Toothpaste extruder

An extruder and toothpaste technology, applied in the field of daily necessities, can solve the problems of waste of living cost, laboriousness in extruding toothpaste, inconvenient use of the toothpaste extruder, etc., and achieve the effect of saving energy and reducing living costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

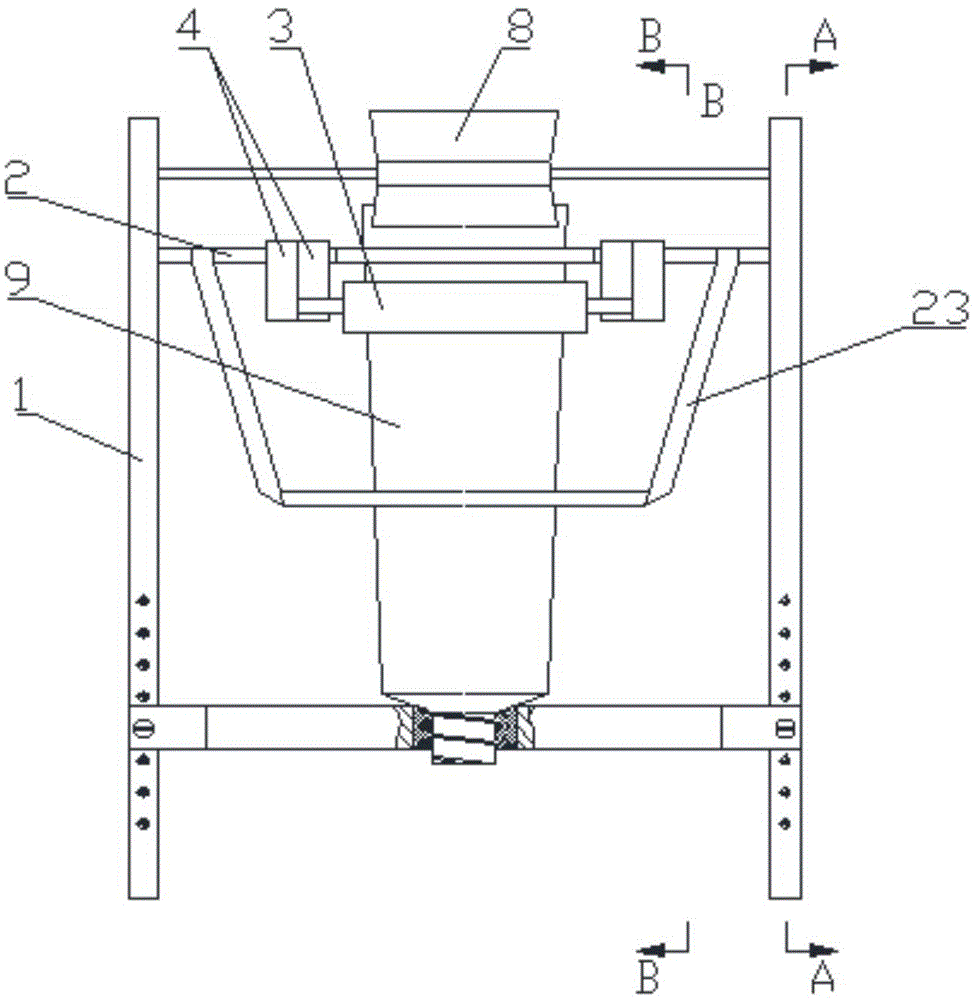

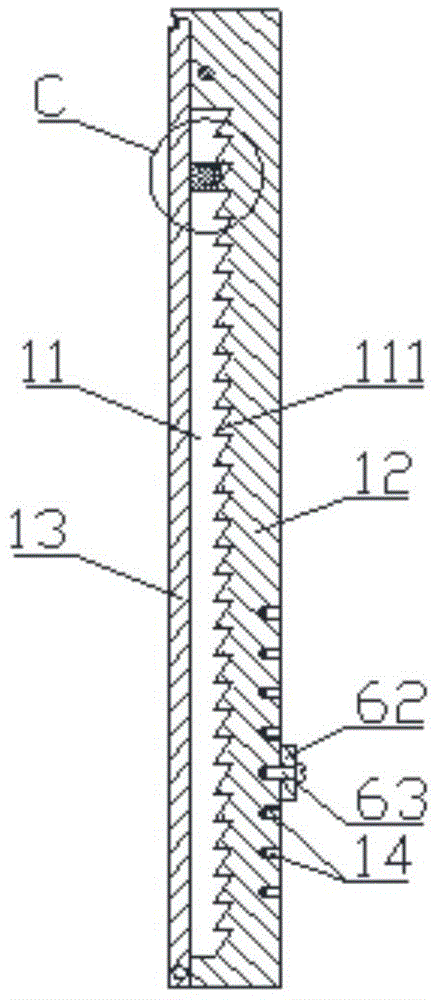

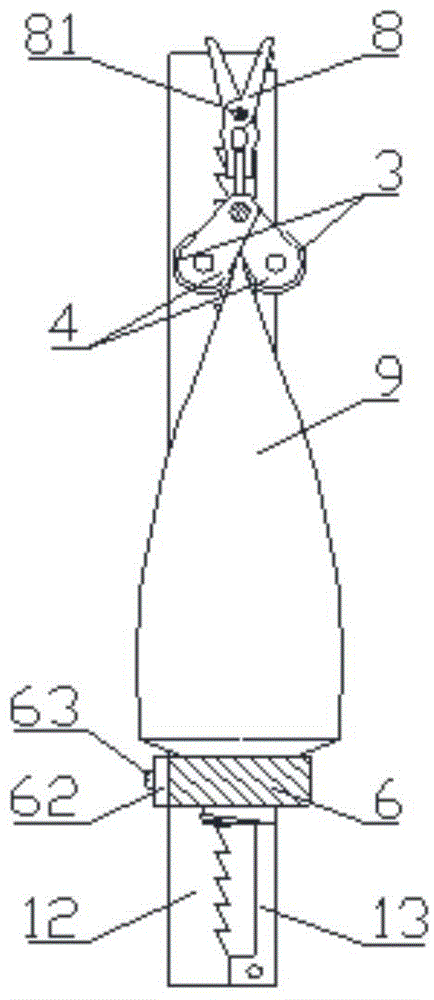

[0026] refer to Figure 1 to Figure 4 , a toothpaste extruder, including a bracket and extrusion parts, the bracket includes vertical plates 1 on both sides, and a first fixing member for fixing the head of the toothpaste case 9 is arranged between the vertical plates 1 on both sides and the second fixing part for fixing the tail of the toothpaste case 9, the extruding part is arranged between the first fixing part and the second fixing part, and the extruding part comprises a connecting rod 2 and an extruding part The roller 3 is provided with a chute 11 on the opposite side of the vertical plate 1 on both sides, the chute 11 extends from one end of the vertical plate 1 to the other end of the vertical plate and the two ends of the chute are closed, The connecting rod 2 is arranged in the chute and can slide along the chute from the tail of the toothpaste case to the head of the toothpaste case; the front and back of the toothpaste case are provided with the squeeze rollers ...

Embodiment 2

[0036] refer to Figure 9 The difference between this embodiment and the above-mentioned embodiment 1 is that two connecting rods are provided, and the two connecting rods are respectively distributed on both sides of the squeeze roller, and one end of the connecting rod is connected to the squeeze roller. connected, and the other end is inserted into the chute. All the other implementations are the same as in Example 1.

[0037] The present invention is generally erect when in use, as Figure 9 As shown, fixing seats 15 can be set at the bottoms of the two vertical plates, which is also convenient for pulling or pressing the connecting rod downwards, and will not retreat upwards.

[0038] In the above-mentioned embodiment 1 and embodiment 2, in order to facilitate the balance of force on the connecting rod, a drawstring 23 can be provided on the connecting rod, and the two ends of the drawstring are arranged close to the two ends of the connecting rod and connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com