Photosensitive layer coating device

A technology of coating device and photosensitive layer, which is applied in the direction of device and coating for coating liquid on the surface, can solve the problems of easy slippage between roller and copper plate, inconsistent linear speed between roller and copper plate, uneven coating of photosensitive adhesive, etc. Achieve the effect of improving coating uniformity and avoiding external scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 is basically as follows:

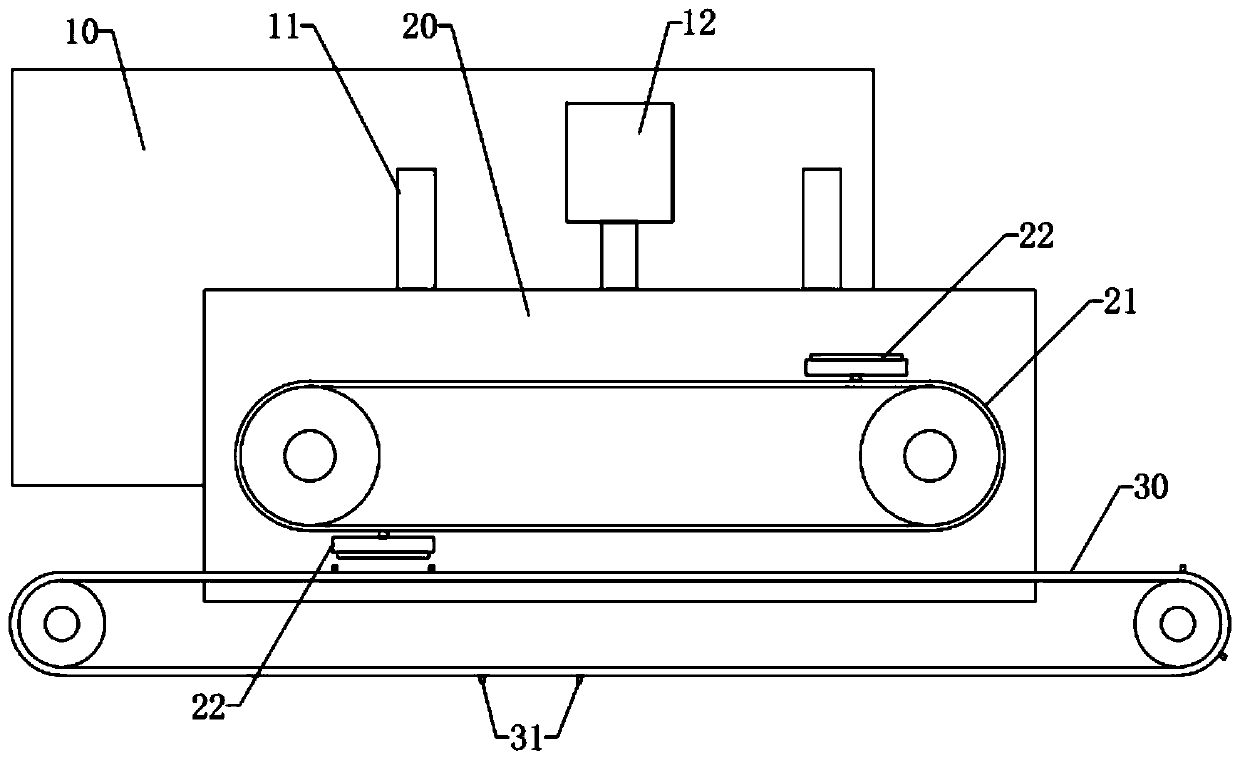

[0027] Apparatus for photosensitive layer coating, including frames, such as figure 1 As shown, a fixed plate 10 is fixed on the frame, and two vertical chutes 11 are provided on the fixed plate 10 , the chute 11 is slidably connected with a slider, and the slider is fixedly connected with a lifting plate 20 . The lifting plate 20 is rotatably connected with two sprockets, and the sprocket wheel on the right is connected with a driving motor, and the driving motor and the lifting plate 20 are fixed. The transmission chain 21 is connected on the two sprockets. The fixed plate 10 is fixedly connected with an air cylinder 12, and the telescopic shaft of the air cylinder 12 is fixed with the lifting plate 20.

