Patents

Literature

43results about How to "Realize online fault diagnosis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

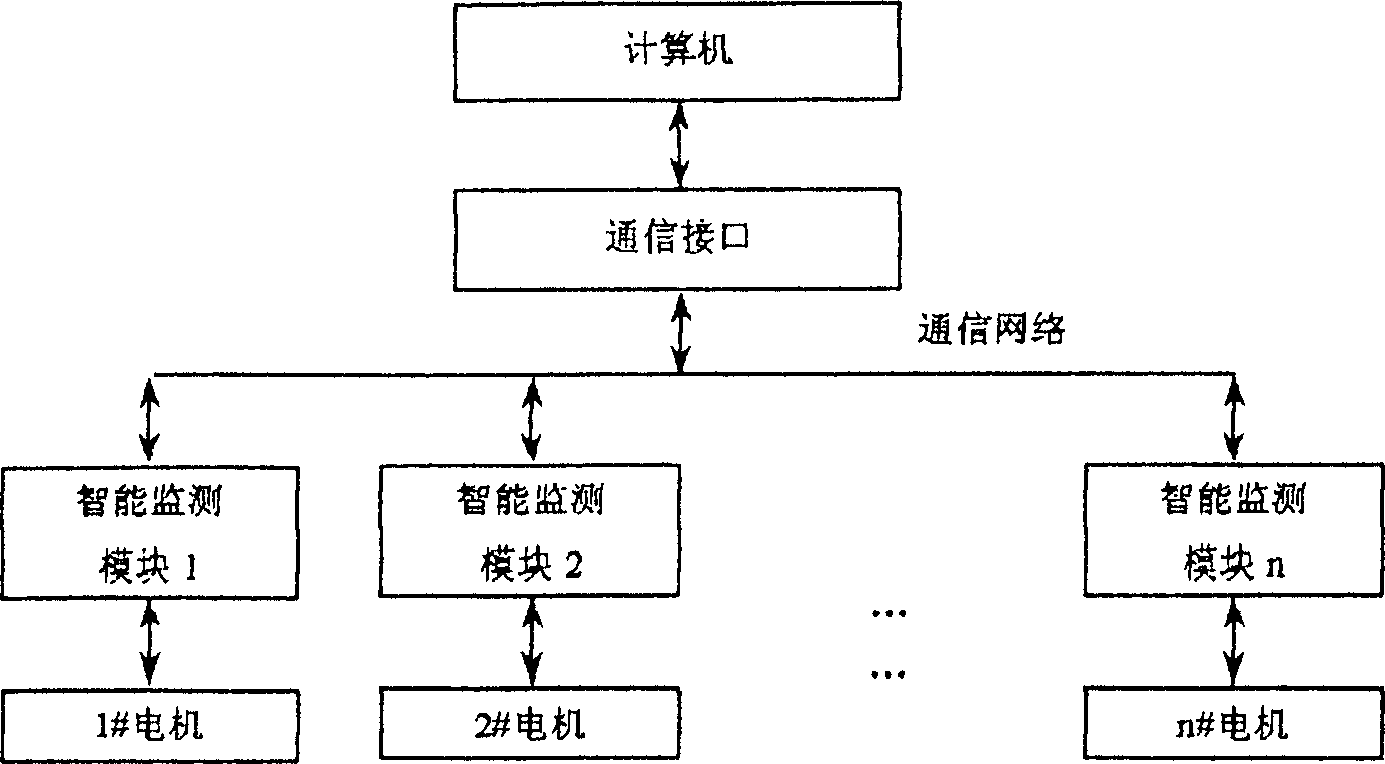

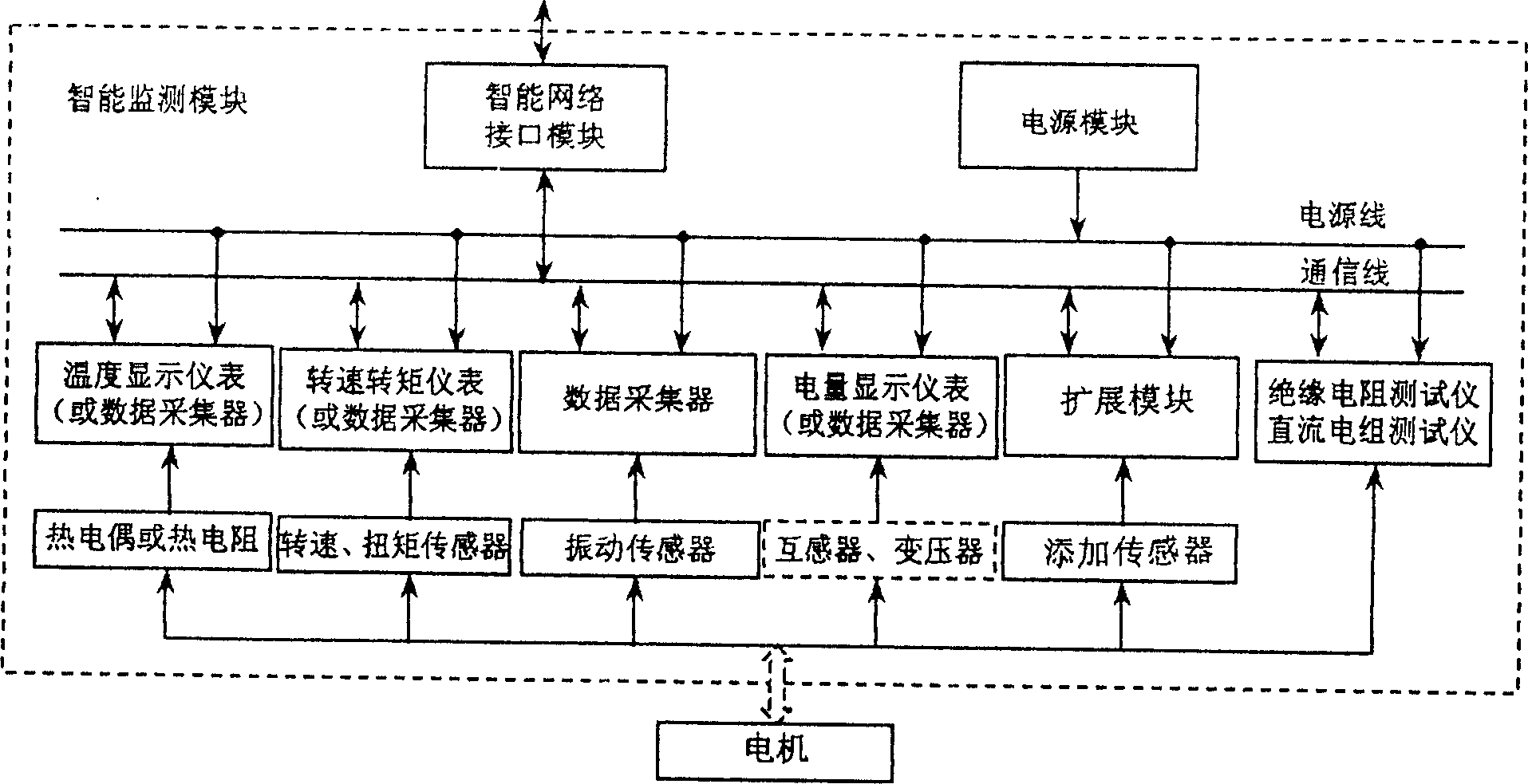

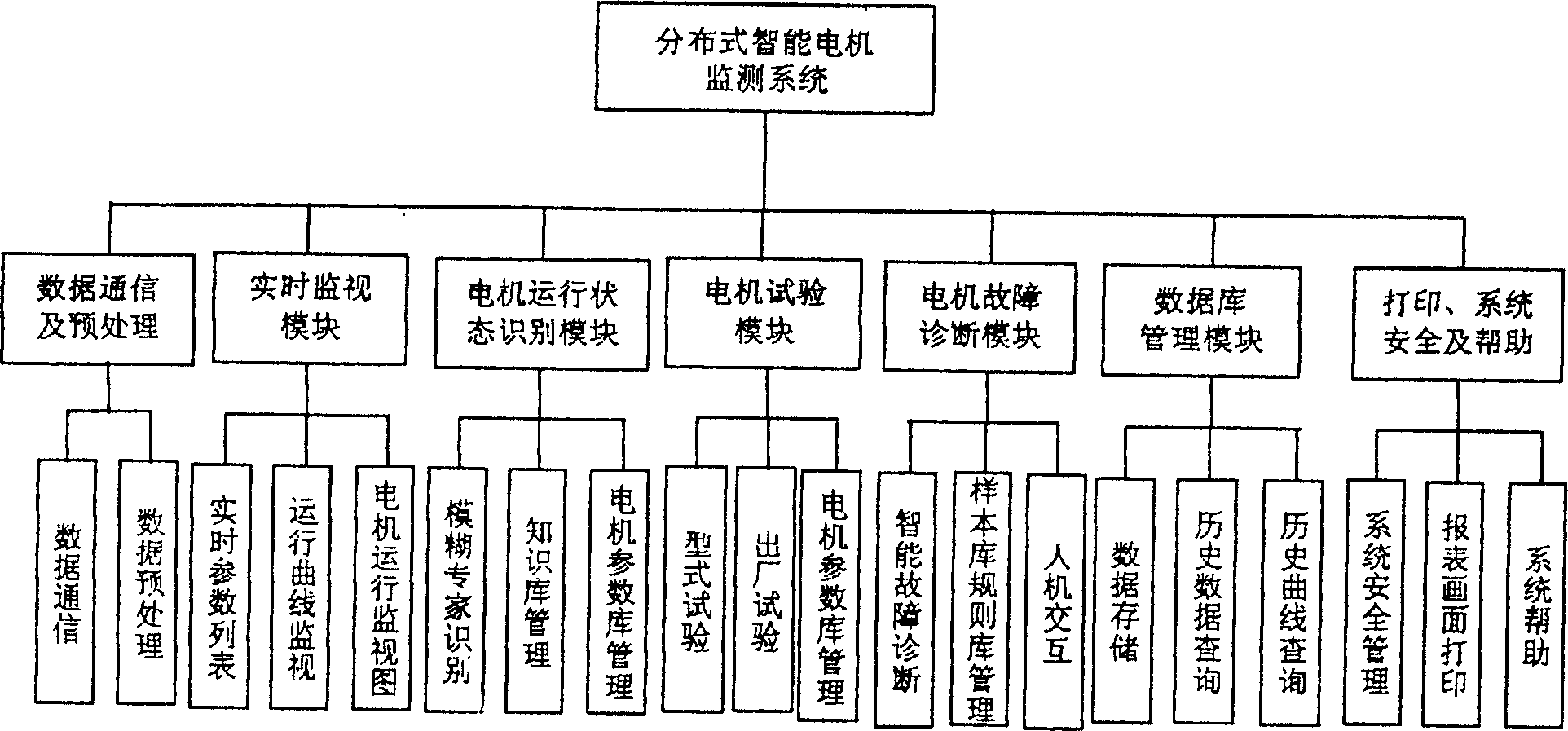

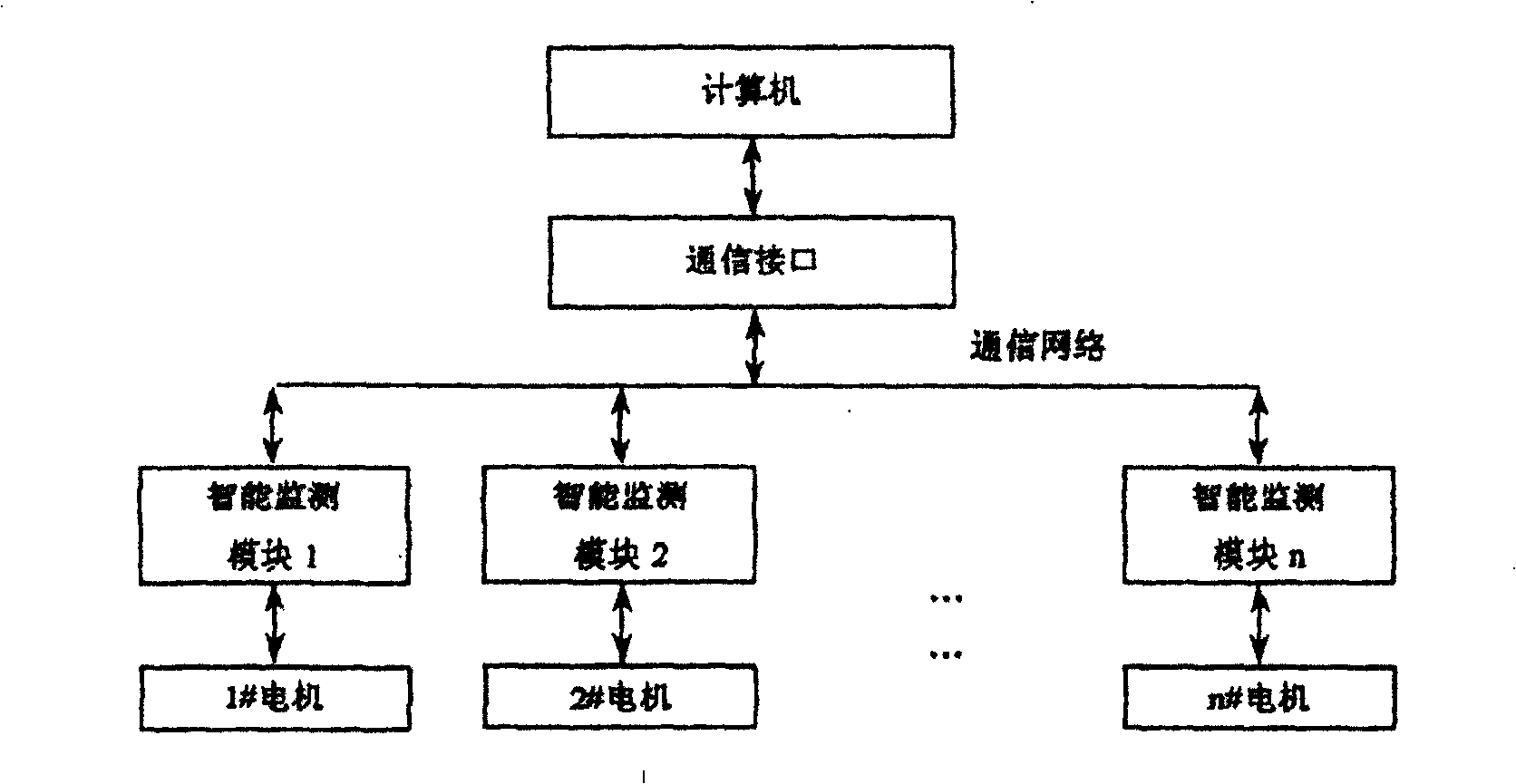

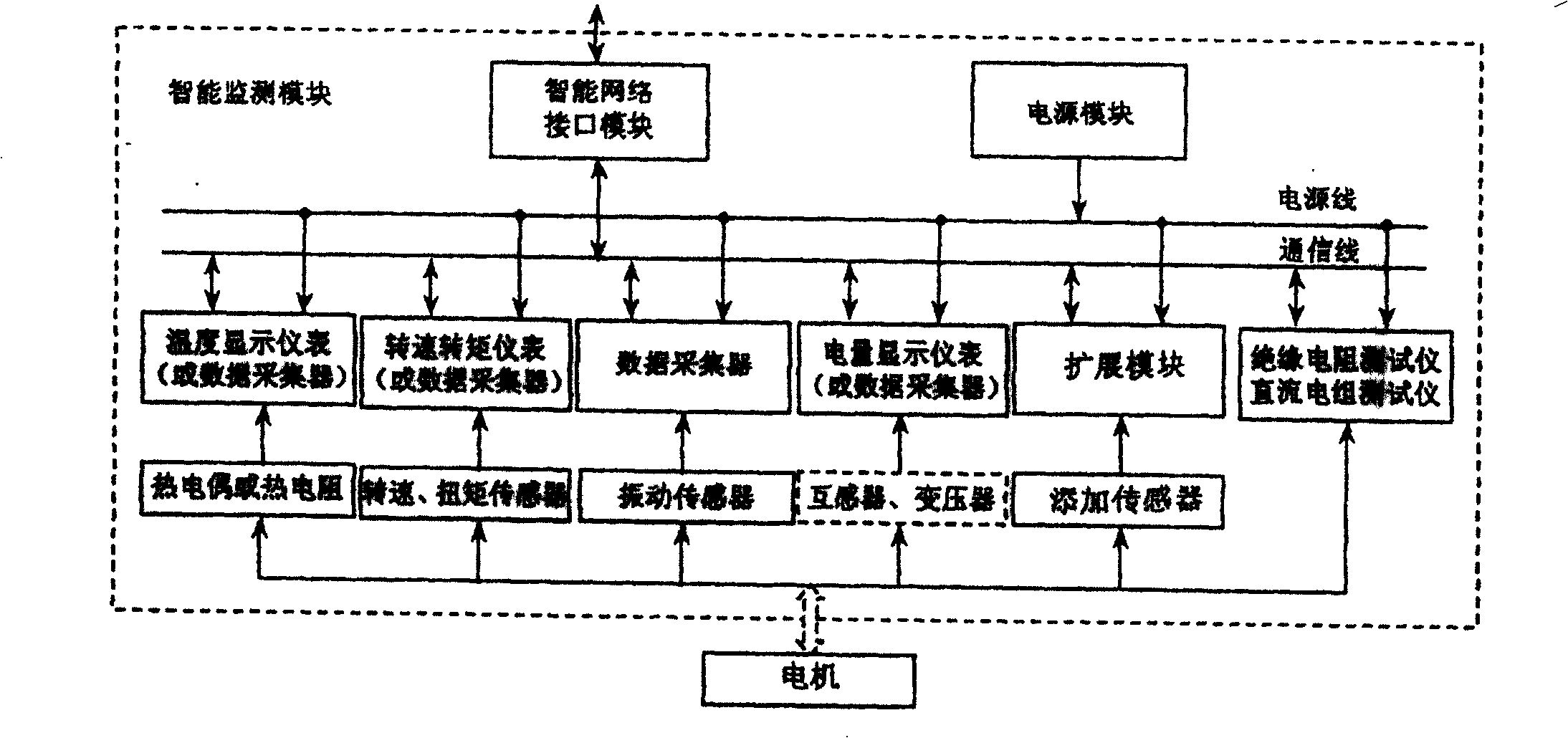

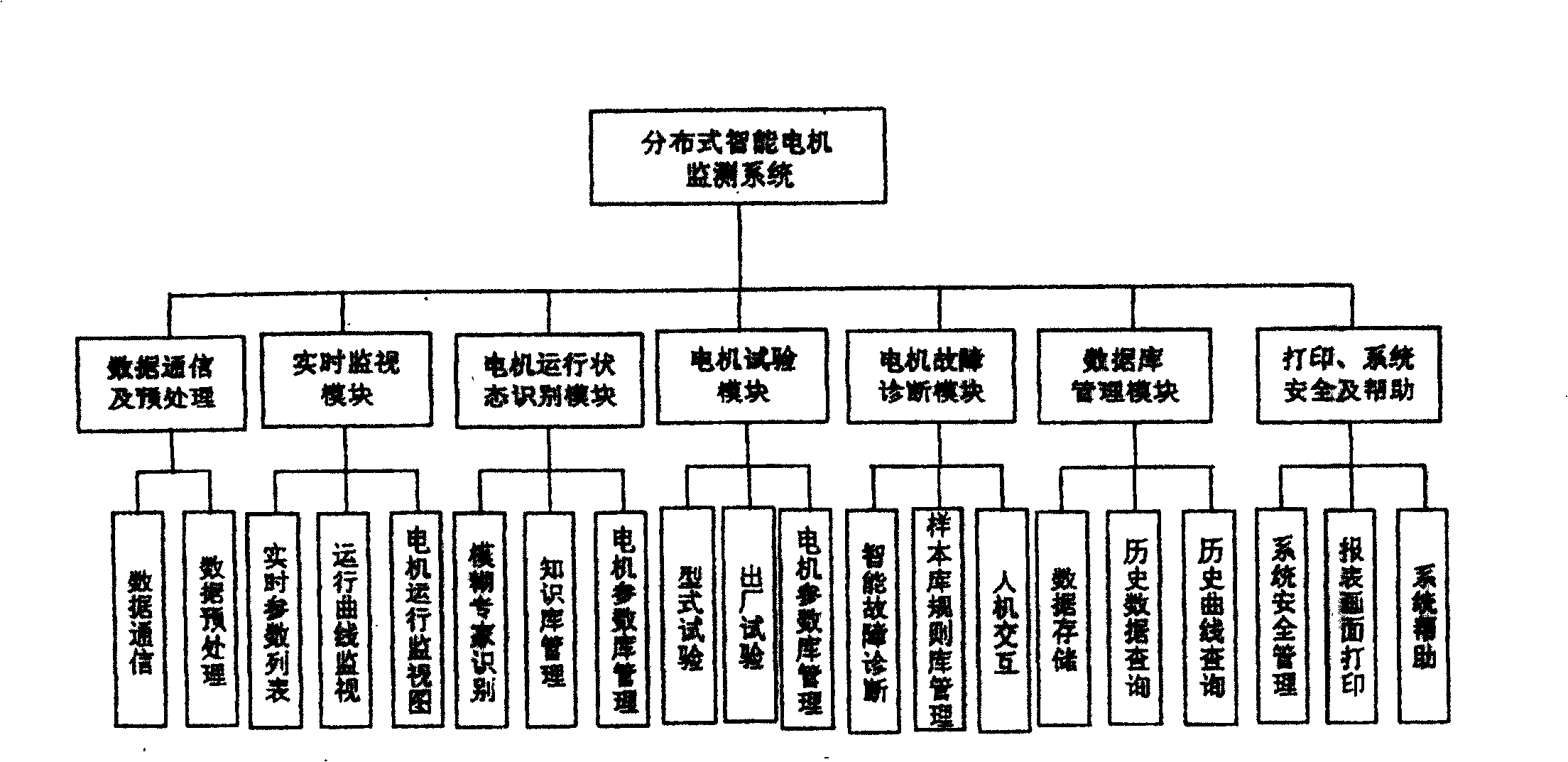

Distributed intelligent monitoring system for motor

InactiveCN1611955AReal-time monitoring of power parametersReal-timeDynamo-electric machine testingChemical industryInformation processing

The present invention relates to a distributed intelligent motor monitoring system. The system includes a locale bottom layer intelligent monitoring substation, a high layer intelligent monitoring main station, and a modular system application software for executing data acquisition and information processing to realize motor monitoring function. Wherein, the monitoring substation is connected to the motor in corresponding position, and is composed of an intelligent monitoring module including monitoring instrument, instrument and data sampler, the intelligent monitoring main station is composed of computers for realizing motor information centralized processing and intelligent monitoring, the substation and the main station is interconnected by data communication network. The system can realize the real time acquisition and local / remote monitoring for the parameters of single or multiple motors, the motor running status recognition and failure diagnosis function. The system not only can