Steel wire rope dirt-removing oiling machine

A steel wire rope and oiler technology, which is applied in the auxiliary devices, cleaning methods and utensils of rope making, and cleaning methods using tools, etc. problem, to achieve a significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

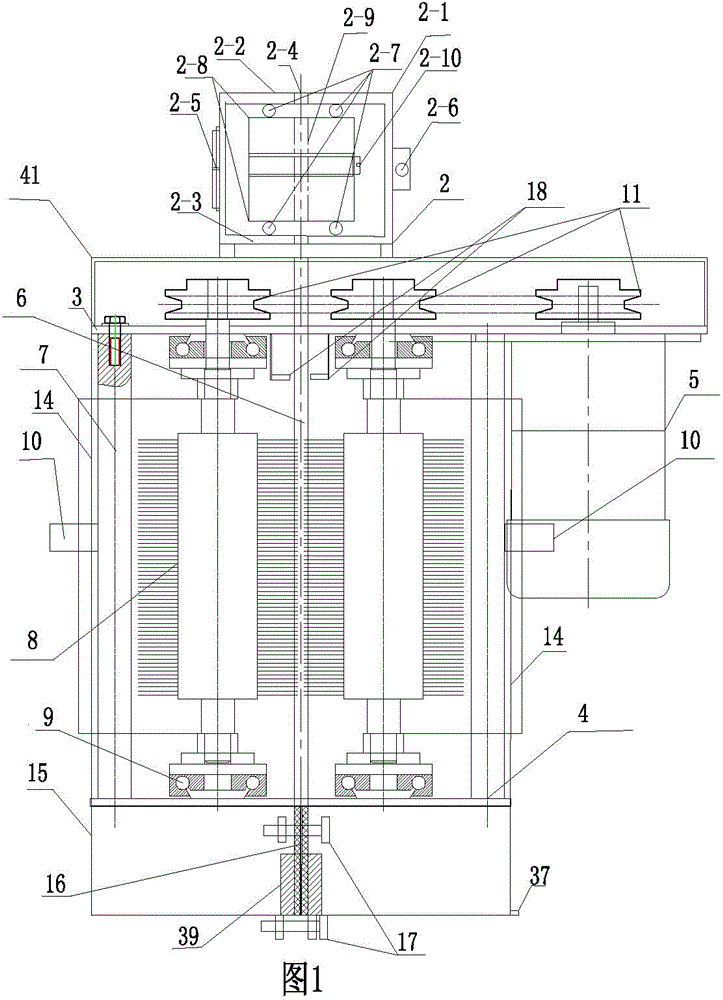

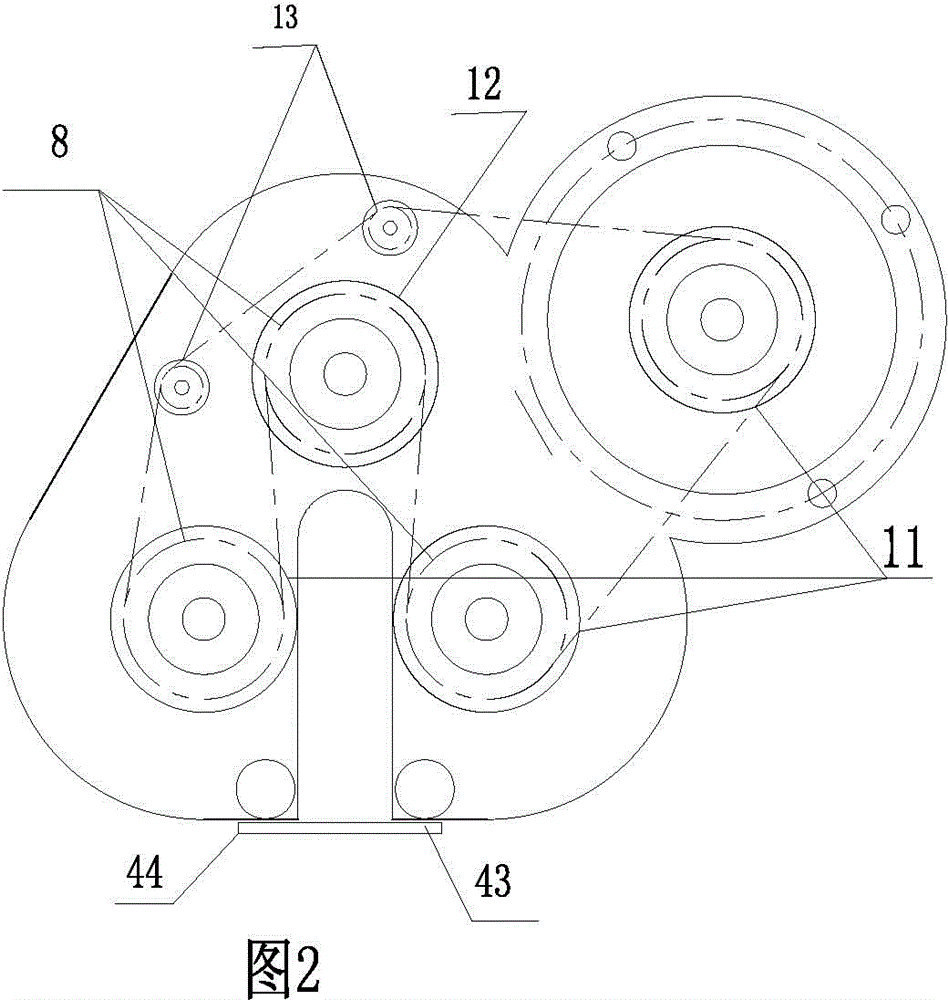

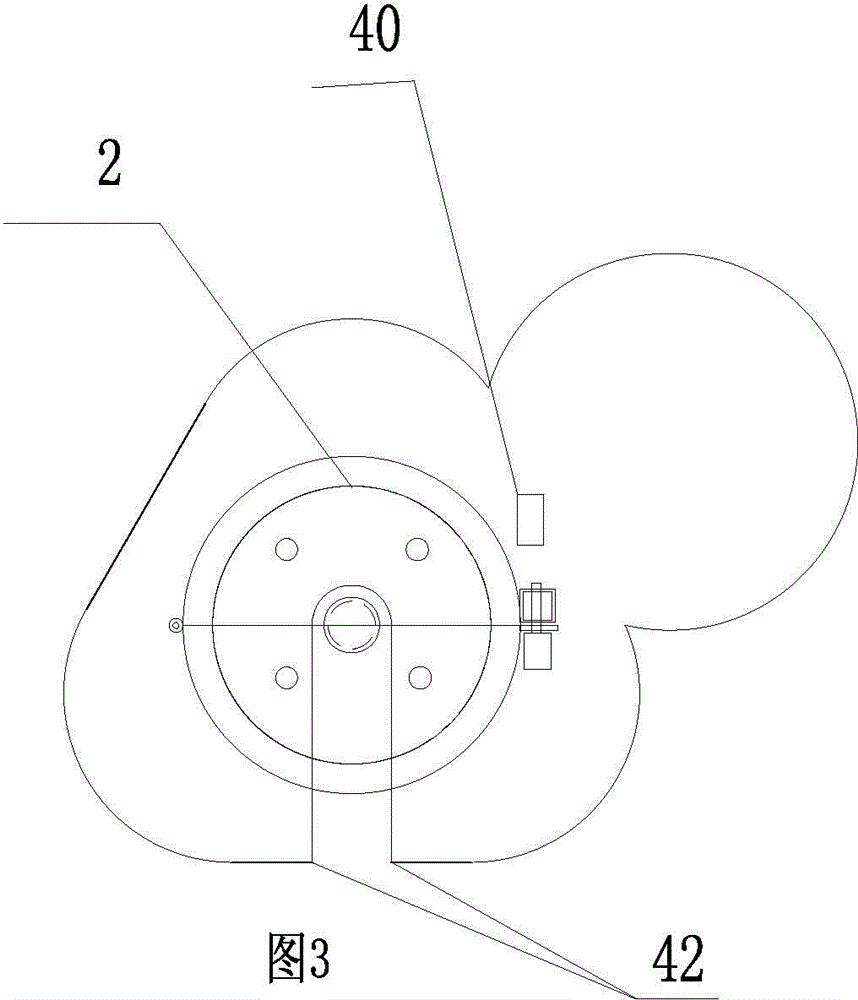

[0023] The present invention as Figure 1 to Figure 9 As shown, the steel wire rope dirt removal and oiling machine includes a cleaning device, a grease injection device, an oil supply vehicle, and a forward and reverse electric hoist is fixed on the upper end of the wire rope. The traction rope of the hoist is connected to the hoisting hook 40 for reciprocating motion, and is characterized in that: The cleaning device includes, spiral type mud removal device 2, inner hollow cylinder 2-1, upper cylindrical sealing plate 2-2, lower cylindrical sealing plate 2-3, upper cylindrical sealing plate 2-2, lower cylindrical sealing plate 2 -3 In the center of the cylinder, there is a hole 2-4 with a diameter of 1mm slightly larger than that of the steel wire rope. Among them, the upper cylindrical sealing plate 2-2, the lower cylindrical sealing plate 2-3 are welded together with the inner hollow cylinder, and then cut in the center and divided into two , and weld the two halves of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com