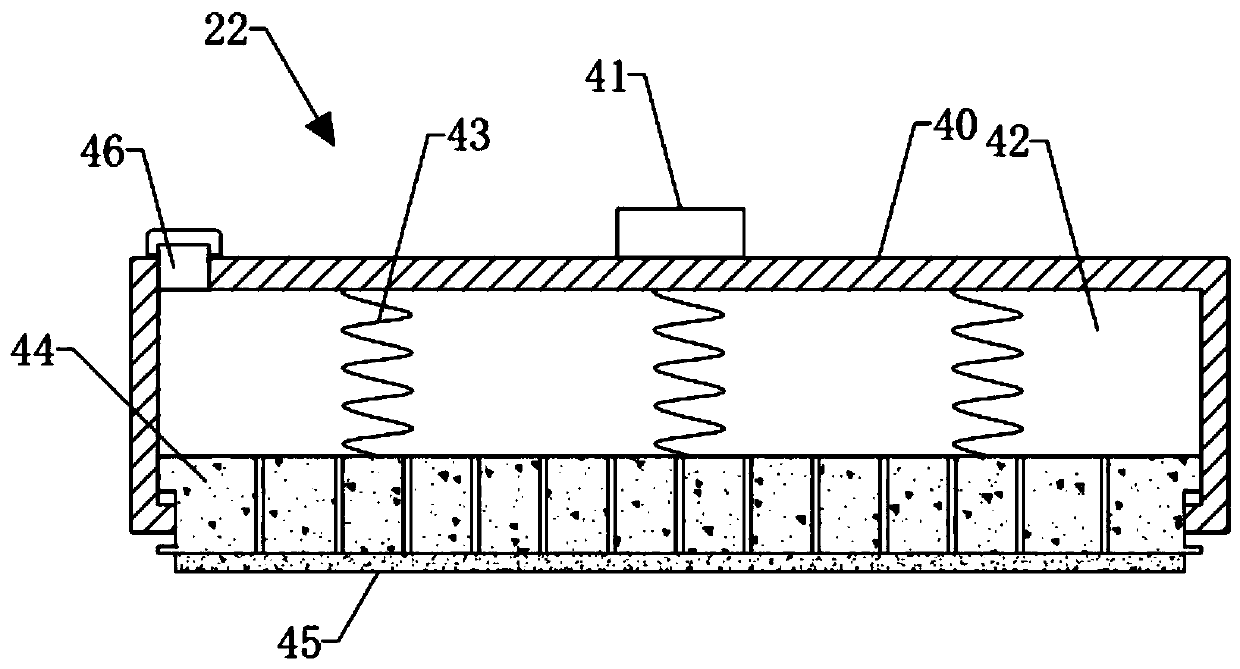

[0028] The conveyor chain 21 adopts a bent plate chain, and a plurality of coating assemblies 22 are fixed on the conveyor chain 21, and there are two coating assemblies 22 in this embodiment. The bottom of the transmission ...

Embodiment 2

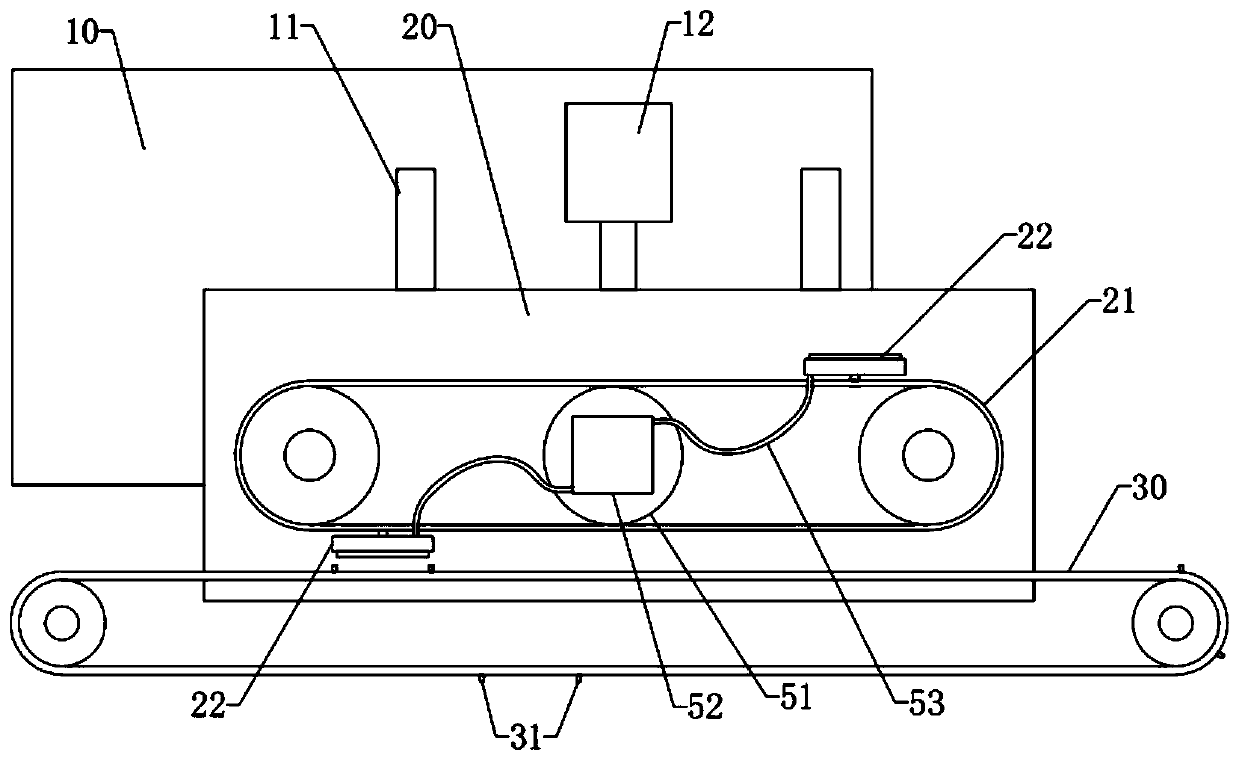

[0032] The difference from Embodiment 1 is that, as image 3 As mentioned above, a driven sprocket 51 is arranged between the left and right sprockets of the transmission chain 21 , and the diameter of the driven sprocket 51 is the same as that of the left and right sprockets, and the driven sprocket 51 meshes with the transmission chain 21 . The driven sprocket 51 is rotatably connected with the lifting plate 20 . A liquid storage tank 52 is fixed on the driven sprocket 51, and the liquid storage tank 52 is connected with a liquid delivery pump, and the liquid storage tank 52 is communicated with a flexible liquid supply pipe 53, such as Figure 4 As shown, the liquid supply pipe 53 communicates with the liquid filling port 46, and the liquid filling port 46 is fixed with a one-way liquid inlet valve.

[0033] In this way, when the photosensitive adhesive in the liquid storage chamber is almost used up, the liquid delivery pump can be opened to add the photosensitive adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com