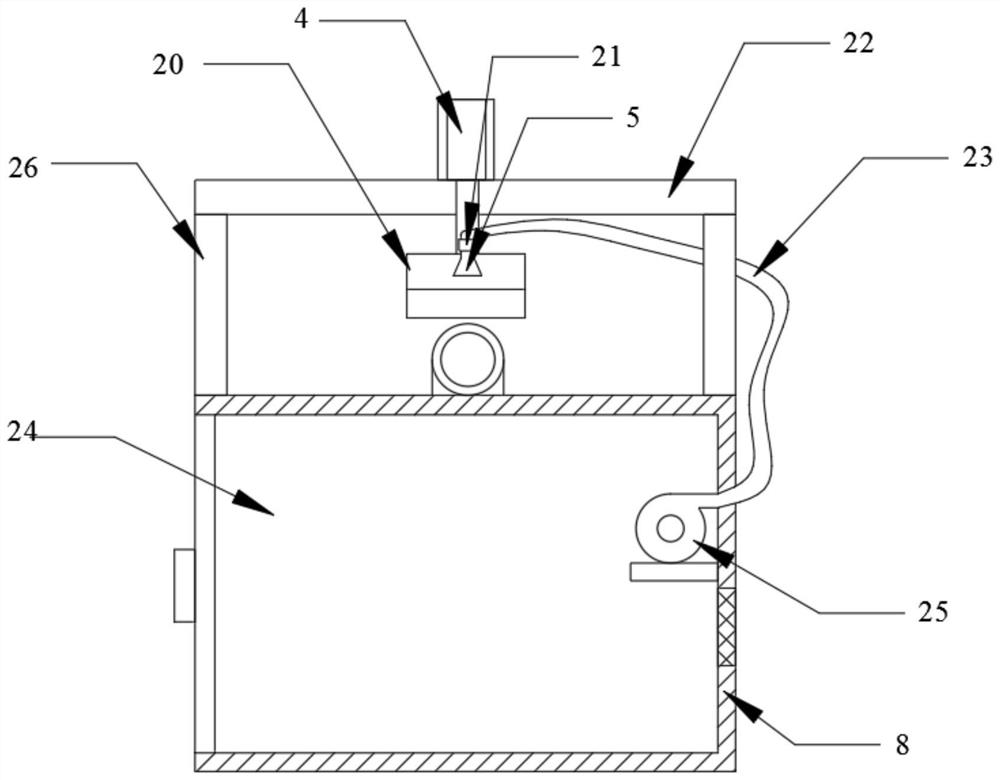

Extrusion recovery device for beverage bottles

InactiveCN110962251AGuaranteed normal extrusionImprove extrusion efficiencyPlastic recyclingGrain treatmentsThermodynamicsProcess engineering

The invention discloses an extrusion recovery device for beverage bottles and relates to the technical field of environmental protection equipment. The device comprises a box body, a discharging hopper, a first recycling box and a second recycling box, wherein a feeding opening is formed at the top of the box body, a discharging hopper is communicated with the interior of the feeding opening, an extrusion mechanism is fixedly mounted in the box body, a first recycling box and a second recycling box are placed at the bottom of the box body, the extrusion mechanism comprises a rotating shell, anextrusion cylinder and an extrusion assembly, and the rotating shell is in transmission connection with a transmission mechanism. The device is advantaged in that a beverage bottle enters a semi-cylindrical ring net under the action of gravity, the extrusion assembly extrudes the beverage bottle, at the moment, the transmission mechanism drives the rotating shell to rotate to block a previous beverage bottle, the squeezed beverage bottle is guided to fall into the first recycling box, the crushed beverage bottle enters the second recycling box through the semi-cylindrical ring net, the screenand the guide sliding way, in the process, the labor pressure of people can be effectively relieved, and recycling efficiency of the beverage bottle is improved.

Owner:界首市利能环保技术开发有限公司

Intelligent 3D printer with high printing precision

ActiveCN107020751AReduce consumptionHigh precisionManufacturing heating elements3D object support structuresEngineering3d printer

The invention relates to an intelligent 3D printer with high printing precision. The intelligent 3D printer comprises a base, a controller, a printing platform, a top plate, a lifting plate, a plane moving mechanism, a printing mechanism and two lifting units; the printing mechanism comprises a material disc, a wire feeding pipe, a heating device, a first flow pipe, a flow guide box, a second flow pipe and a printing head, wherein a flow guide mechanism is arranged in the flow guide box and comprises a second driving motor, a first connecting rod, a second connecting rod, a piston, a flow guide cylinder, a blocking mechanism and two third flow pipes; and a heating mechanism is arranged in the controller and comprises a heating unit and two translation units. According to the intelligent 3D printer with the high printing precision, the translation units are used for driving the heating unit to move to preheat the printing platform in sequence, the electric energy consumption is reduced, and the energy-saving effect is achieved; and moreover, and the material extrusion amount of the printing head is guaranteed each time through the flow guide mechanism, so that the heights of printing layers are equal, and then the precision of a printed sample and the practicability of equipment are improved.