be used as the special equipment for delivery tests and type approval test for the motor manufacturer, but also can be broadly used for the motor real time monitoring or on line failure monitoring for the industrial department such as metallurgy, chemical industry, petroleum and pharmacy.

Owner:杜玉晓

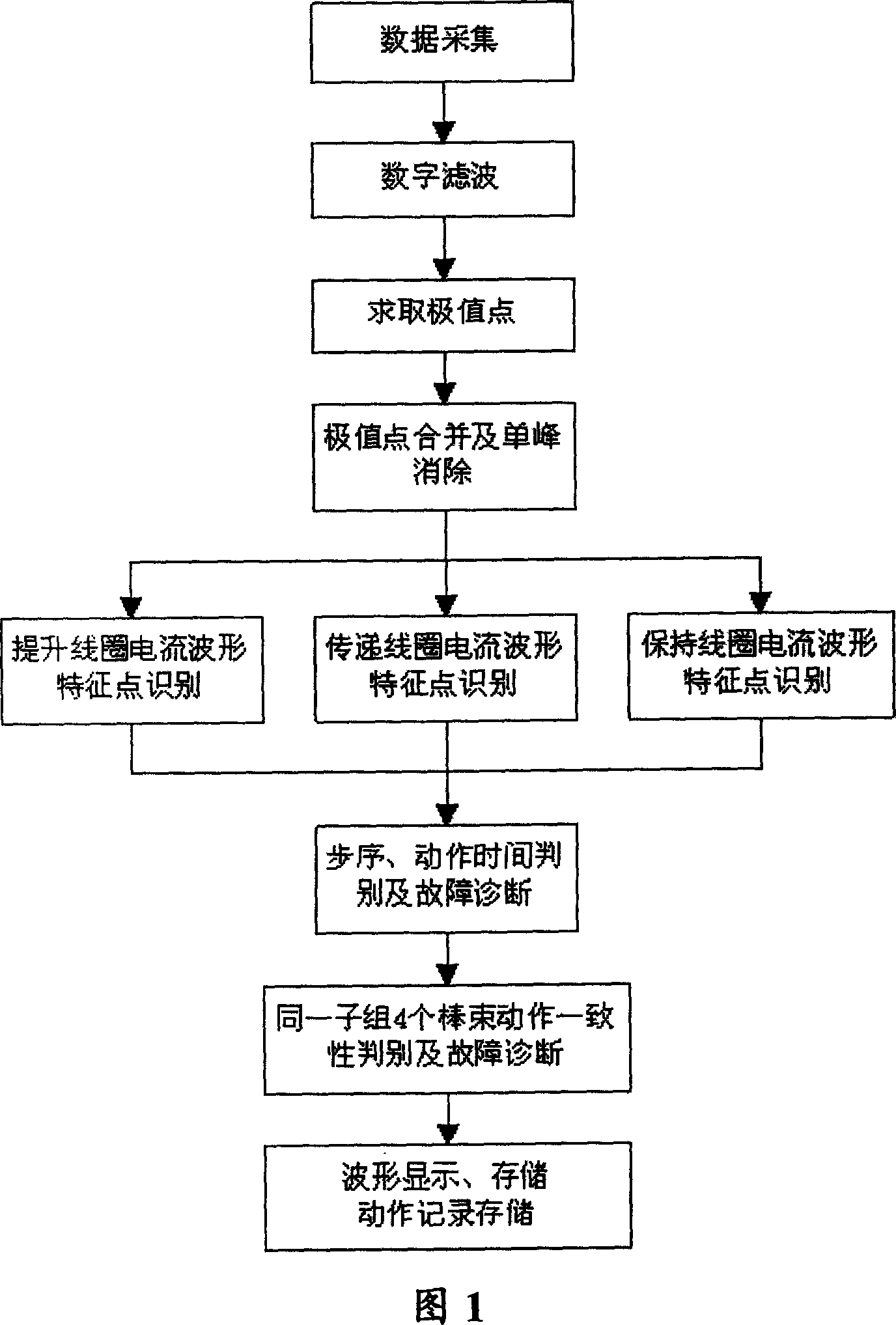

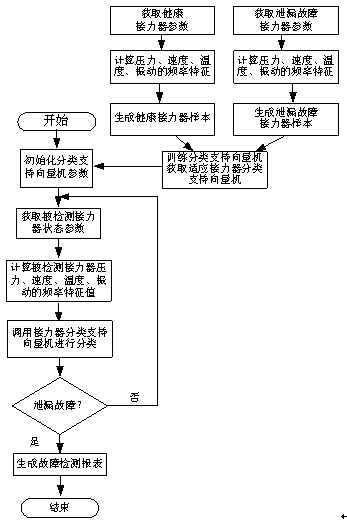

Pressurized water reactor nuclear power station control bar driving mechanism on-line monitoring and fault diagnosing method

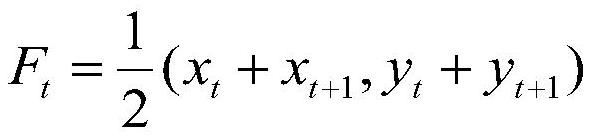

ActiveCN101067976ALong-term accumulation of action time dataReduce data volumeNuclear energy generationNuclear monitoringNuclear powerData acquisition

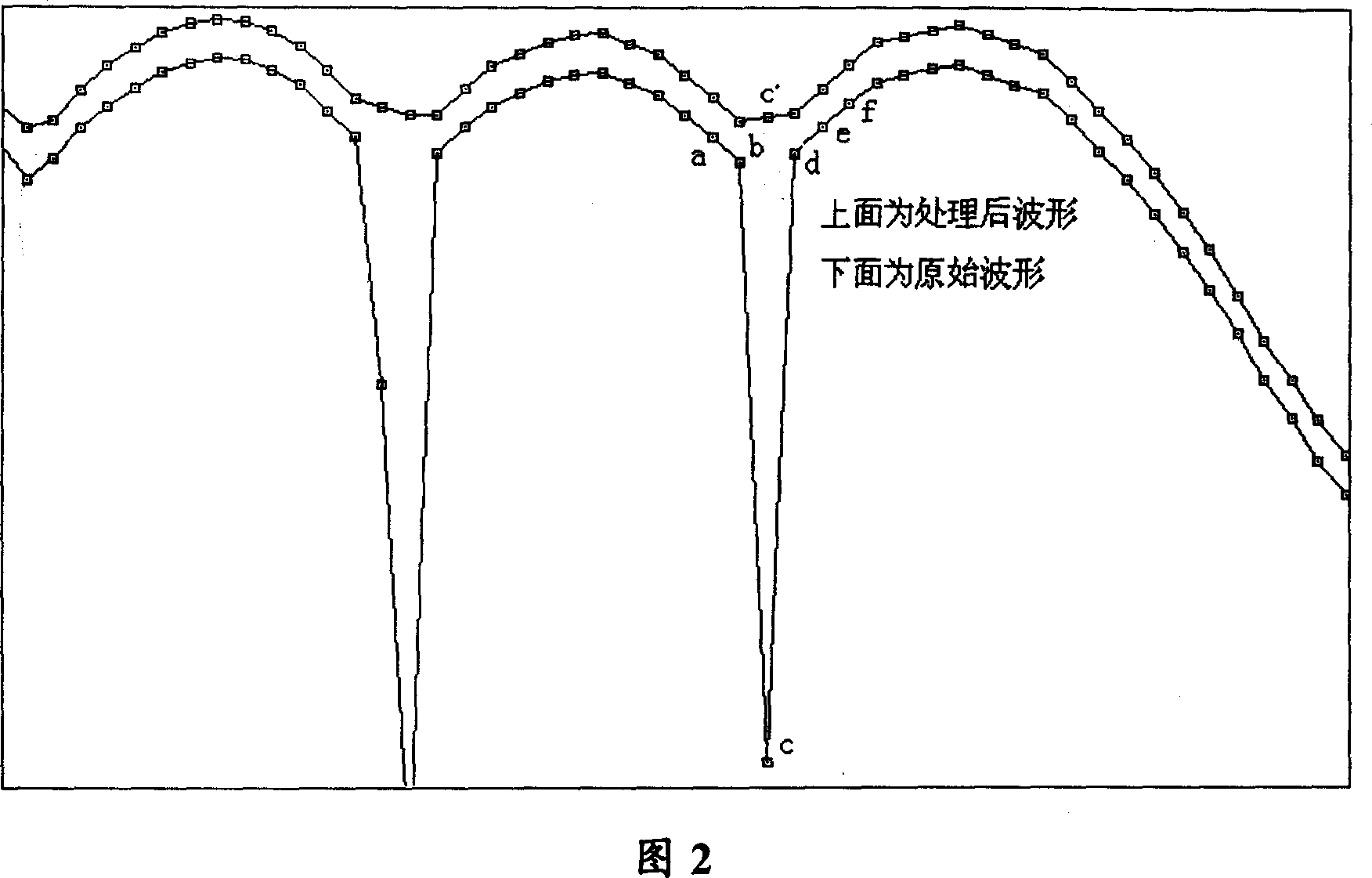

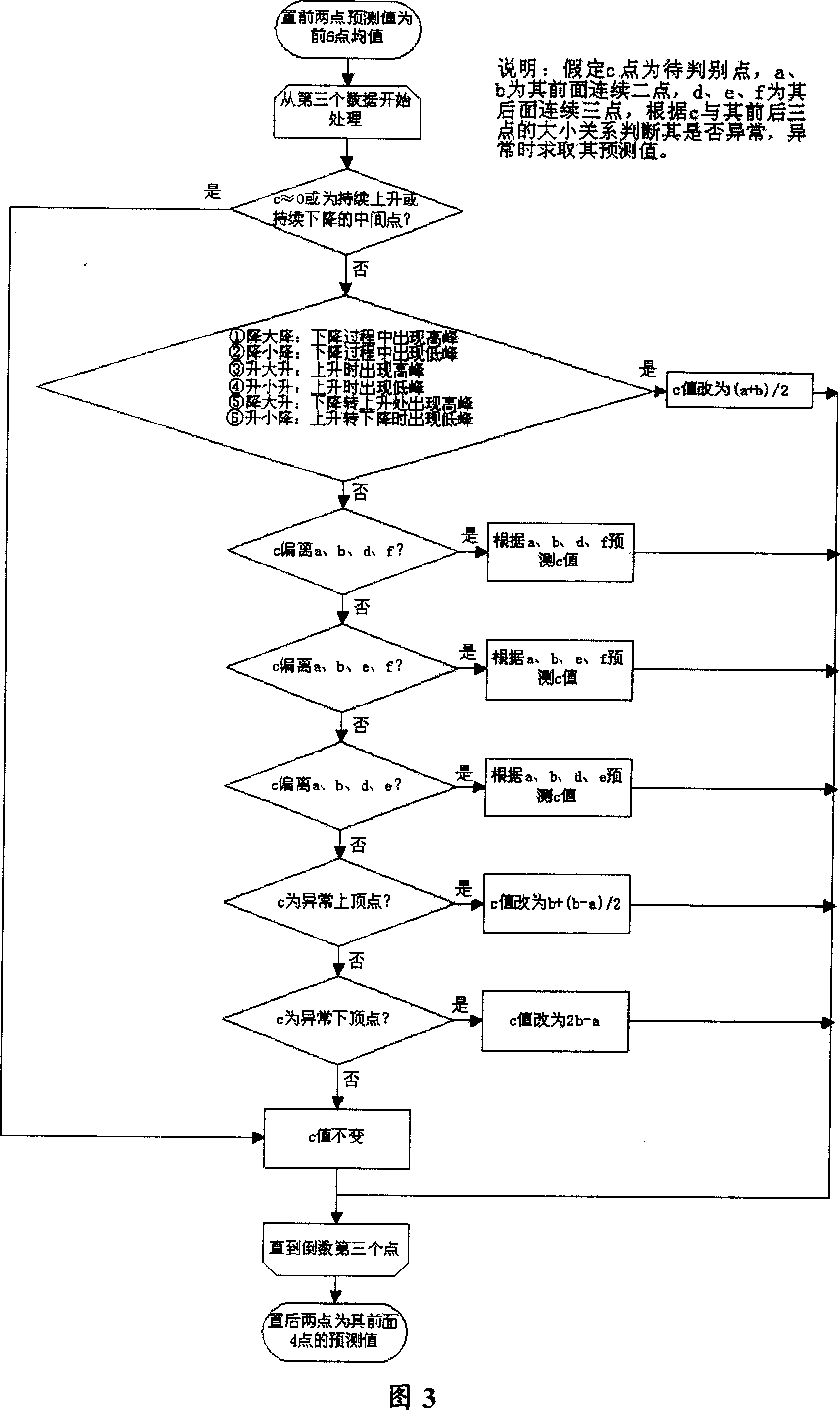

This invention provides an on-line monitor and fault diagnosis method for PWR nuclear power plant including the following steps: 1, data collection, 2, digit filtration and pre-process, 3, acquiring extremum points to carry out polygon process to the waveforms, 4, merging the extremum points and eliminating single peaks, 5, identifying character points of the waveforms in terms of upgrading, transmission and keeping to check current and waving amplitude, 6, judging step sequence and operation time and diagnoses fault, 7, comparing the consistency of four rod-beam operations of a sub-set to estimate them according to deviations and finish single-step analysis of the sub-set waveform, 8, collecting and displaying waveforms, storing effective data and storing action recordings.

