Method for fault diagnosis of rotating mechanical equipment based on interval-type evidence fusion

A technology of rotating mechanical equipment and evidence fusion, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as insufficient capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

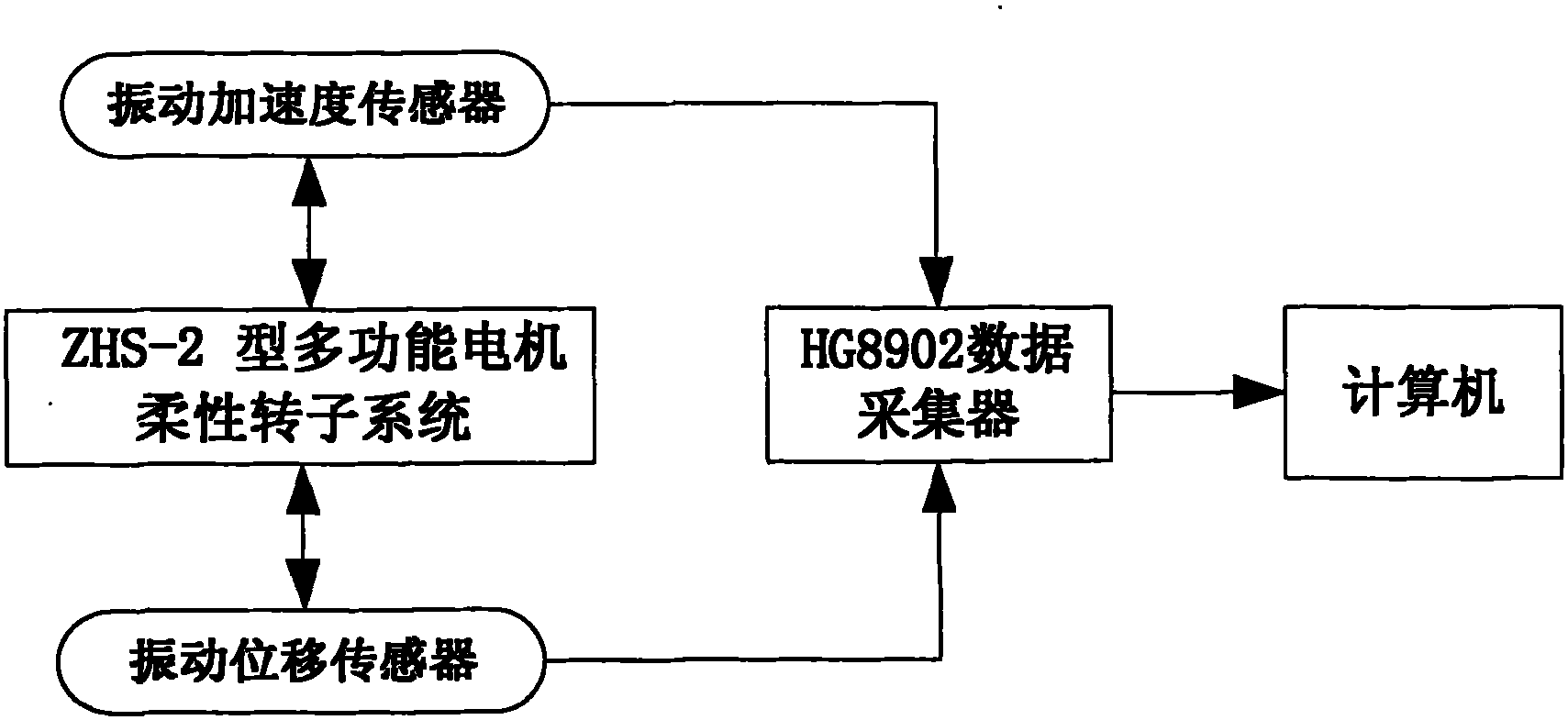

Examples

Embodiment Construction

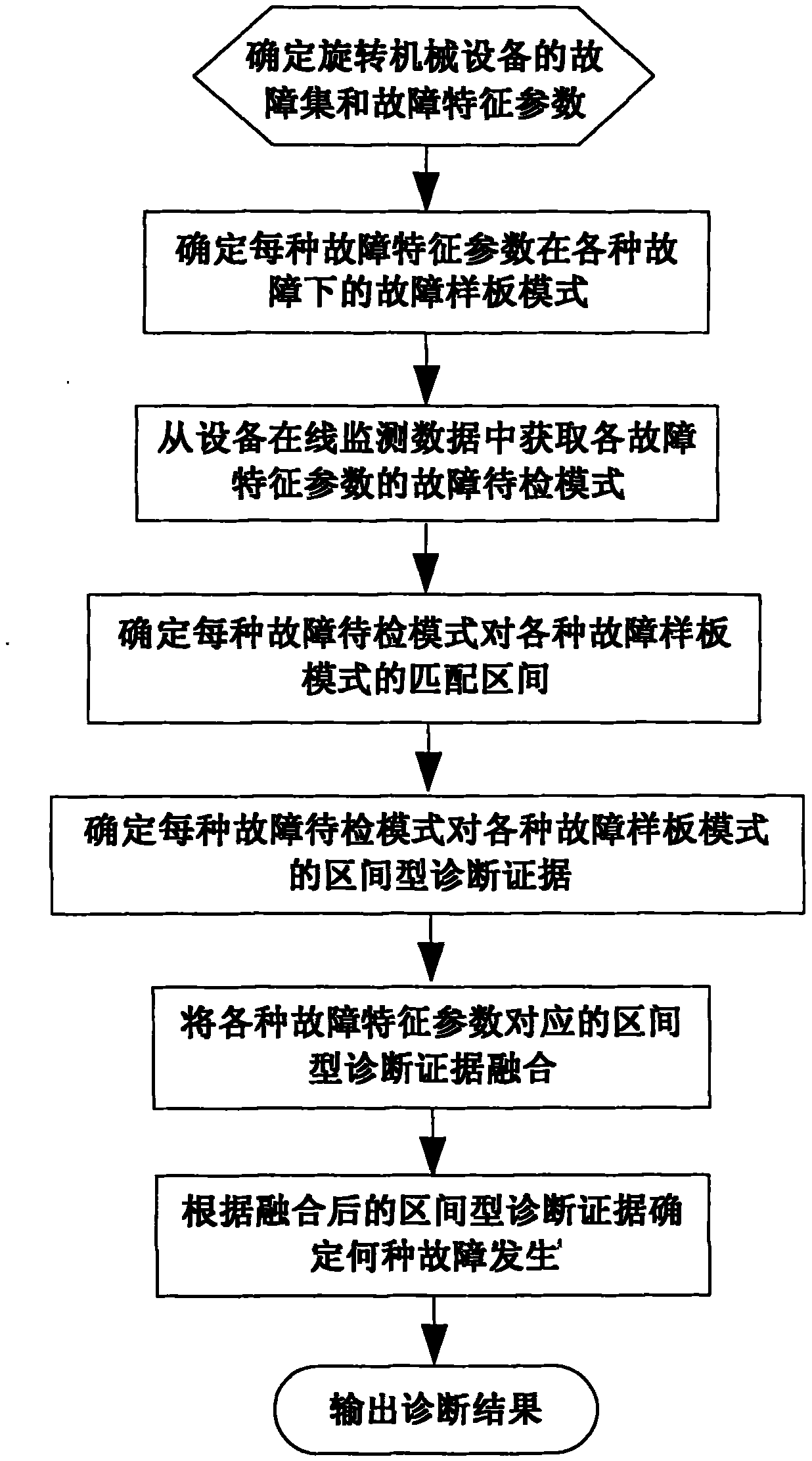

[0050] The fault diagnosis method for rotating mechanical equipment based on interval type evidence fusion proposed by the present invention, its flow chart is as follows figure 1 shown, including the following steps:

[0051] (1) Set the fault set of rotating mechanical equipment as Θ={F 1 ,...,F j ,...,F N}, F j Represent the jth fault in the fault set Θ, j=1, 2, ..., N, N is the number of faults;

