Extrusion recovery device for beverage bottles

A recycling device and beverage bottle technology, applied in plastic recycling, recycling technology, grain processing, etc., can solve problems such as unfavorable recycling efficiency, occupied space, and reduced single-way transportation volume, so as to improve extrusion efficiency and reduce labor pressure , to ensure the effect of normal extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

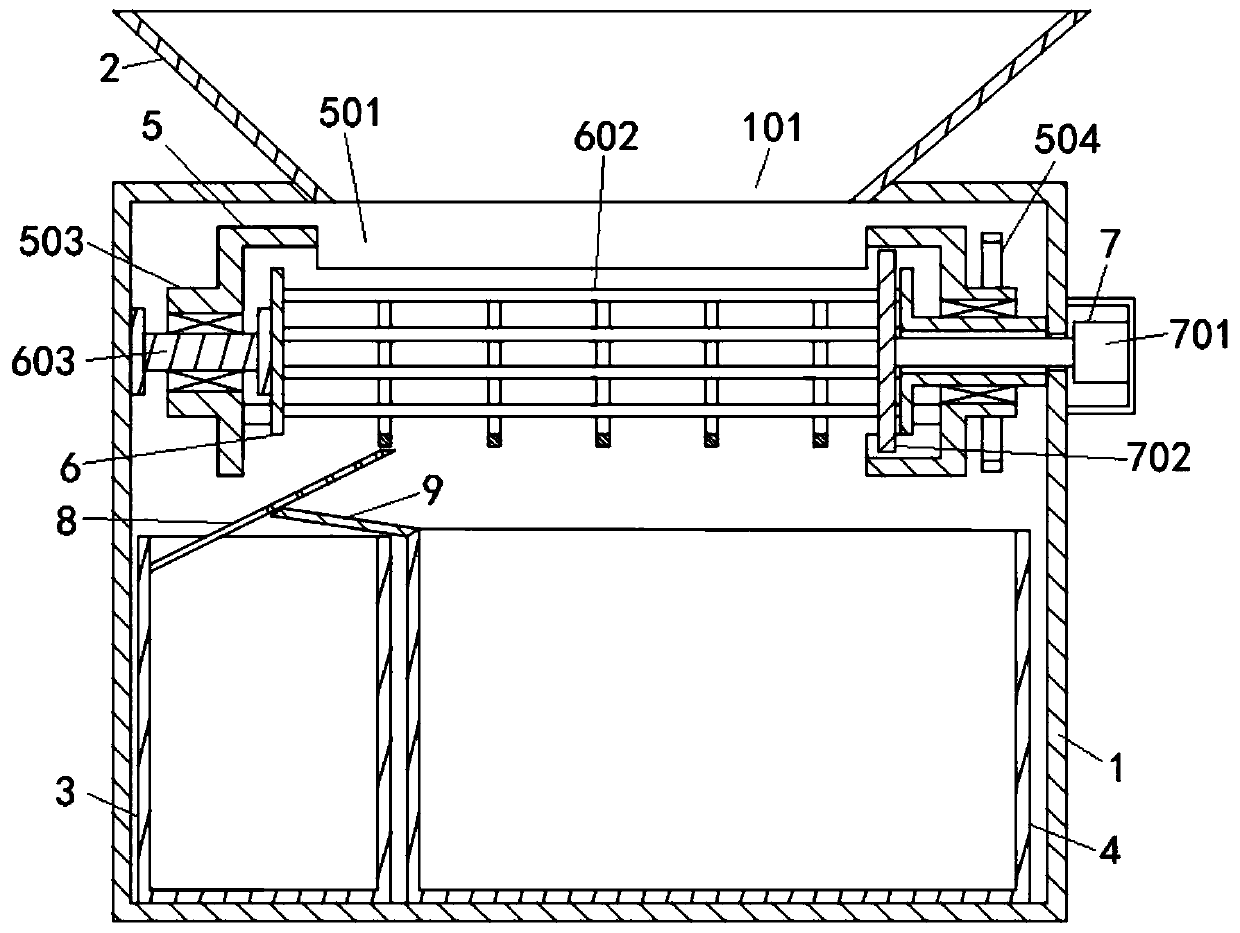

[0027] Such as figure 1 As shown, the present invention is a squeeze recovery device for beverage bottles, including a box body 1, a lower hopper 2, a first recovery box 3 and a second recovery box 4; the top of the box body 1 is provided with a feeding port 101, There is a lower hopper 2 connected to the feeding port 101; an electromagnetic vibrator can be installed on the lower hopper 2 to prevent the beverage bottles from being stuck and not falling, and the beverage bottles are controlled by the microprocessor;

[0028] An extruding mechanism is fixedly installed inside the box body 1; a first recovery box 3 and a second recovery box 4 are respectively placed at the bottom of the box body 1;

