High-precision frequency-modulated screen dot printing process

A high-precision dot printing technology, applied in the field of high-precision FM dot printing technology, can solve problems such as inappropriateness, and achieve ink saturation and good effect of imprinted dot restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention provides a high-precision frequency modulation printing process, which includes the following steps:

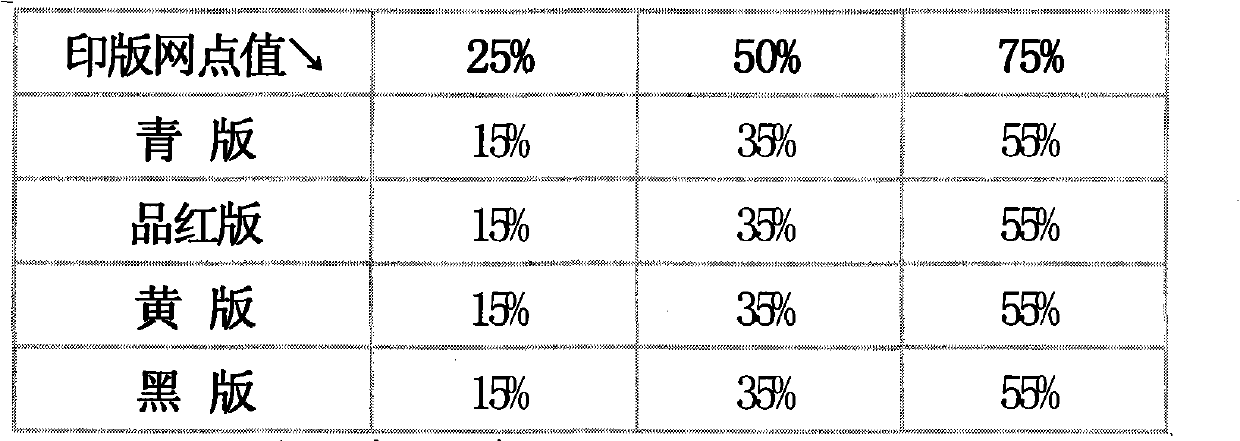

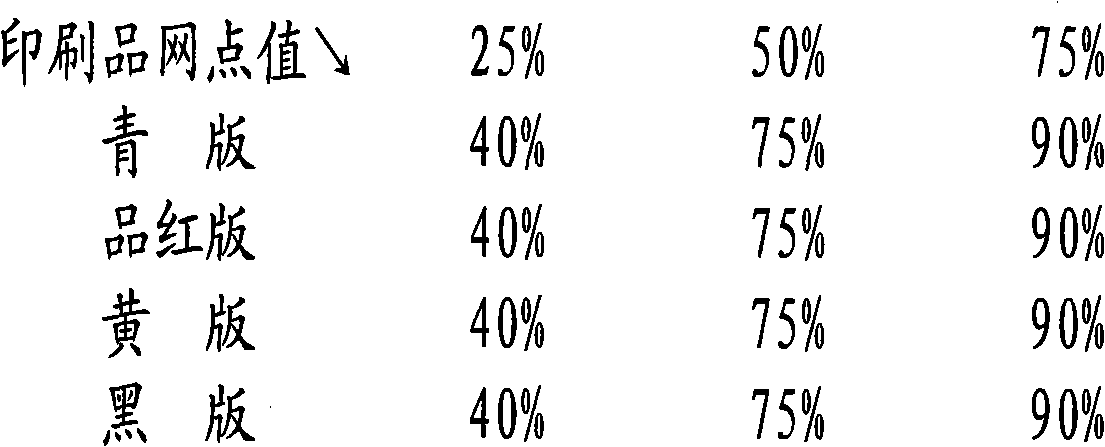

[0047] Step 1. Determine the best printing plate dot value and printing plate output curve suitable for 10 micron frequency modulation dots, and standardize the best printing solid density, the best dot expansion value and the best ink overprint sequence process standard for 10 micron frequency modulation dot printing , In order to obtain the printing color gamut of high color rendering range.

[0048] 1.1 Design a printing quality data test version suitable for 10 micron FM dot printing.

[0049] Beta version such as figure 1 As shown, the layout basically covers 30 ink zones of the folio printing machine, and the size is 860×574 mm. The test version includes signal strips and test strips. The signal bar includes the gray balance detection section, the overall gray balance test color block, the four-color monochrome gradient test strip, the printing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com