Special screw thread joint of high air-tight seal oil sleeve

A special thread and air-tight technology, which is applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of special thread corrosion, leakage, over-torque, sticking and other problems of the downhole pipe string, and achieve the prevention of stress corrosion, low contact stress, The effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

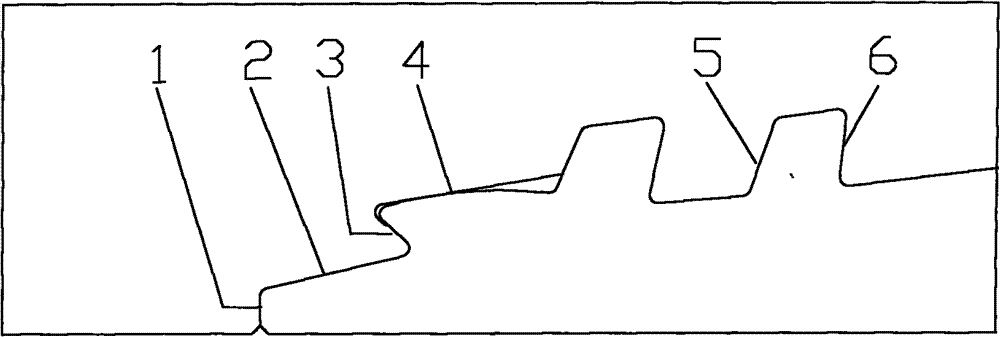

[0020] The thread of the special threaded joint of the high air-tight oil casing pipe according to the present invention is composed of corresponding internal and external threads, and the structure starts from the front end in order of auxiliary shoulder 1, first-level main seal 2, main shoulder 3, and second-level Main seal 4, guide surface 5, bearing surface 6;

[0021] The auxiliary shoulder is a corresponding right-angle structure with a width of 1.0-1.5mm; the first-stage main seal is a conical surface corresponding to a conical surface structure, the length is 4-5mm, and the taper is 1:7-10, connecting the auxiliary shoulder and the main shoulder; The shoulder is the corresponding reverse shoulder structure, the shoulder width is 2~2.5mm, the shoulder angle is 15~20°, the shoulder transition arc radius is 0.2~0.5mm; the secondary main seal is a spherical surface corresponding to the conical surface structure, the spherical surface is round The radius of the arc is 10-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com