Method and device for monitoring the fill level of a liquid in a liquid container

A liquid container and liquid level technology, applied in liquid level indicators for physical variable measurement, measuring devices, liquid/fluid solid measurement, etc., to achieve the effects of shortening trigger reaction time and simplifying heating current regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

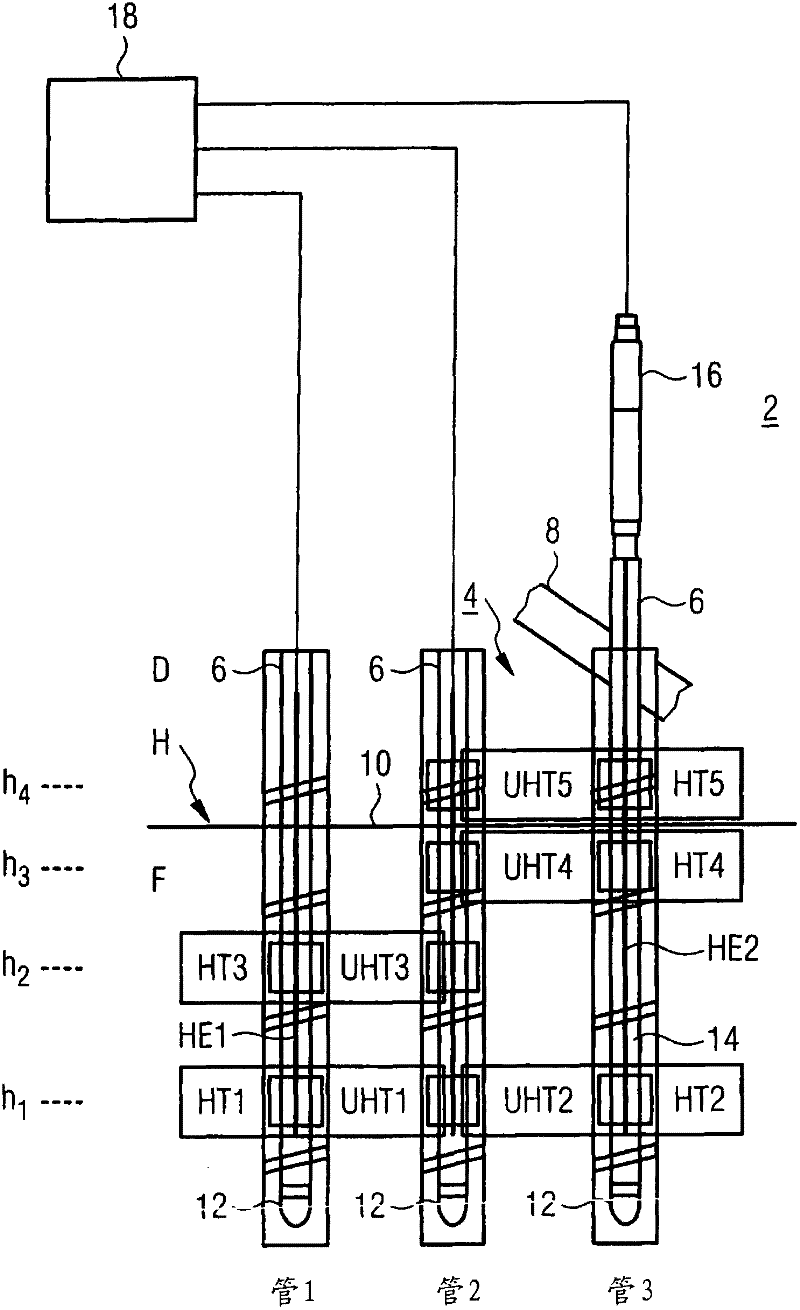

[0085] The three measuring pipes 6 of the device 2 are vertical, and they are installed in the reactor pressure container at a certain distance; therefore they are parallel to each other and do not contact each other.Each measuring pipe 6 has a sealing and waterproof cylindrical shell 12 at the end of its lower part.In the example, valuable metals are used for this purpose.

[0086] There are multiple thermocouples in the inner cavity 14 of each measuring pipe 6.The measuring tube identified as "Tube 1" contains two heated thermocouples, which is at the height position H 1 The heated thermocouple HT1 and the height above it at the height of it 2 The heated thermocouple HT3.The measuring tube identified as "Tube 3" contains three heated thermocouples in its inner cavity 14, that is, at the height position H 1 The heated thermocouple HT2 and the height above it at the height of it 3 The heated thermocouple HT4, finally at the height of HT4 4 The heated thermocouple HT5.The relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com