Automatic mould opening machine of glass-blowing altar mouth

A mold-opening machine and altar-mouth technology, which is applied to the special transmission machinery for glass blowing machines, glass manufacturing equipment, and glass blowing, etc., can solve the problems of high labor intensity, affecting product quality and quantity, and low production efficiency. , to achieve the effect of simple device structure, safe and fast production, and labor reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

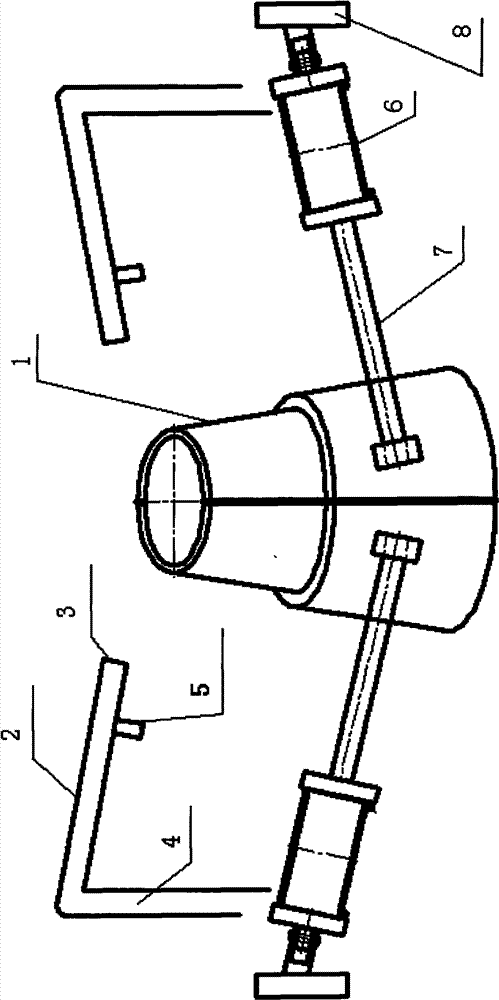

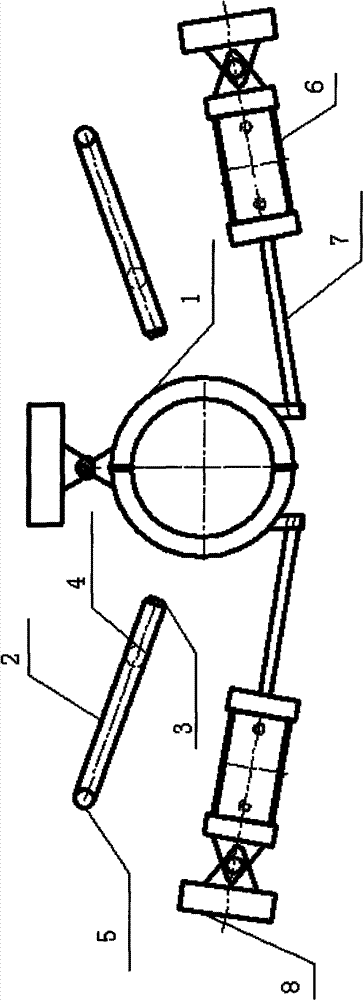

[0012] An automatic mold opening machine for glass blowing altars, comprising a mold 1, cooling pipes 2 are respectively arranged on both sides of the upper end of the mold 1, nozzles 3 are respectively installed on the front ends of the cooling pipes 2, and an air intake pipe is connected to each cooling pipe 2 4 and water inlet pipe 5; both sides of the lower end of the mold 1 are respectively provided with fixing seats 8, and cylinders 6 are respectively installed on the fixing seats 8, and the piston 7 rods of the cylinder 6 are respectively fixed on the side walls on both sides of the mold 1, The mold 1, cylinder 6 and cooling pipe 2 are all connected to a control system.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap