Quick pipe joint

A pipeline joint, fast technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of incompatibility and inconvenience, and achieve the effect of simplifying workshop equipment and convenient use

Inactive Publication Date: 2011-04-27

陈超

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problem that the existing pipe joints of large and small diameters must be matched and cannot be used together, resulting in inconvenient use, the present invention proposes a quick pipe joint. There is a rubber tube at the end of the tube, that is, in the direction of compressed air input. One end of the rubber tube is set on the guide tube, and the other end extends in the direction of compressed air input. When the joint is not in use, the rubber tube is compressed by the compressed air. The rubber tube blocks the overflow of compressed air

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

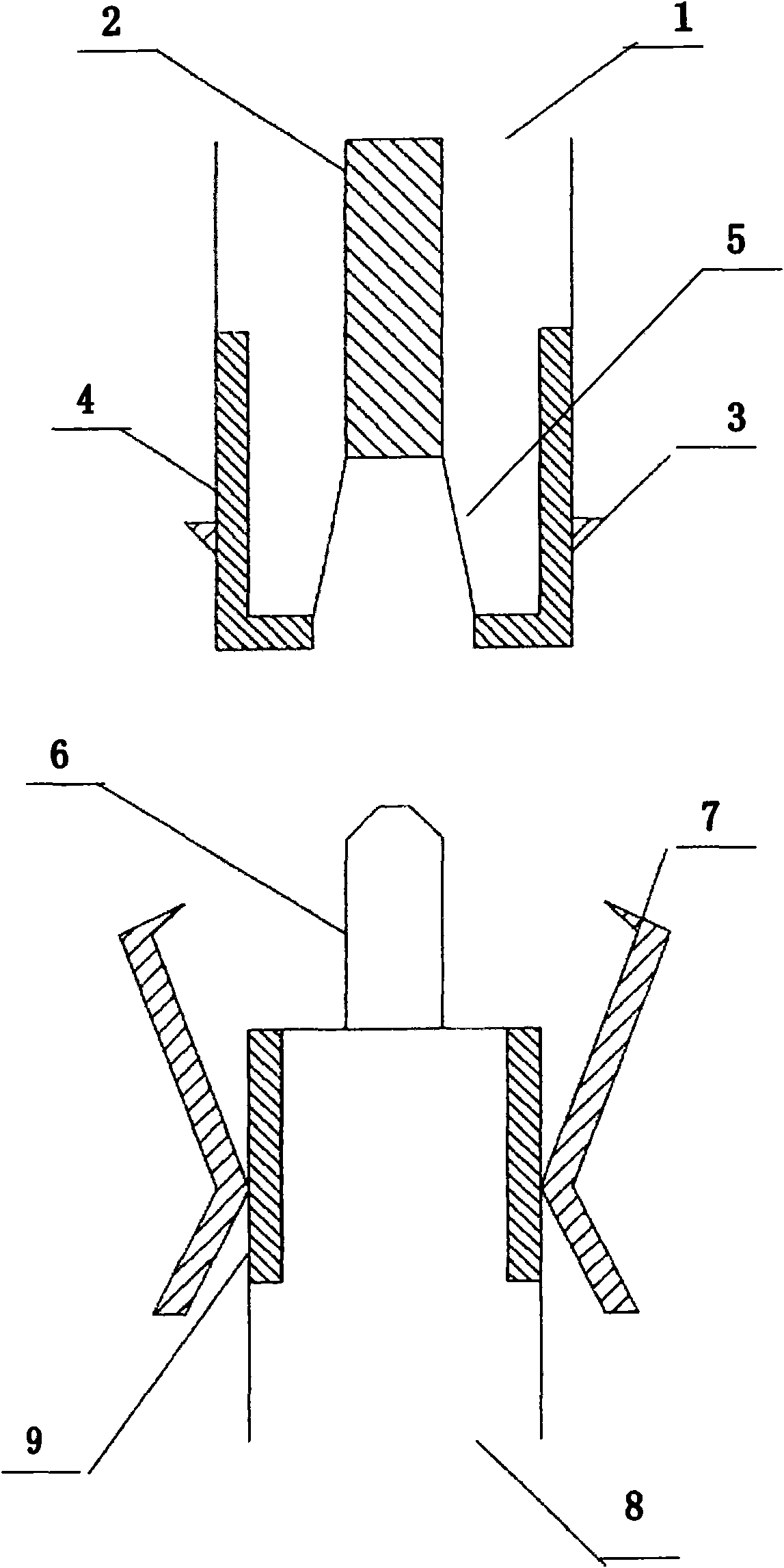

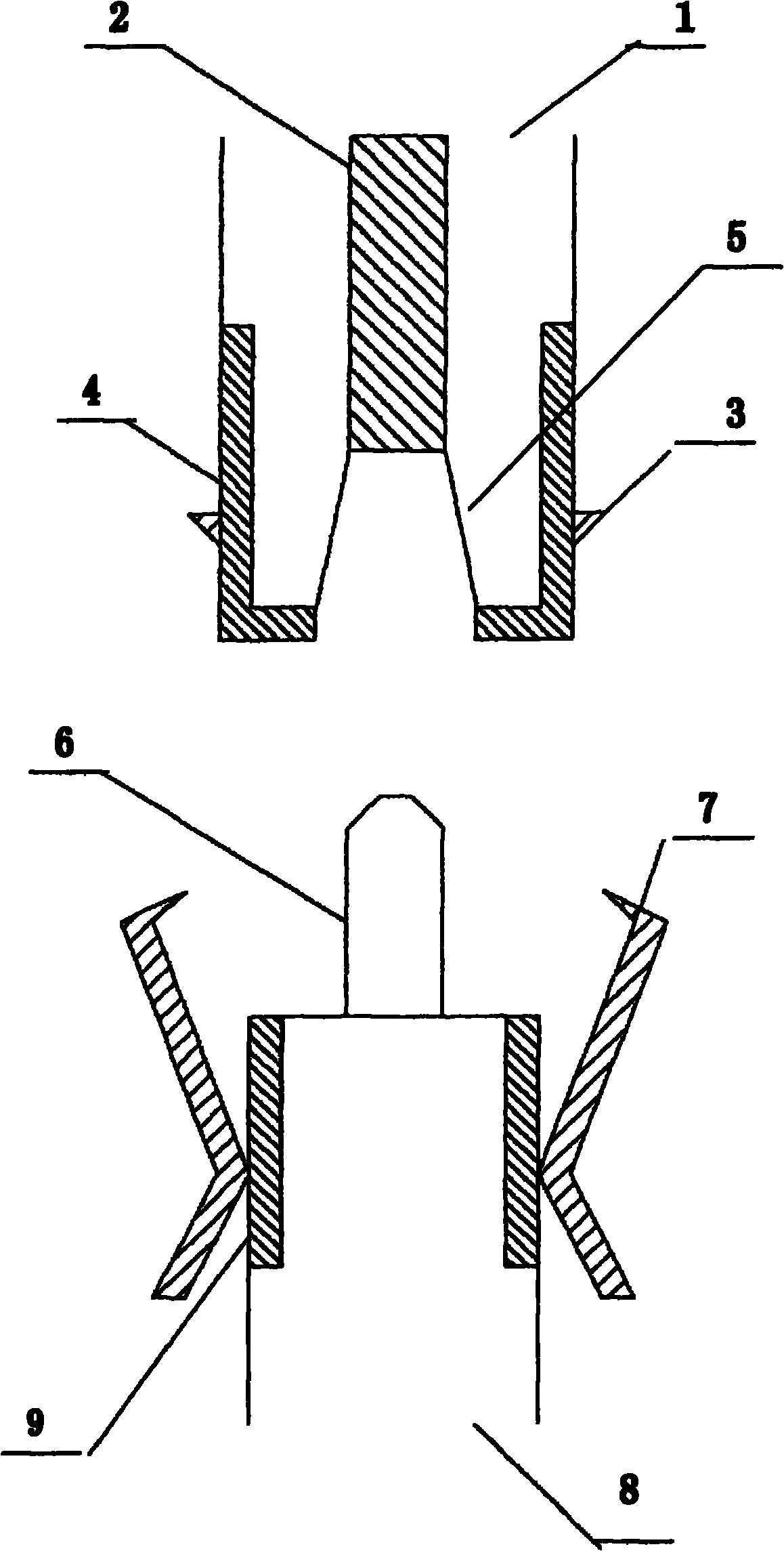

[0009] As shown in Figure 1, the compressed air output joint (4) is equipped with a guide tube (5), and the end of the guide tube (5) is covered with a rubber tube (2). When the compressed air output joint (4) is connected with the input joint (9) , the air needle (6) penetrates the rubber tube (2), the compressed air is conducted immediately, and the anti-off hook (7) is hung on the shoulder (3) to prevent the two from getting loose.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a quick pipe joint, which is used for quickly connecting a low-pressure compressed air pipeline. In order to realize conveying of compressed air, most conventional joints can only be used together with matched pipes, namely, a large-caliber pipe is matched with a large joint, a small-caliber pipe is matched with a small joint and the