Double-cylinder multistrip single-stage vacuum extruder

A vacuum extruder, single-stage technology, applied in the field of brick and tile machinery manufacturing, can solve the problems of increased power bearing, increased difficulty in forming the machine mouth, small output, etc., and achieves the effect of improving air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

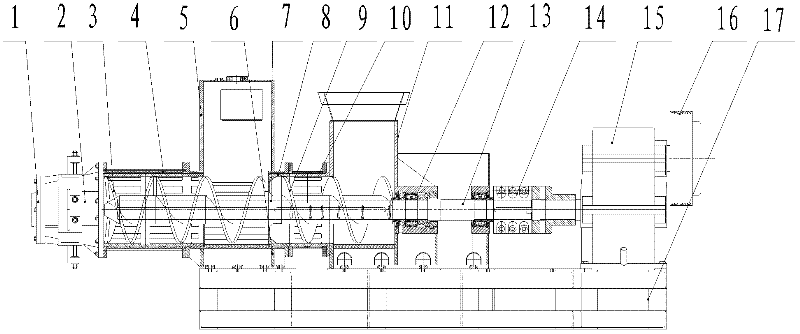

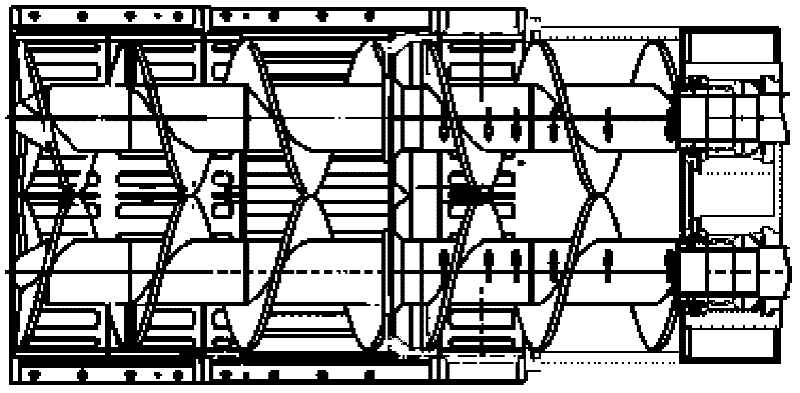

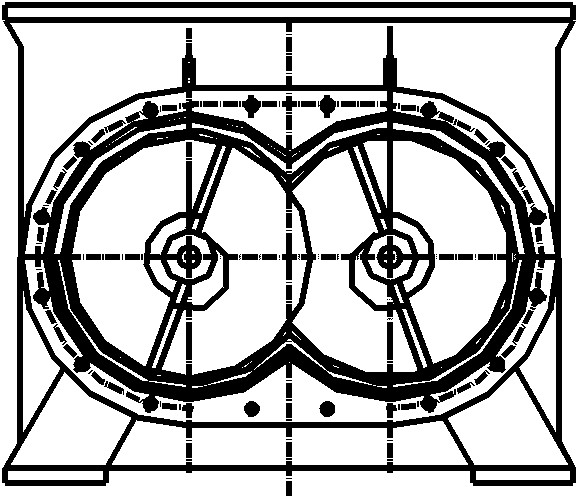

[0018] Such as Figure 1-3 A specific embodiment of the present invention is given, a double-cylinder multi-strip single-stage vacuum extruder, which consists of a double machine port 1, a machine head 2, a double reamer 3, a double mud cylinder 4, a vacuum chamber 5, and a mud adding box Base 6, outer taper sleeve 7, inner taper sleeve 8, double Hough reamer 9, Hough cylinder 10, blanking box 11, bearing group 12, double main shaft 13, coupling 14, reducer 15 and pneumatic clutch 16 It is formed and all components are located on the chassis 17. A motor drives a reducer 15 with double output shafts. The double output shafts of the reducer 15 drive the rotation of the double main shaft 13 through the coupling 14, and the double main shaft 13 is connected by the bearing group 12. The double Huff reamer 9, the double Huff reamer 9 is connected with the double reamer 3 through the inner cone sleeve 8 and the outer cone sleeve 7 to compress and extrude the mud, the double reamer 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com