Anti-dripping anticorrosive paint spraying equipment

A technology for spraying equipment and anti-corrosion coatings, which is applied to spraying devices, liquid spraying devices, etc., can solve the problems of working environment impact, waste of resources, paint dripping, etc., to ensure normal use, avoid skinning, and ensure the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

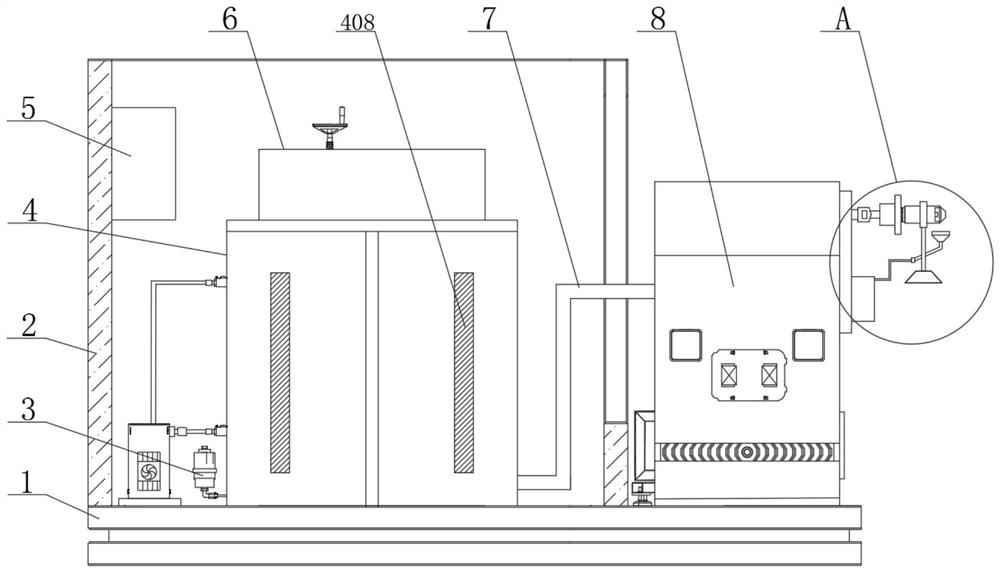

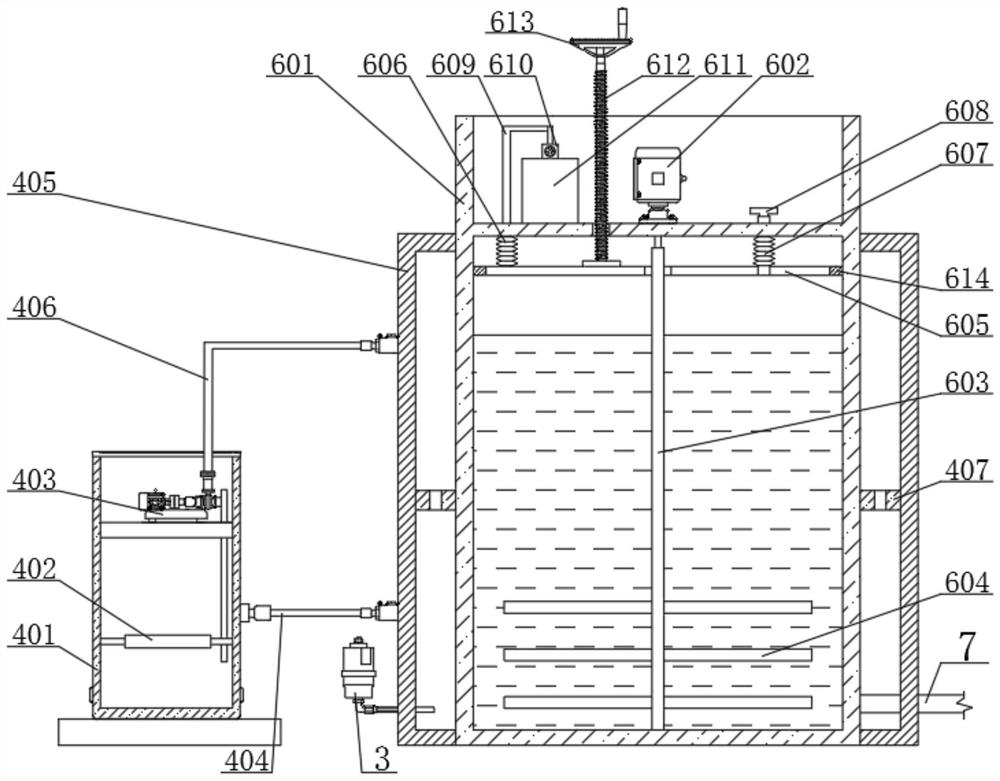

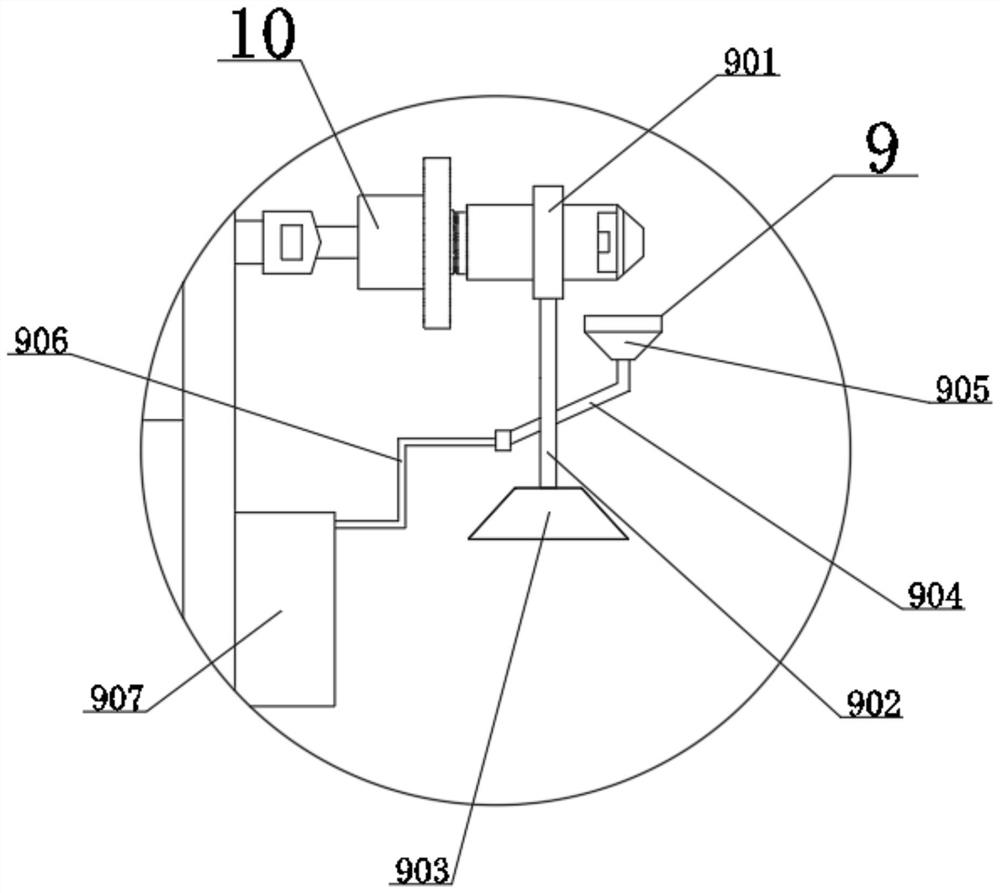

[0025] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution:

[0026]An anti-dripping anti-corrosion paint spraying equipment, comprising a base 1 and a fixed frame 2, the fixed frame 2 is fixedly connected to the left side of the upper end surface of the base 1, and a heating mechanism 4 is provided on the inner side of the fixed frame 2, and the heating mechanism 4 includes a heating Box 401 and heating wire 402, the lower end surface of heating box 401 is fixedly connected with base 1, the inside of heating box 401 is fixedly connected with water pump 403 and heating wire 402 distributed up and down, and the right side of heating box 401 is fixedly connected with input pipe 404 , the other end of the input pipe 404 is fixedly connected to an incubator 405, the upper end of the water pump 403 is fixedly connected to an output pipe 406, the other end of the output pipe 406 is fixedly connected to the incubato...

Embodiment 2

[0029] In embodiment 2, the same part as embodiment 1 will not be repeated. The difference is that when it is used in winter, the fluidity of its paint becomes worse. At this time, by starting the heating wire 402, it is heated to the water source, and the warm water passes through The water pump 403 is drawn out, and is input into the incubator 405 through the output pipe 406, and then the paint bucket 601 can be heated to ensure the fluidity of the paint and ensure its normal use. The water source enters the heating box 401 for heating, and when the temperature sensor 3 detects that the temperature is 20°C, a signal is sent to the controller 5 at this time, and the controller 5 controls the heating wire 402 and the water pump 403 to stop working, and the paint can flow normally at this time , has very good practical value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com