Method for purifying ceramic-metal structural component

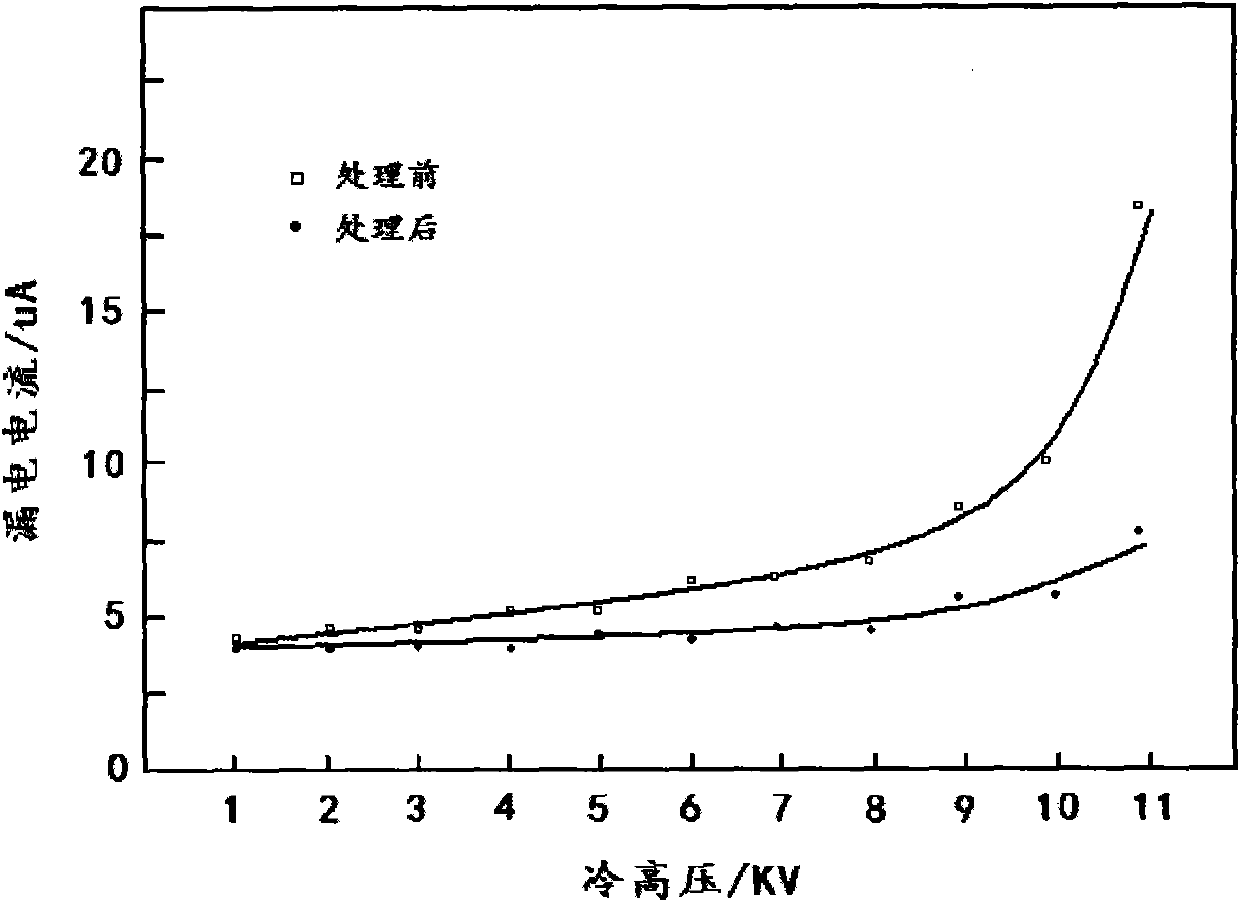

A metal structure and component technology, which is applied in the field of purification of ceramic-metal structure components, can solve problems such as desoldering, component cracking, organic pollution of component processing grease, etc., and achieve the effect of reducing the number of sparks and improving the pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Take the purification of an electron gun shell that has undergone secondary refinement for a traveling wave tube as an example.

[0034] (1) Submerge the electron gun shell in a beaker filled with acetone, ultrasonically clean it for 15 minutes at room temperature, remove surface organic pollutants, and rinse it with flowing tap water for 4 minutes after taking it out;

[0035] (2) Submerge the electron gun shell degreased in step 1 in 1% dilute hydrochloric acid solution, ultrasonically clean it for 12 minutes, and control the solution temperature at 40-60°C;

[0036] (3) After pickling, immediately take it out with metal tweezers and place it in a beaker, and rinse it with running clean tap water for 6 minutes;

[0037] (4) After taking it out, immediately put it into a clean beaker filled with deionized water (the deionized water should be completely submerged in the electron gun shell), ultrasonically clean it for 12 minutes, and control the water temperature at roo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap