Heating component for plastic extruding machine

A technology of heating components and extruders, applied in the field of extruders, can solve the problems of low heating efficiency and uneven heating of the barrel, and achieve the effects of improving heating efficiency, simple structure, and convenient setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

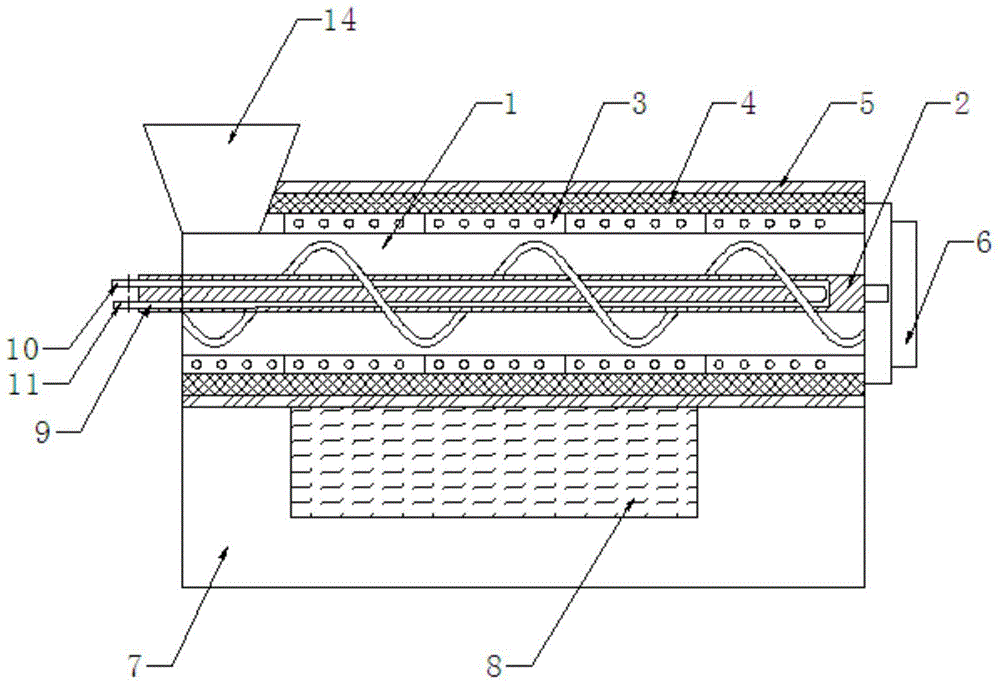

[0018] Such as figure 1 As shown, in the extruder, the raw material enters the barrel 1 from the feed hopper 14, is heated by the heating device and melted under the extrusion of the screw 2 and the barrel, and is driven by the movement of the screw 2 at the head connector 6. , Extruded by mold.

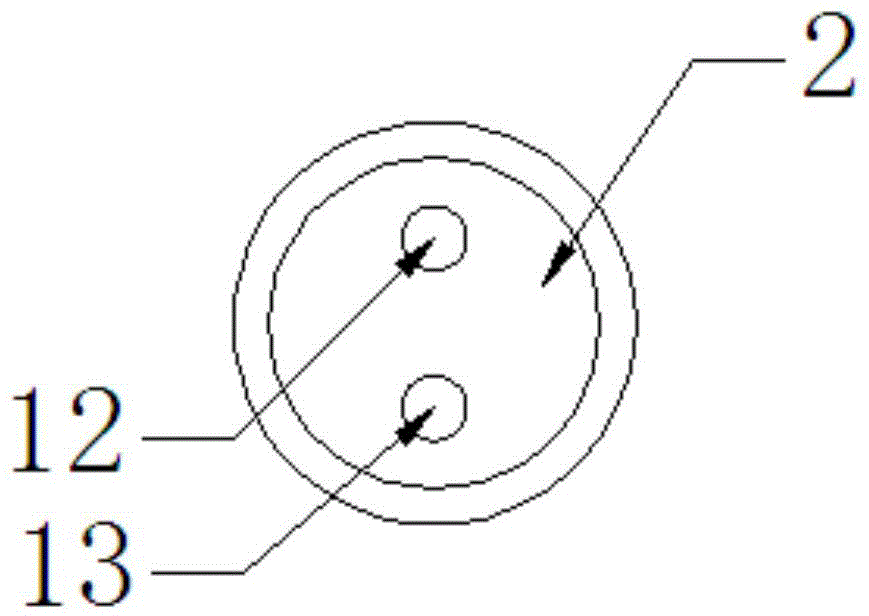

[0019] Such as figure 1 with figure 2 As shown, a heating assembly of an extruder includes at least three sets of heating devices 3 set outside the barrel 1 and a casing 5 set outside the heating device 3 to protect the heating device 3 .

[0020] Heating device 3 infrared heating device or electromagnetic heating device. The heating devices 3 are evenly arranged along the axis of the barrel 1 .

[0021] The screw 2 is provided with an auxiliary heating channel 9 which is U-shaped and arranged sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com