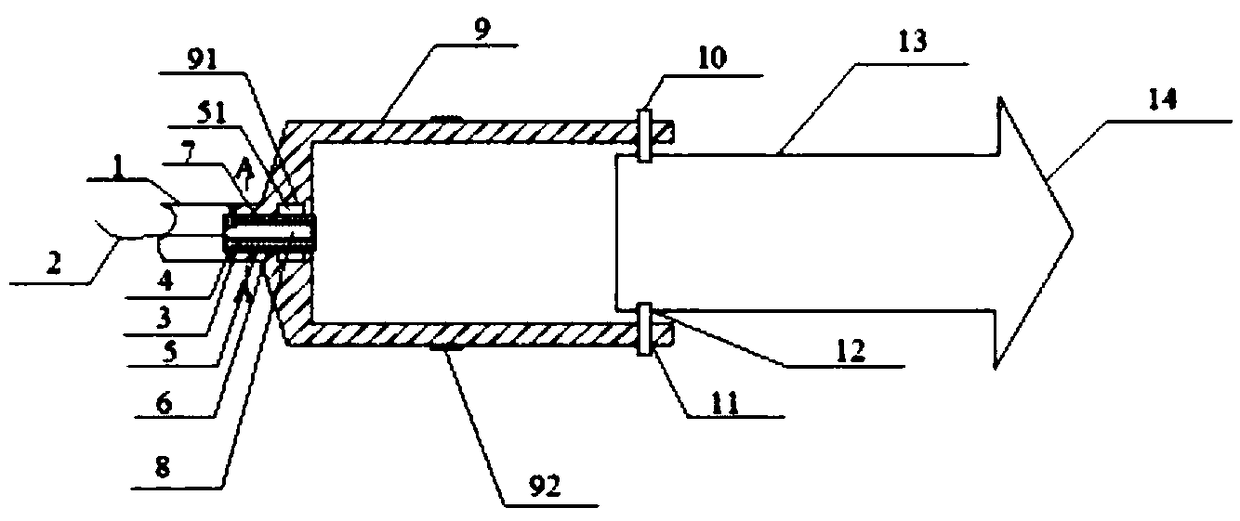

Hollow inclusion stressometer and measuring method

A hollow inclusion, stress gauge technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problem of not being able to accurately determine the complete extrusion of epoxy resin colloid, achieve convenient installation and disassembly, avoid damage, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Using the above-mentioned hollow inclusion stress gauge to test the ground stress includes the following steps:

[0028] (1) According to the required measurement area on the project site, carry out the design of the test plan, determine the position of the measurement point, and design the depth of the measurement point;

[0029] (2) Carry out on-the-spot drilling at the selected in-situ stress measurement points according to the layout plan of the measuring points, and drill a pilot hole with a diameter of 120mm perpendicular to the side of the roadway according to the predetermined inclination and depth of the design plan. The wall of the pilot hole is required to be complete, The hole diameter is consistent, and the phenomenon of drilling bending and hole collapse cannot occur;

[0030] (3) After the depth of the pilot hole reaches the ideal lithology, drill a stress sensor installation hole with a diameter of 100mm at the concentric position at the bottom of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com