Owner:NUCLEAR POWER QINSHAN JOINT VENTURE

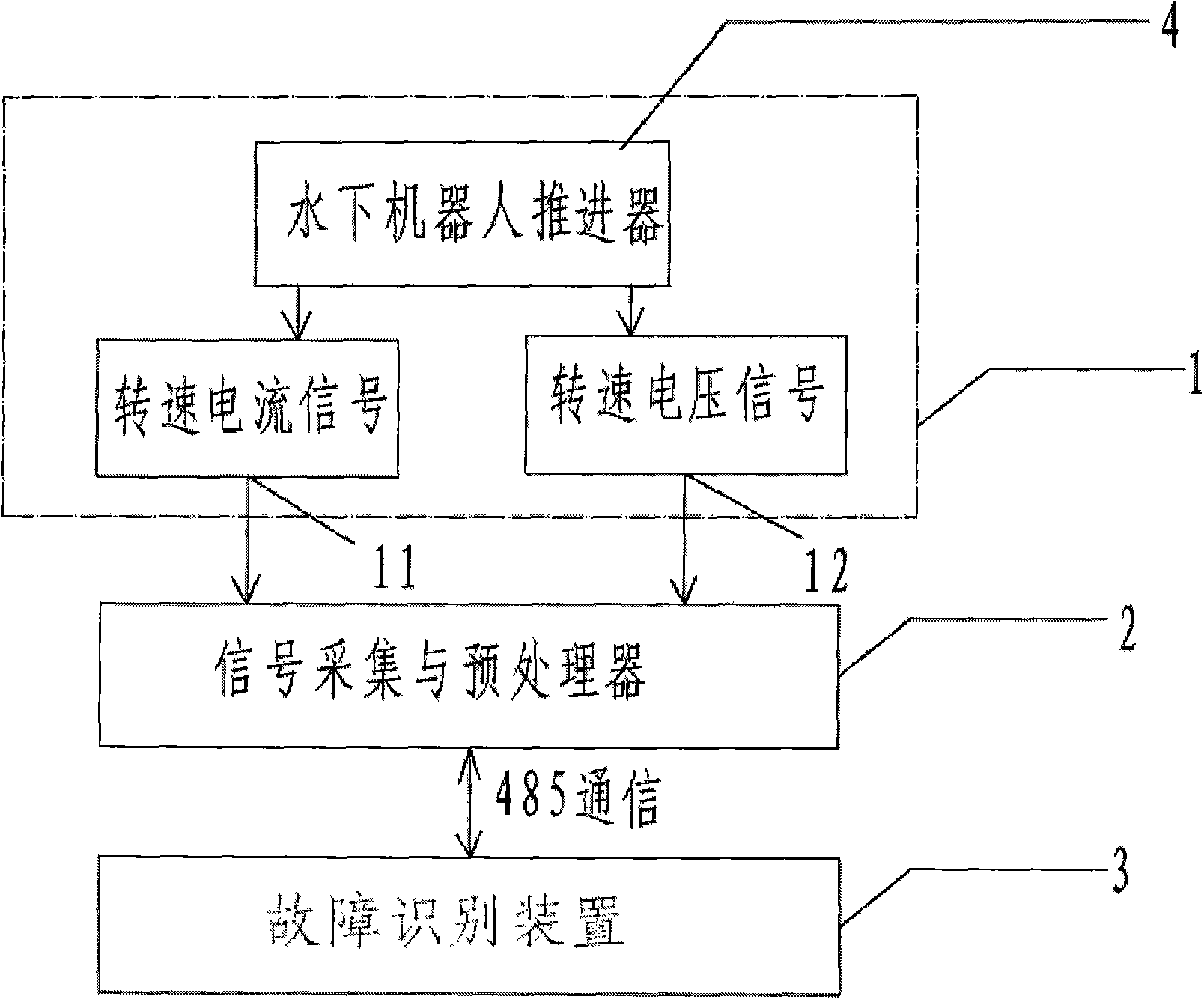

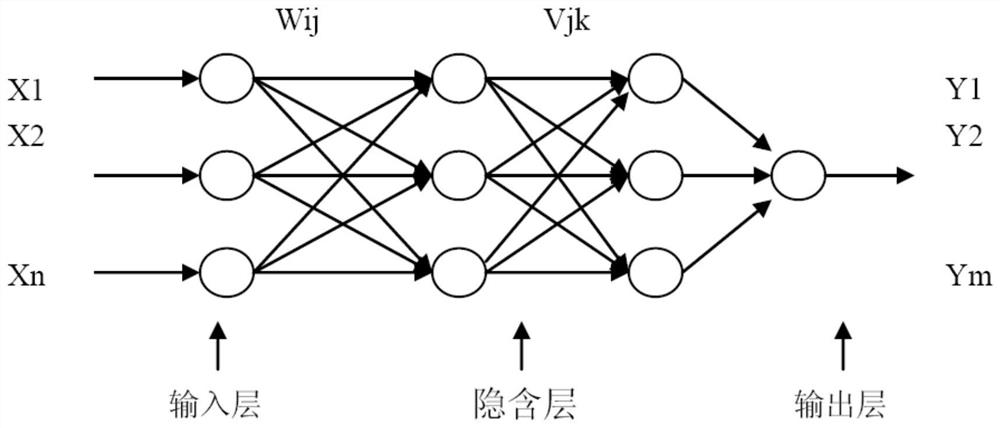

Method and device for diagnosing information fusion fault of underwater robot propeller

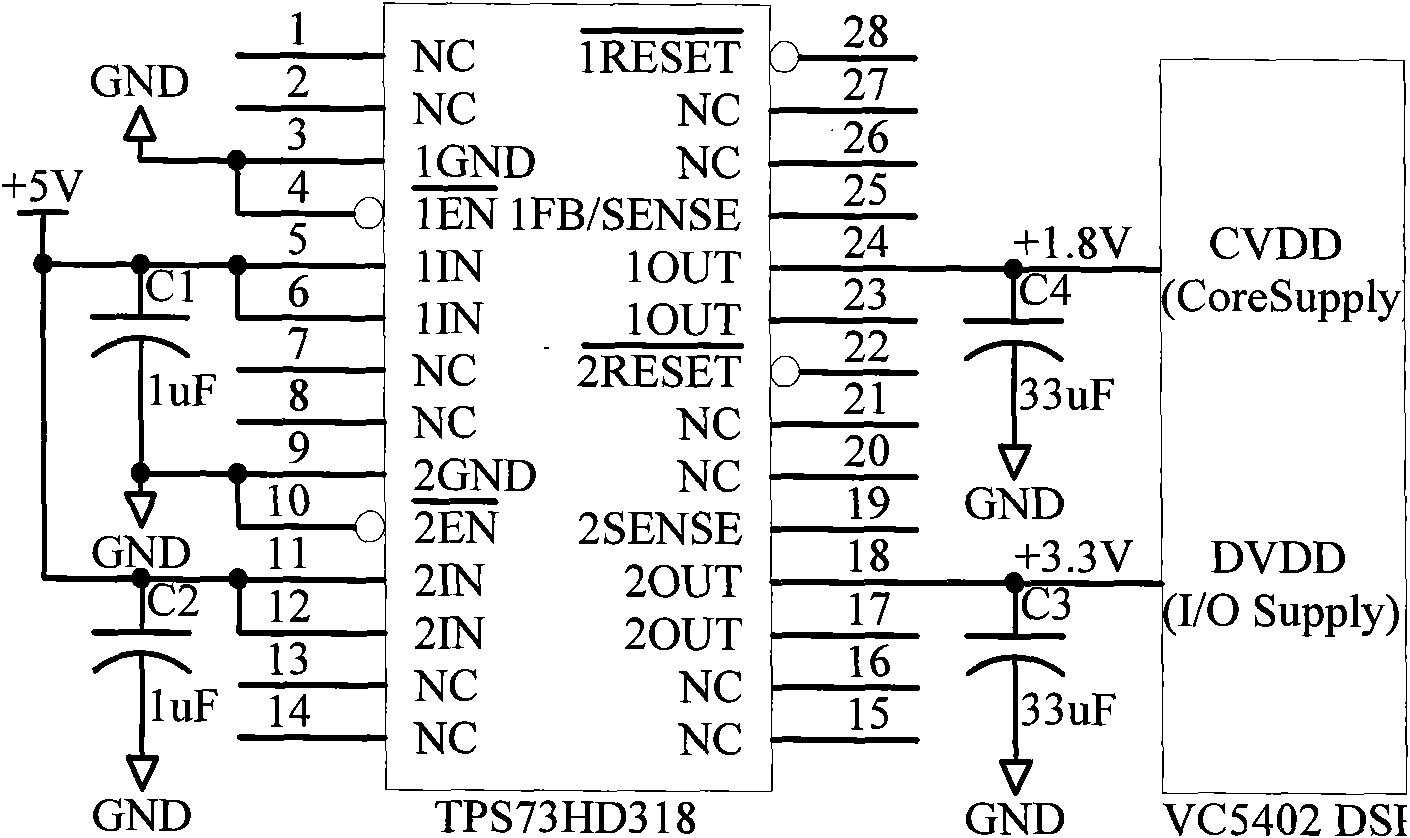

ActiveCN101670886ARealize online fault diagnosisPredicted valueStructural/machines measurementUnderwater vesselsPower flowDiagnosis methods

The invention discloses a method and a device for diagnosing an information fusion fault of an underwater robot propeller. The device comprises a signal acquisition and preprocessing device and a fault identification device, wherein the fault identification device compares propeller voltage and current signals acquired by the signal acquisition and preprocessing device with voltage and current signals in the state of normal rotating speed, detects whether a fault occurs or not, and calculates size of the blocking fault. The method and the device fill the blank in fault diagnosis of the underwater robot propeller, and have the advantages that rotating speed signals of the underwater robot propeller acquired by a rotating speed sensor can be processed by a neural network of a cerabellar modearticulation controller (CMAC); the neural network of the CMAC is trained by classical fault mode data of the propeller; the trained neural network of the CMAC is used to identify the fault and calculate the blocking size of the fault so as to realize fault online diagnosis for the propeller; and the method and the device not only can diagnose the fault condition of the underwater robot propeller, but also can forecast the numerical values of the propeller in normal working state.

