Hasp and leather belt type water tank fixing structure for road roller

A fixed structure and road roller technology, applied in the field of traffic engineering machinery, can solve problems such as bolts and belts being easily loosened by vibration, water tank surface wear, water tank displacement, etc., to achieve solid and reliable fixation, convenient and simple use and maintenance, and long service life Effect

Inactive Publication Date: 2011-04-20

柳工无锡路面机械有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the water tank of the road roller is generally fixed by bolt connection and belt tension and pressure. In the case of strong vibration of the road roller, the bolts and belt are easily loosened, resulting in the displacement of the water tank.

If the water tank cannot be fixed, it will easily cause the surface of the water tank to wear out, and long-term friction will cause the water tank to leak

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

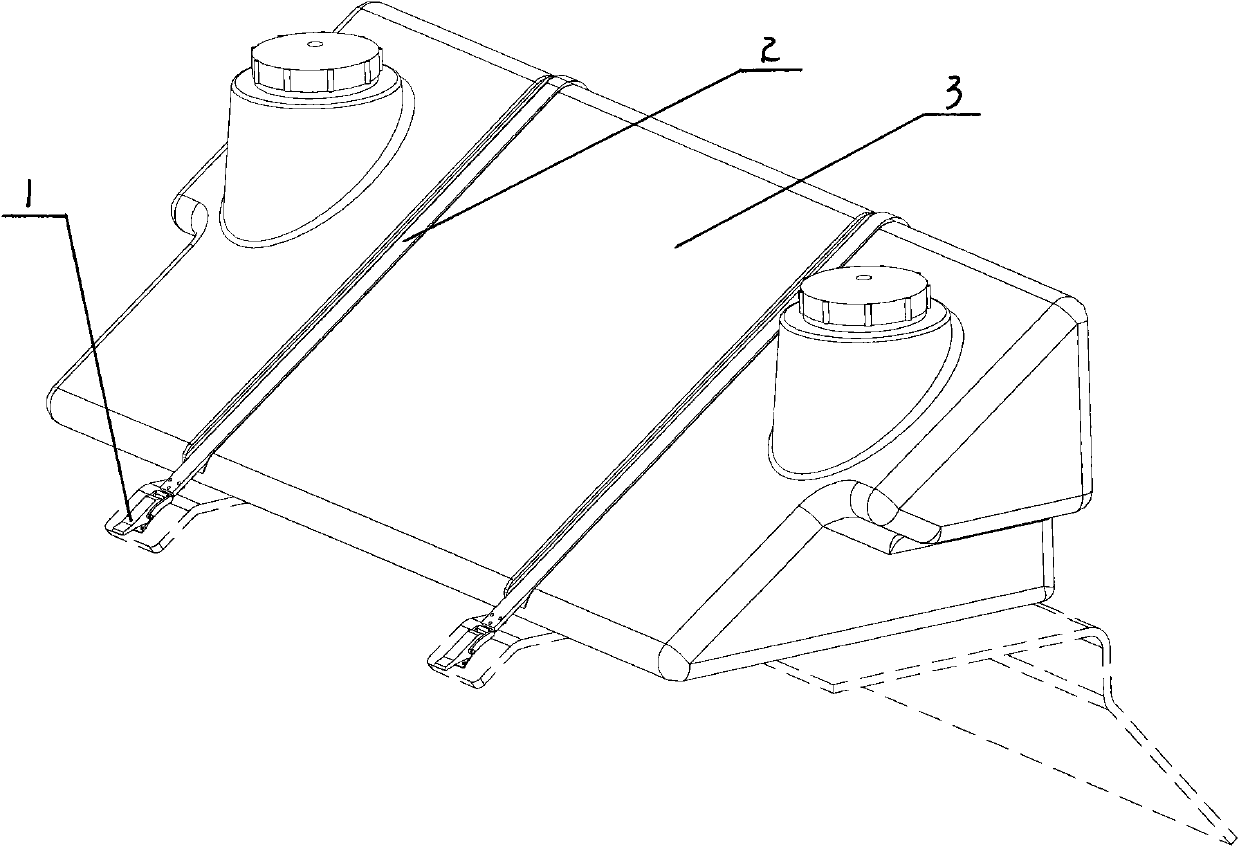

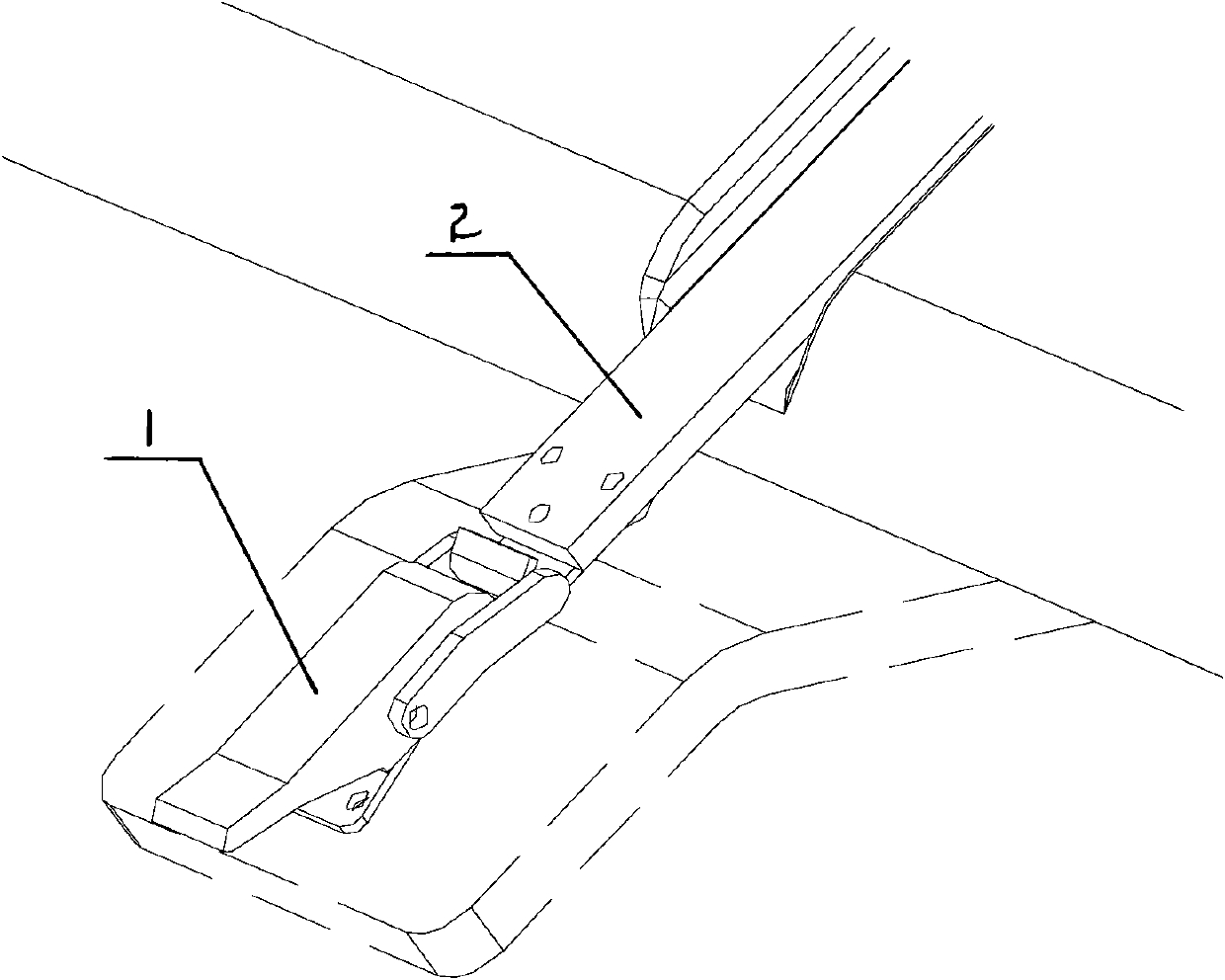

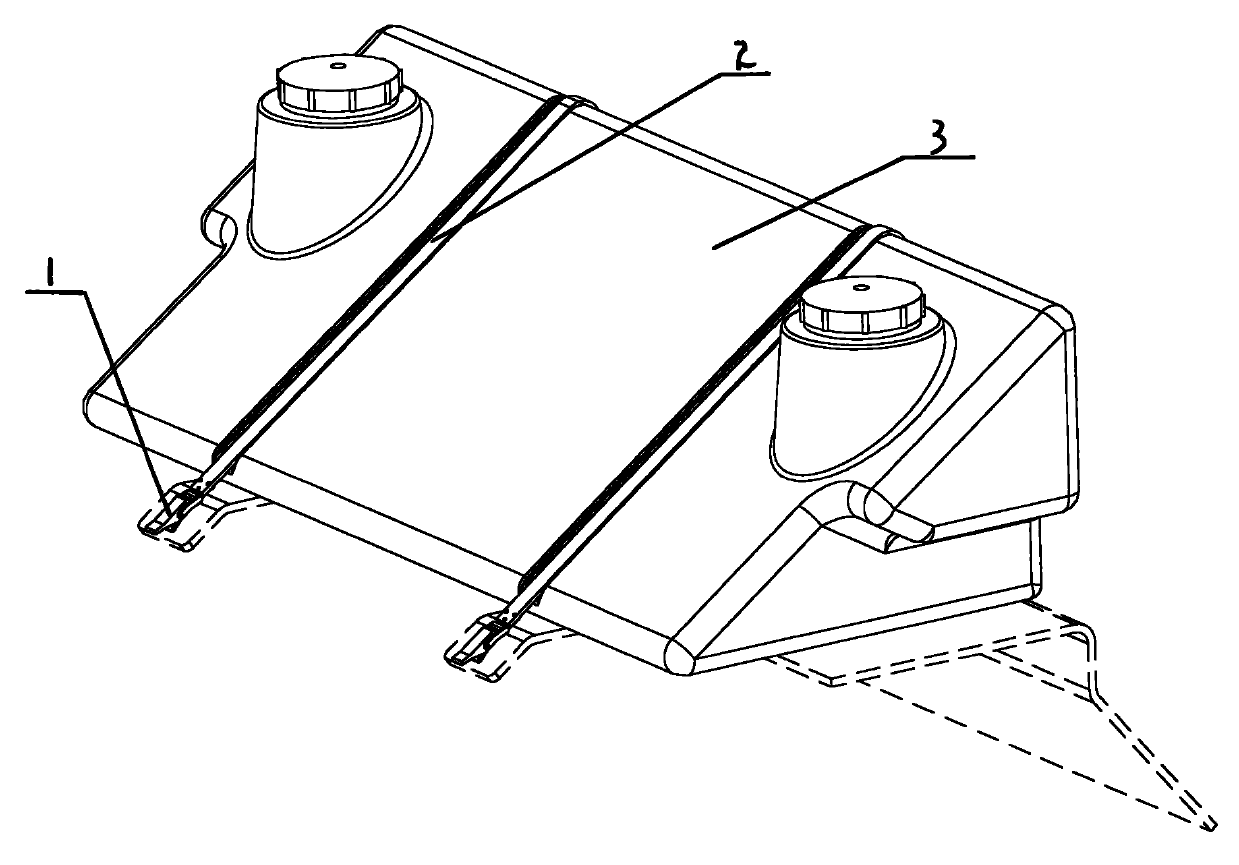