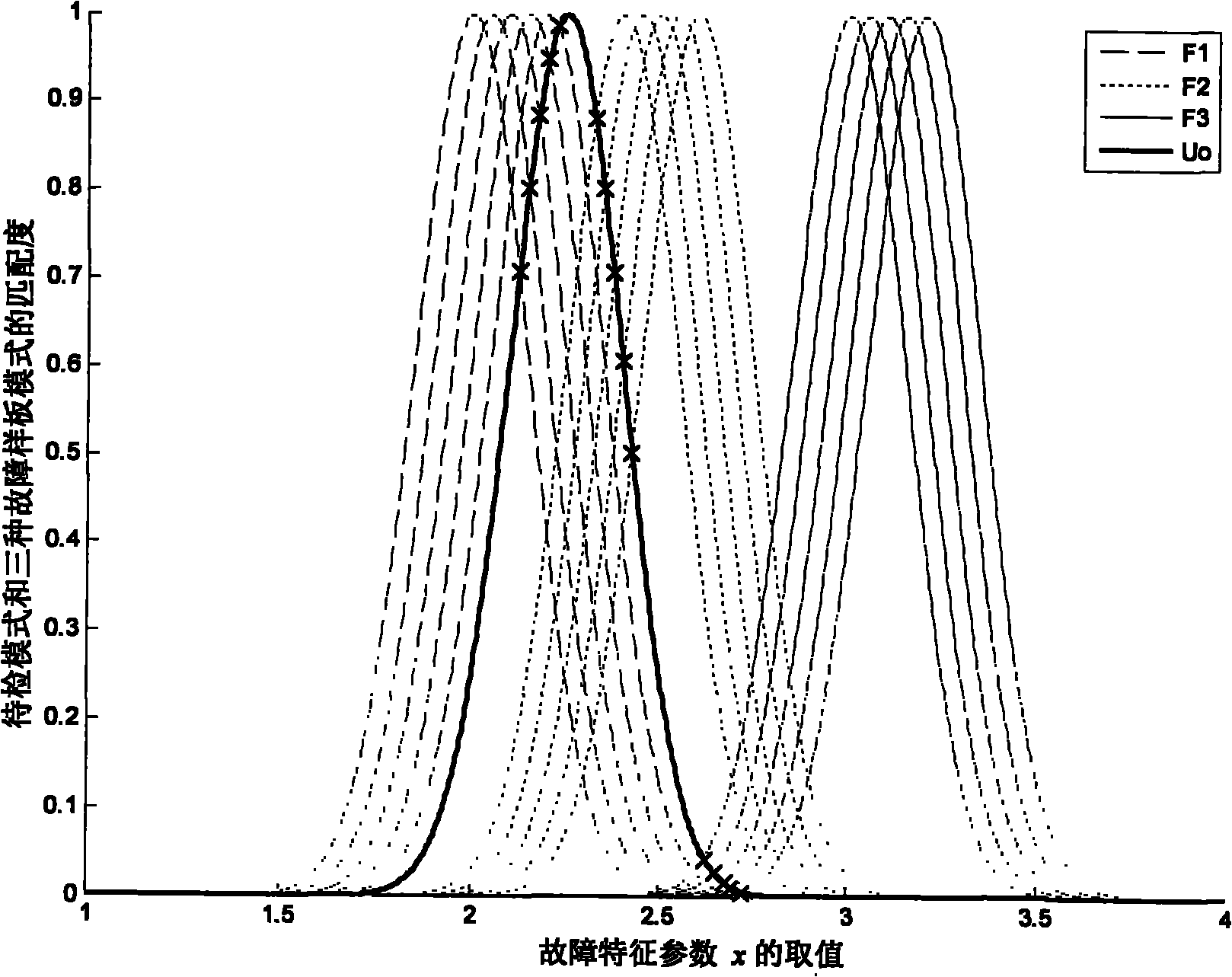

[0052] (2) Let x be a fault characteristic parameter of the fault set Θ, and establish a fault model model of the fault characteristic parameter x for fault F j A membership function set of , Get the membership function set The steps of each membership function in are as follows:

[0053] (2-1) Observe each fault F in the fault set Θ j The fault characteristic parameter x of the fault is recorded continuously for 30 to 50 times, and the observation results are recorded as one group, and a total of m groups of observations are carried out, 5≤m≤10;

[0054] (2-2) Calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com