Bearing ring leak working procedure detection machine

A bearing ferrule and testing machine technology, applied in sorting and other directions, can solve the problems that manual visual inspection is prone to missed inspection, low reliability of manual visual inspection, and labor intensity of workers, so as to reduce labor intensity, improve reliability, reduce The effect of participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

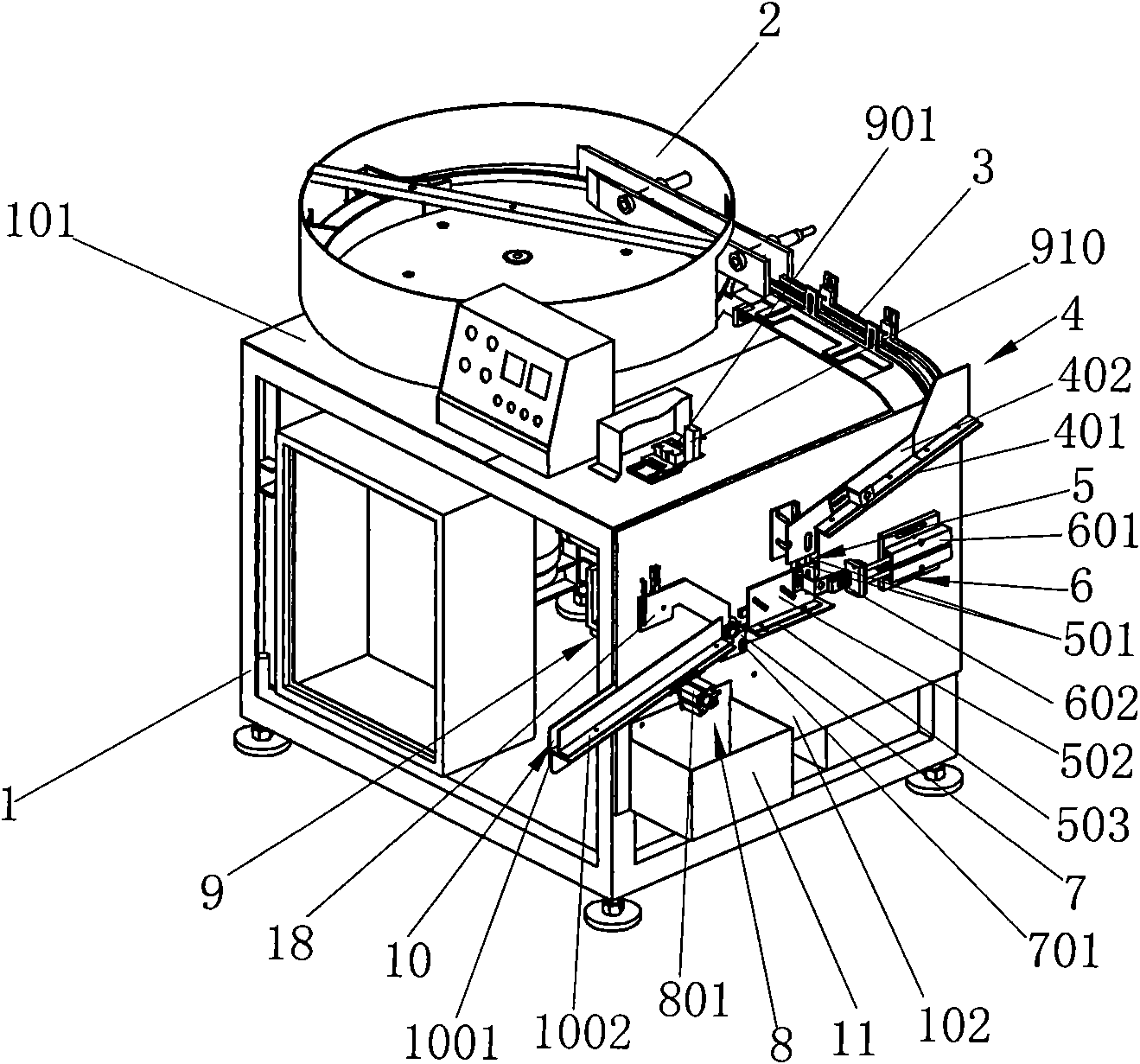