Owner:广东顺德优线三维科技有限公司

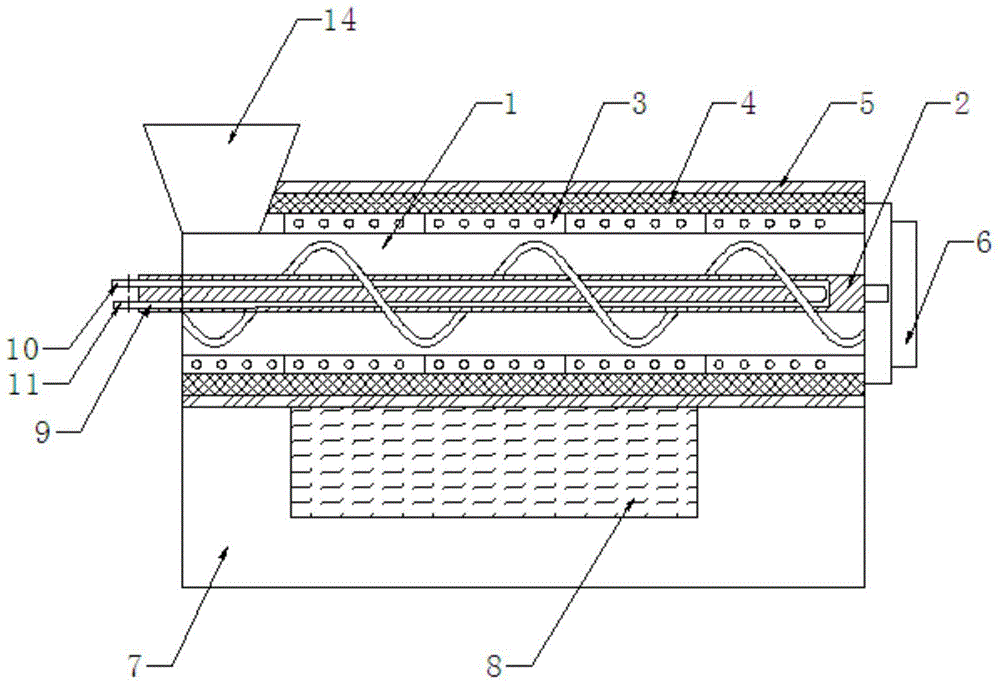

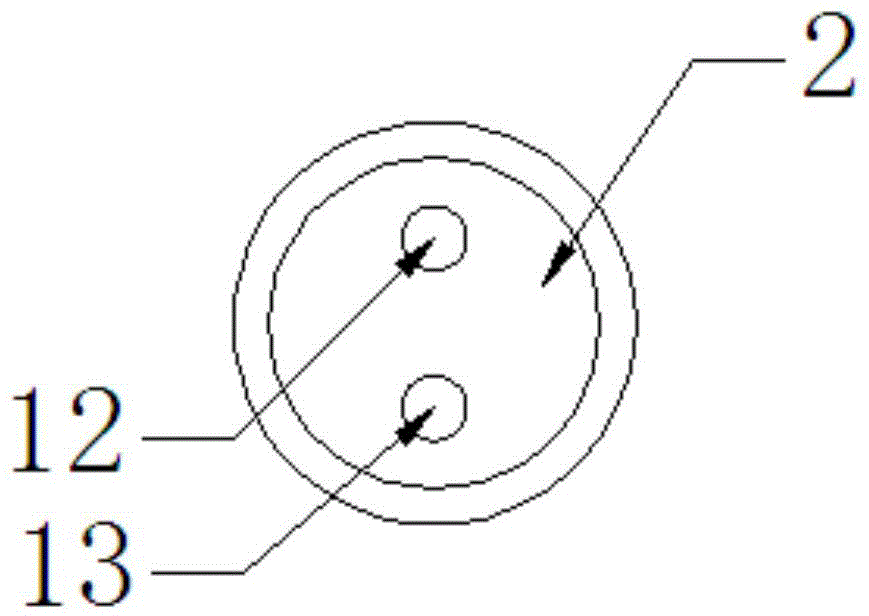

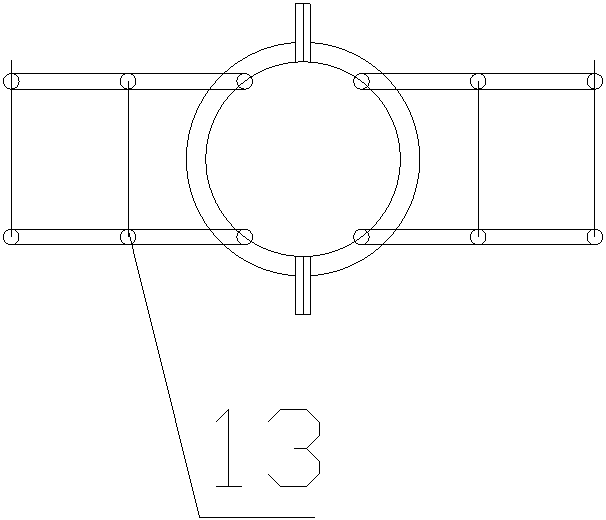

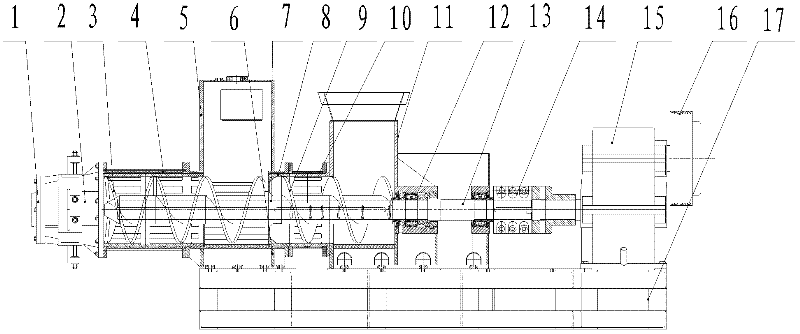

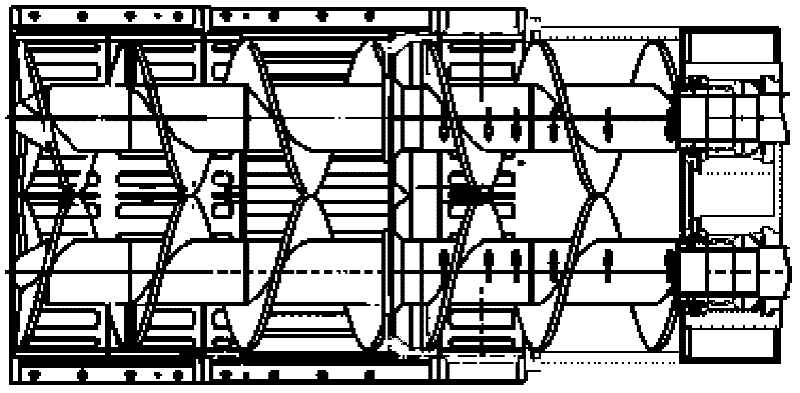

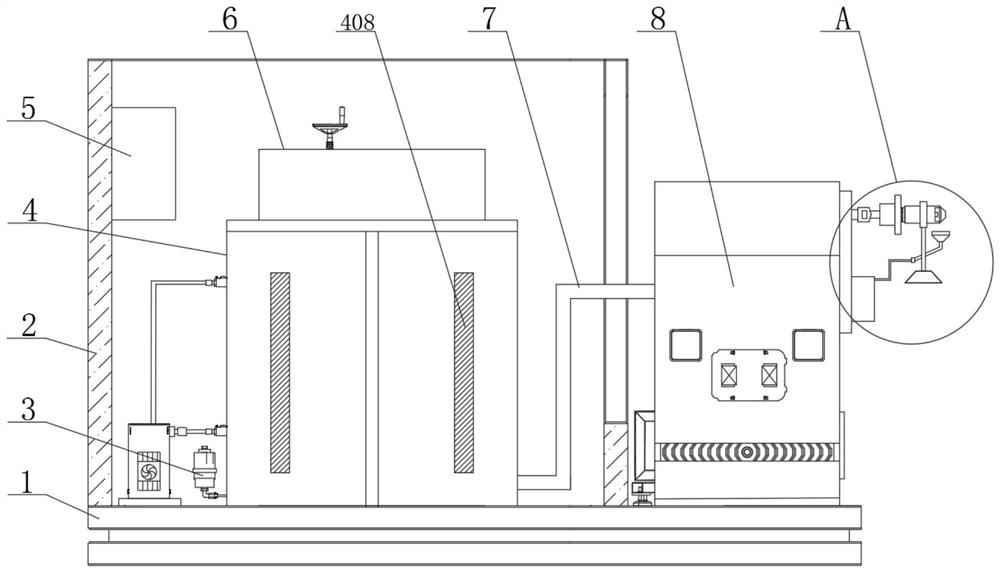

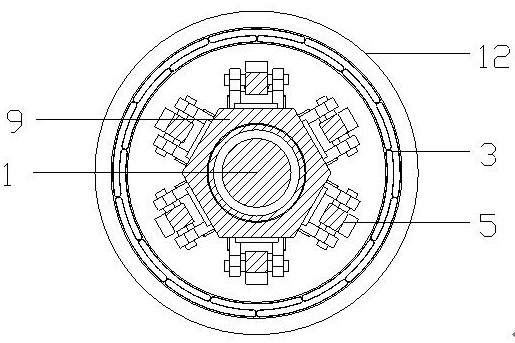

Double-cylinder multistrip single-stage vacuum extruder

InactiveCN102398300ANo anti-sludge phenomenonSmooth entryCeramic shaping apparatusSingle stageCoupling

The invention belongs to a double-cylinder multistrip single-stage vacuum extruder in a building machinery, which is formed by double machine openings, a machine head, double reamers, double pug cylinders, a vacuum chamber, a pug addition tank base, an outer taper sleeve, an inner taper sleeve, double half reamers, a half cylinder, a blanking tank, a bearing pack, double spindles, a coupling, a speed reducer and a pneumatic clutch. All components are positioned on an underframe. The speed reducer with double output shafts is driven by a motor. The double output shafts of the speed reducer drive the double spindles to rotate by the coupling. The double spindles are connected with the double half reamers through the bearing pack. The double half reamers are connected with the double reamers through the inner taper sleeve and the outer taper sleeve to compress and extrude pug. The double reamers are positioned in the double pug cylinders and the outlet ends of the double pug cylinders are sequentially connected with the machine head and the double machine openings. The vacuum chamber is directly arranged between the double pug cylinders and the half cylinder and is positioned on the double pug cylinders. The blanking tank is arranged on the half cylinder. The double pug cylinders are horizontally arranged side by side. The center distance of the two pug cylinders is equal to the diameters of the reamers. The double spindles take relative rotating motion under the drive of the speed reducer, so that the two reamers also take relative rotating motion under the action of the spindles and materials in the vacuum chamber can be smoothly conveyed into the double pug cylinders without generating the pug return phenomenon.

