Shear blade device for velour knitting machine

A technology of scissors blade and towel machine, which is applied in textile and papermaking, cutting loop, weft knitting, etc., can solve the problems of inability to remove cotton wool, unfavorable shearing, and unreasonable overall size of scissors blade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

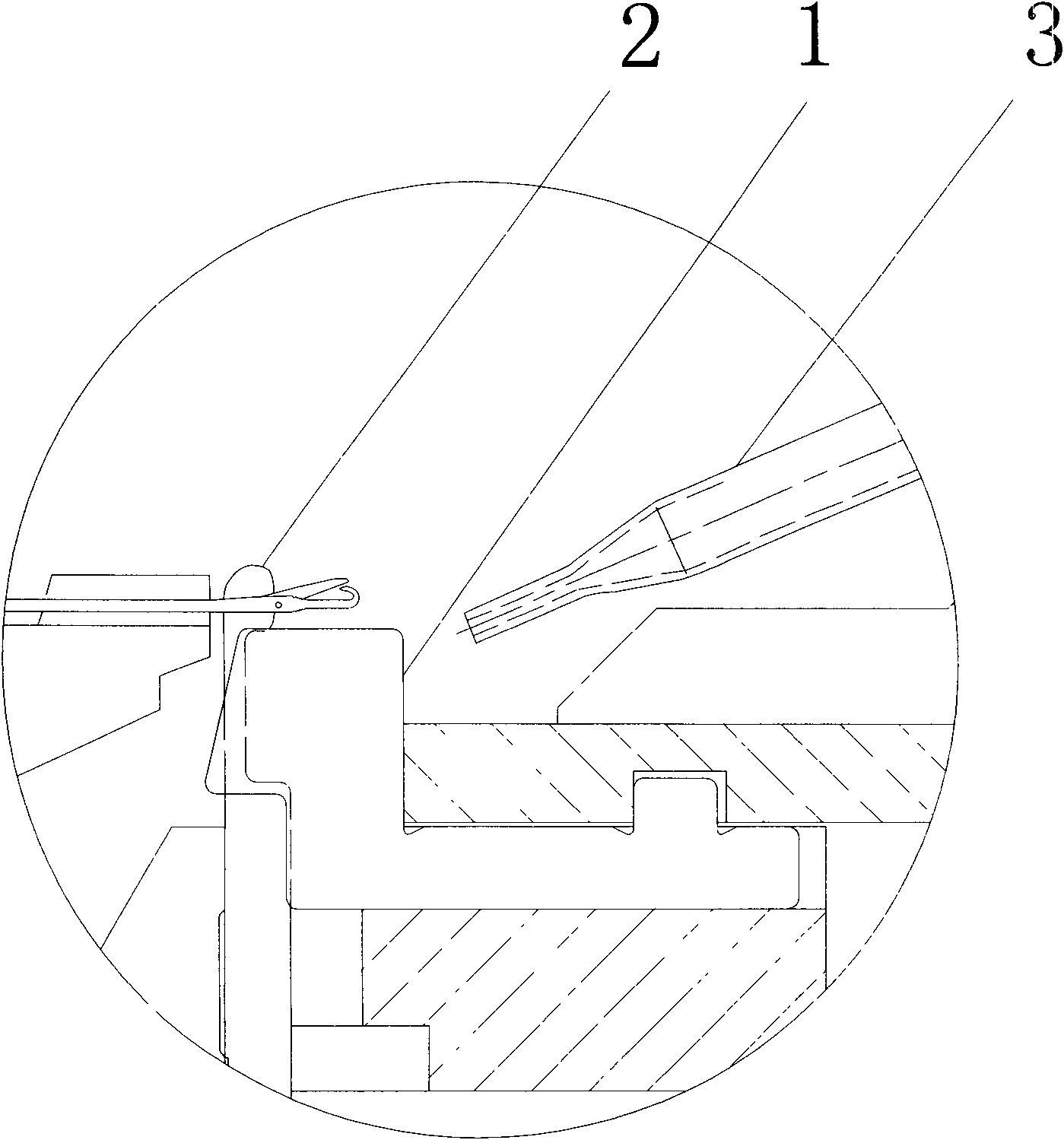

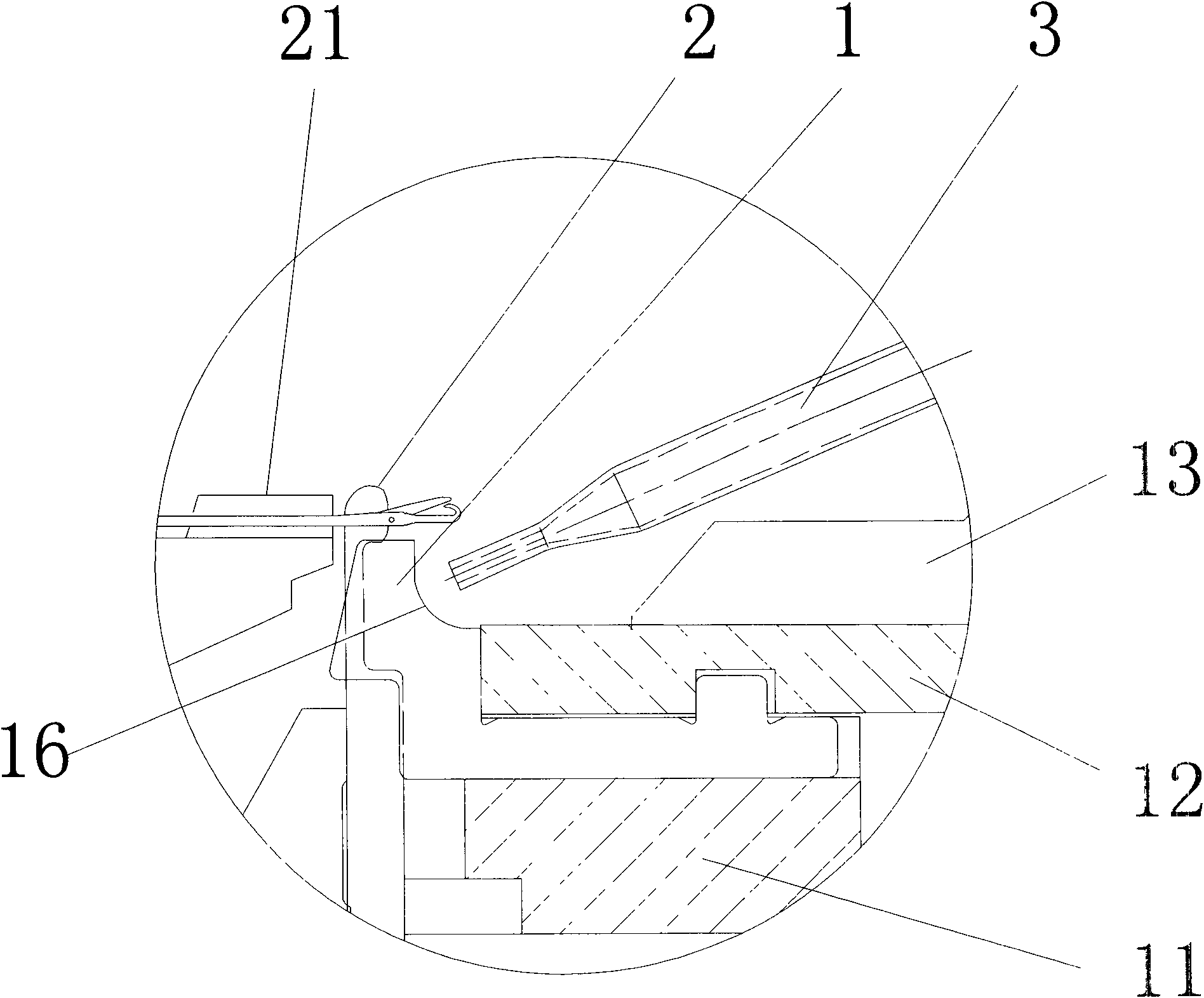

[0011] Such as figure 1 , figure 2 As shown, the scissors device of the turned-up towel machine is installed on the automatic shearing and turned-up towel machine, and consists of a scissors 1 and a lower raw gram 2 tangent to the scissors 1. The scissors 1 are arranged in the syringe 11 On the upper part, it is fixed on the gram triangle 12 and can move left and right. The gram triangle 12 is provided with an upper cutting block 13, and the lower gram piece 2 is arranged on the inner side of the dial 21, and is overlapped with the scissors 1. It can move up and down, and the top right of the scissors blade 1 is provided with a gap 16 . The present invention adopts a new type of shape for the scissors of all machine sizes of the automatic hair-shearing and turning-up towel machine, and removes the material of the non-working position of the scissors as much as possible without affecting the working strength of the scissors. That is: a larger gap of the same size is dug out ...

