Nozzle-free spray blow pipe

A blowing pipe, no nozzle technology, applied in the field of solar silicon material cleaning equipment and wet processing equipment, can solve the problems of uniform workpiece spraying or blowing, complicated structure of cleaning equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

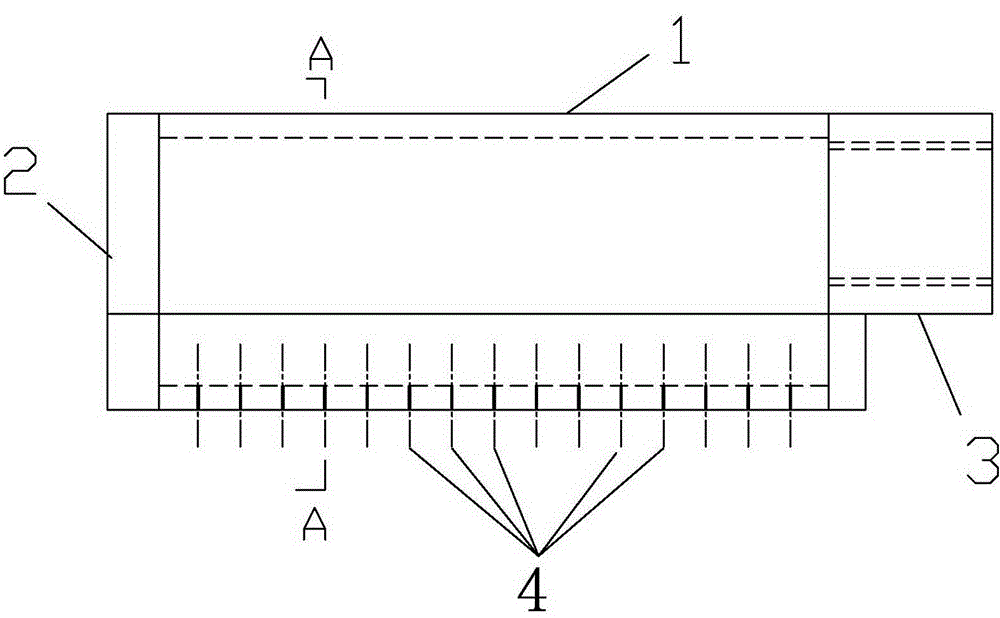

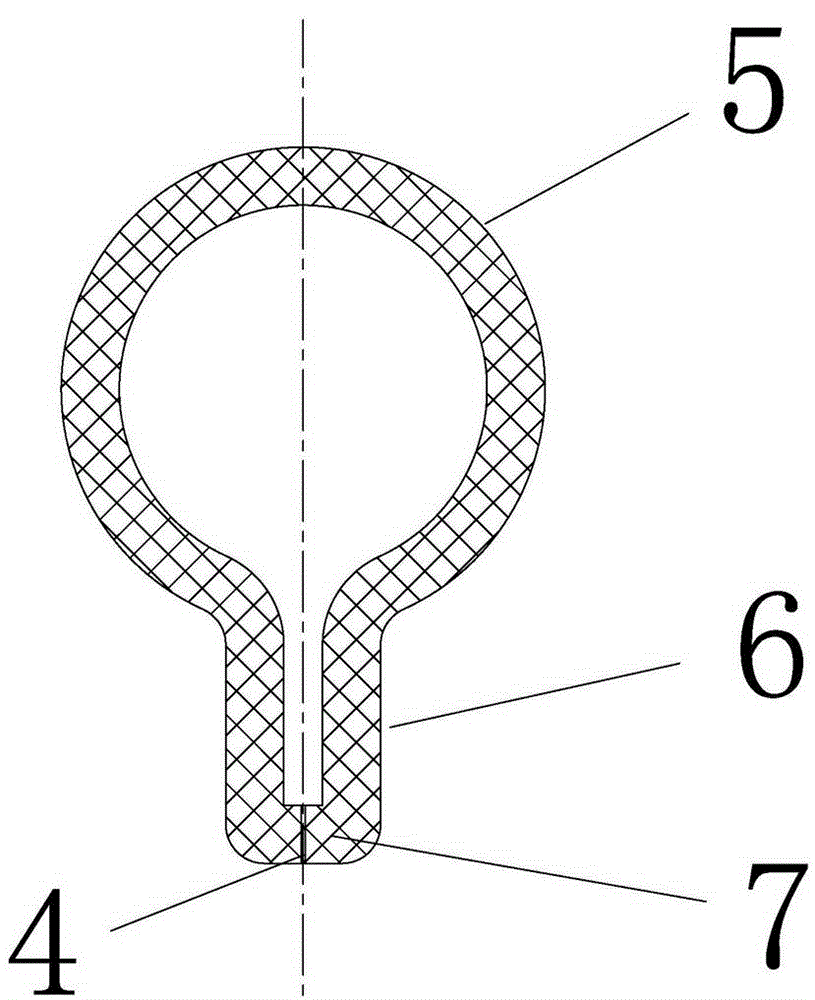

[0012] Such as figure 1 , and shown in 2 are structural schematic diagrams of a preferred embodiment of the present invention. The nozzleless spray blowpipe includes a tubular main body 1, a plug 2 arranged at the left end of the tubular main body 1, and a plug 2 arranged at the tubular main body 1. There is a connector 3 with an internal thread at the right end of the main body 1 . Microholes 4 are uniformly arranged on the lower side wall of the tubular body 1 along the axial direction thereof. In this embodiment, the tubular body 1 includes a cylindrical tube body 5 and a rectangular tube body 6 arranged on the lower side of the cylindrical tube body 5. The rectangular tube body 6 is connected to the cylindrical tube body 5 along the axial direction of the cylindrical tube body. The cavities are connected, and the microholes 4 are arranged on the wall body of the rectangular tube body 6 , which is a wall body 7 perpendicular to the diameter of the cylindrical tube body 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com