Owner:常熟海量声学设备科技有限公司

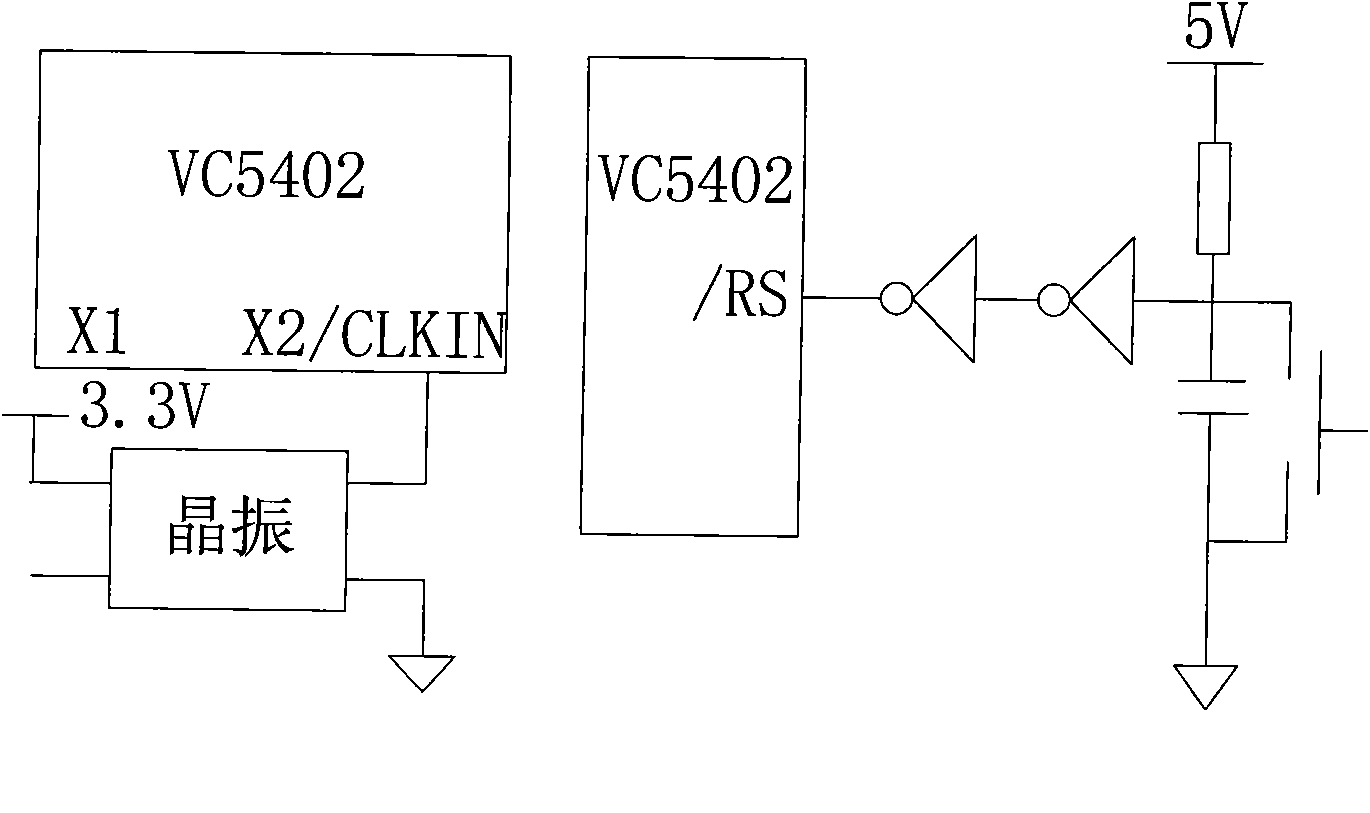

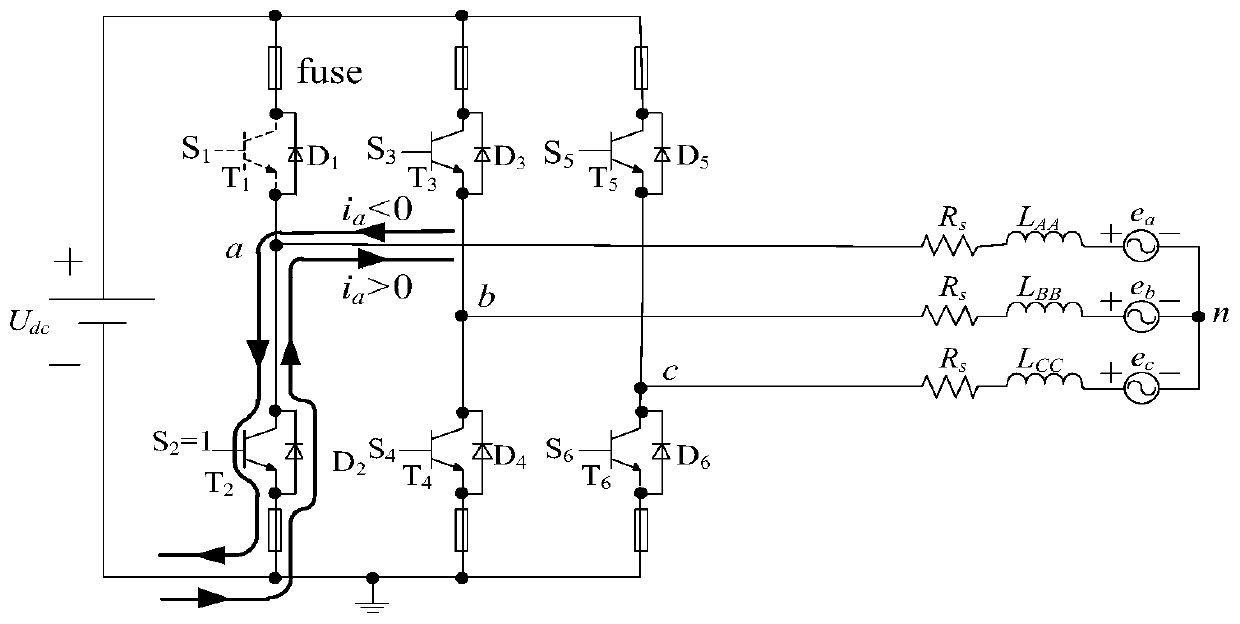

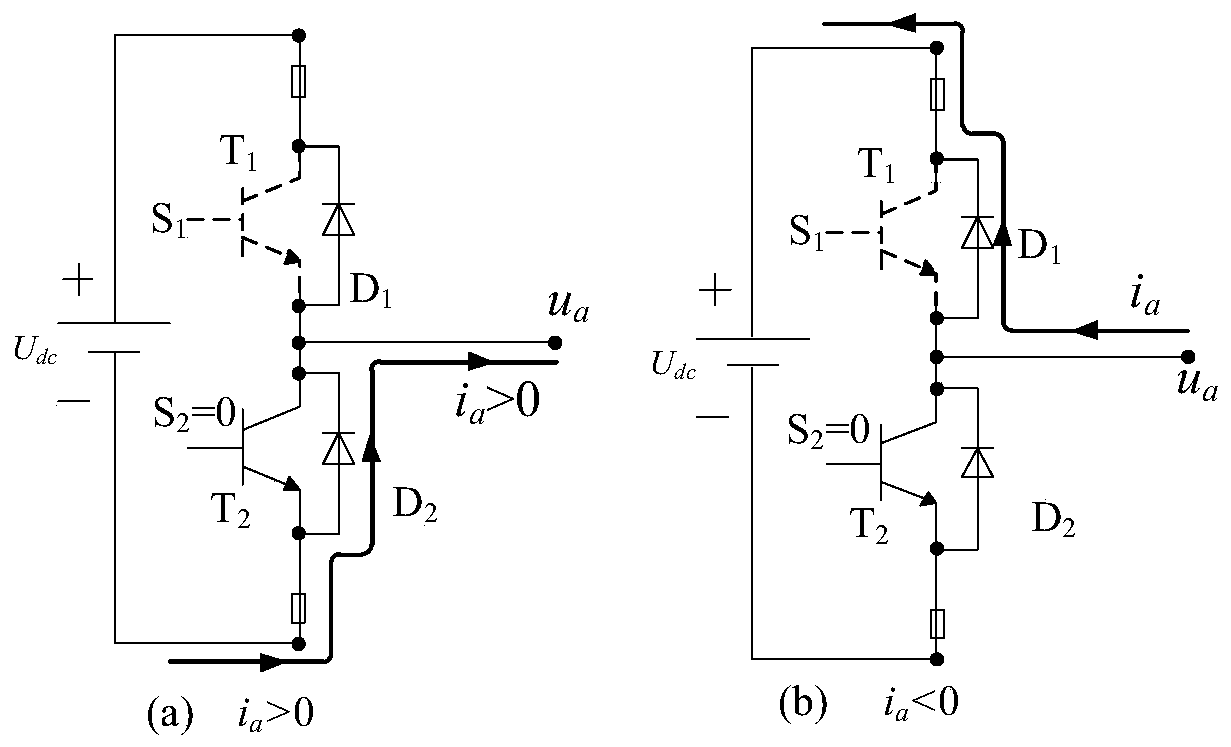

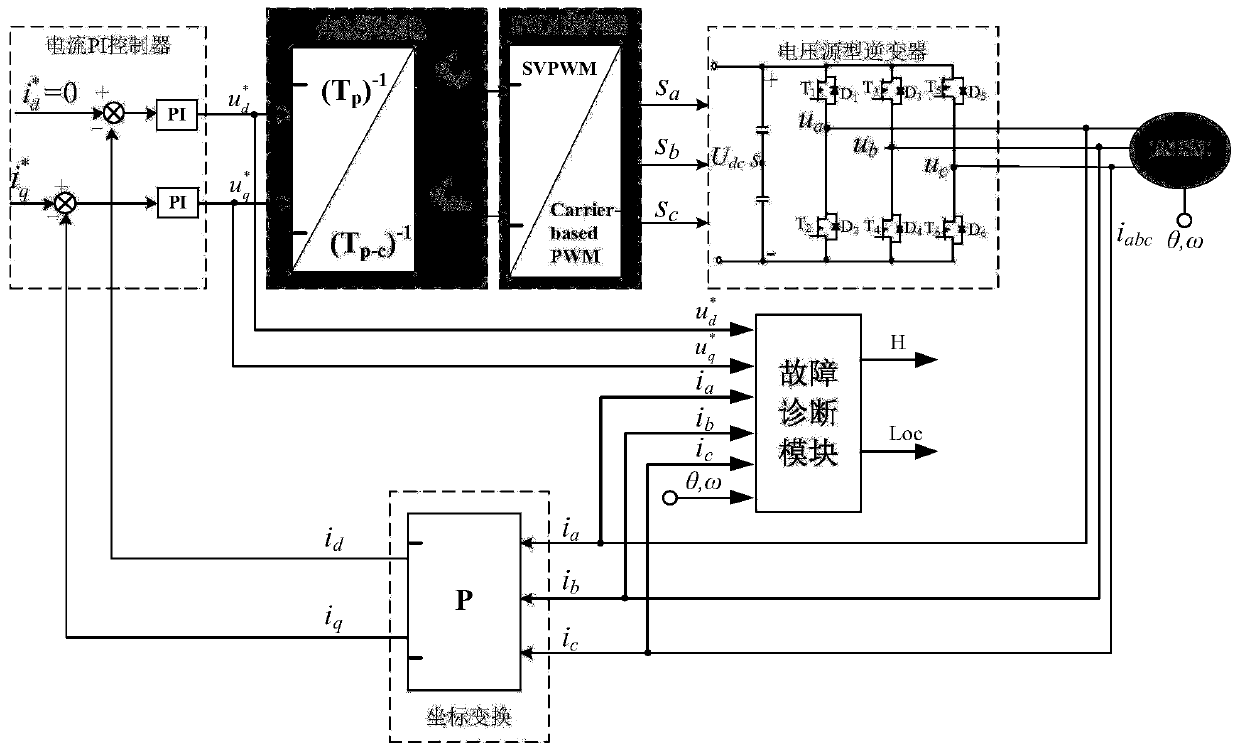

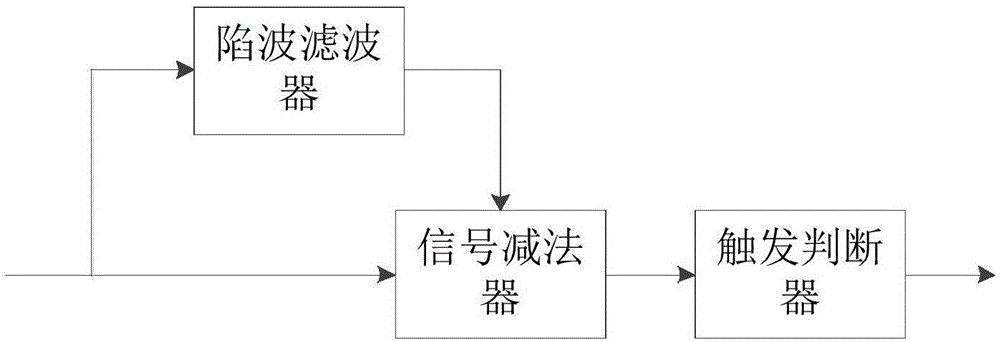

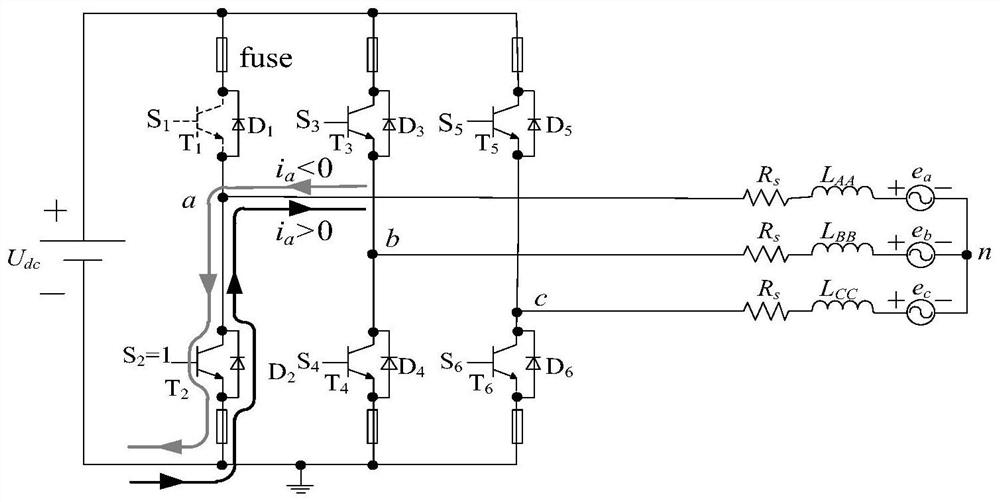

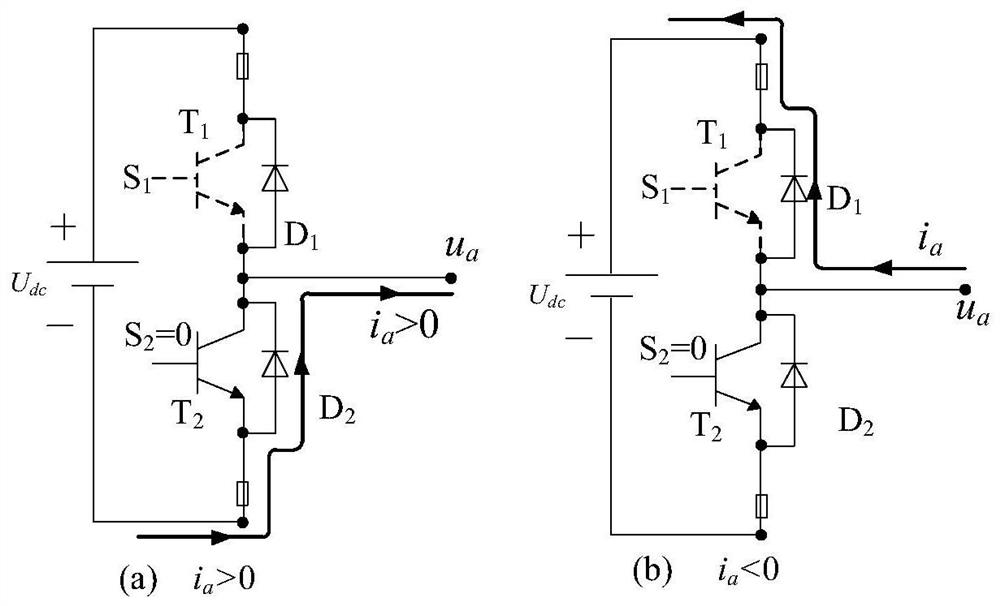

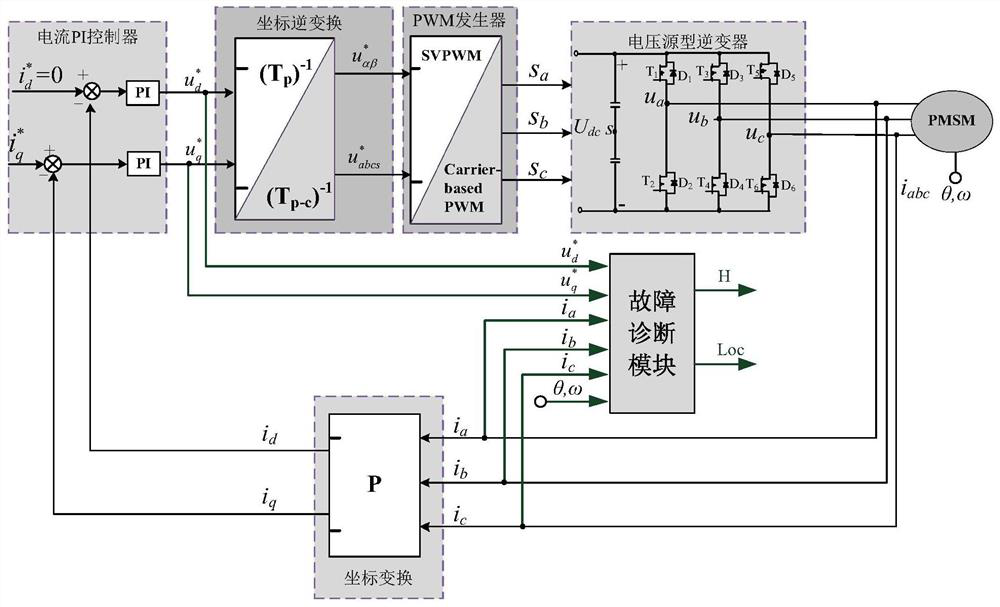

Inverter power tube open circuit fault diagnosis method in permanent magnet synchronous motor control system

ActiveCN110441643ARealize online fault diagnosisImprove anti-interference abilityElectrical testingComplex mathematical operationsMotor speedAnti jamming

The invention relates to an inverter power tube open circuit fault diagnosis method in a permanent magnet synchronous motor control system. According to the method, a differential current state observer is designed based on a voltage balance equation to estimate the ideal differential current of the permanent magnet synchronous motor, and the distortion amount of the motor differential current isestimated by combination of the measured value of the differential current; and then a corresponding fault detection and positioning algorithm is designed according to the distortion rule of the motordifferential current caused by faults, so that the rapid and accurate on-line fault diagnosis of the circuit fault of the inverter switch tube is realized. The method has the advantages of being highin anti-jamming capability, strong in robustness, high in detection speed, high in detection accuracy and the like. In addition, the method can also be suitable for motor speed stabilization and speed change stages, and is suitable for two different modulation modes (a spatial voltage pulse width modulation mode or a carrier-based pulse width modulation mode). Therefore, the method is a universalvoltage source type inverter single switch tube open circuit fault diagnosis method.

Owner:BEIHANG UNIV

Method for on-line diagnosing gradually-changing fault of electronic current transformers

ActiveCN102967842ASimple and fast operationImprove calculation accuracyTransformers testingBusbarElectricity