[0015] see Figure 1~2 , the fixing structure of the water tank of the buckle belt road roller of the present invention includes a water tank 3, the width direction of the water tank 3 is at least two belts 2, and the two ends of the belt 2 are fastened with the buckle 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a hasp and leather belt type water tank fixing structure for a road roller, which belongs to the technical field of traffic engineering machinery. The structure comprises a water tank (3), wherein at least two leather belts (2) are bound in the width direction of the water tank (3); and the two ends of each leather belt (2) are buckled by hasps (1). The leather belts are buckled and strained by the hasps, so that the leather belts are closely attached to the surface of the water tank to bind the water tank. Stretchable stainless steel hasps are adopted, when the road roller vibrates, the water tank also jumps, and the lengths of springs of the hasps are changed along with the jump at the moment, so that the leather belts are closely attached to the surface of the water tank all the time. In addition, the self-locking devices of the hasps can prevent breakaway, so that the hasps are always at locking positions during the continuous jump and cannot be automatically opened. In the aspect of dismantling, the hasps can be easily opened by lightly jacking the self-locking devices, so that the leather belts are loosened.

Description

(1) Technical field [0001] The invention relates to a road roller, in particular to a fixing structure for a water tank of the road roller. It belongs to the technical field of traffic engineering machinery. (2) Background technology [0002] At present, the water tank of the road roller is generally fixed by bolt connection and belt tension and pressure. When the road roller vibrates strongly, the bolts and the belt are easily loosened, resulting in the displacement of the water tank. If the water tank cannot be fixed, it will easily cause the surface of the water tank to wear out, and long-term friction will cause the water tank to leak. (3) Contents of the invention [0003] The object of the present invention is to overcome the above-mentioned shortcomings, and provide a solid and reliable fixing structure for the water tank of the buckle belt road roller. [0004] The object of the present invention is achieved in the following way: a water tank fixing structure for...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E01C19/23

Inventor 揭晓辉黄宁波郭启华谈鸿雁

Owner 柳工无锡路面机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com