Owner:程永科

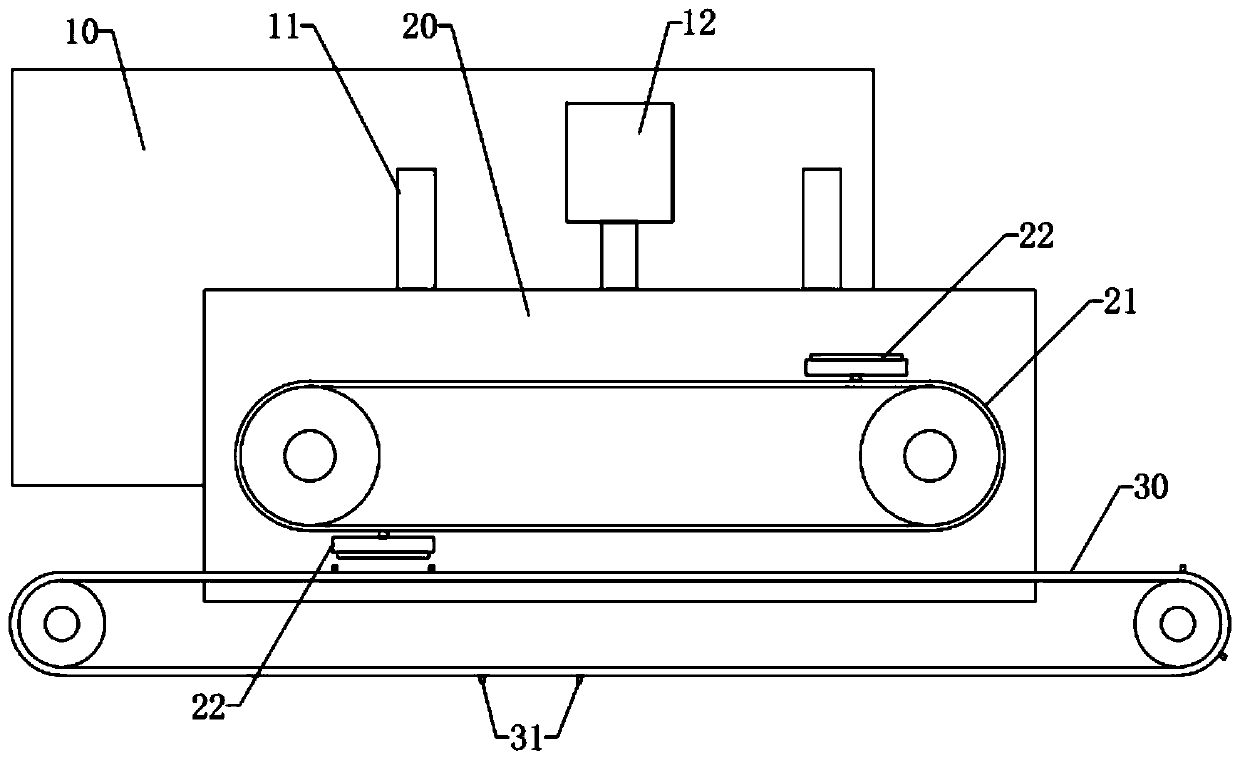

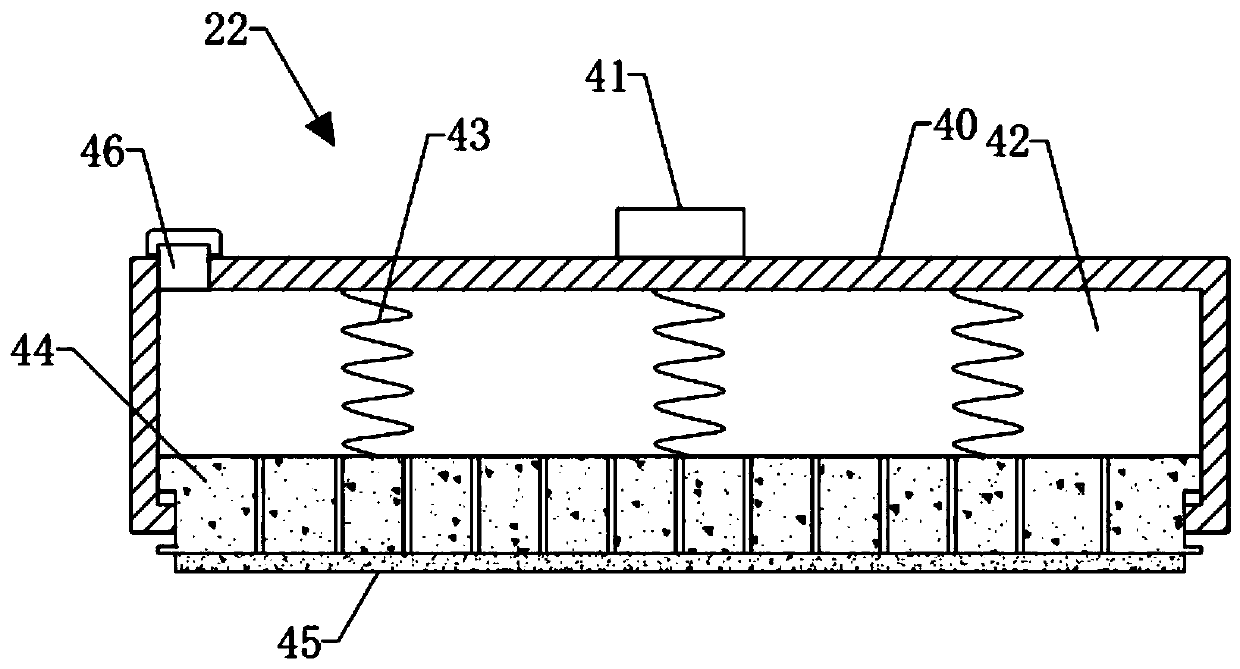

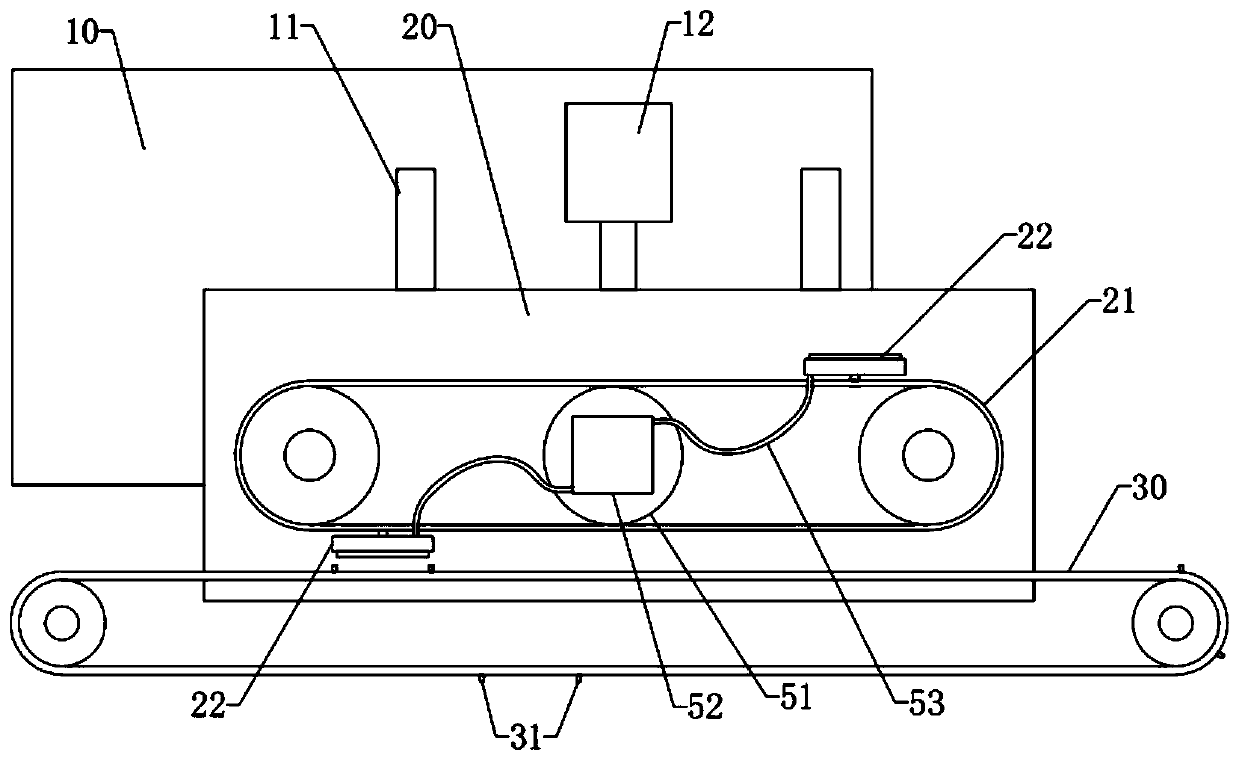

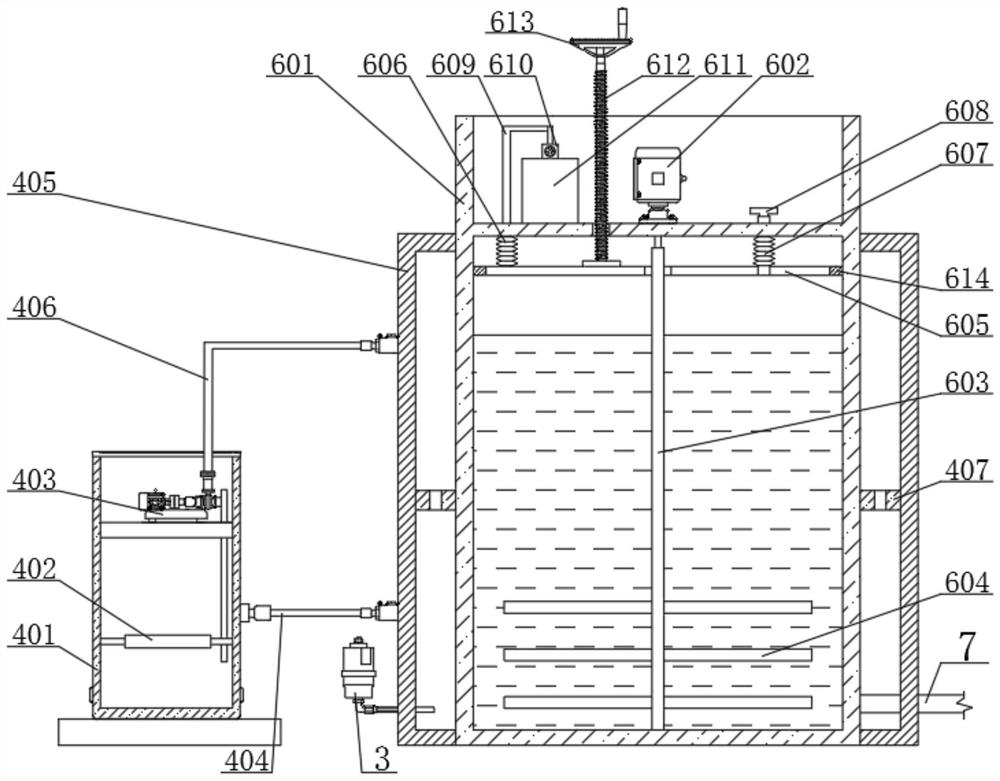

Laminated glass bubble removing device

PendingCN113665216AGuaranteed normal extrusionLaminationLamination apparatusElectric machineryLeather belt

The invention discloses a laminated glass bubble removing device, which comprises a power distribution cabinet box body, wherein a lower belt conveying frame is fixedly installed on the surface of the power distribution cabinet box body; and a upper belt conveying frame is arranged over the lower belt conveying frame, and a driving structure for driving the upper belt conveying frame and the lower belt conveying frame to move synchronously is installed on the surface of the power distribution cabinet box body. The conveying device has the beneficial effects that the driving gear is in meshing transmission with the driven gear, the main belt wheel is installed on the outer side of the driven gear, and the main belt wheel is connected with the driven belt wheel through the belt, so that a stepping motor drives the upper conveying frame, the lower conveying frame and the upper belt to conduct conveying at the same time; and the laminated glass located between the upper belt conveying frame and the lower belt conveying frame is pressed and conveyed, and it is guaranteed that bubbles existing between the laminated glass are extruded out in the pressing and conveying process.