A method for on-line diagnosing gradually-changing fault of electronic current transformers comprises the following steps: collecting output signals of electronic transformers of a whole transformer substation, calculating instant value of theoretical current at the tail ends of power transmission lines and on secondary sides of transformers at any moment, comparing the instant value of the theoretical current with the corresponding collected value, respectively calculating residual errors of the electronic current transformers at the front and tail end of each power transformation line and the primary side and the secondary side of each transformer, judging whether gradually-changing fault occurs on the electronic current transformers by comparing the residual errors with preset threshold values, and simultaneously performing Kirchhoff detection by injecting current into a busbar to position a fault transformer. The method is easy and convenient to operate, high in calculation accuracy, and capable of achieving on-line diagnosis on the gradually-changing fault under the condition that the electronic current transformers have no power failure or offline and require no other additional hardware device.

Owner:CHONGQING UNIV

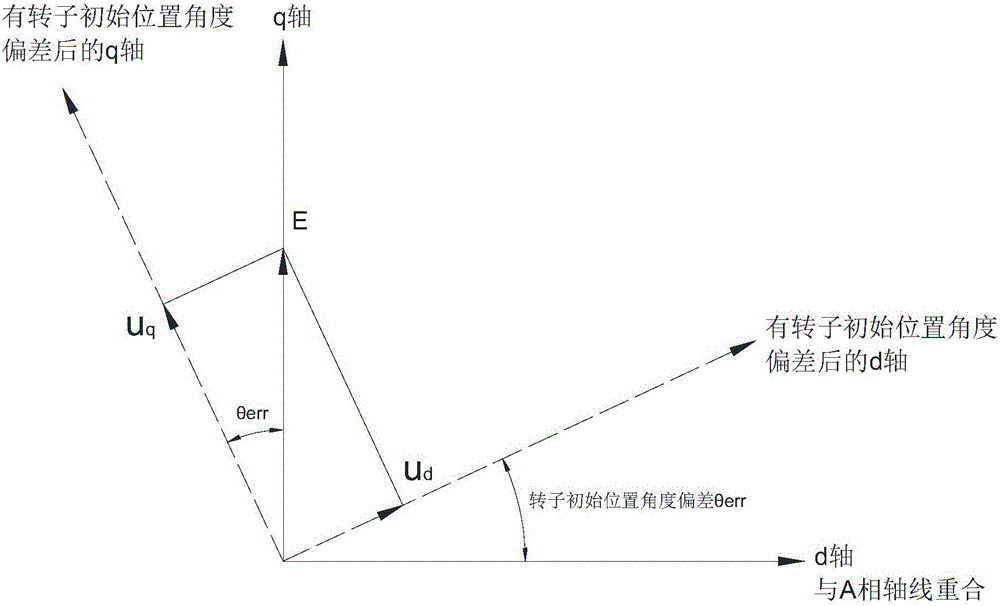

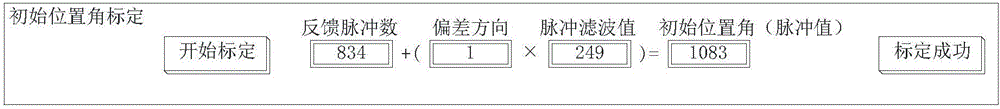

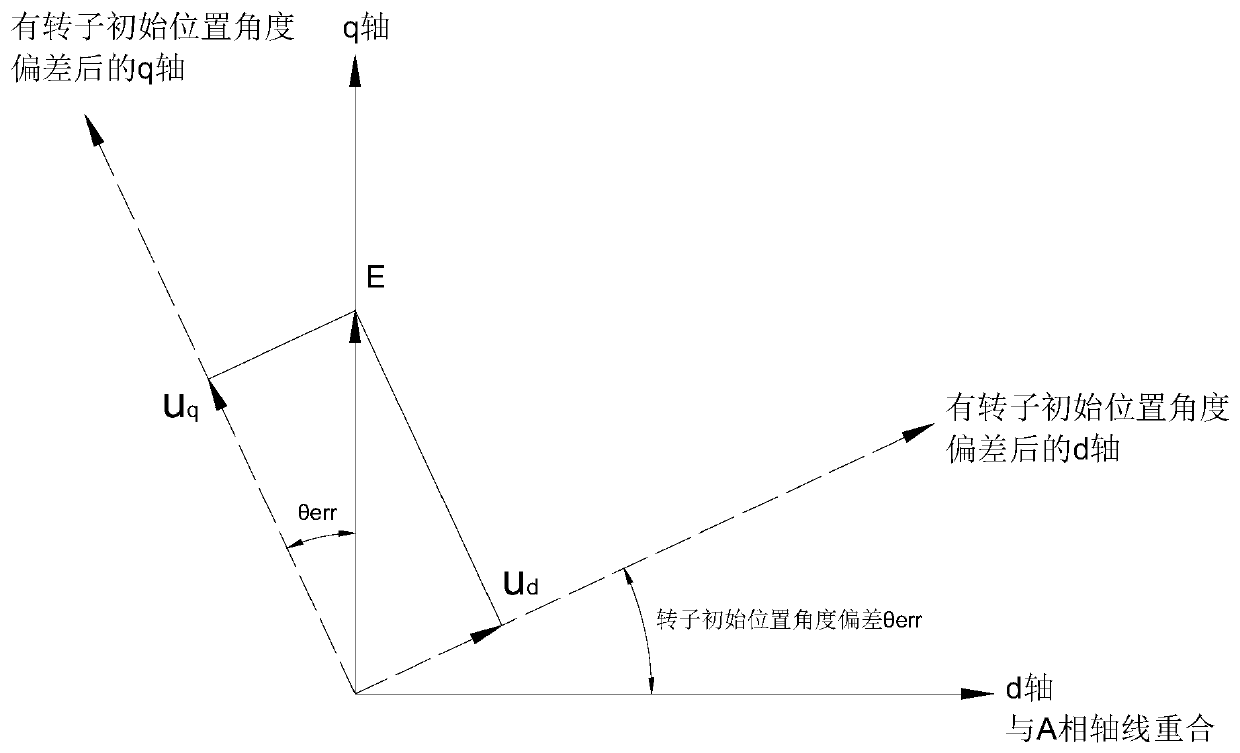

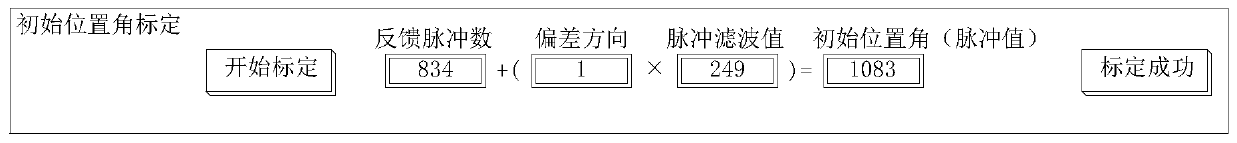

Method for testing initial position angle of motor rotor

ActiveCN106787995AImprove performanceLow test conditionsVector control systemsElectronic commutatorsStatorVoltage

The invention discloses a method for testing initial position angle of a motor rotor and solves the technical problem that the prior art is high in requirements on initial position angle testing conditions of the motor rotor and difficult in actual operation. The method includes following steps: step 1, applying a current i on a to-be-tested motor to enable the same to run; step 2, after the motor runs, enabling the current i to be zero; step 3, measuring voltage ud and uq of a shaft d and a shaft q of a motor stator; step 4, calculating according to a triangular function relation between ud and uq to acquire initial position angle deviation theta err of the motor rotor. The initial position angle deviation of the motor rotor is calculated by directly using the voltage of the d shaft and the q shaft of the motor stator, and corresponding relation between voltage at the motor end in a motor controller and the initial rotor position angle is made clear; the method is simple and suitable for engineering site operation; online fault diagnosis and error correction control can be realized, and system function safety can be improved.

Owner:JING JIN ELECTRIC TECH HEZE CO LTD

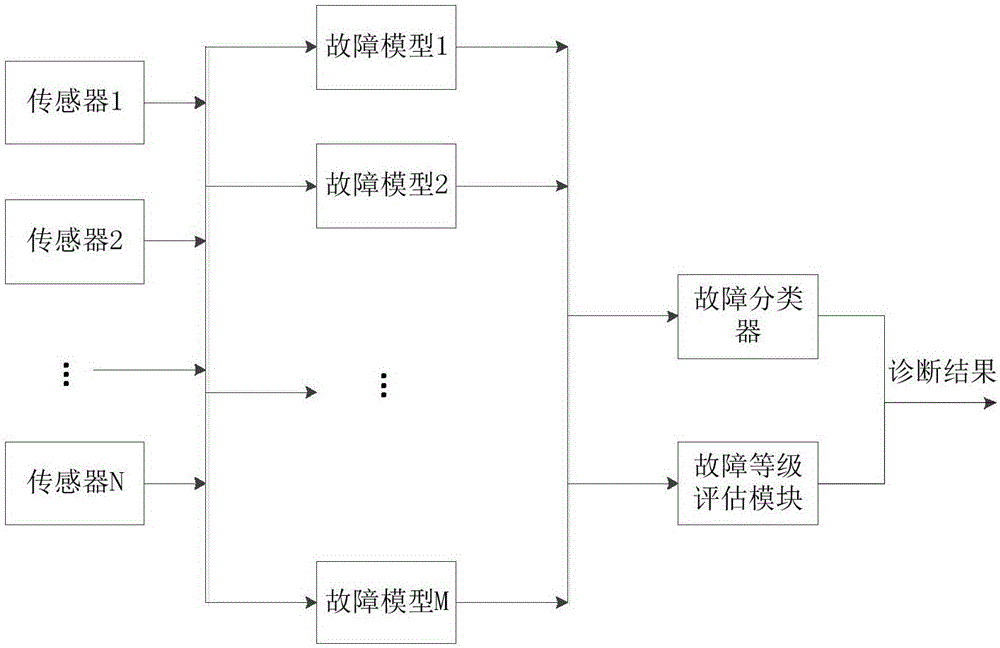

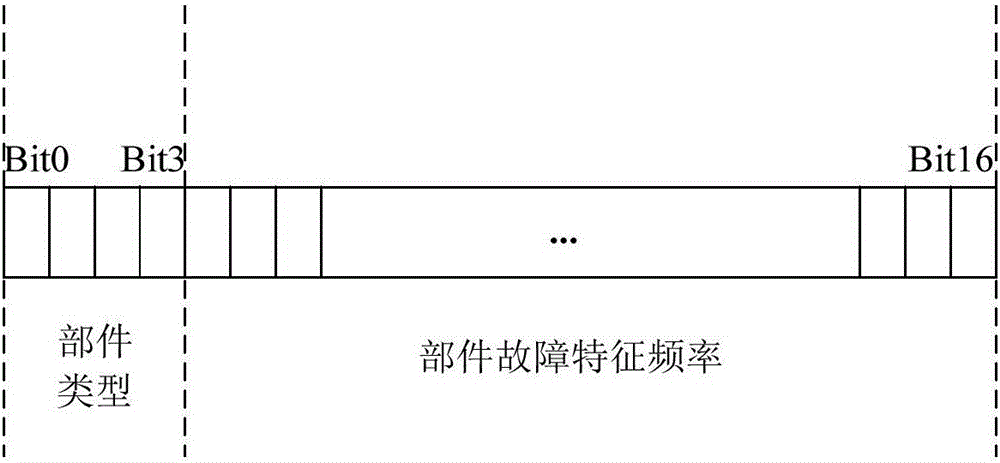

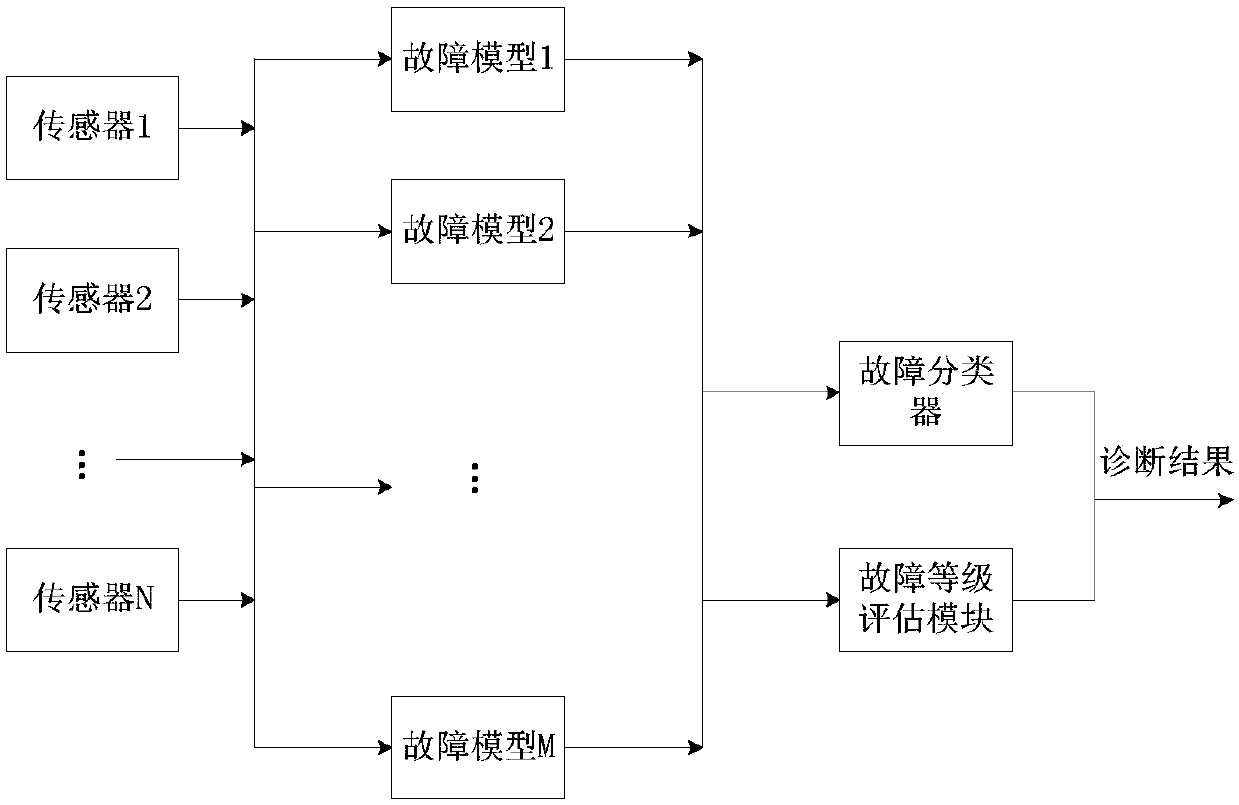

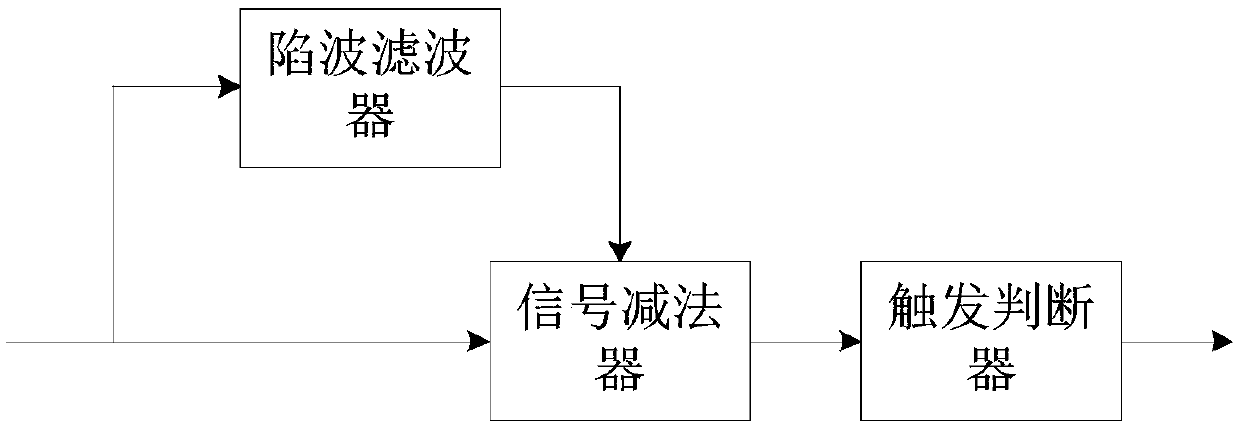

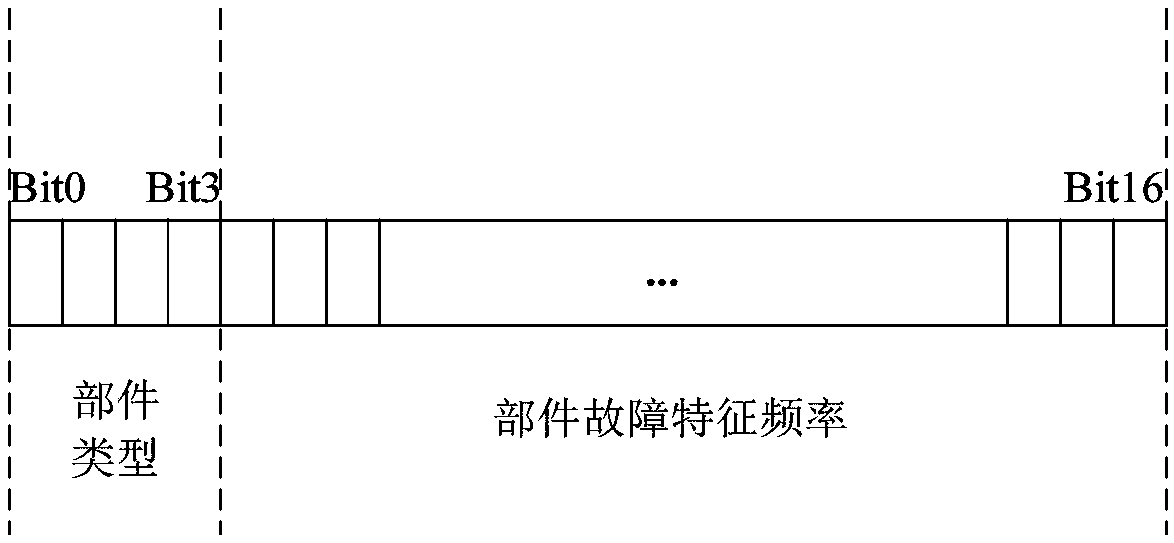

Automatic fault diagnosis system based on fault model trigger

ActiveCN106837707ARealize online fault diagnosisRealize automatic fault diagnosisMachines/enginesWind motor monitoringElectricityVibration acceleration

An automatic fault diagnosis system triggered by a fault model disclosed in the present invention includes: a sensor for obtaining vibration acceleration signals of each component of the equipment to be detected; a fault model for storing the corresponding component type, component fault characteristic frequency and corresponding component type and the component fault code of the component fault characteristic frequency, when there is a frequency component matching the component fault characteristic frequency in the vibration acceleration signal, the component fault code is sent to the fault classifier and the start signal is sent to the fault level evaluation module; the fault classifier, for the component The fault code is classified and the corresponding fault type information is searched, and the fault type information is output as the fault type diagnosis result; the fault level evaluation module calculates the vibration intensity according to the vibration acceleration signal after receiving the start signal, and evaluates the fault level to obtain the fault level diagnosis result . The invention can improve the fault diagnosis efficiency of wind turbines and other equipment.

Owner:北京能高普康测控技术有限公司

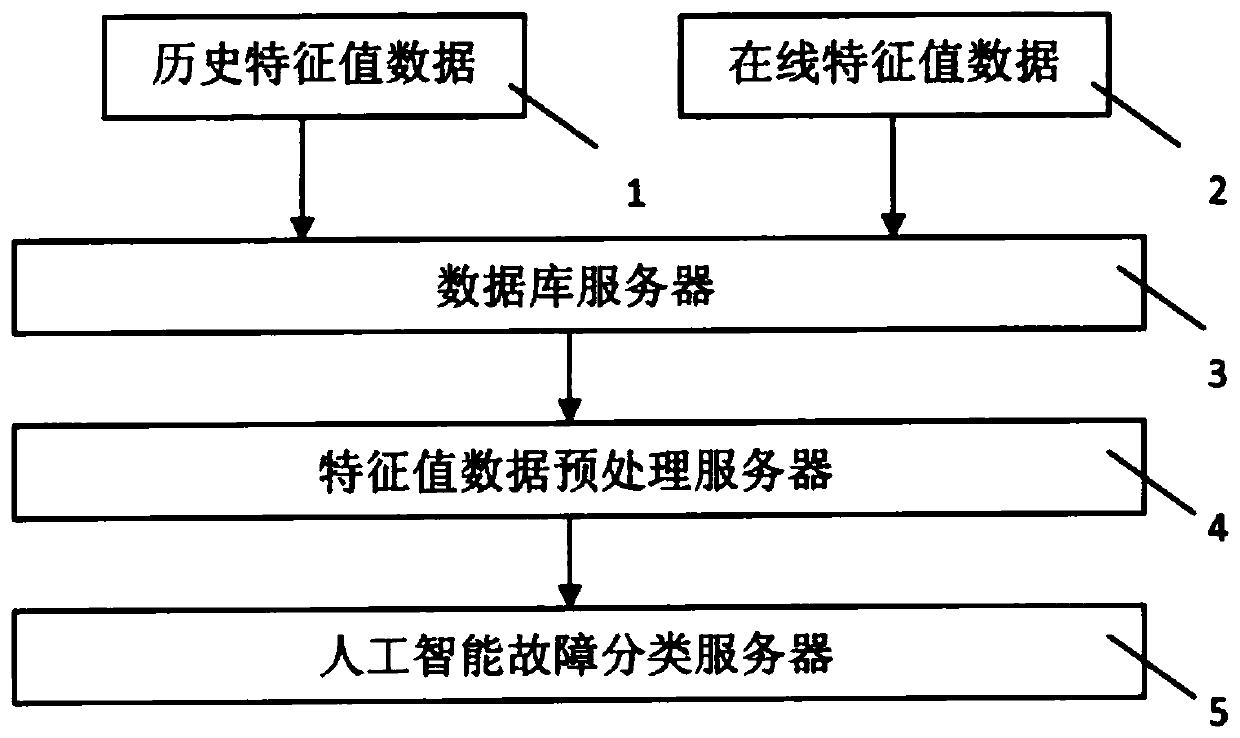

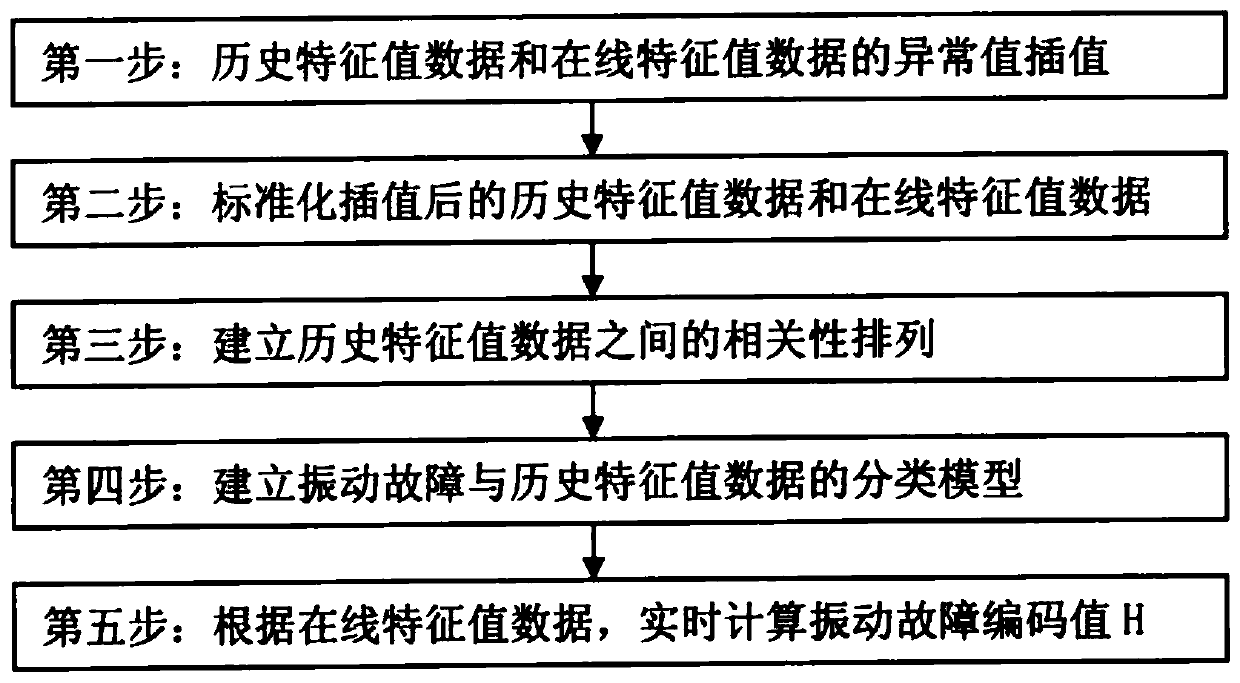

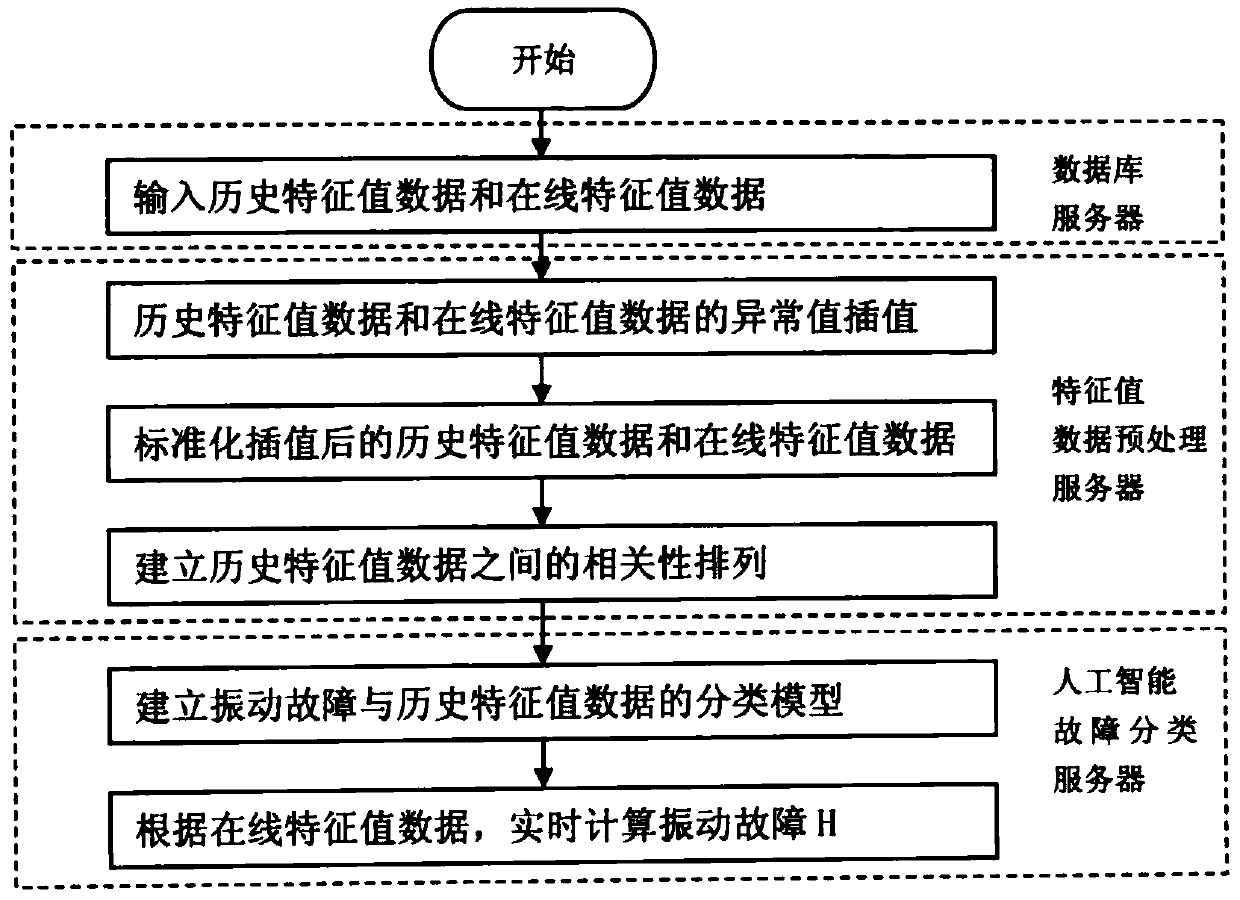

Power plant induced draft fan vibration fault diagnosis method

InactiveCN110188143ARealize online fault diagnosisRealize high-precision online computingRelational databasesSpecial data processing applicationsPower stationDiagnosis methods

The invention provides a power plant induced draft fan vibration fault diagnosis method, which comprises the following steps: representing the state of an induced draft fan through different characteristic values, setting characteristic value measuring points on the induced draft fan, and obtaining the detection data of each characteristic value through the characteristic value measuring points. According to the method, historical data and online data are combined, an artificial intelligence technology is utilized, the vibration fault coding value of the induced draft fan is calculated in realtime according to the online characteristic value data, the vibration fault of the induced draft fan is obtained, and maintenance guidance is conducted. According to the power plant induced draft fanvibration fault diagnosis method, the correlation between the vibration characteristic value data is considered, online fault diagnosis of the state of the induced draft fan is achieved, and a basisis provided for state maintenance of the induced draft fan.

Owner:SHANGHAI POWER EQUIP RES INST

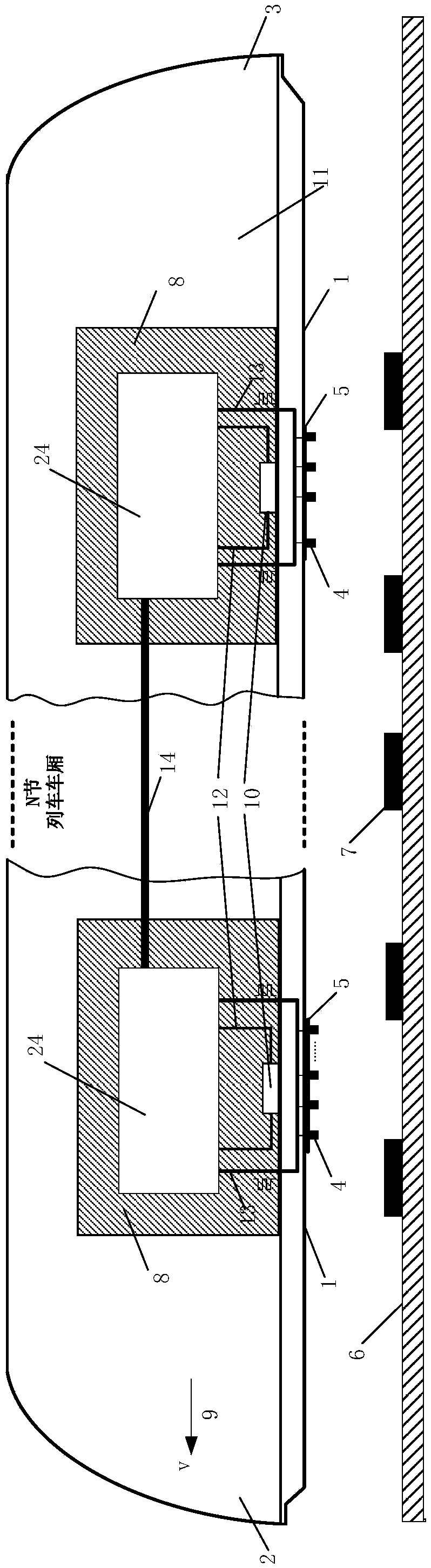

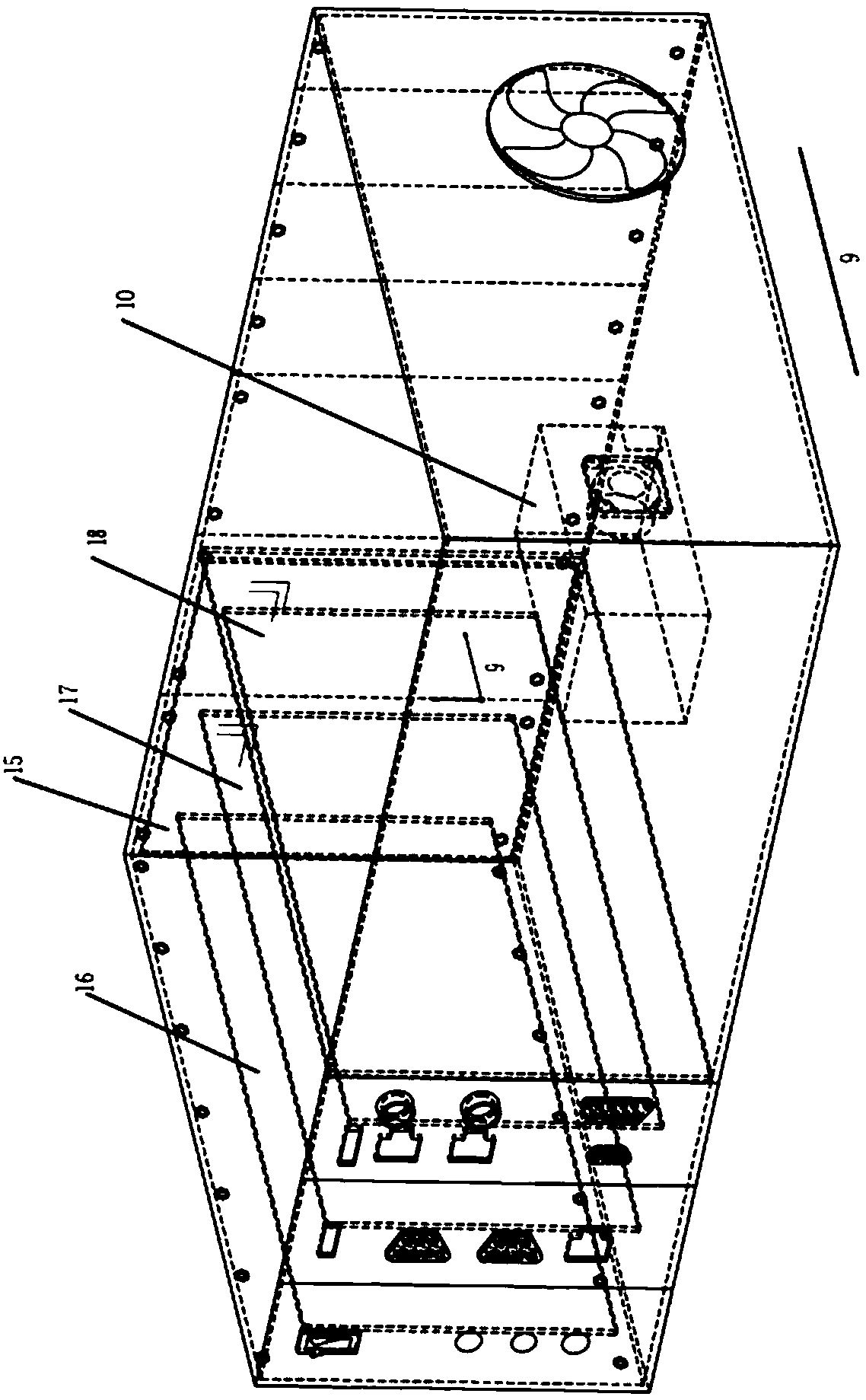

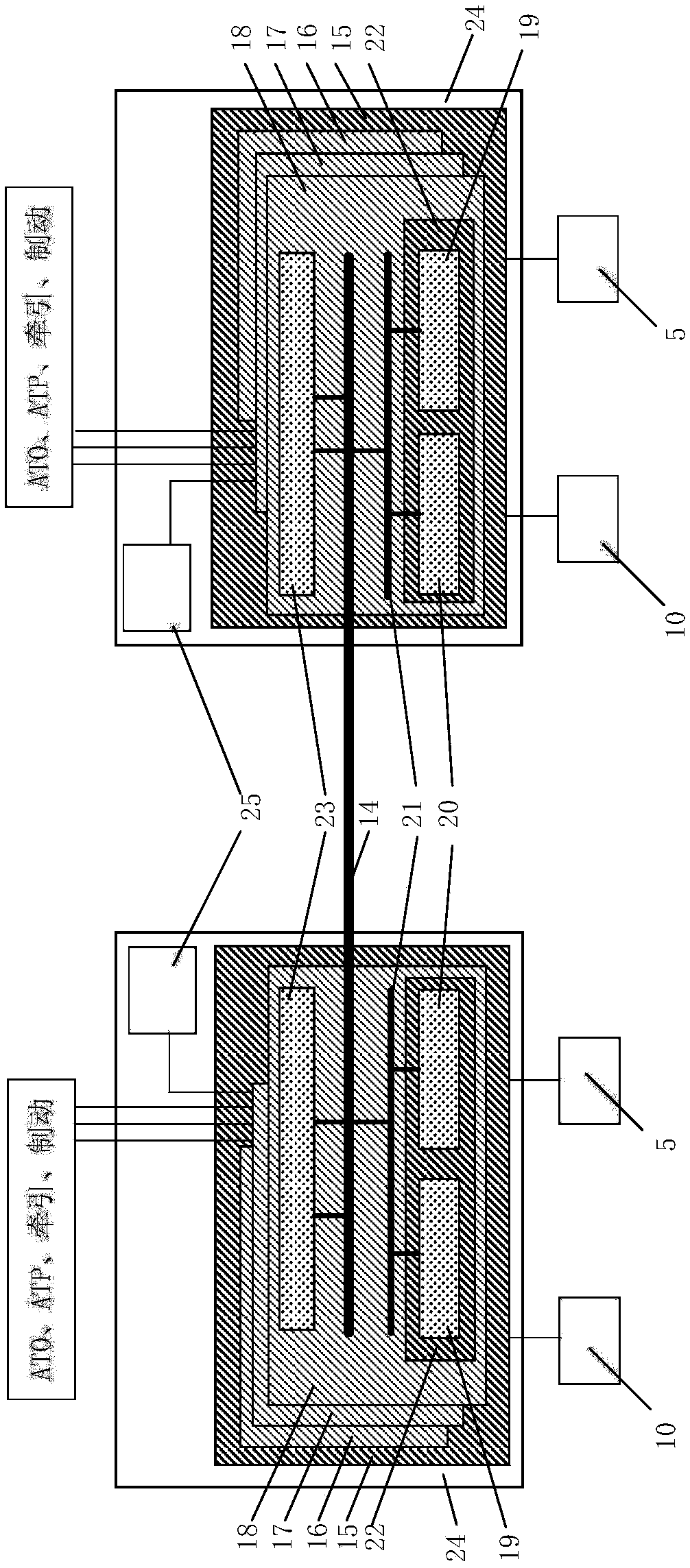

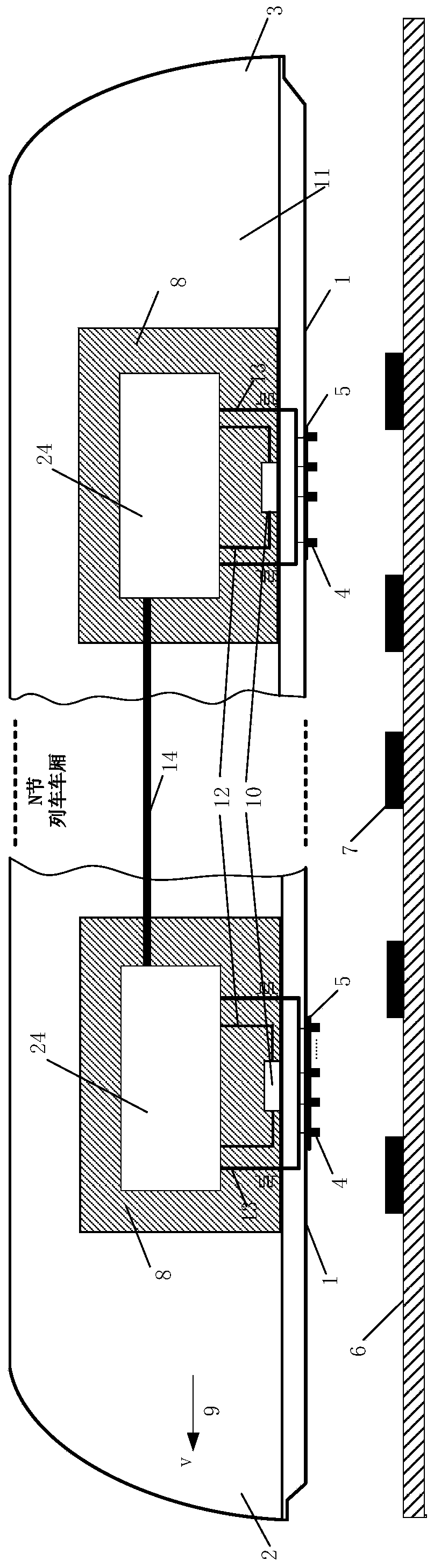

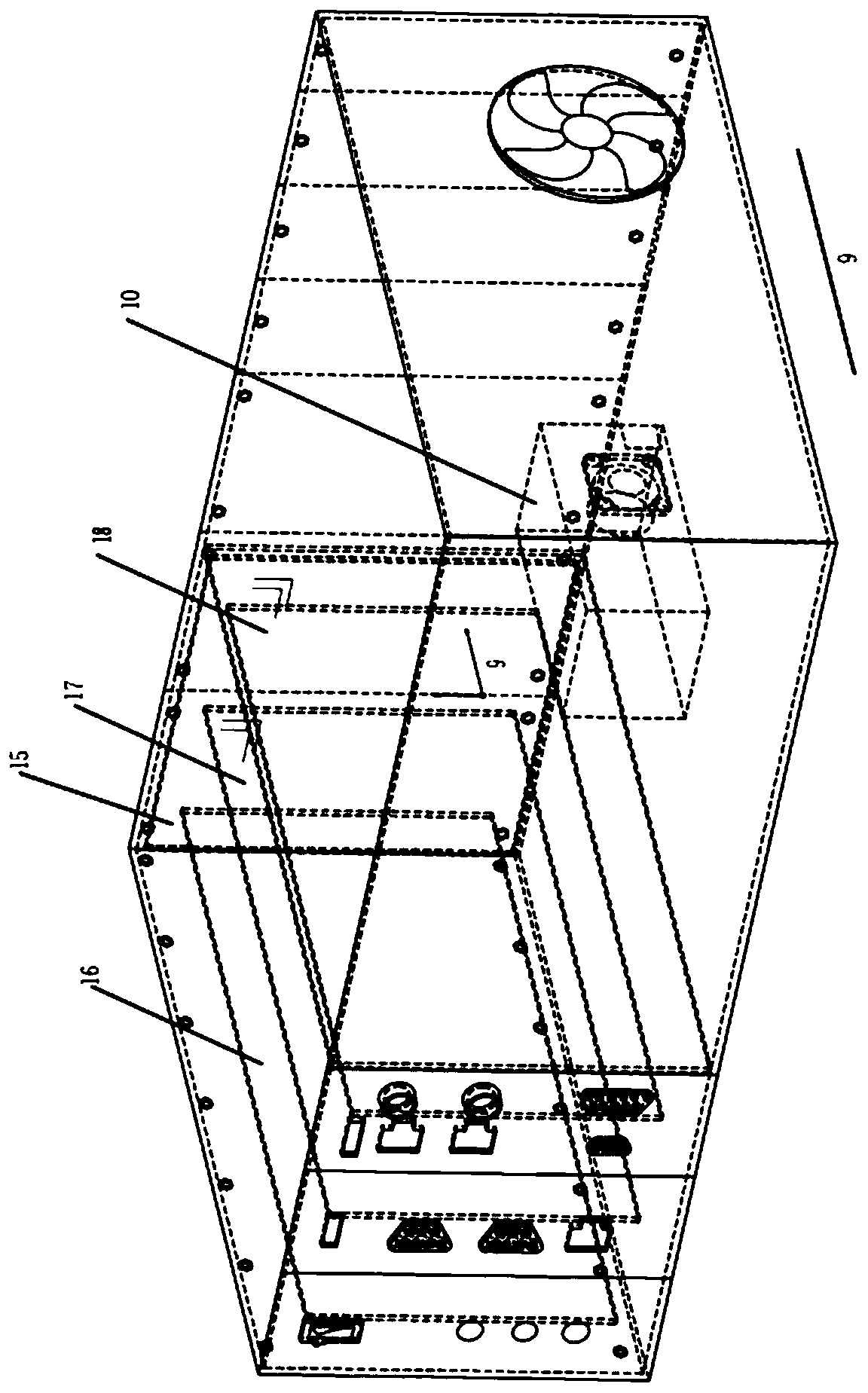

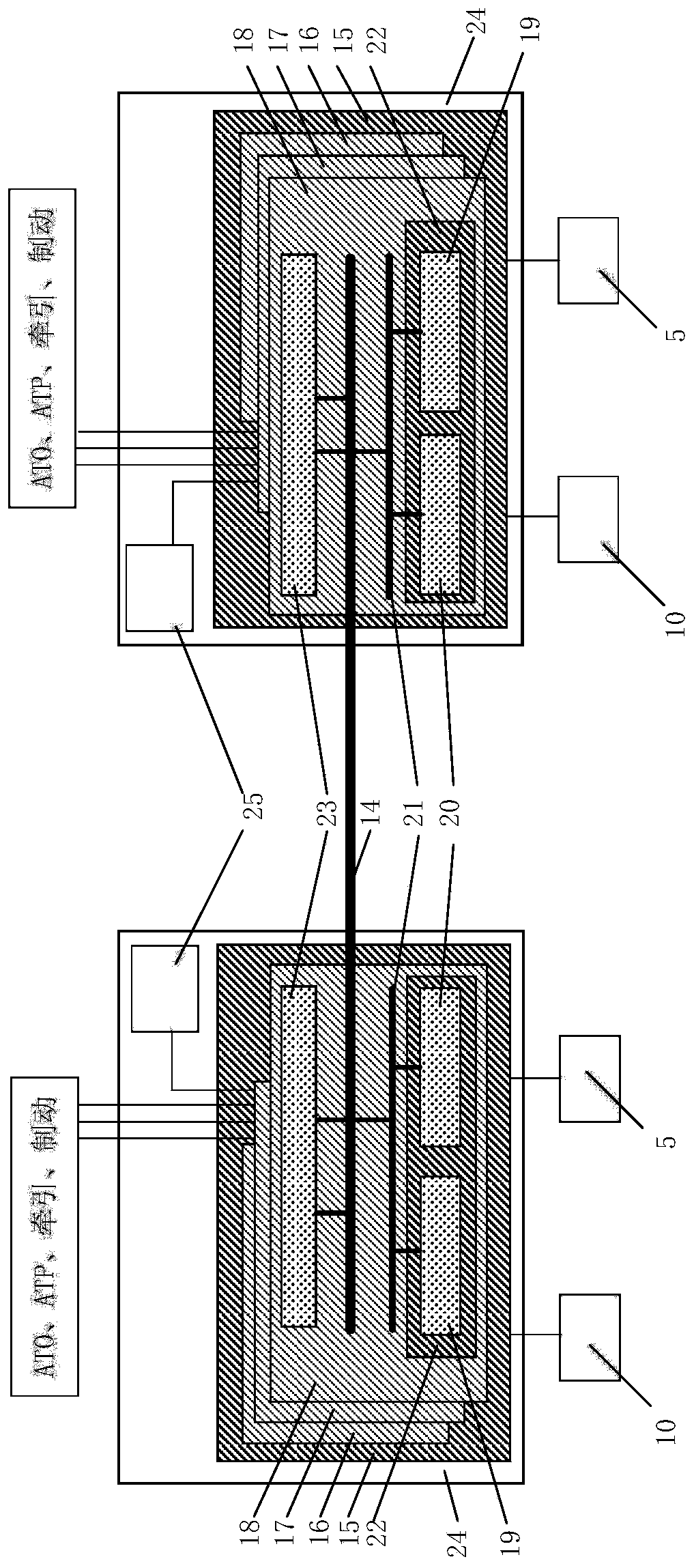

Magnetic levitation train speed and distance measuring system

ActiveCN109318938ACompact structureReduce installation difficultyRailway signalling and safetyObservational errorAnti jamming

The invention relates to a magnetic levitation train speed and distance measuring system. The magnetic levitation train speed and distance measuring system comprises a plurality of induction proximityswitch sets arranged at the bottom of a train, speed and distance measuring control boxes arranged in train-mounted equipment cabinets at the activated end and the non-activated of the train, digitalservo acceleration sensors arranged at the bottoms of the speed and distance measuring control boxes for detecting the acceleration of the train, induction proximity switch detection objects, and speed and distance measuring control units arranged in the speed and distance measuring control boxes at the two ends of the train; and the speed and distance measuring control units are connected with the digital servo acceleration sensors and the induction proximity switch sets correspondingly, and metal sleepers parallelly distributed on a rail serve as the induction proximity switch detection objects. Compared with the prior art, the magnetic levitation train speed and distance measuring system has the advantages of low cost, accurate measuring, high environmental adaptability, small measuring error, high anti-jamming ability, high usability, reliability, safety and the like.

Owner:TONGJI UNIV

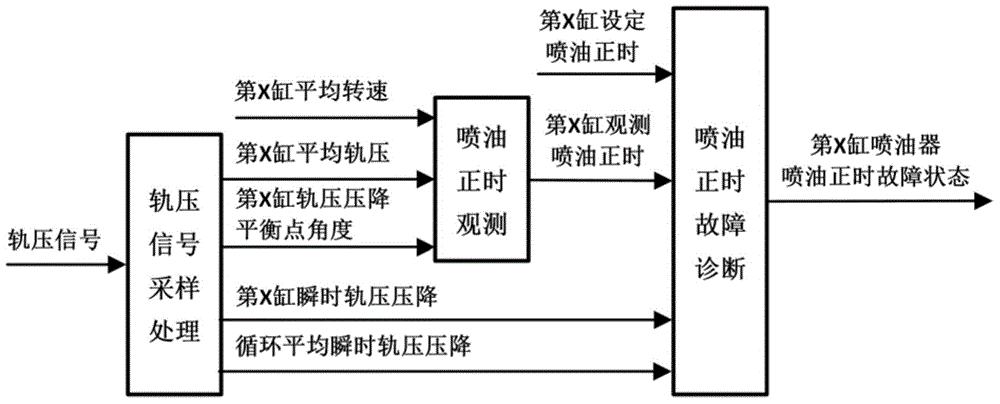

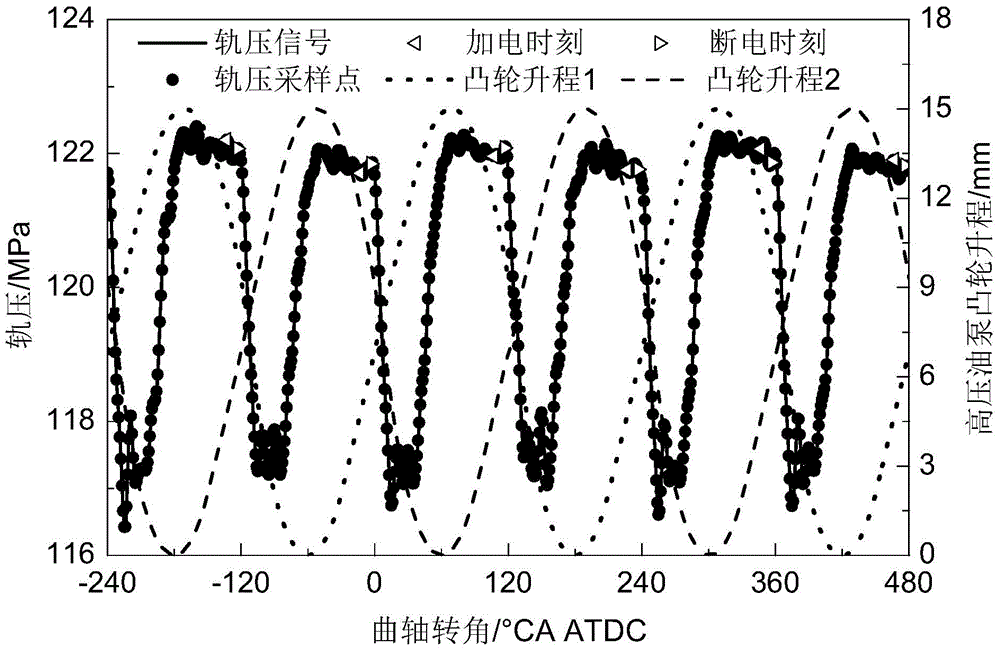

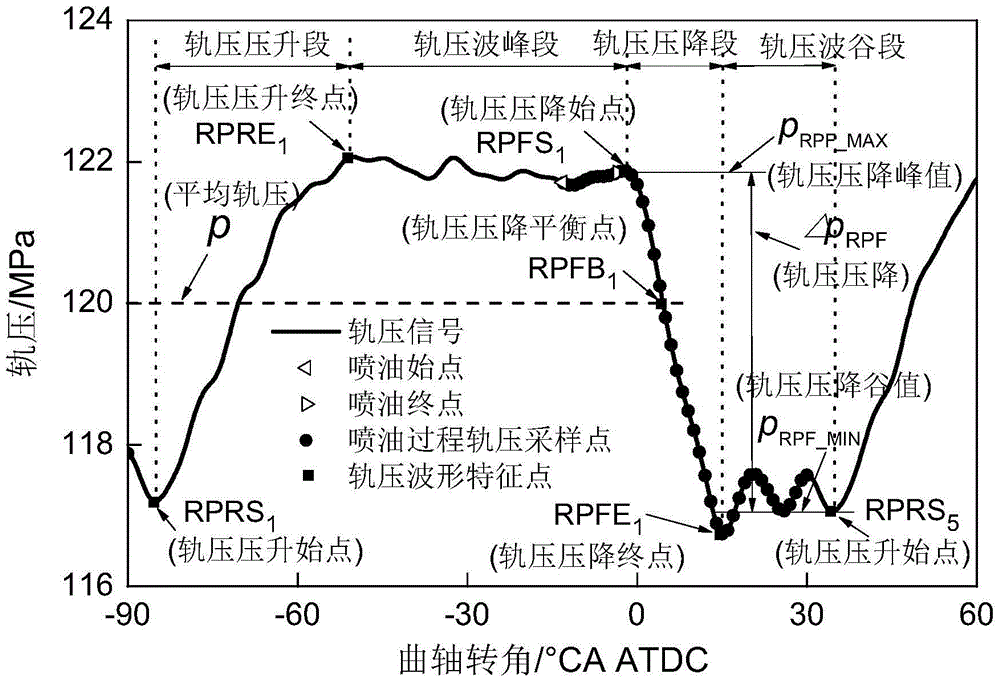

Fault diagnosing method of observing injection timing based on characteristic parameters of waveform of rail pressure

ActiveCN105003373ARealize online fault diagnosisImprove observation accuracyEngine testingFuel injection apparatusRail pressureIgnition timing

The invention discloses a fault diagnosing method of observing injection timing based on characteristic parameters of waveform of rail pressure. The fault diagnosing method comprises the following steps: firstly sampling a rail pressure signal, and processing the sampled rail pressure signal, so that a balance point of the pressure drop of the rail pressure and average rail pressure, which correspond to each cylinder of a diesel engine, are obtained; secondly observing the injection timing based on the characteristic parameters of the waveform of the rail pressure, and then calculating an injection timing observing model according to the average speed of the diesel engine corresponding to each cylinder of the diesel engine so as to obtain an observed injection timing; finally, diagnosing a fault of the injection timing based on the observed injection timing, diagnosing a fault of the injection timing of an fuel injector of each cylinder of the diesel engine through comparing the observed injection timing with pre-setting injection timing set in advance, and outputting a fault condition of the injection timing of the fuel injector of each cylinder of the diesel engine. Tests prove that the fault diagnosing method disclosed by the invention has a good fault diagnosing effect on the injection timing of the fuel injector in the practical application.

