Post processor dedicated for digital control circular engravure machine and processing method of post processor

A post-processor and round engraving machine technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of unguaranteed machining accuracy, reduced efficiency, and time-consuming production, so as to save time, improve machining accuracy, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

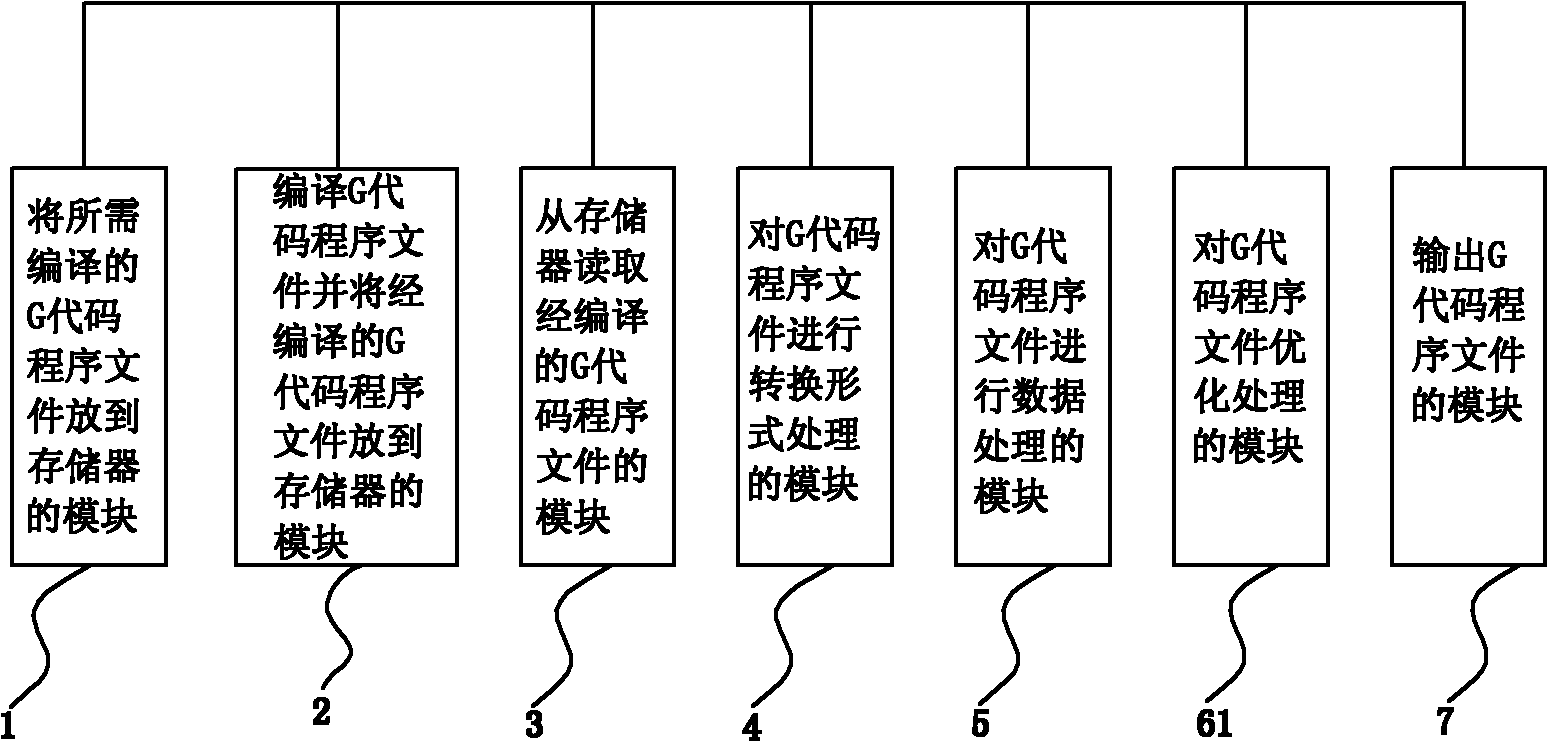

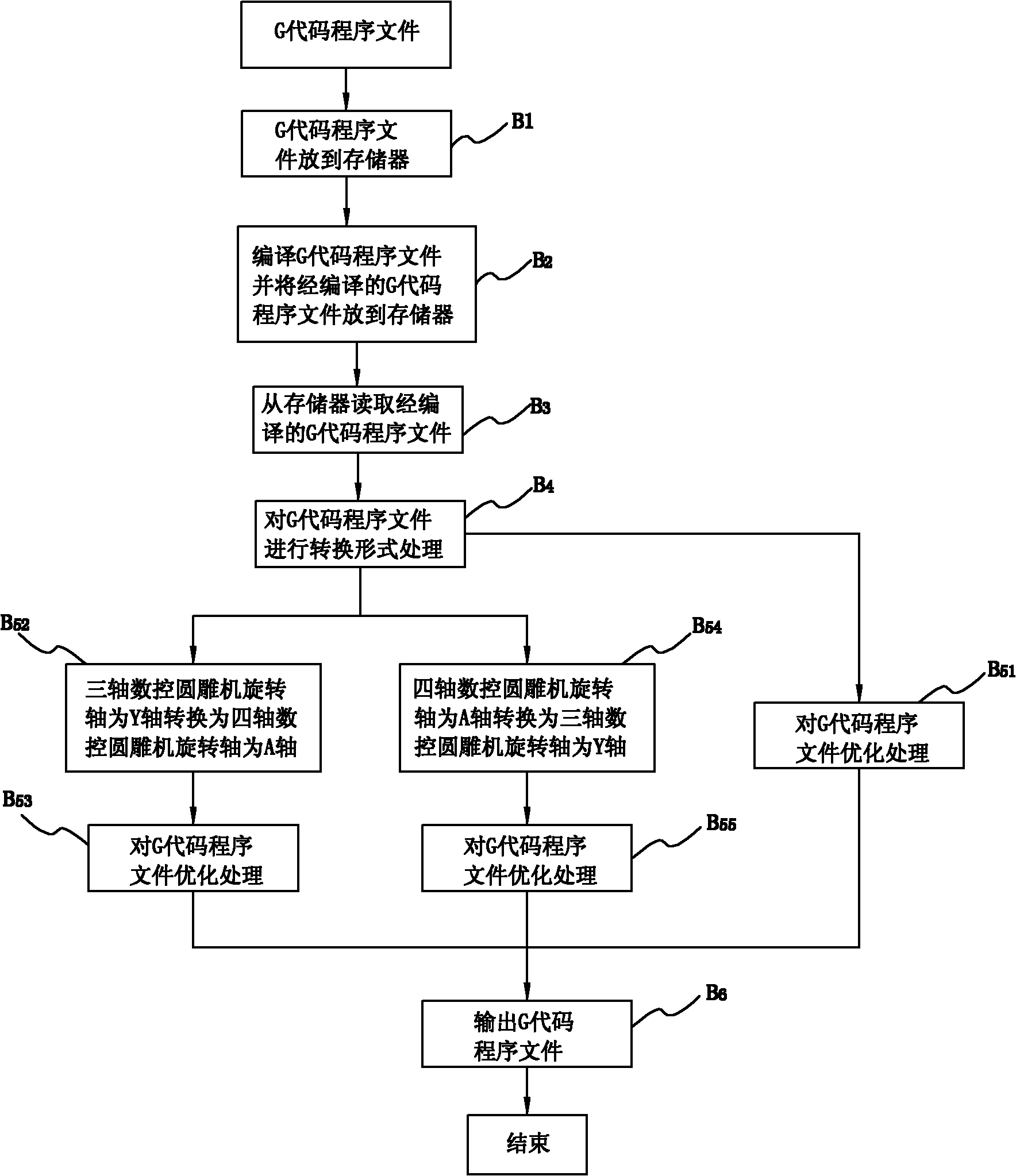

[0015] Such as figure 1 , figure 2 As shown, the post-processor dedicated to the CNC circular engraving machine of the present invention includes computer program software for processing the G code program files generated by the machine tool rotation axis characteristics and workpiece processing procedures, and the program software Comprise the function module that works in the following order: put the G code program file of required compiling into the module 1 of memory, compile described G code program file and put the module 2 of the G code program file through compiling into memory, from memory A module 3 for reading the compiled G code program file, a module 4 for converting the G code program file, a module 5 for data processing the G code program file, a module for optimizing the G code program file, Module 7 that outputs the G code program file.