Owner:CHAOHU CITY WEIYE GLASS CO LTD

High-voltage cable sheath extrusion technology, anti-sticking mold device and drying device

The invention discloses a high-voltage cable sheath extrusion technology and a device. The technology comprises the following steps: a, blowing residual asphalt paint attached to the surface of the cable core; b, threading the cable core into a plastic extrusion mold core in a machine head of a plastic extrusion machine; and c, carrying out plastic extrusion on the sheath by the plastic extruding machine to enable the sheath to be formed on the surface of the cable core. According to the invention, before plastic extrusion, the residual asphalt paint on the surface of the cable core is dried so as to prevent the temperature reduction of the plastic extrusion mold core in the plastic extrusion process, and guarantee the normal extrusion of a non-metallic sheath, and consequently the quality of the non-metallic sheath is enhanced greatly.

Owner:CHONGQING TAISHAN CABLE

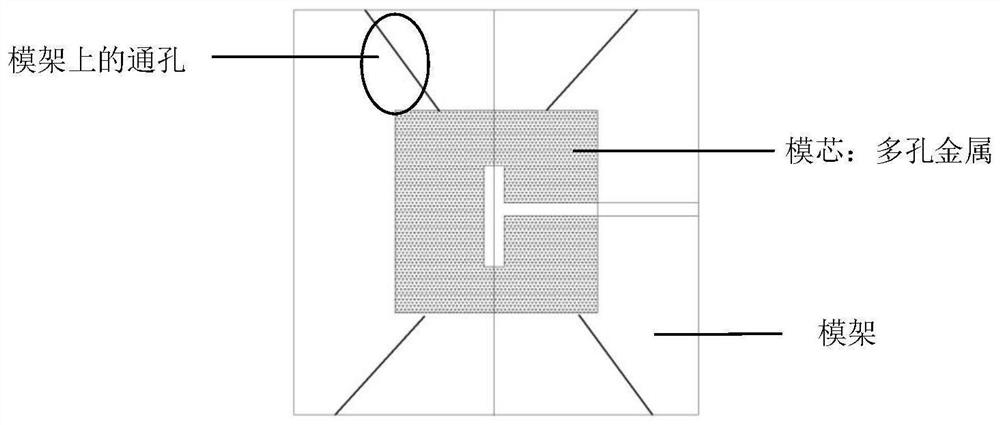

Method for realizing metal injection molding by injection slurry

The invention discloses a method for realizing metal injection molding by injection slurry and belongs to the field of metal injection molding. According to the invention, metal powder, a polymer monomer, a dispersing agent and a solvent serve as raw materials and are evenly mixed to obtain the injection slurry, the injection slurry is injected into a heated mold through an injection machine (a mold core of the mold is made of porous metal), bubbles and the solvent in the slurry are removed through a porous channel, and solvent volatilization is realized under the effect of mold temperature; and then in-situ curing forming of an injection green body is realized, and the injection green body obtained after demolding is degreased and sintered to obtain a metal part in a complex shape. solvent volatilization of the injection slurry is realized by using the porous metal as an injection mold, so that in-situ curing is triggered, and an injection green body is obtained. The preparation and injection of the injection slurry can be carried out at normal temperature, so that the requirements on the production environment are reduced, the traditional solvent removal / acid removal process is omitted, degumming and sintering can be directly carried out, and the method is simple in process, short in flow, high in applicability and suitable for large-scale industrial production.

