Film tearing device and method

A film device and lamination technology, applied in packaging, transportation and packaging, unsealing of objects, etc., can solve the problems of empty welding of electronic devices and PCBA, high labor cost, product deformation, etc., to avoid hidden quality problems and reduce labor costs. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment discloses a film tearing device, which is used to tear off the film material on the surface of the product.

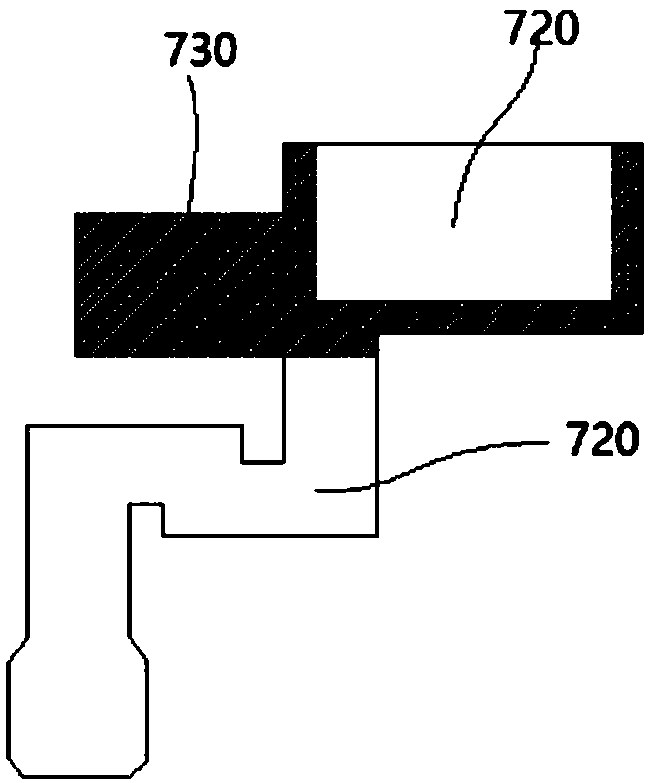

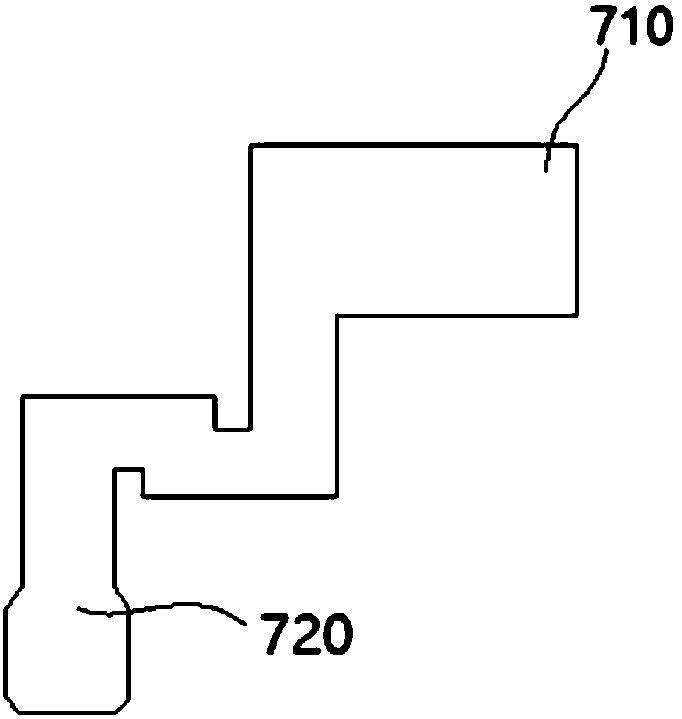

[0062] The film tearing device is a general-purpose device, not limited by product type. For convenience of description, this embodiment uses figure 1 , figure 2 The products shown in are the implementation objects, figure 1 It is a schematic diagram when there is a film material 730 on the surface of the product, the number 720 is the bare part, and the area covered with the film material 730 is the film part 710 . The schematic diagram of the product after removing the film material 730 is shown in figure 2 As shown, the film material is a general term, which generally refers to the structure that needs to be torn off on the surface of the product, which can be a film, adhesive tape or organic film material.

