Air suction and air blow-combined separation type grain cleaning device for reaping machine

A separate harvester technology, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of low power consumption and small size, and achieve the effect of low power consumption, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

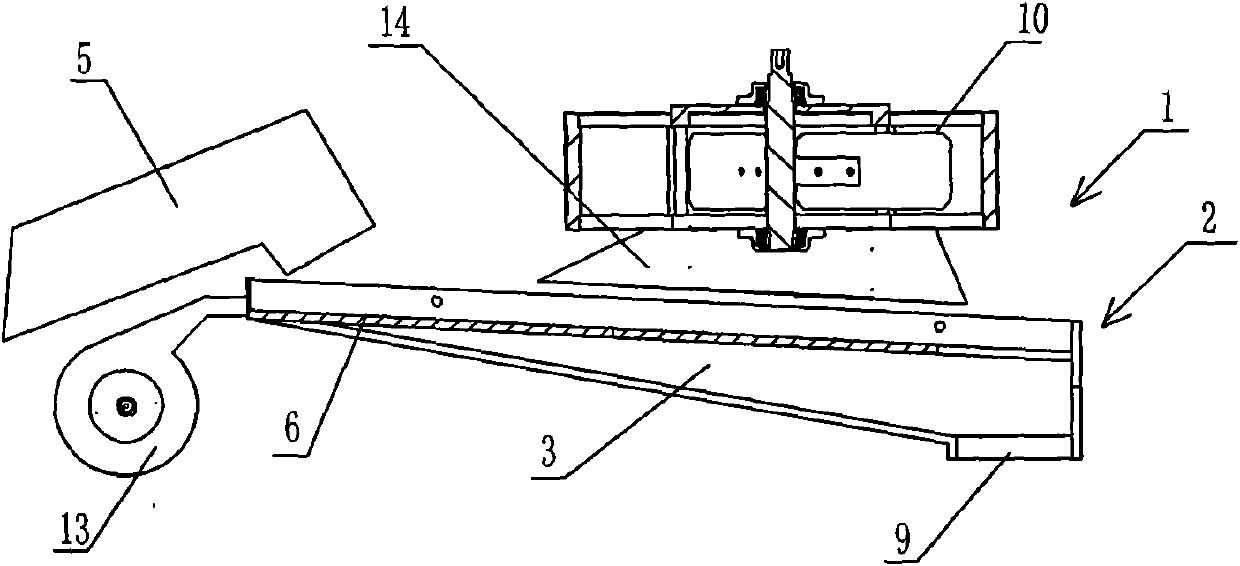

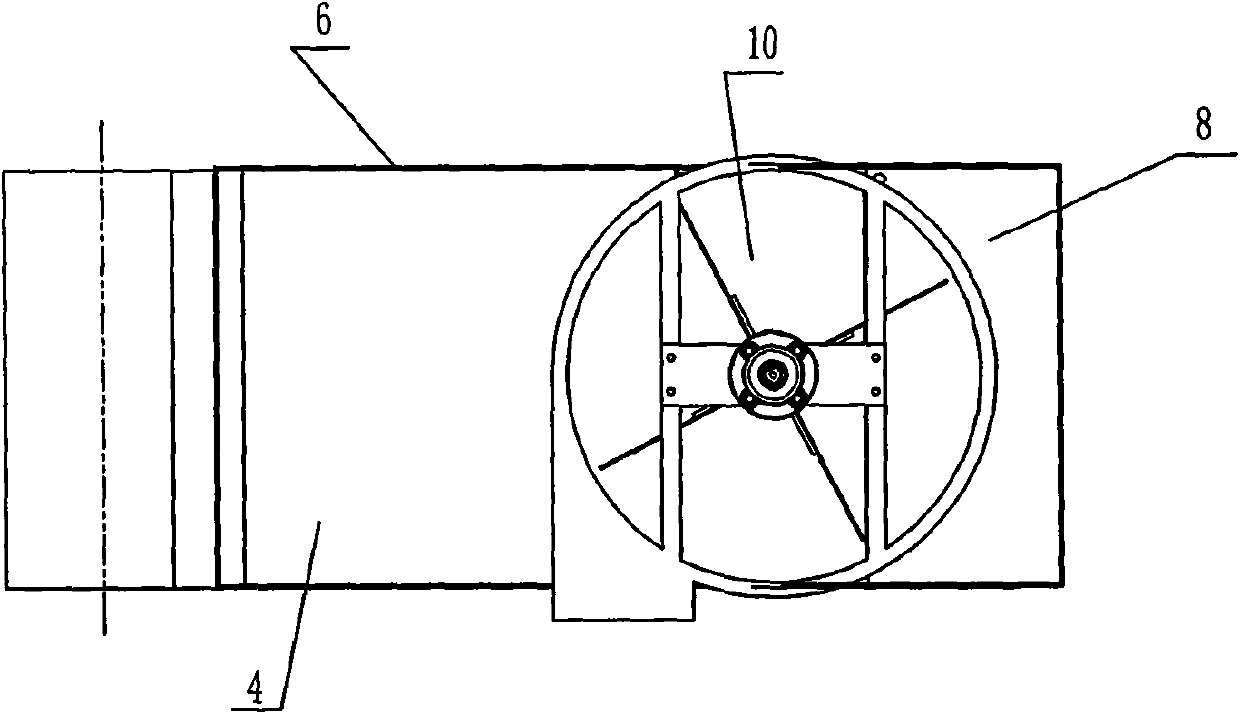

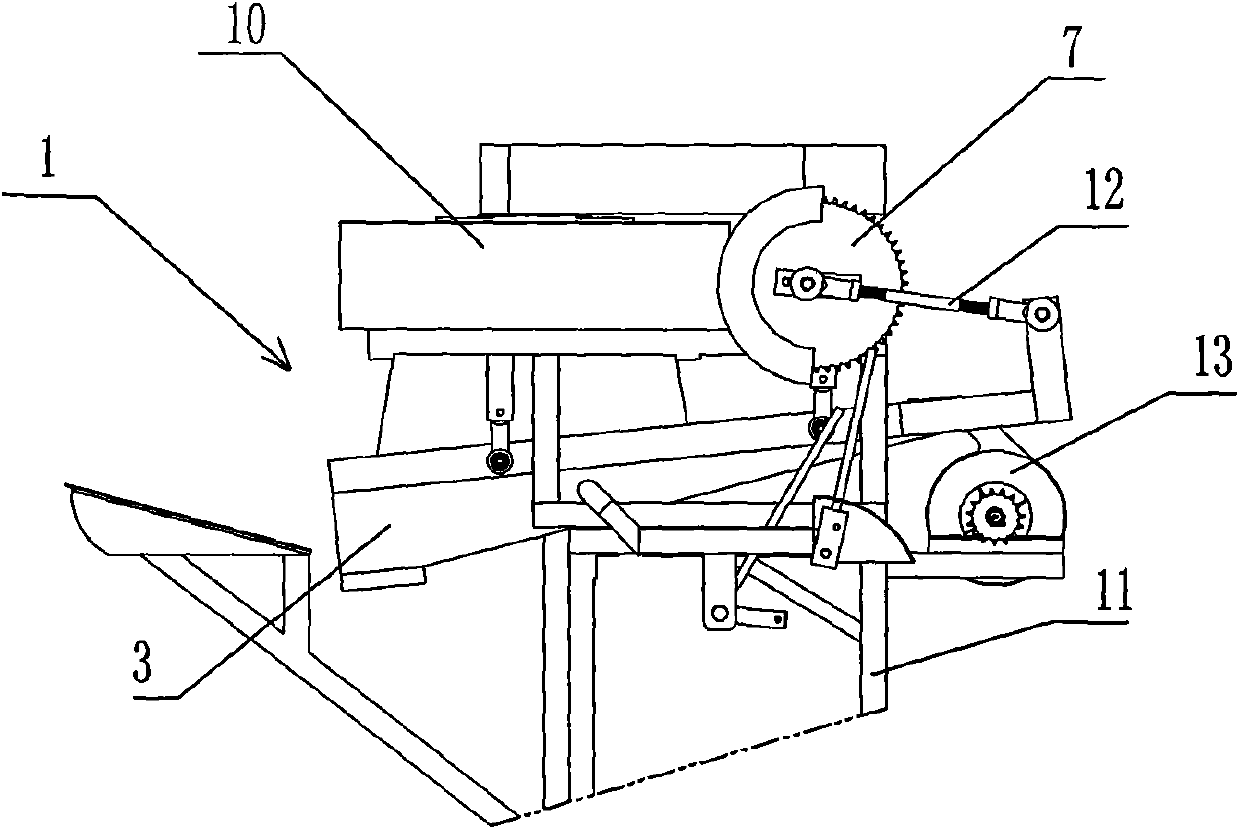

[0019] See figure 1 versus figure 2 , Said a kind of suction and blast combined separation type grain cleaning device of the harvester, including a screen 1 installed on the frame and reciprocating swing driven by a driving mechanism. The screen 1 consists of a single-layer sieve body 2 and a sieving grain bin 3, the single-layer sieve body 2 includes a sieve bottom plate 4 and a box baffle 6. The front section of the box baffle 6 is equipped with a sieve bottom plate 4, and the rear section is an inlet 8, such as image 3 with Figure 4 As shown, the sieve 1 is suspended on the frame 11, one end of the connecting rod 12 is hinged to the eccentric sprocket 7, and the other end is hinged to the swing lever 15 on the side of the sieve 1. When the eccentric sprocket 7 rotates, the sieve is driven 1 is reciprocating (jittering), the top of the screen 1 is equipped with an exhaust fan 10 and a wind collecting hood 14, and one end of the screen 1 is equipped with a blower 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com