Fuel cell cooling circulation water tank heating device

A fuel cell and cooling cycle technology, used in fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of difficult heating control, difficult production, etc. The effect of large water capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiment that accompanying drawing provides.

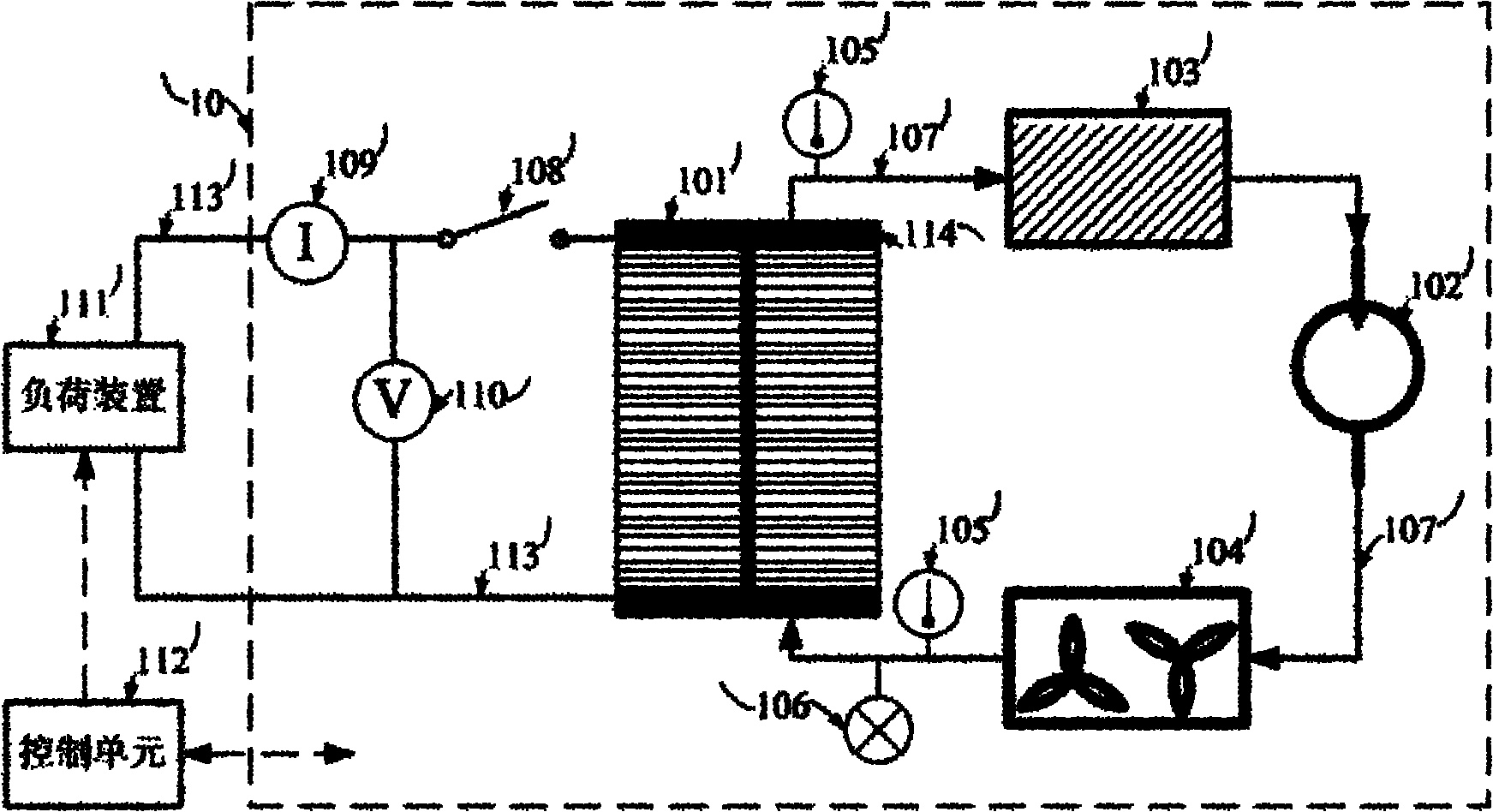

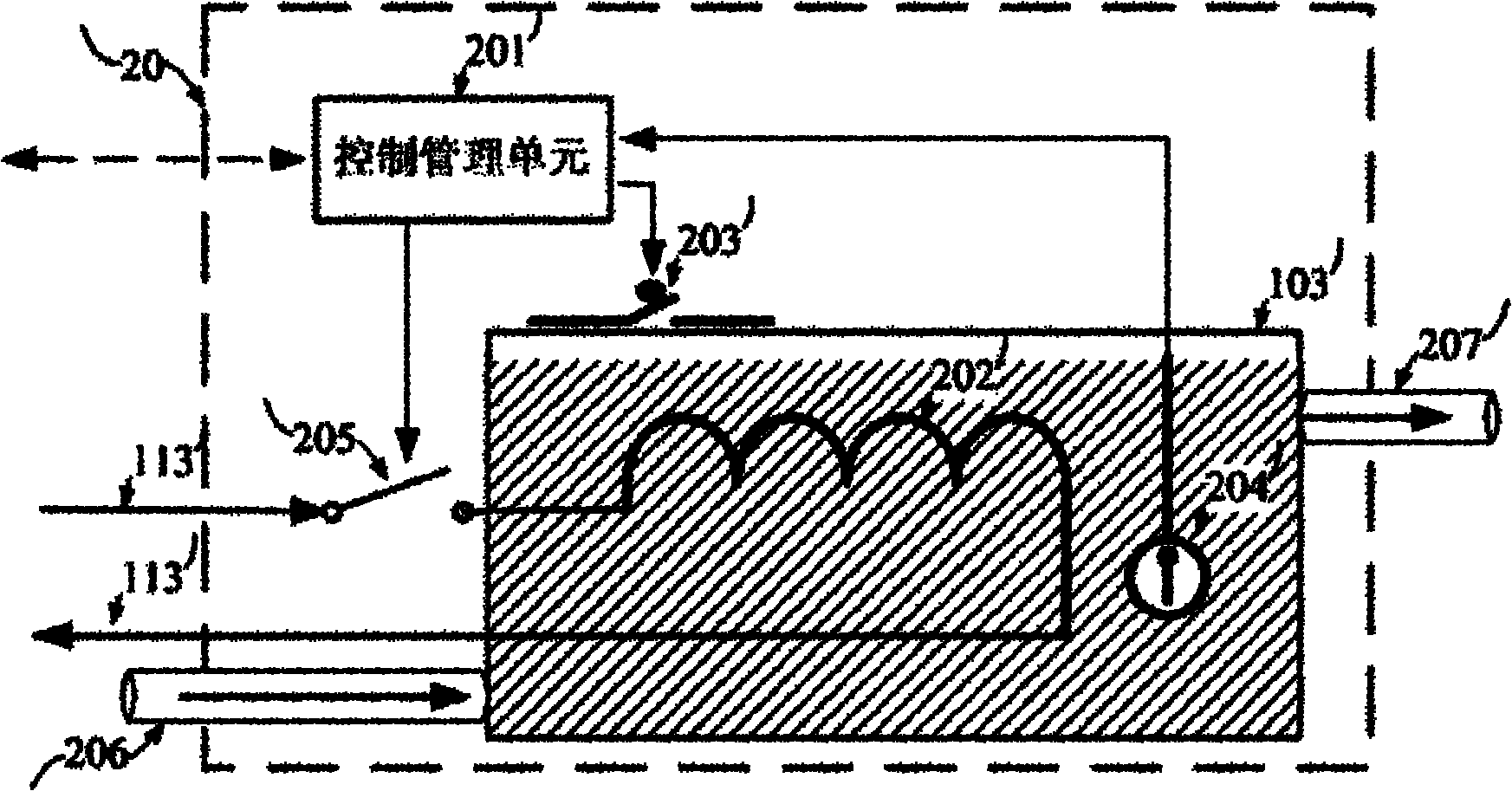

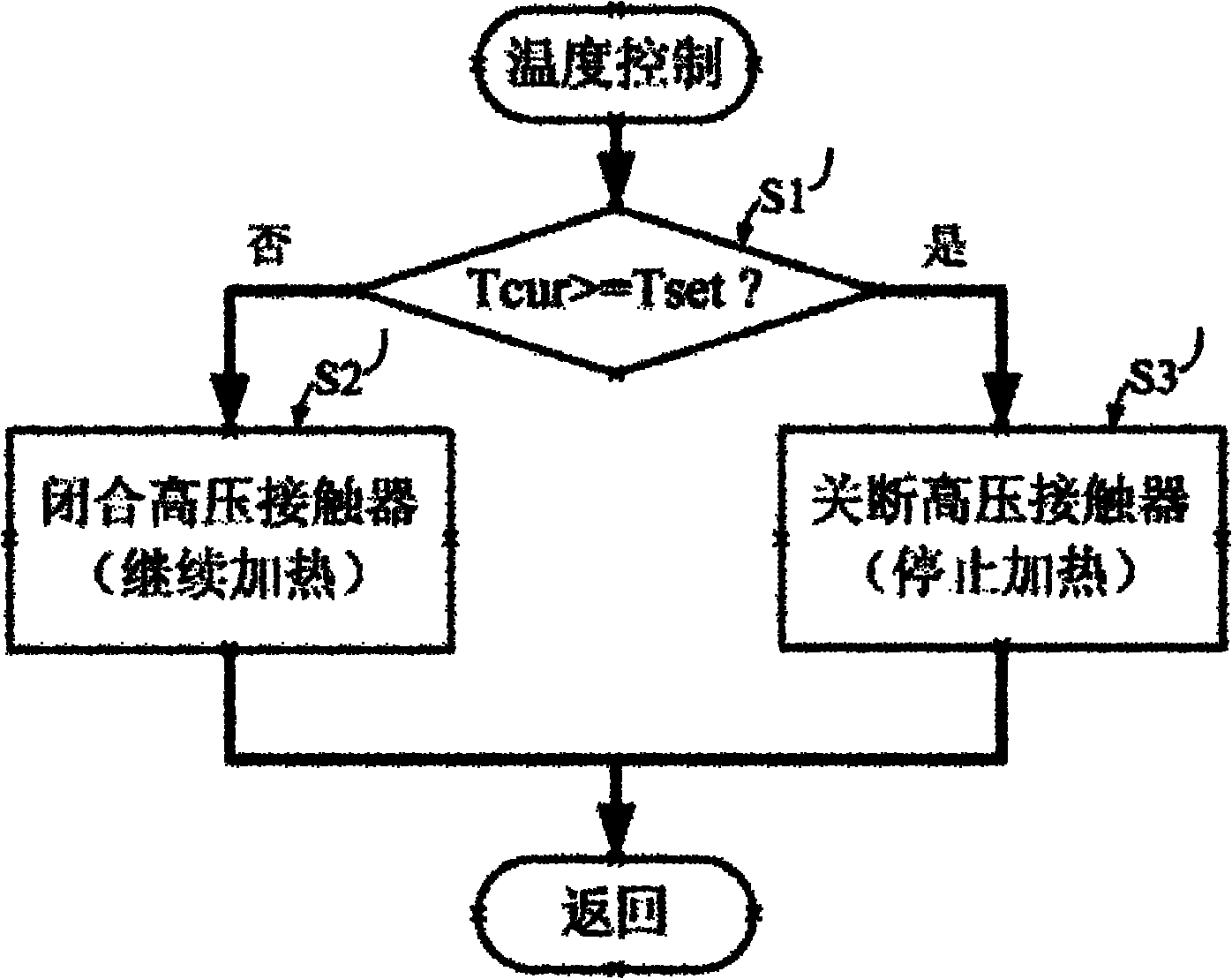

[0022] The fuel cell system 10 of this embodiment includes a fuel cell 101, a water pump and a frequency converter 102, a circulating water tank 103, a cooling fan 104, a temperature sensor 105, a pressure sensor 106, a cooling water pipeline 107, a high voltage contactor 108, a current sensor 109, a voltage Sensor 110, load device 111, control unit 112, load line 113, heating device 20, heating control management unit 201, electric heating tube 202, temperature switch 203, heating temperature sensor 204, heating high voltage contactor 205, water inlet 206, water outlet 207. Fuel cell 101 , water tank 103 , water pump and frequency converter 102 , cooling fan 104 and cooling water pipeline 107 form a closed circuit. The heating control management unit 201 is composed of a microprocessor and a hardware protection circuit. The electric heating tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com