Embodiment 2

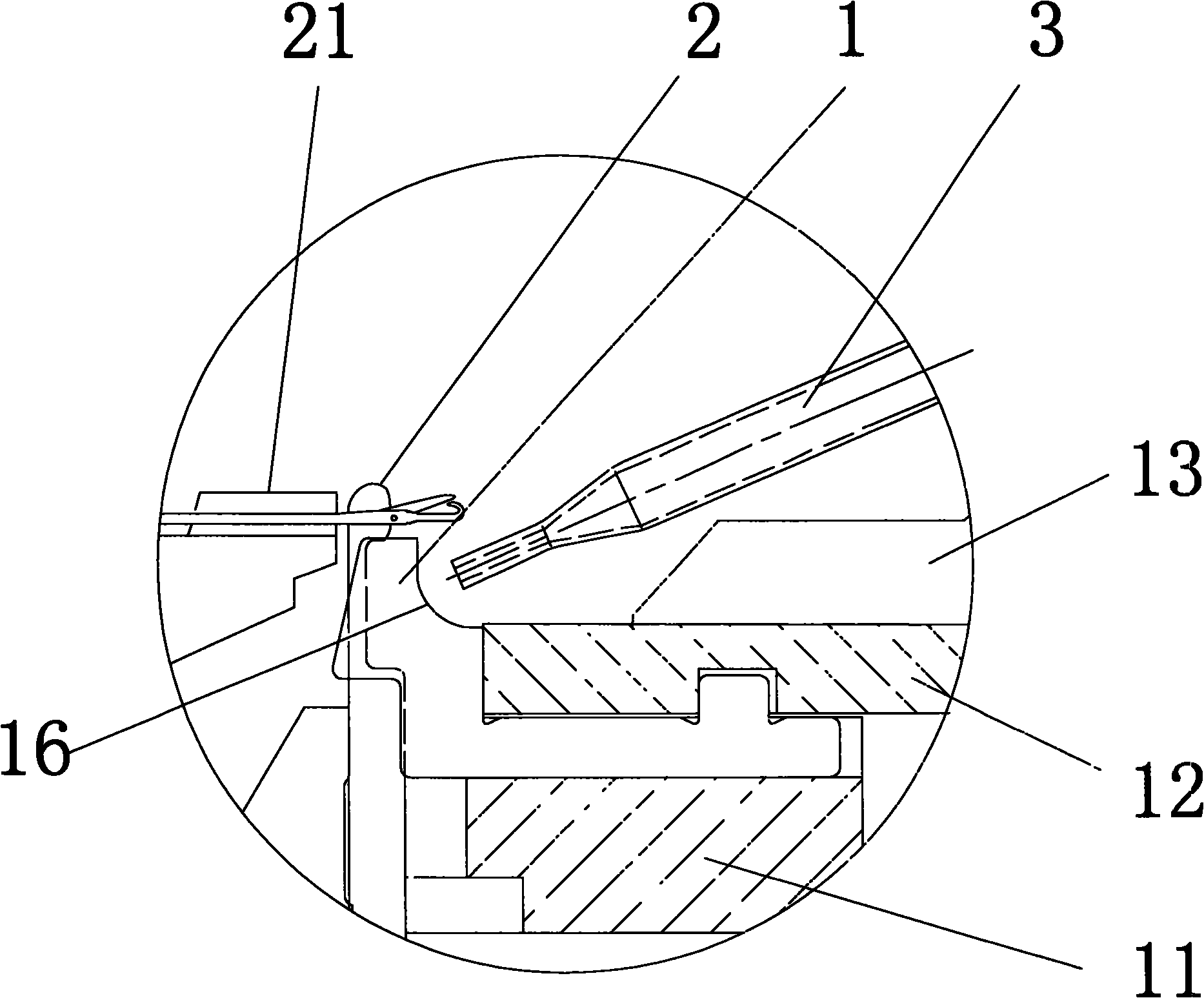

[0013] Such as figure 2 As shown, the scissors device of the turned-up towel machine is installed on the automatic shearing and turned-up towel machine, and consists of a scissors 1 and a lower raw gram 2 tangent to the scissors 1. The scissors 1 are arranged in the syringe 11 On the upper part, it is fixed on the gram triangle 12 and can move left and right. The gram triangle 12 is provided with an upper cutting block 13, and the lower gram piece 2 is arranged on the inner side of the dial 21, and is overlapped with the scissors 1. Can move up and down, the top right of the scissor blade 1 is provided with a gap 16, in order to increase the air pressure, the gap 16 is provided with a dust removal nozzle 3, and the dust removal nozzle 3 faces the shearing place. The pressure of the air is strong, and it is easier to remove cotton waste. The notch 16 is at right angles, and the corners are arc transitioned. The lower right-angled side of the notch 16 is on the same level as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com