Fast detachable transportation frame

A technology of transport frame and bottom frame, which is applied in the field of transport frame, which can solve the problems of heavy weight, increased cost, low recycling rate of transport frame, etc., and achieve the effect of convenient and quick assembly and reduced space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

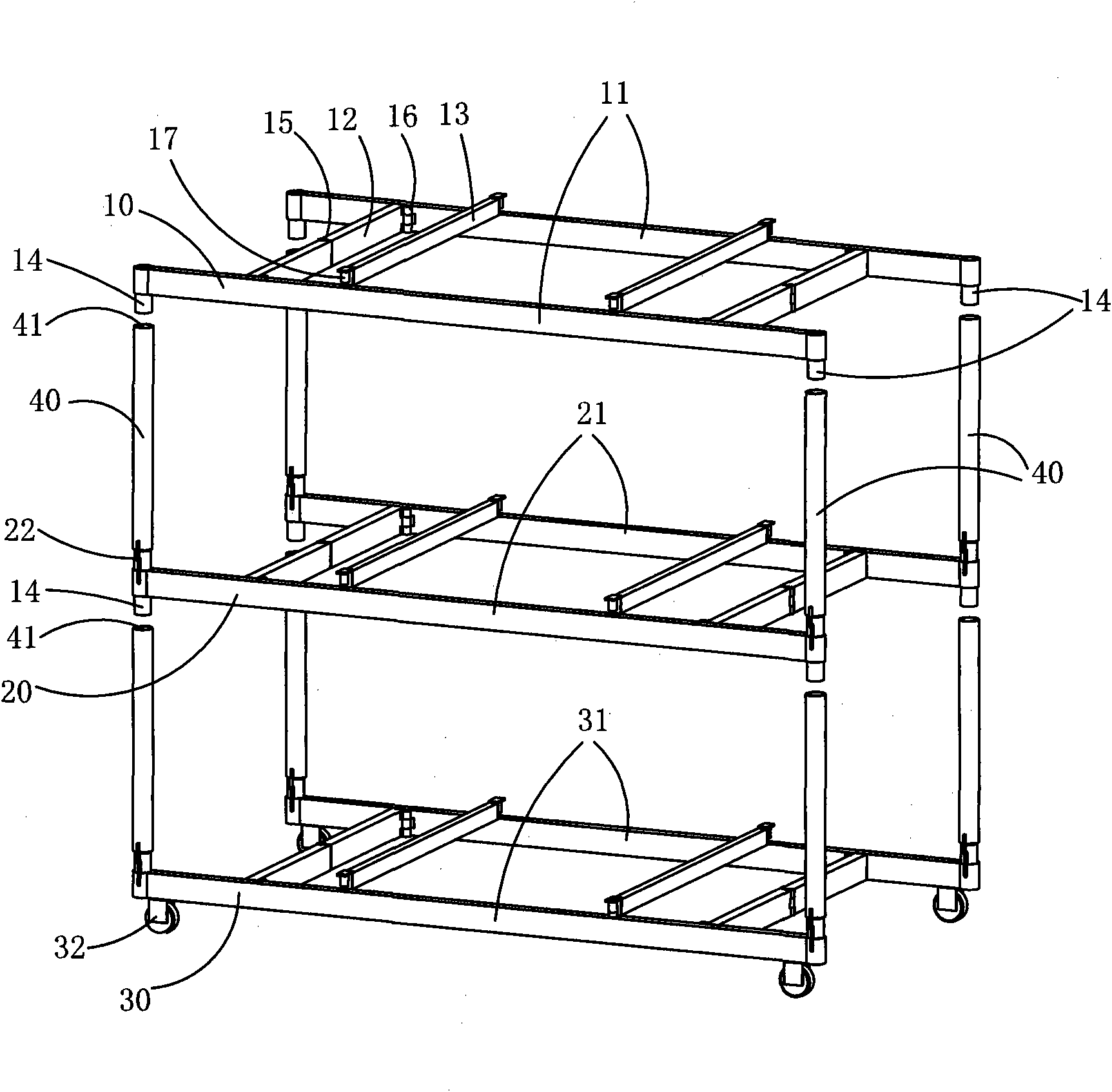

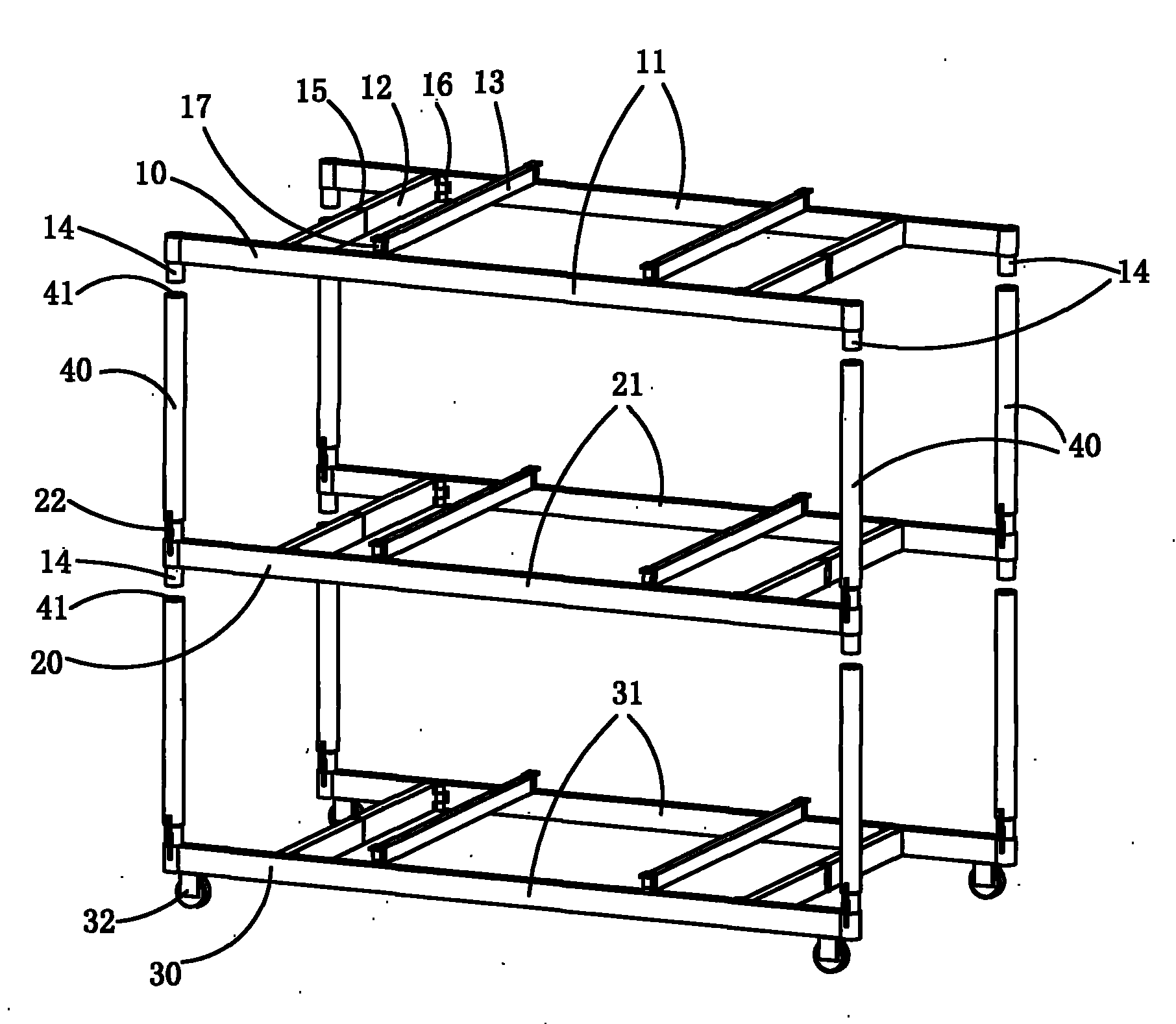

[0008] Such as figure 1 As shown, the present invention provides a transport rack for containers, which includes upper, middle and lower layers, which are respectively used to carry goods. The transport frame includes a top frame 10 on the upper layer, a middle frame 20 on the middle layer, a bottom frame 30 on the lower layer and several support rods 40 connecting the top frame 10 , the middle frame 20 and the bottom frame 30 .

[0009] ginseng figure 1 As shown, the top frame 10 is provided with two relatively parallel first beams 11 , a first adjusting arm 12 hinged to the first beams 11 , and a positioning tube 13 connecting the two first beams 11 . The first beam 11 is elongated, and fixed legs 14 protruding downwards are installed at both ends of the first beam 11 . Each of the first adjusting arms 12 is composed of two mutually hinged half-arms, one end of the two half-arms is hinged together by a hinge 15, and the other end of the two half-arms is respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com