large and small joints cannot replace each other. A compressed air output joint is provided with a metal guide pipe; the tail end of the guide pipe, namely, a compressed air input direction, is provided with a rubber pipe; a compressed air input joint is provided with a pneumatic needle; and the pneumatic needle is pushed into a flattened rubber pipe, so that compressed air flows inwards from a hollow pneumatic needle and a communicating process is finished. Simultaneously, the compressed air output joint is provided with a shoulder port and the input joint is provided with a hook, so that the compressed air output joint and the input joint are prevented from falling.

Description

Technical field: [0001] The invention relates to a quick pipeline connector, which is used for quick connection of low-pressure compressed air pipelines. Background technique: [0002] Compressed air is a common tool in industrial production. In order to realize the delivery of compressed air, there are now various types of joints, but most of the existing joints can only be used in matching models. Large-diameter pipes are equipped with large joints, and small-diameter pipes Equipped with small joints, the large and small joints cannot be mixed, so that some stations in the workshop are equipped with multiple compressed air joints of different calibers for the setting of different air consumption. Invention content: [0003] In order to solve the problem that the existing pipe joints of large and small diameters must be matched and cannot be used together, resulting in inconvenient use, the present invention proposes a quick pipe joint. There is a rubber tube at the end ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L37/098F16L37/133

Inventor 陈超郭夙人

Owner 陈超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com