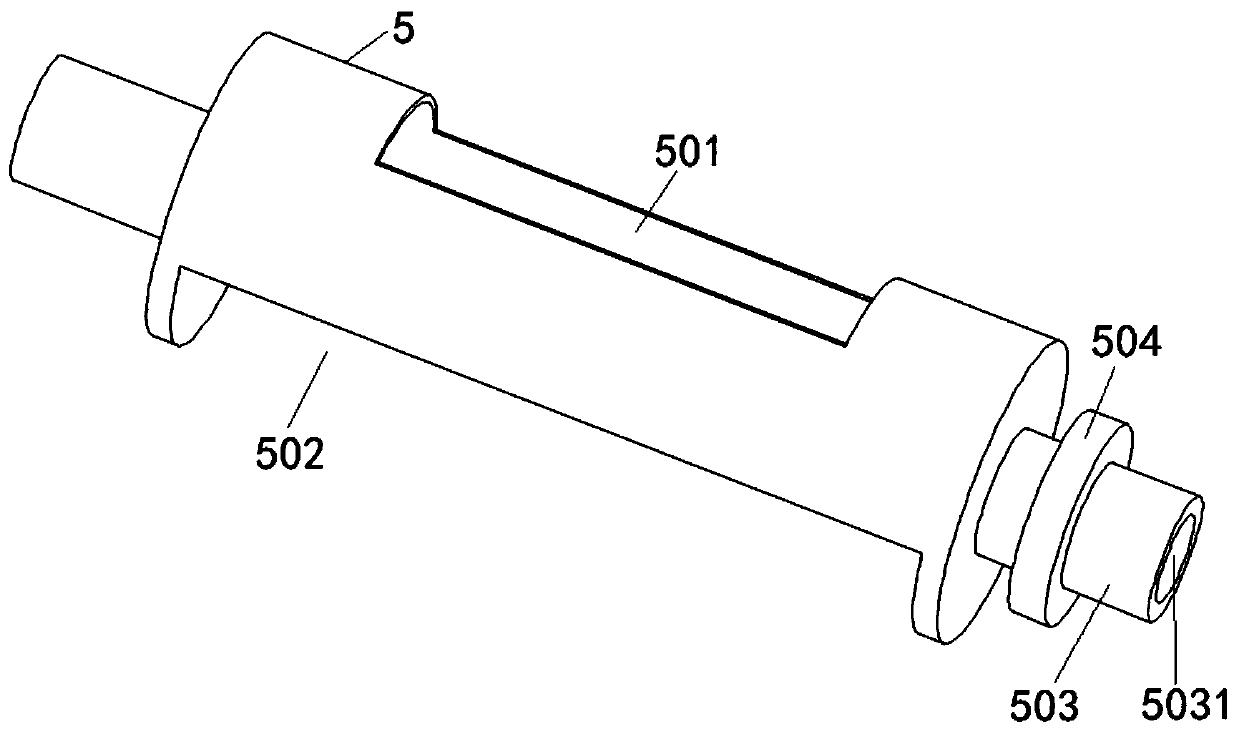

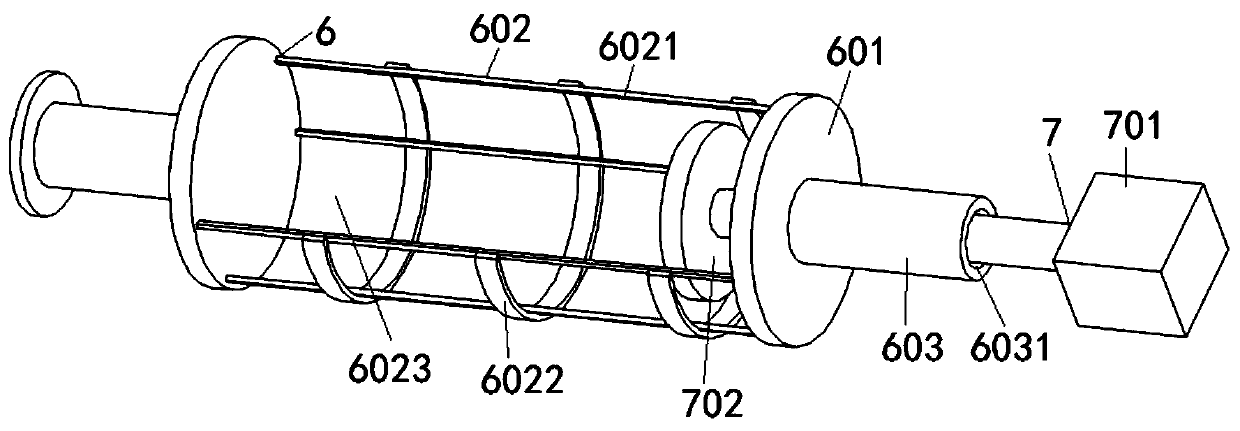

[0029] The extruding mechanism includes a rotating shell 5, an extruding cylinder 6 and an extruding assembly 7; the rotating shell 5 is connected to a transmission mechanism; the extruding cylinder 6 is installed in the rotating shell 5;

[0030] Such as Figure 1-2 As shown, the ...

Embodiment 2

[0045] Such as Figure 5 As shown, in order to rationally utilize the bottom space of the box body 1 and reasonably allocate the storage space of the first recovery box 3 and the second recovery box 4, the first recovery box 3 and the second recovery box 4 can be designed respectively according to the use environment and storage capacity. The recovery box 4, the first recovery box 3 and the second recovery box 4 are not necessarily rectangular, but may be irregular.

Embodiment 3

[0047] In combination with embodiment one, Image 6 Can be seen as figure 1 According to the left view sectional view of the hopper 2, a plurality of discharge channels 201 can be arranged inside the discharge hopper 2, and extrusion mechanisms are respectively provided below the plurality of discharge channels 201, and the principle of squeezing the beverage bottle is the same as that of the first embodiment The beverage bottles squeezed by the three extrusion mechanisms enter the first recovery box 3 after being guided by the guide mesh plate 8 to be recycled, and the broken glass slag after the three extrusion mechanisms will leak through the screen 802 The guiding function of the guide slideway 9 enters into the second recovery box 4 or leaks from the semi-cylindrical ring net 602 into the second recovery box 4; it can improve the extrusion and recovery efficiency of beverage bottles and reduce people's labor pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com