LED bulb

A technology of LED light bulbs and LED chips, which is applied to lampshades, cooling/heating devices of lighting devices, lighting and heating equipment, etc. Fast, light coverage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

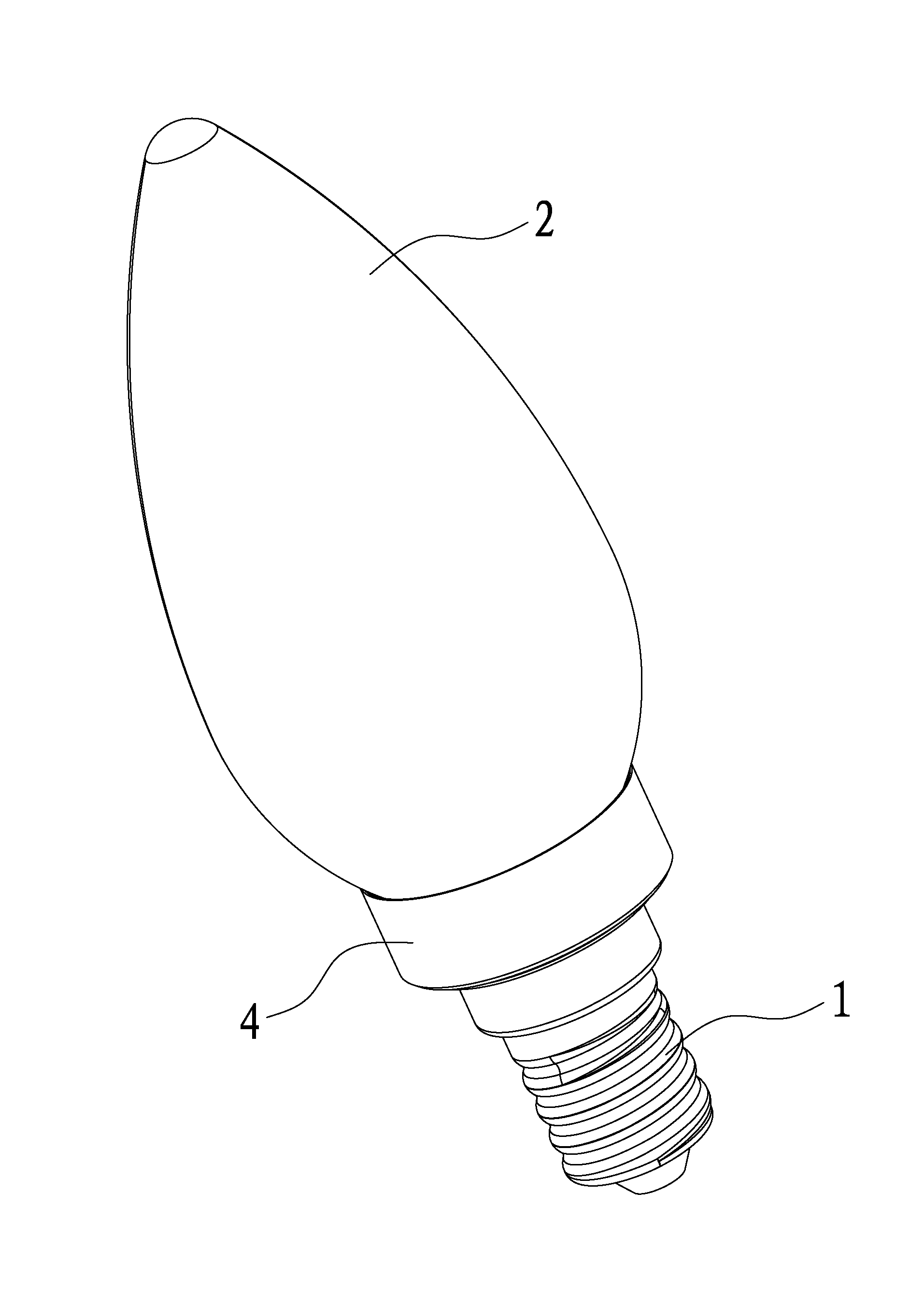

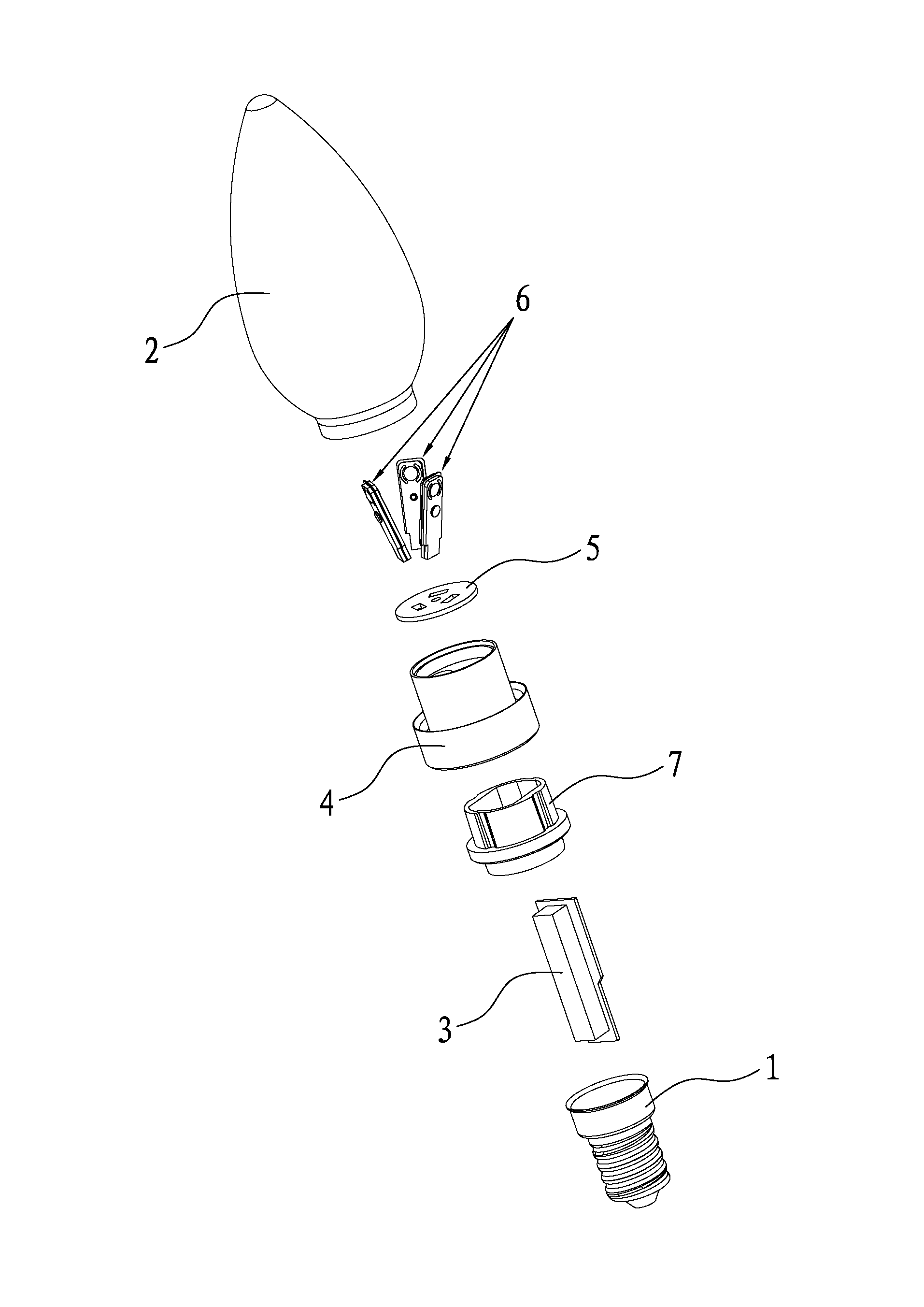

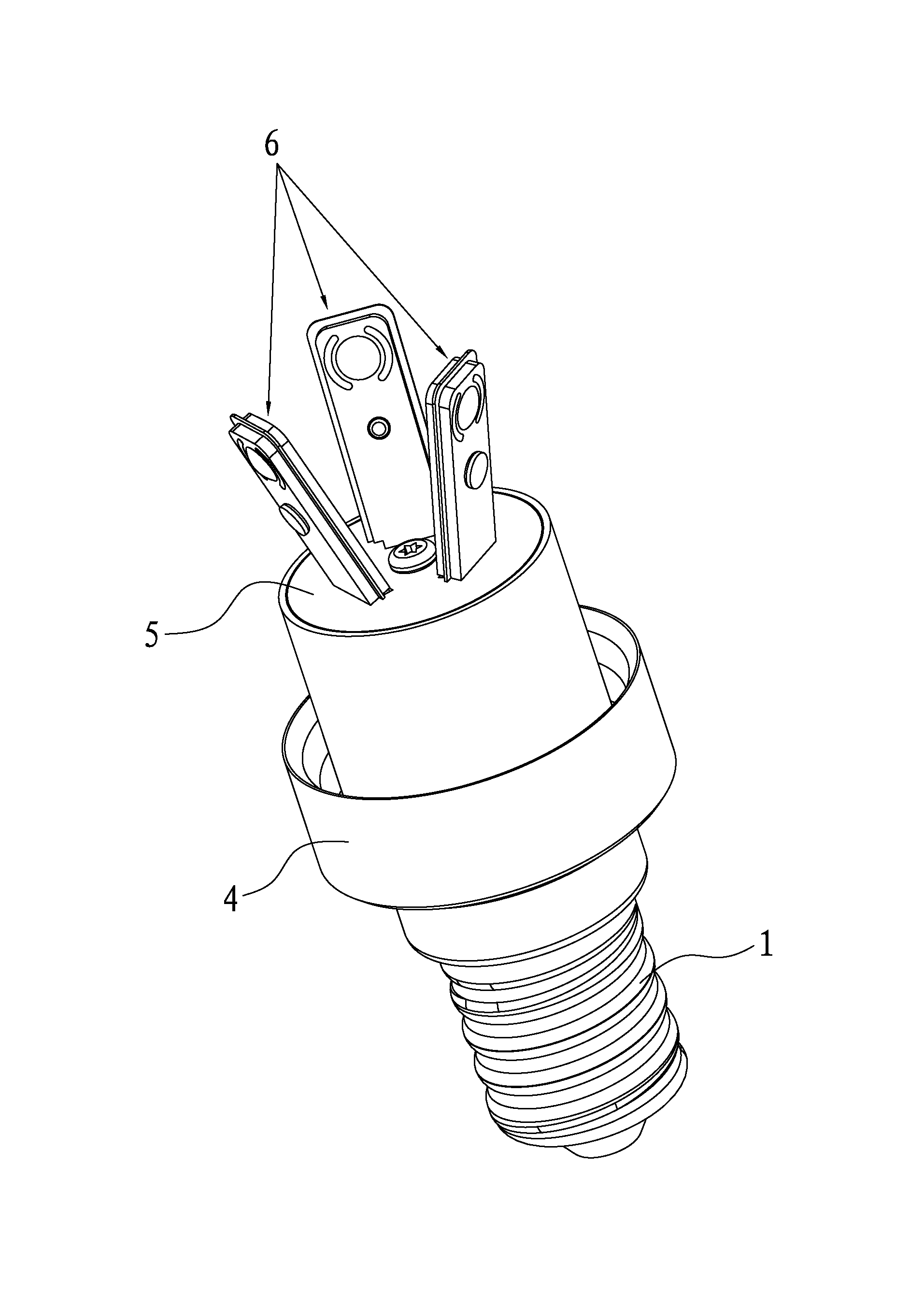

[0034] A kind of LED bulb of the present invention, as Figure 1~6 As shown, it includes a lamp cap 1, a lampshade 2, and a power supply 3 located in the lamp cap 1. The power supply 3 is electrically connected to the lamp cap 1, so that the power supply 3 can be connected to an external AC power through the lamp cap 1. A heat-dissipating metal is clamped between the lamp cap 1 and the lampshade 2. Shell 4, the top of the heat dissipation metal shell 4 is located in the lampshade 2, and the top of the heat dissipation metal shell 4 is clamped and fixed with a heat dissipation substrate 5, so that the heat dissipation substrate 5 can transfer heat to the heat dissipation metal casing 4, and the heat dissipation substrate 5 is plugged and fixed. LED luminous column 6, LED luminous column 6 comprises two PCB substrates 61, and the fronts of two PCB substrates 61 are all packaged with LED chip 62, namely LED chip 62 is directly packaged on PCB substrate 61, to reduce LED luminous c...

Embodiment 2

[0045] Embodiment 2 of an LED light bulb of the present invention. The difference between this embodiment and Embodiment 1 is that the lampshade 2 is a spherical lampshade, and the spherical lampshade can be selected as a glass spherical lampshade or a plastic spherical lampshade according to the actual application environment. It can also be a transparent spherical lampshade or a translucent spherical lampshade. Of course, the lampshade of the present invention can also be in other shapes, not limited to candle-shape or spherical shape. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com