Continuously variable transmission (CVT) method and device for static fluid

A transmission device and variable technology, applied in transmission device, fluid transmission device, transmission device control and other directions, can solve the problem of incomplete constraint of the robot end trajectory, and achieve the control method is easy to implement, improve the operation feeling, and the device structure is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

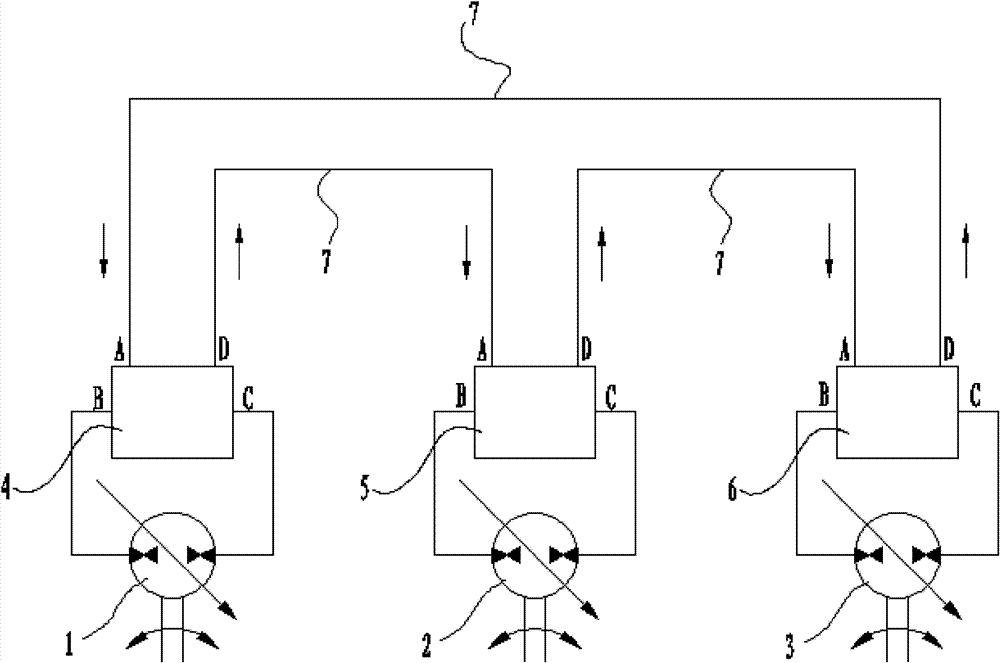

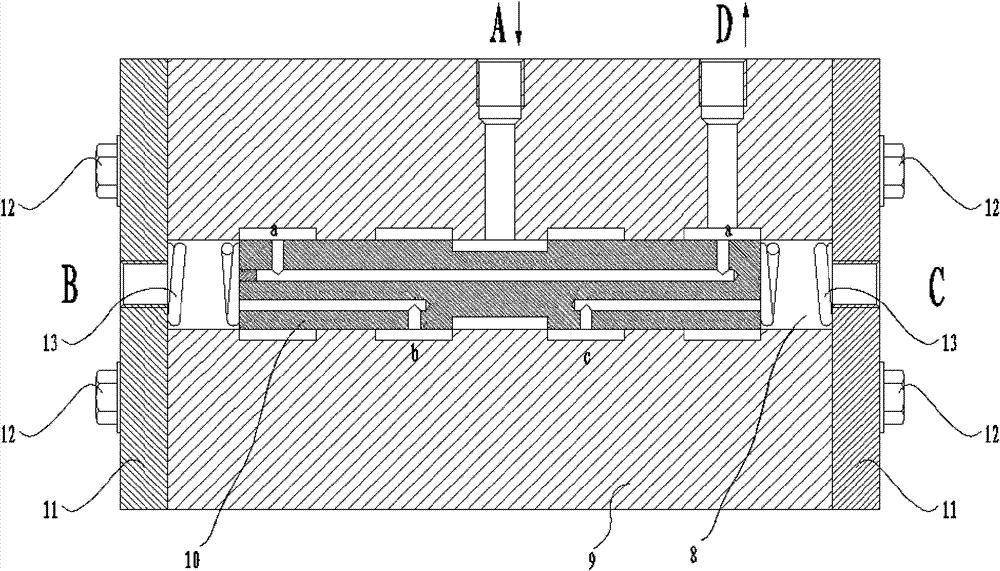

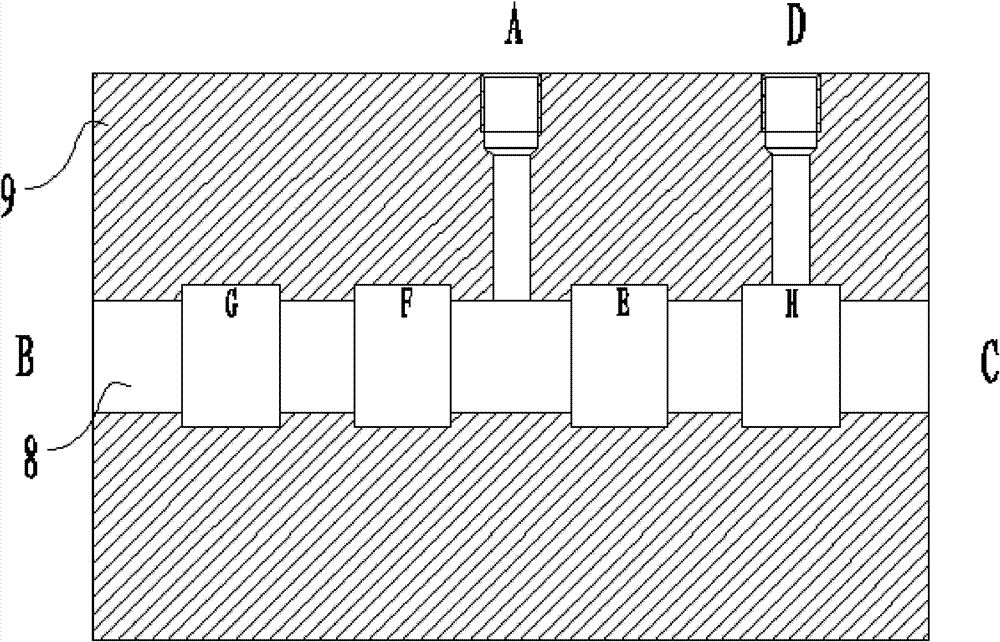

[0052] A hydrostatic continuously variable transmission method of the present invention, taking three variable units as an example, includes the following steps:

[0053] Step 1: Install a rectifier in parallel on the variable element to form a variable unit;

[0054] Since the steering of the rotating shaft of the series variable element can be arbitrary according to the working conditions, the oil flow direction through each variable element can be arbitrary, but the flow direction of the oil in the closed oil circuit trunk must be consistent, so for each All variable components need to be equipped with rectifiers.

[0055] Utilizing the principle that the direction of oil passage in the check valve is irreversible, the rectifier can still maintain the consistency of the oil flow direction of the main road when the steering of the variable element changes, and avoid the conflict of the variable element steering;

[0056] The oil circuit switching relationship of the rectifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com