Owner:UNIV OF SCI & TECH BEIJING

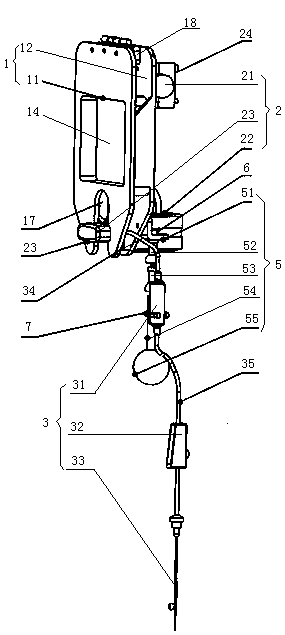

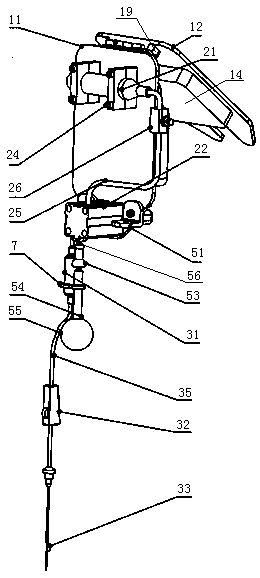

Shearing-type infusion squeezing device

PendingCN109364327APracticalGuaranteed normal extrusionMedical devicesPressure infusionGravitational forceEngineering

The invention discloses a shearing-type infusion squeezing device. The device comprises a squeezing device, a pressure driving device and an infusion device, the squeezing device is composed of a fixing plate, a moving plate hinged to the fixing plate, a pressure driving device is fixed to the outer side of the fixing plate, a gravitational force balancing device is arranged at the bottom of the outer side of the fixing plate and is composed of an L-shaped hanging panel, a ball hinge A, a ball hinge B, a connecting rod and a heavy hammer, one face of the L-shaped plate is fixed to the fixing plate, the other face is suspended on the ball hinge A, the bottom of the ball hinge A is rotatably connected with the top of the ball hinge B, the bottom of the ball hinge B is rotatably connected with the top of the connecting rod, the bottom of the connecting rod is fixed to the heavy hammer, and a Murphy's dropper is fixed to the connecting rod through a clamping hoop. According to the device,infusion liquid is squeezed in a shearing-type progressive squeezing manner, the infusion liquid does not need to be hanged high, the Murphy's dropper is allowed to be always in a perpendicular statethrough the cooperation of the ball hinge A, the ball hinge B and the heavy hammer, the observation of the dripping speed of medicinal liquid is convenient, and the dripping speed is further controlled through a speed regulator.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

Garbage bag separation type garbage can for community

InactiveCN112644919ARealize deliveryAchieve scratchWaste collection and transferRefuse receptaclesComputer hardwareCommunity setting

The invention discloses a garbage bag separation type garbage can for a community. A garbage bag collecting box is mounted at a garbage bag outlet in the top of a can body, two clamping rollers are slidably mounted between a garbage inlet and the garbage bag outlet through a sliding frame, a clamping gap extending in the direction of a sliding rail is formed between the two clamping rollers, and a scratching knife is located below the two clamping rollers. A can cover is installed at the garbage inlet in one side of the can body and connected with the sliding frame through a connecting rod. According to the optimally-designed garbage bag separation type garbage can for the community, switching of the positions of clamping mechanisms is achieved through opening and closing of the can cover, so that garbage throwing, garbage bag scratching and garbage and garbage bag separation are achieved, meanwhile, through relative rotation of the clamping rollers, it is guaranteed that the garbage in the garbage bag is thoroughly extruded out, and the garbage bag is fed into the garbage bag collecting box.

Owner:阜阳莱纳环保科技有限公司

High-voltage cable sheath extrusion process, anti-mold device and drying device

The invention discloses a high-voltage cable sheath extrusion technology and a device. The technology comprises the following steps: a, blowing residual asphalt paint attached to the surface of the cable core; b, threading the cable core into a plastic extrusion mold core in a machine head of a plastic extrusion machine; and c, carrying out plastic extrusion on the sheath by the plastic extruding machine to enable the sheath to be formed on the surface of the cable core. According to the invention, before plastic extrusion, the residual asphalt paint on the surface of the cable core is dried so as to prevent the temperature reduction of the plastic extrusion mold core in the plastic extrusion process, and guarantee the normal extrusion of a non-metallic sheath, and consequently the quality of the non-metallic sheath is enhanced greatly.

Owner:CHONGQING TAISHAN CABLE

Manufacture method of aluminium boron alloy board for nuclear power

InactiveCN103341518AGuaranteed normal extrusionImprove product qualityNuclear power5005 aluminium alloy

A provided manufacture method of an aluminium boron alloy board for nuclear power comprises the following steps: step 1, powder metallurgy: 65% by mass percent of a 6061 aluminium alloy and 35% by mass percent of a boron carbide powder are employed for powder metallurgy, and an aluminium boron alloy flat ingot with an elliptical section is prepared, wherein the elliptical section has a semi-major axis of 110 mm and a semi-minor axis of 30 mm; step 2, extrusion moulding: the flat ingot is placed in a flat extrusion container and is extruded to form a board with a rectangular section, wherein the rectangular section has a length of 200 mm and a width of 3 mm; step 3, rolling and flattening: the extrusion moulded board is rolled for removing of extrusion-caused mixed waste materials of aluminium and the aluminium boron alloy; and step 4, surface treatment: the board is subjected to oxidation treatment. The extrusion moulding of the aluminium boron alloy board can be guaranteed, and the production quality of the aluminium boron alloy board is improved.