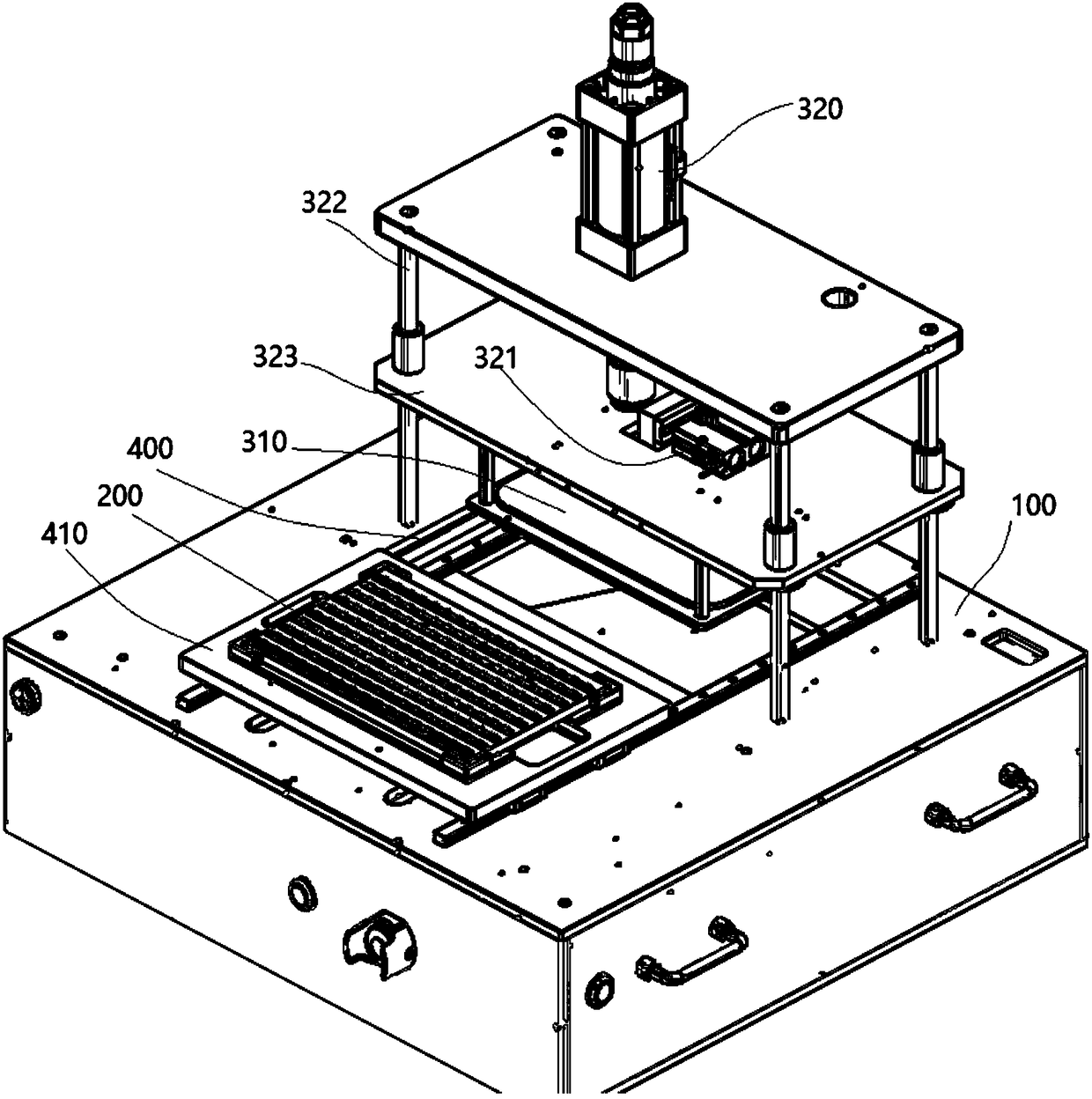

[0063] refer to image 3 , The film tearing device includes a frame 100, a tray 200, a cover plate 210 and a jaw assembly. Wherei...

Embodiment 2

[0076] Such as image 3 As shown, on the basis of Embodiment 1, the frame 100 includes a film tearing station and a discharging station, wherein the film tearing station is located below the jaw assembly, and a recycling tank 500 is also provided below the film tearing station.

[0077] The frame 100 is provided with a recovery tank 500, and the recovery tank 500 is located below the film tearing station.

[0078] The film tearing device further includes a plate-moving mechanism, which includes a fourth drive cylinder, a slide rail 400 and a tray 410. The carrier plate 200 is detachably mounted on the tray 410, and the slide rail 400 connects the film-tearing station and the discharger. position, the fourth driving cylinder drives the tray 410 to slide on the slide rail 400 . The plate moving mechanism is used to transfer the carrier tray between the film tearing station and the discharging station. The film tearing station is located under the jaw assembly to facilitate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com