Process for plating gold on long and short gold fingers

A gold finger, length and short technology, which is applied in the field of gold plating process of long and short gold fingers, can solve the problems of difficult control of key dimensions of gold fingers, long time spent on gold-plated wires, poor graphics and dimensional accuracy, etc., so as to shorten the production cycle and flexibly arrange production. , the effect of less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

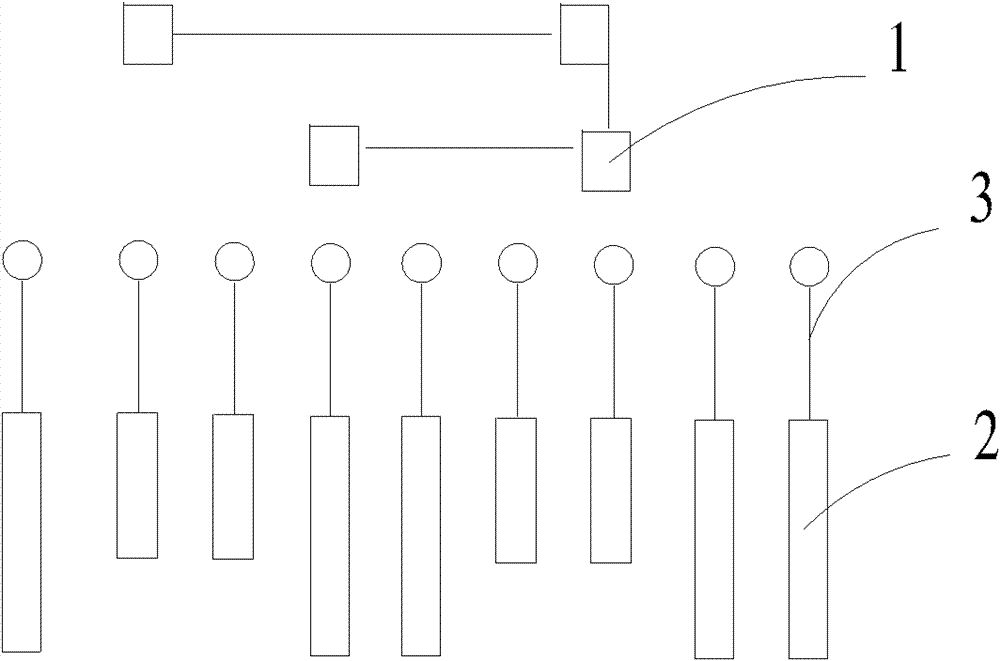

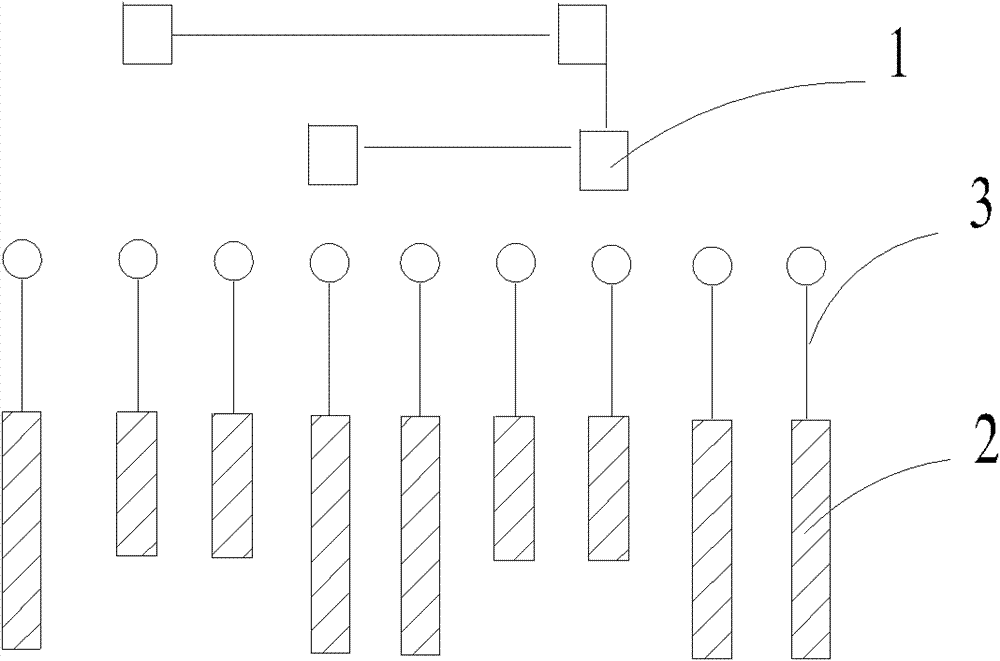

[0032] see Figure 1-Figure 3 , the gold plating process of the long and short golden fingers 2 of the first embodiment of the present invention comprises the following steps:

[0033] Prepare a PCB board, and make an in-board graphic 1 and a long and short gold finger 2 on the PCB, and the long and short gold fingers 2 are connected to the in-board graphic 1 through the lead 3;

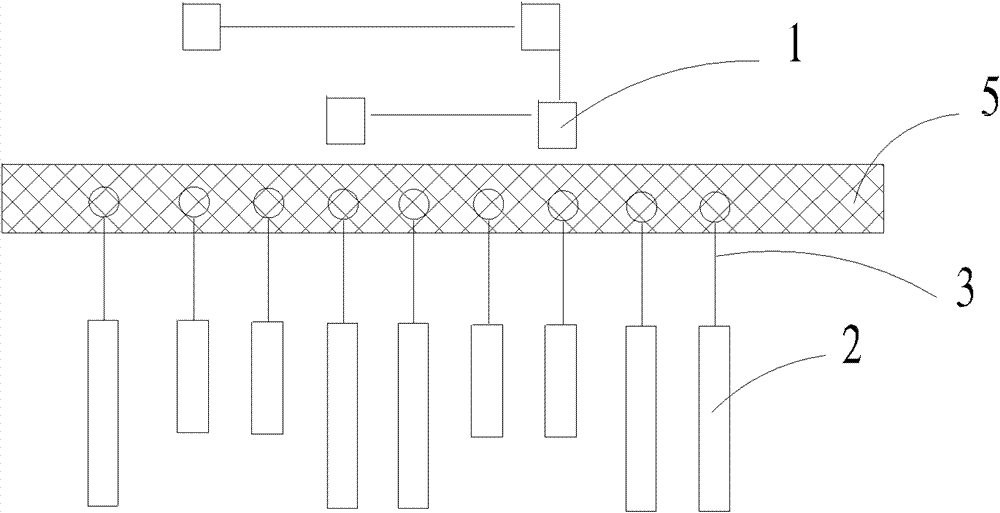

[0034] Use conductive tape 5 to stick the lead wires 3 of the long and short gold fingers 2 in sequence, so that the long and short gold fingers 2 are connected to each other;

[0035] Utilize the conductive tape 5 as the gold-plated wire to carry out gold-plating to the long and short gold fingers 2;

[0036] Tear off the conductive tape 5 .

[0037] Compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com