Split solar water tank

A solar water tank and split technology, which is applied to solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of complex production process, high production cost, low heat exchange efficiency, etc., and achieve simple production process and low production cost. , the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the examples. The following examples are only used to illustrate the present invention, but do not limit the present invention.

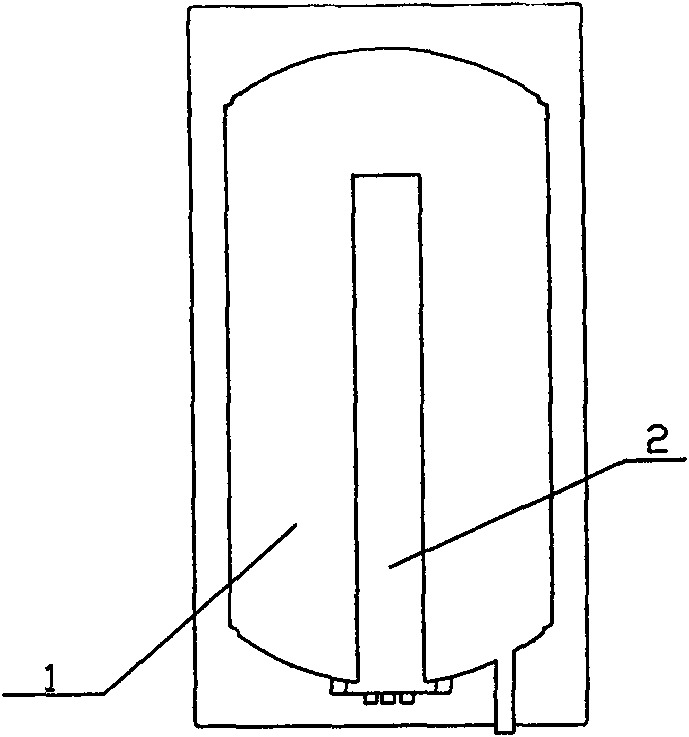

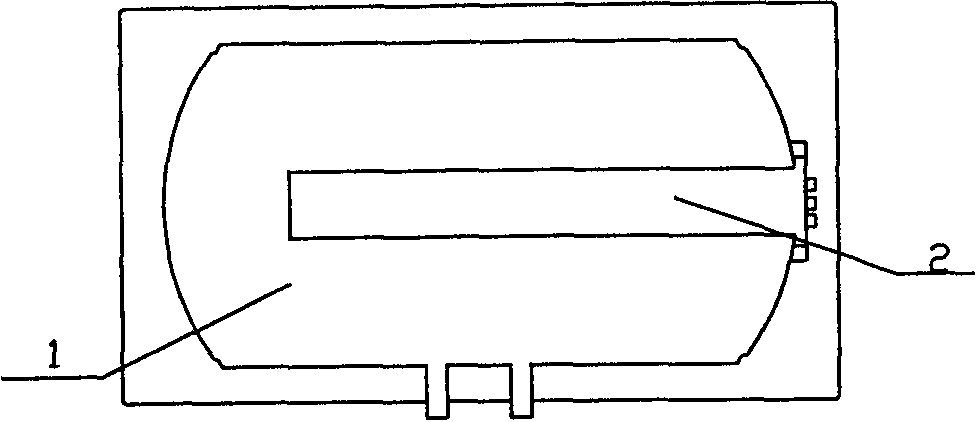

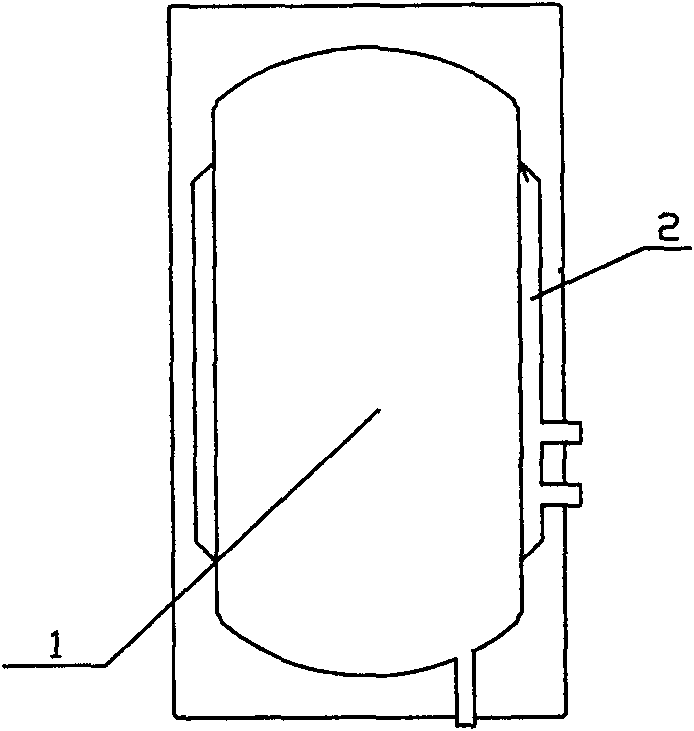

[0013] A split solar water tank, comprising an inner tank 1 and a heat exchanger 2, characterized in that the heat exchanger 2 is outside the semicircular head of the inner tank of the water tank.

[0014] Attached table: Split solar (jacket) water tank heat exchange efficiency comparison test data record table

[0015] Split solar water tank heat exchange efficiency comparison test data recording table

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com