Dual-fluid synchronous slip casting and cleaning switching mechanism

A technology of simultaneous grouting and switching devices, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve problems such as blockage of pipelines, and achieve the effects of reducing pipeline blockage rate, realizing timeliness, and controlling soil settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

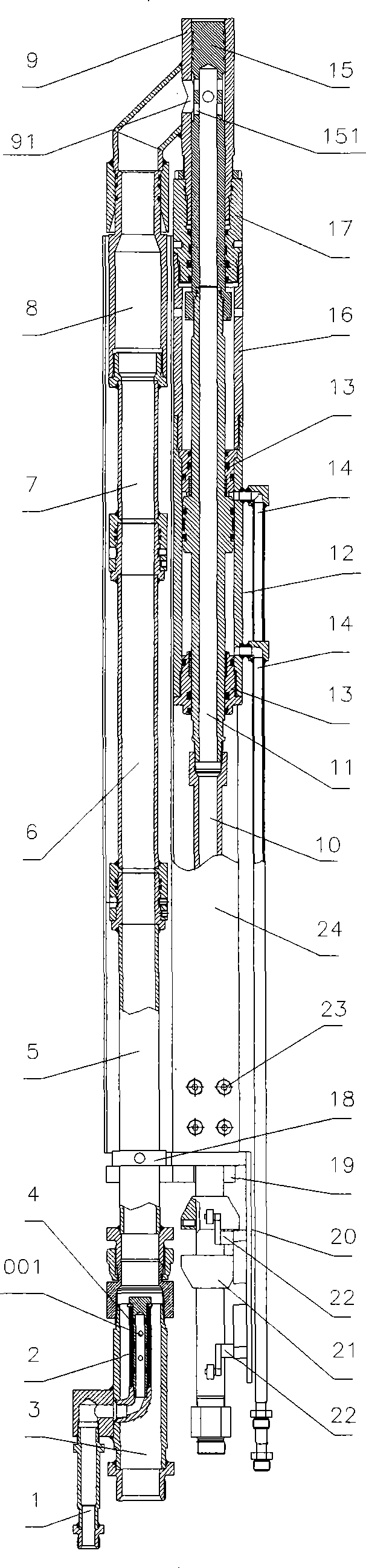

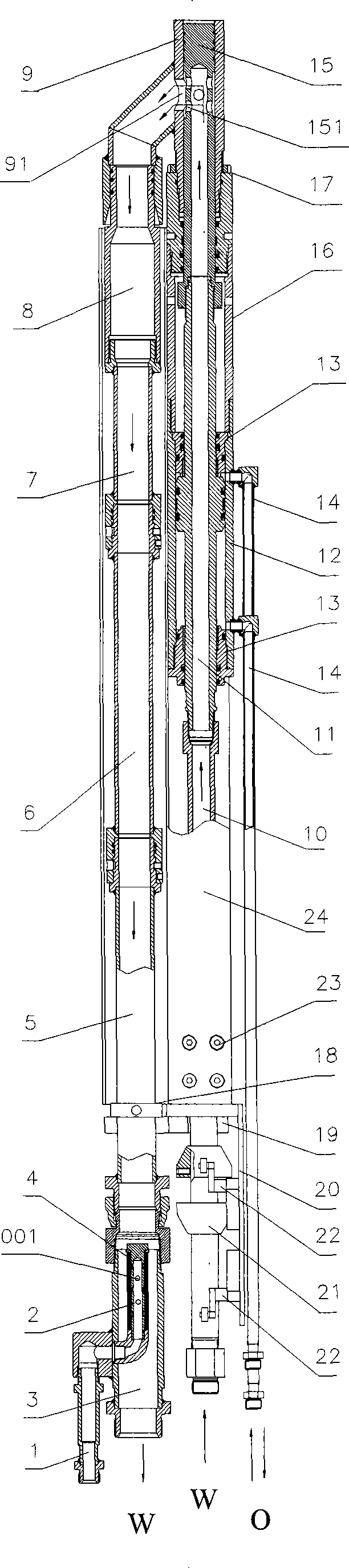

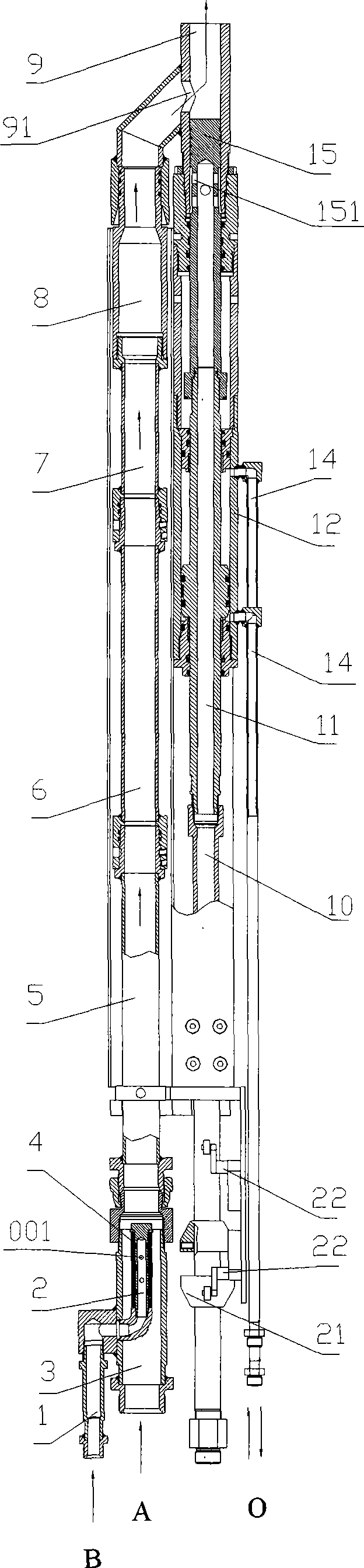

[0014] The present invention will now be described in further detail in conjunction with the accompanying drawings and specific embodiments.

[0015] See first figure 1 The schematic diagram of the structure of the present invention shows that the double-fluid synchronous grouting and cleaning switching device is a flat and narrow structure as a whole, installed in the outer casing of the shield machine, and includes a main grouting pipeline, an outlet pipe 9, a switching valve core 15, a cleaning Oil cylinder, cleaning water pipe 10, support mechanism and limit device.

[0016] The main grouting pipeline includes a mixing pipe at the grout inlet and several grout pipes connected thereto. The several slurry pipes are the main pipelines for conveying the slurry, which adopt a segmented structure, and the number of the slurry pipes is determined according to the specific conditions of the shield machine. In this embodiment, the pulp pipes include four: pulp pipes 5, 6, 7 and 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com