Method for realizing metal injection molding by injection slurry

A technology of injection molding and slurry, which is applied in the field of metal injection molding by injecting slurry, which can solve the problems of complex process, large metal specific surface area, and the risk of aggravating powder oxidation, and achieve the effect of simplifying the process and avoiding component segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for injecting slurry to realize metal injection molding, the specific preparation steps are as follows:

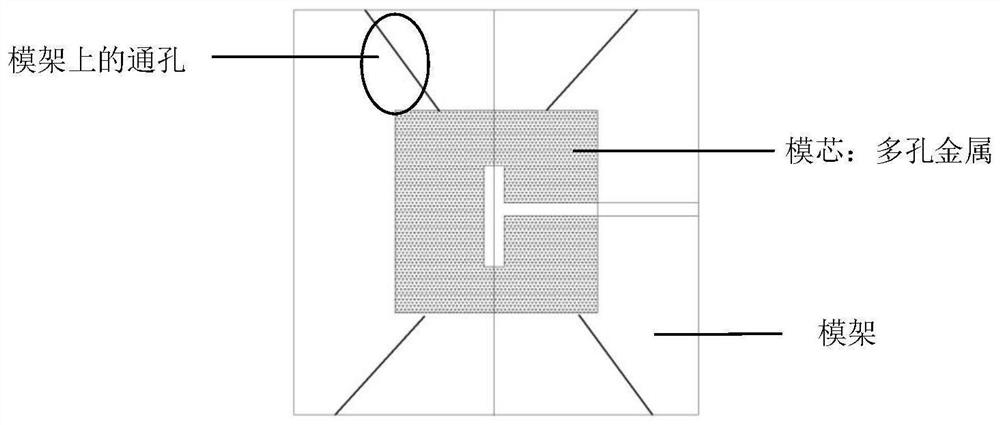

[0029] (1) Design the mold according to the target shape. The mold core of the mold is made of porous 45 steel with a relative density of 88% and is full of connected pores. The mold base is made of Q235 steel, and the vent hole is reserved.

[0030] (2) Mix 40 μm spherical titanium powder with isopropanol, polyvinyl acetate, and oleic acid in a volume percentage of 60:19:20:1, and mix evenly with a ball mill to obtain a uniform powder suspension slurry;

[0031] (3) Heat the mold to 50°C with a mold temperature controller, inject the injection slurry in step (2) into the mold, set the mold clamping time to 15s, and take out the injection body after the solvent is volatilized and solidified;

[0032] (4) Degumming and sintering the injection green body in step (3) in a degreasing and sintering furnace. The degumming process is 300°C for 2h, 500°C for 3h, an...

Embodiment 2

[0034] A method for injecting slurry to realize metal injection molding, the specific preparation steps are as follows:

[0035] (1) Design the mold according to the target shape. The mold core of the mold is made of porous 45 steel with a relative density of 85% and is full of interconnected pores. The mold base is made of Cr12 steel, and vent holes are reserved.

[0036] (2) Mix 10 μm 316L stainless steel powder with tert-butanol, polyisobutylene, and polyethylene glycol at a ratio of 53:25:20:2, and beat with ultrasonic vibration to obtain a uniform powder suspension slurry;

[0037] (3) Heat the mold to 40°C with a mold temperature controller, inject the injection slurry in step (2) into the mold, set the mold clamping time to 10s, and take out the injection body after the solvent is volatilized and solidified;

[0038] (4) Degumming and sintering the injection green body in step (3) in a degreasing and sintering furnace. The degumming process is to keep warm at 450°C for ...

Embodiment 3

[0040] A method for injecting slurry to realize metal injection molding, the specific preparation steps are as follows:

[0041] (1) Design the mold according to the target shape. The mold core of the mold is made of porous Cr12 steel with a relative density of 80% and is full of interconnected pores. The mold base is made of Q235 steel, and vent holes are reserved.

[0042] (2) Mix 20 μm high-speed steel W18Cr4V powder with deionized water, chlorosulfonated polyethylene, and ammonium citrate at a ratio of 60.5:18:20:1.5, and mix evenly by ultrasonic vibration to obtain a uniform powder suspension slurry;

[0043] (3) Heat the mold to 55°C with a mold temperature controller, inject the injection slurry in step (2) into the mold, set the mold clamping time to 8s, and take out the injection body after the solvent is volatilized and solidified;

[0044] (4) Degumming and sintering the injection body in step (3) in a degreasing and sintering furnace. The degumming process is 400°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com