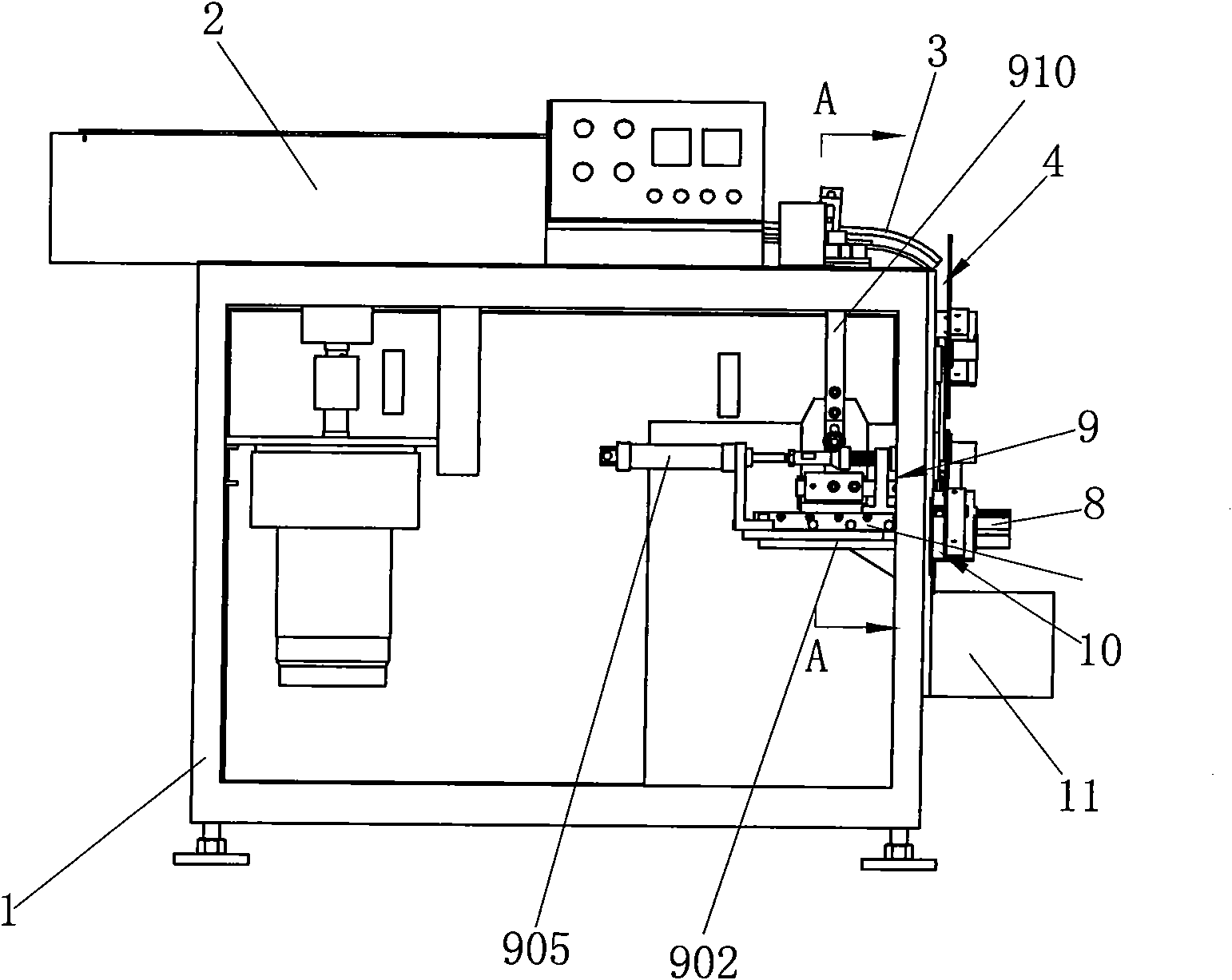

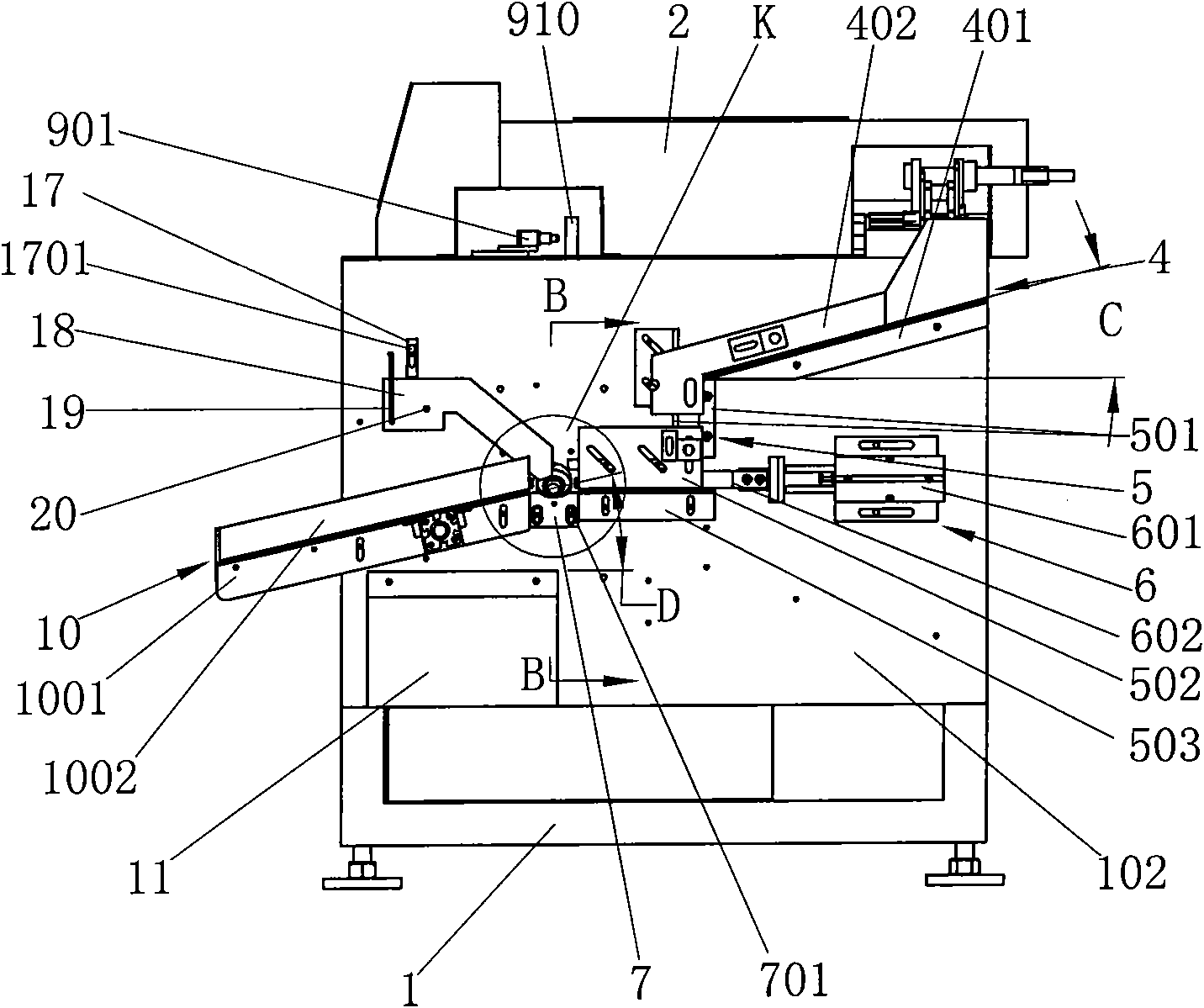

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0043] Such as Figure 1-9 As shown, the present invention comprises frame 1, and the top surface of frame 1 is equipped with workbench 101, and side plate 102 is installed on one side of frame 1, and control system is installed on the frame (not drawn in the figure) , the control system controls the actions of the coordinated components. The rotary feed tray 2 is installed on the worktable 101 of the frame 1, and the feed track 3 is connected to the discharge port of the rotary feed tray 2. The rotary feed tray 2 is a prior art, and the rotary feed tray 2 rotates the bearing rings therein. Arrange them and push the bearing rings into the feeding track 3 one by one. The feeding raceway 4 is obliquely installed on the outside of the side plate 102, the storage tank 5 is vertically installed on the outside of the side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com