Owner:浙江富丽华铝业有限公司

Photosensitive layer coating device

ActiveCN111111999ARelieve pressureAvoid spreadingLiquid surface applicatorsCoatingsEngineeringElasterell

The invention relates to the technical field of printed circuit board manufacturing equipment, in particular to a photosensitive layer coating device. The device comprises two conveying devices whichare arranged in an up-down mode and have the same linear speed, wherein one of the conveying devices conveys a circuit board, a plurality of coating assemblies are fixed to the other one conveying device, each coating assembly comprises a corresponding shell, a corresponding glue solution cavity is formed in each shell, the glue solution cavities are provided with openings capable of facing the circuit board correspondingly, pressing plates capable of being attached to the circuit board are slidably connected to the insides of the openings correspondingly, a plurality of pore channels enablingthe glue solution cavities to communicate with the outside are fully distributed in the pressing plates correspondingly, and elastic pieces capable of pushing the pressing plates to slide relative tothe openings are arranged between the pressing plates and the inner walls of the glue solution cavities correspondingly. According to the scheme, coating of photo-sensitive resist is completed by attaching the pressing plates to the surface of the circuit board, and the uniformity of coating of the photo-sensitive resist in the prior art is improved.

Owner:重庆市和鑫达电子有限公司

Gluing device for building device engineering construction

ActiveCN113389359AApply evenlyImprove uniformityBuilding constructionsGear wheelArchitectural engineering

The invention discloses a gluing device for building device engineering construction. The device comprises a sliding seat, a glue containing vessel is slidably arranged on the lower wall of the sliding seat, an annular sliding groove corresponding to the glue containing vessel is formed in the lower wall of the sliding seat, the four walls of the glue containing vessel are slidably arranged in the annular sliding groove, a glue injection opening is fixedly formed in the upper wall of the sliding seat, the glue injection opening communicates with the glue containing vessel, a sealing cover is arranged on the glue injection opening, and a glue conveying plate is fixedly arranged on the side wall of the sliding seat and communicates with an inner cavity of the glue containing vessel through a conveying pipe. According to the device, the sliding seat is driven to slide down by virtue of the gravity of the sliding seat, and all parts of the device are driven to transmit through the matching of a clamping gear and a clamping tooth plate, so that glue is extruded and uniformly smeared without being sequentially smeared manually, and the gluing efficiency is greatly improved; and the problem that the attractiveness is affected due to non-uniform coating of glue on the wall is effectively avoided, and the gluing effect is greatly improved.

Owner:南通东泓建筑装饰工程有限公司

Anti-dripping anticorrosive paint spraying equipment

The invention relates to the technical field of anticorrosive paint spraying, in particular to anti-dripping anticorrosive paint spraying equipment. The equipment comprises a base and a fixed frame, wherein the fixed frame is fixedly connected to the left side of the upper end face of the base, a heating mechanism is arranged at the inner side of the fixed frame, a temperature sensor is fixedly connected to the left side of the heating mechanism, a controller is fixedly connected to the inner wall of the left side of the fixed frame, a storage device is fixedly connected into the heating mechanism, the lower end face of the heating mechanism is fixedly connected with the base, and a connecting pipe is fixedly connected to the right side of the heating mechanism. According to the equipment,through the arrangement of a rotating ring, a flow guide pipe, a containing hopper, a hose and a storage box, in the spraying process of a spraying gun, the arranged containing hopper can collect dripped paint and prevent the dripped paint from polluting the environment; and when the spraying gun conducts rotary spraying or movable spraying, the containing hopper is accurately located below the spraying gun, it is guaranteed that the material accurately drips into the containing hopper to be collected, and resource waste is avoided.

Owner:湖南开磷雁峰塔涂料有限公司

End-expanded anchor rod and construction method thereof

PendingCN112575779AGuaranteed reliabilityGuaranteed extrusionExcavationsBulkheads/pilesRubber ringArchitectural engineering

The invention discloses an end-expanded anchor rod and a construction method thereof, and belongs to the technical field of anchoring. The end-expanded anchor rod comprises an anchor rod body, a firstpressing mechanism, a bag body, a locking plug, a first supporting rod, a second supporting rod, a third supporting rod, a grouting pipe, a sleeve, a slurry discharging channel, an end plate, a second pressing mechanism, a sliding sleeve, a smooth surface pipe and a jacking plate, wherein the first pressing mechanism comprises a mechanism main body, a locking buckle, a sealing rubber ring, a ballvalve, a supporting guide frame, a grouting channel, a pressing plug and a pressing spring; and the construction method of the end-expanded anchor rod comprises the following construction steps of pre-testing, drilling construction, anchor rod lowering, bag body grouting, prestress tensioning and construction ending. According to the end-expanded anchor rod and the construction method thereof, main power is applied to supporting rod pieces through slurry pressure, so that the reliability of full expansion of the bag body is guaranteed; the plurality of supporting rod pieces are arranged, so that the strength of an anchoring body is enhanced; and the bag body is made of a rigid material, so that the extrusion and expansion effect of the bag body on surrounding soil is enhanced.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com