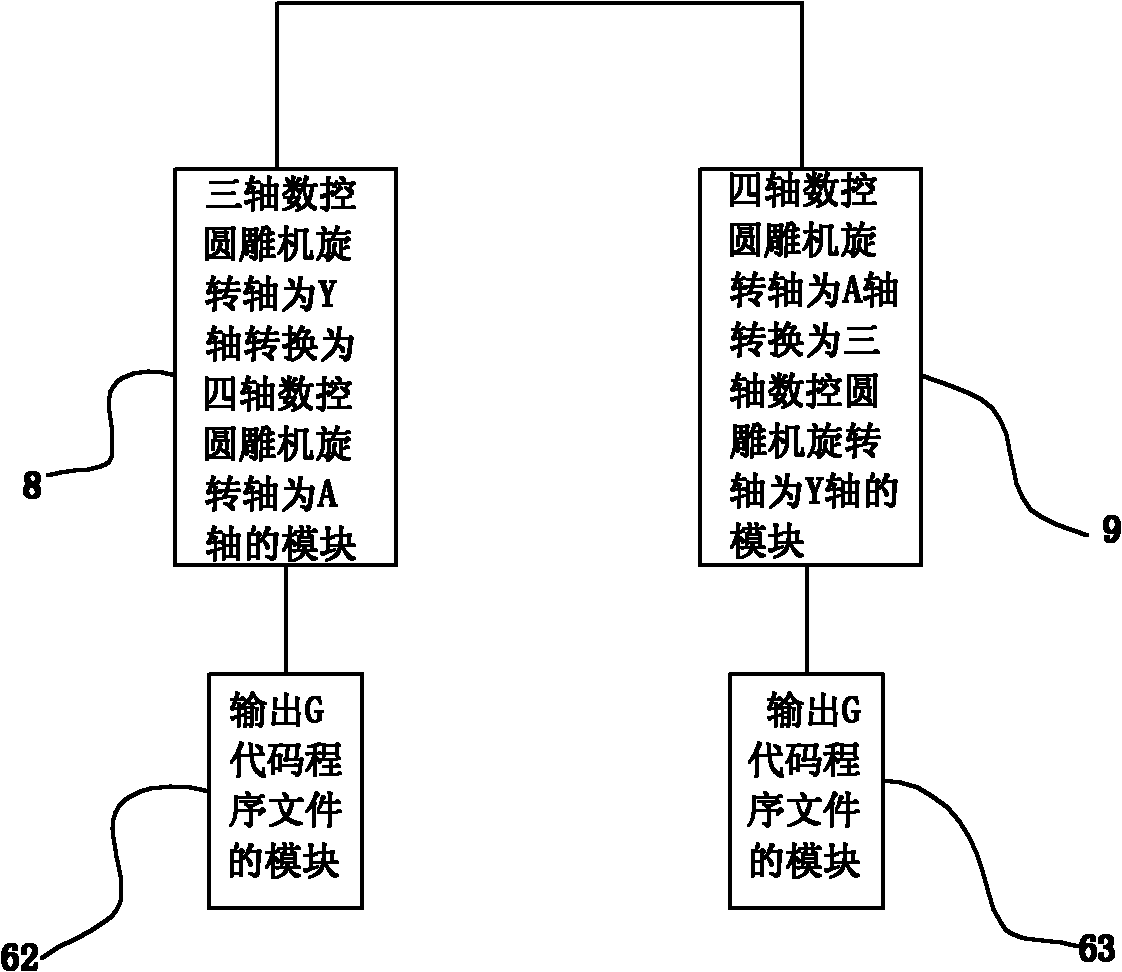

[0016] Among them, the module 5 for data processing of the G code program file includes: the rotation axis of the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com