Owner:TIANJIN UNIV

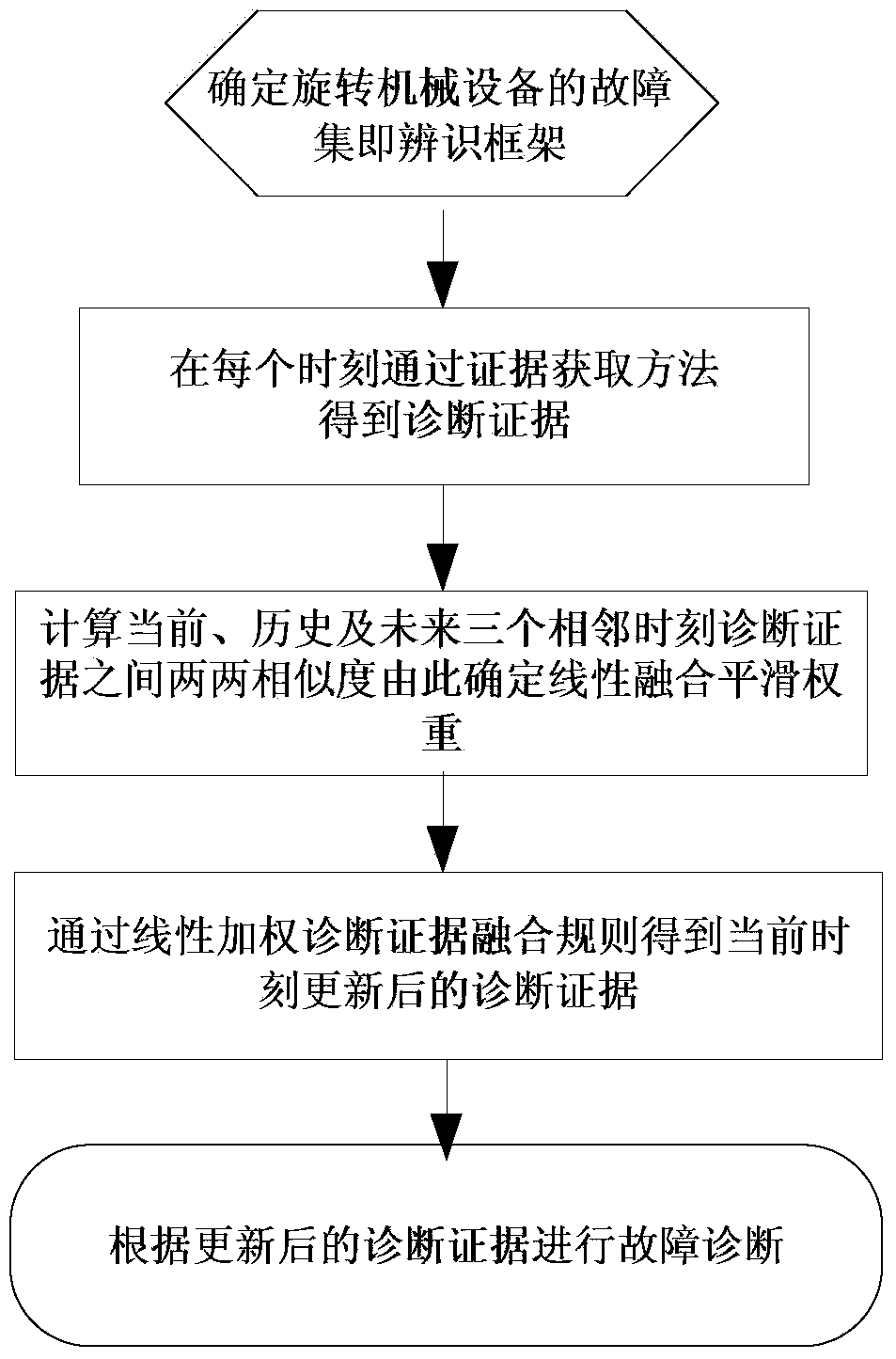

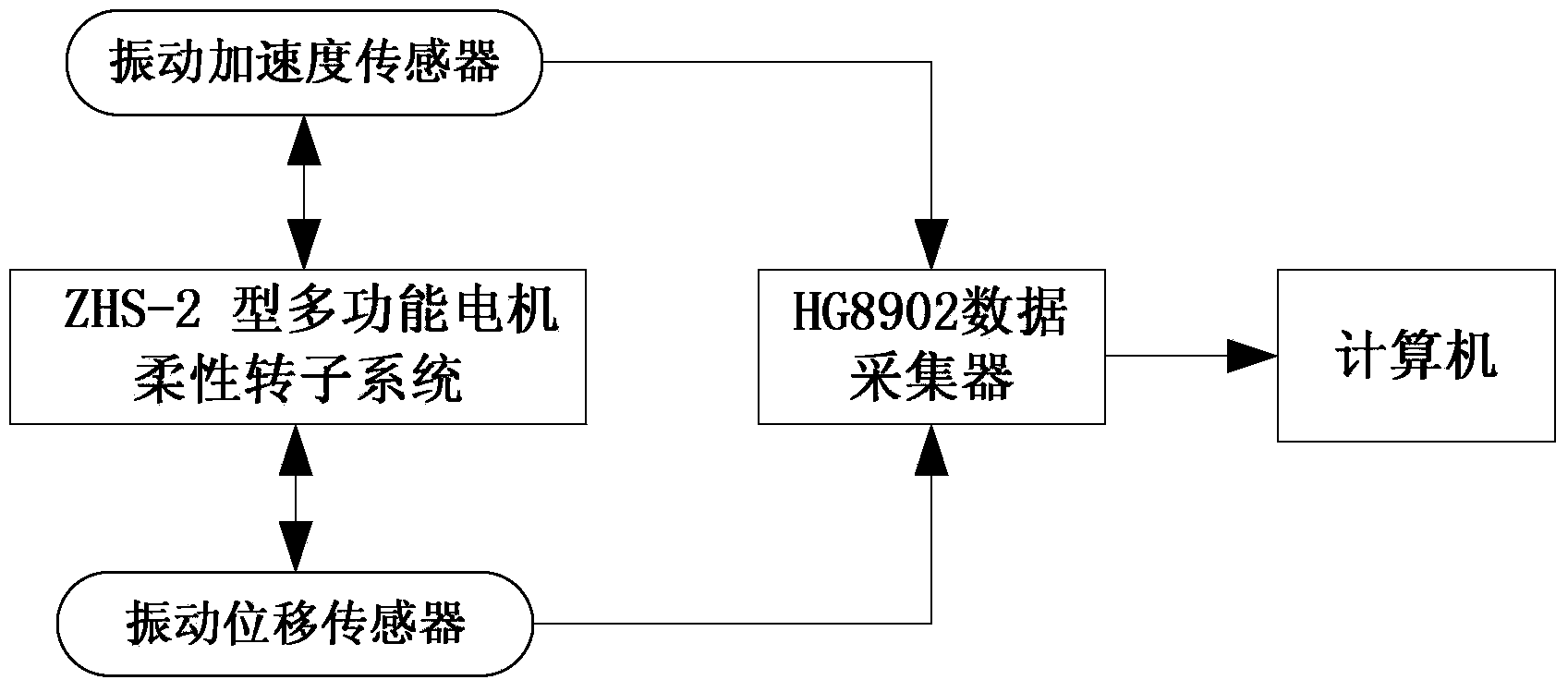

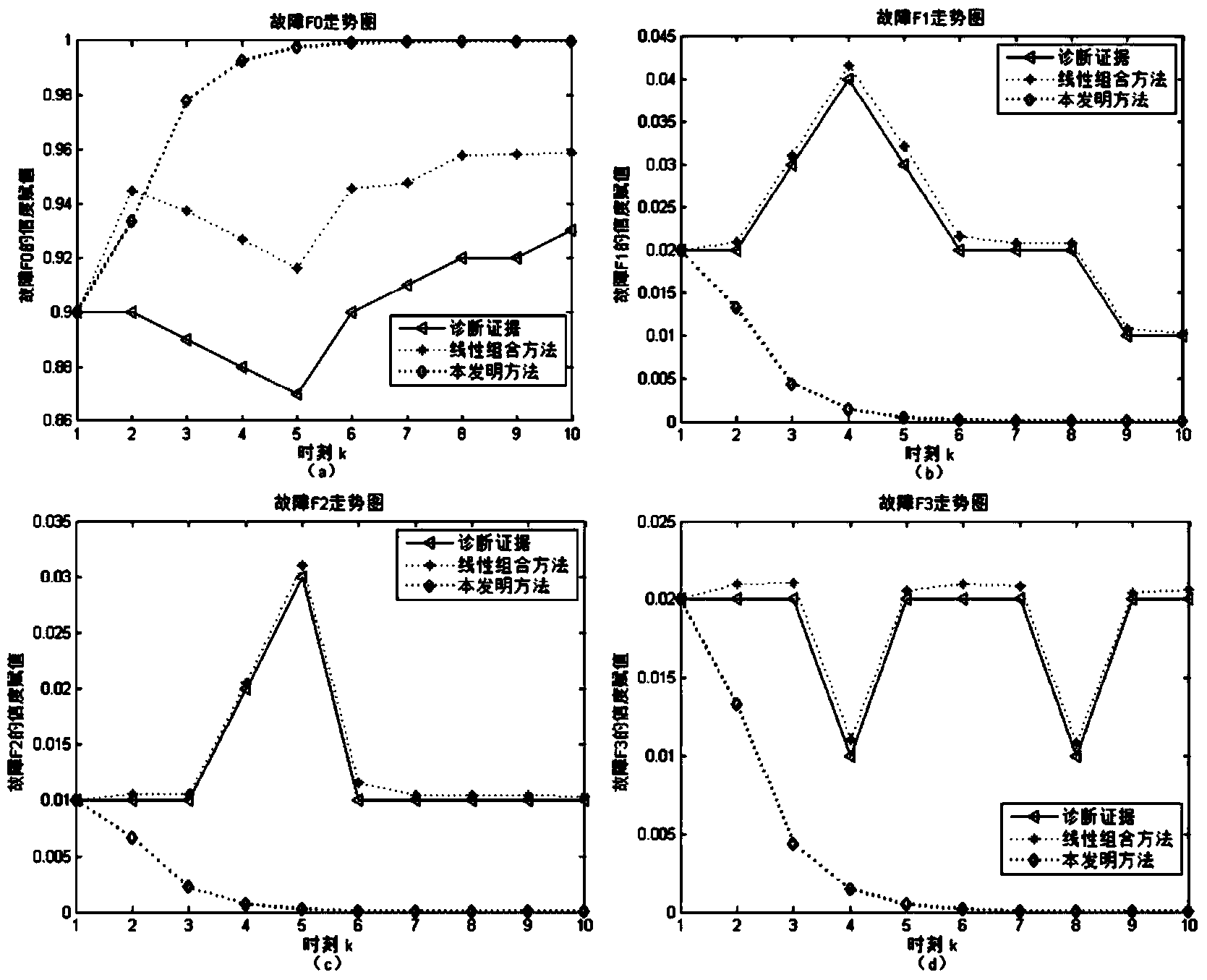

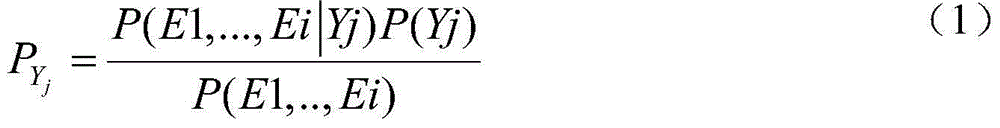

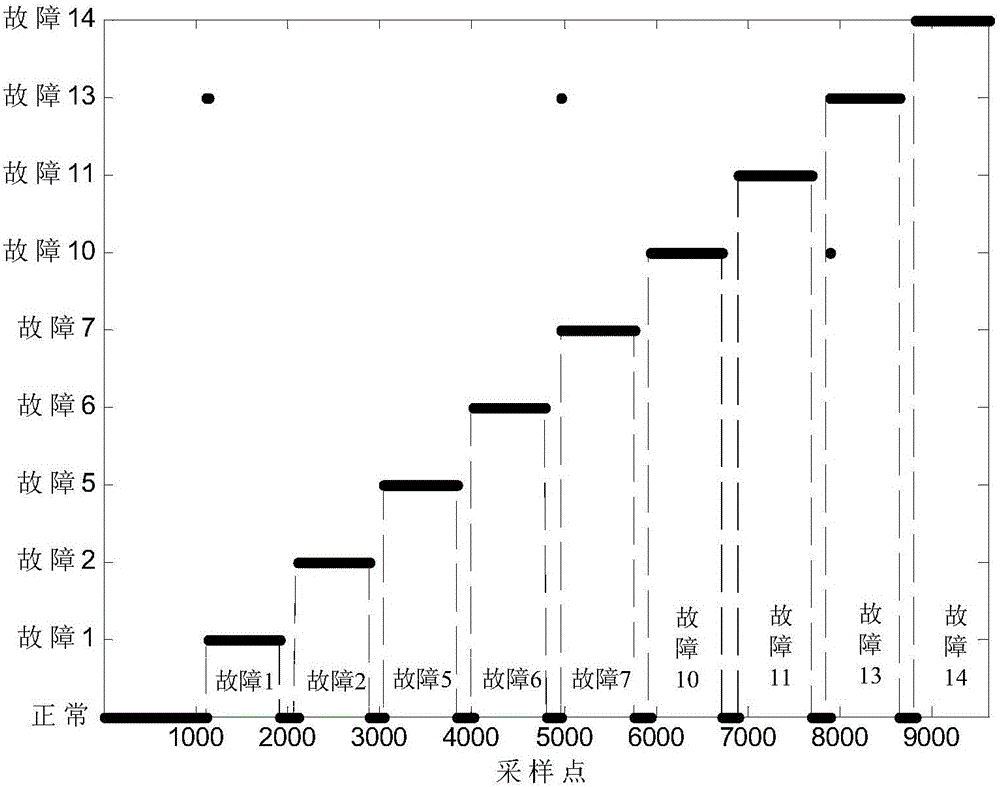

Rotary mechanical equipment fault diagnosing method based on diagnosing evidence smooth updating

ActiveCN103617350ARealize online fault diagnosisMonitor running statusSpecial data processing applicationsEngineeringMechanical equipment

The invention relates to a rotary mechanical equipment fault diagnosing method based on diagnosing evidence smooth updating and belongs to the technical field of rotary mechanical equipment fault monitoring and diagnosing. The diagnosing evidence during equipment operation is obtained through an evidence acquiring method, a conditioning linear weighting evidence fusion rule is recursively used to update the diagnosing evidence updated at the previous moment with the current-moment diagnosing evidence, and the updated current-moment diagnosing evidence is obtained. Under a certain decision making rule, the updated diagnosing evidence is used for fault decision making. On the basis of the reliability of the current-moment, historical-moment and future-moment diagnosing evidences, the smooth weighting in linear fusion evidence updating is determined, the updated current-moment diagnosing evidence is enabled to have useful diagnosing information of historical and future moments, and the decision made on the basis of the updated diagnosing evidence is more accurate and reliable than the decision made on the basis of diagnosing evidence not updated.

Owner:HANGZHOU DIANZI UNIV

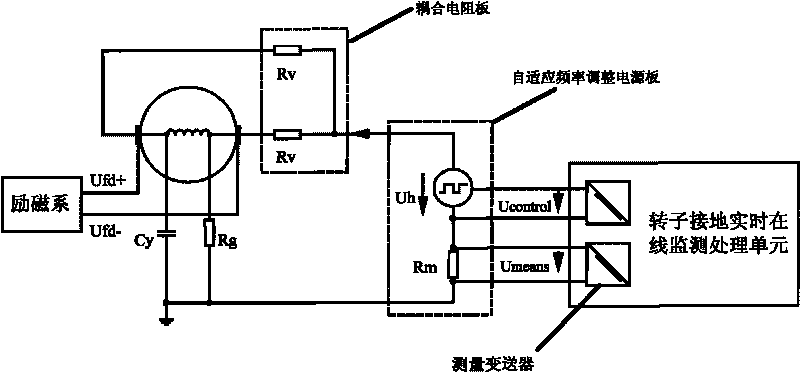

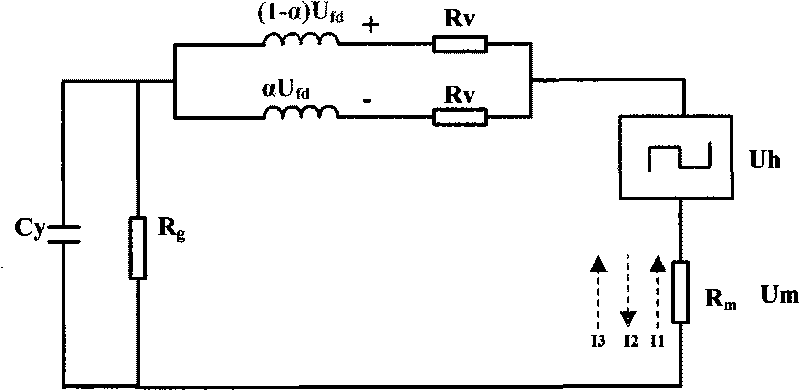

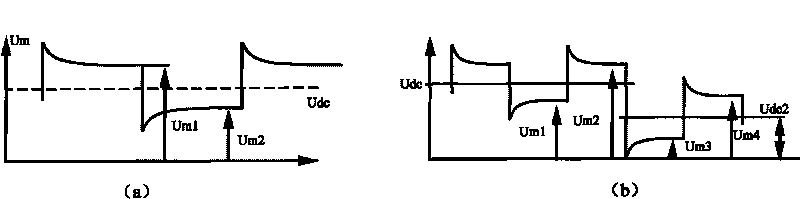

Rotor ground on-line monitoring device and method based on adaptive frequency square-wave voltage

InactiveCN101710161AImprove precise positioningGuaranteed accuracyDynamo-electric machine testingSelf adaptiveDynamo

The invention discloses rotor ground on-line monitoring device and method based on adaptive frequency square-wave voltage. The device comprises a rotor ground real-time on-line monitoring processing unit, an adaptive frequency regulation square-wave power panel, a coupling resistance board and first and second measuring transducers. In the method, the coupling resistance board is adopted to prevent excitation high voltage from striking back the monitoring device; the adaptive frequency square-wave power panel adaptively regulates control voltage frequency corresponding to the power panel according to a fault mode of a motor rotor; the measuring transducers acquire control voltage and measuring voltage which are output by the adaptive frequency square-wave power panel; and the rotor ground real-time on-line monitoring processing unit judges a generator fault according to the control voltage and the measuring voltage. The invention has high monitoring precision and can simply find the fault point, thereby shortening repair time and reducing economic loss brought by power failure.

Owner:HOHAI UNIV

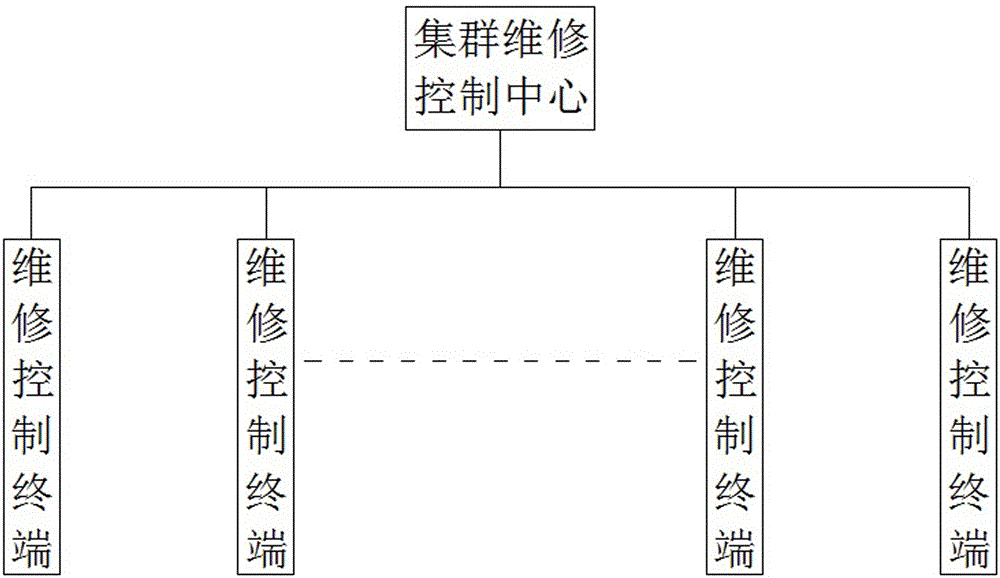

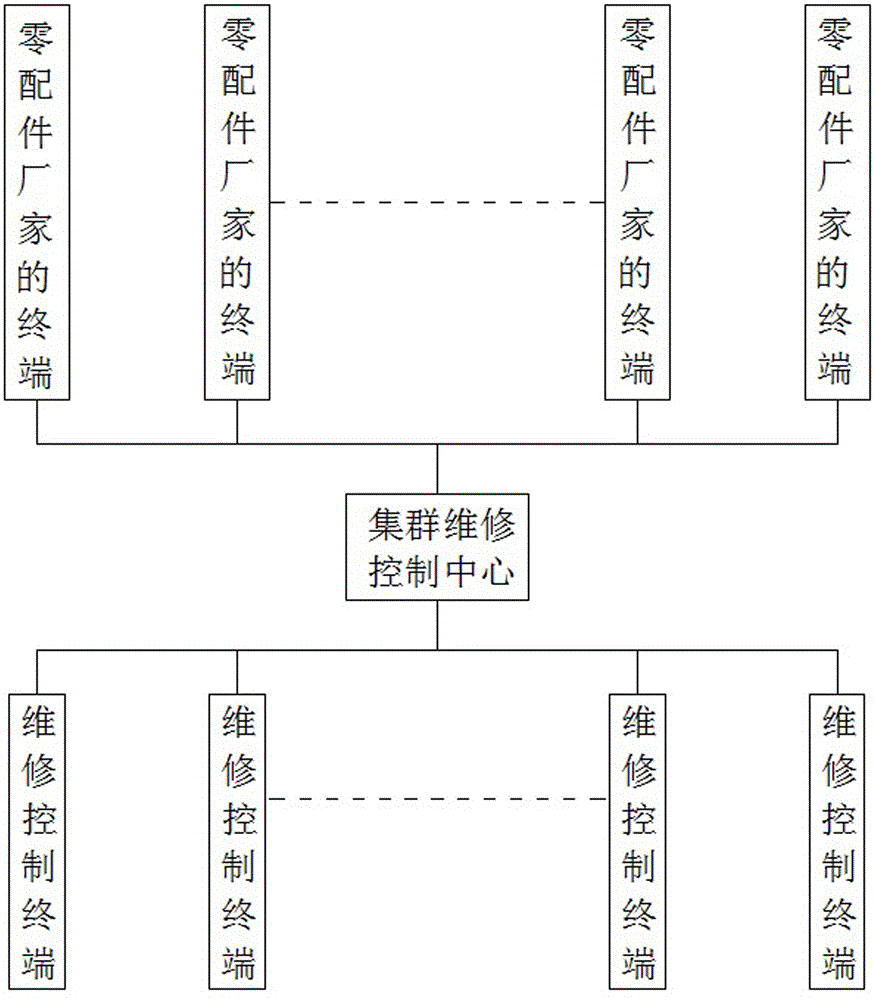

Online comprehensive service system for electric automobiles

InactiveCN105005814ARealize online fault diagnosisOvercome shortageData processing applicationsComputer terminalTechnician

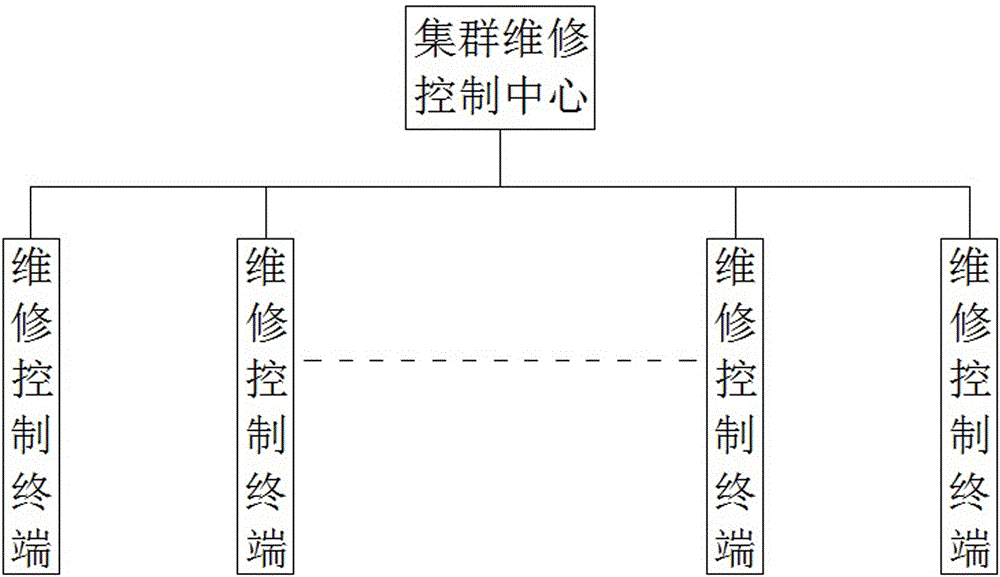

The invention discloses an online comprehensive service system for electric automobiles. The online comprehensive service system comprises a clustered repair control center and a plurality of repair control terminals. The repair control terminals are connected to the clustered repair control center through a communication network. When electric automobiles need repairing at the repair control terminals, the electric automobiles to be repaired are placed to a repair platform. An electric automobile fault detection device detects the faults in the electric automobiles and transmits the detection result to the clustered repair control center through the repair control terminals. The electric automobile repairmen at the clustered repair control center operate and initiate online electric automobile repair robots at the repair control terminals to complete the repair work to the electric automobiles. The service system of the invention is capable of online detecting faults and remotely controlling repair robots and integrates online repair guidance and skill training. Further, with such a service system, the problem of shortage of technicians can be overcome and online teaching can be given to electric automobile repairmen.

Owner:蔡乌力吉

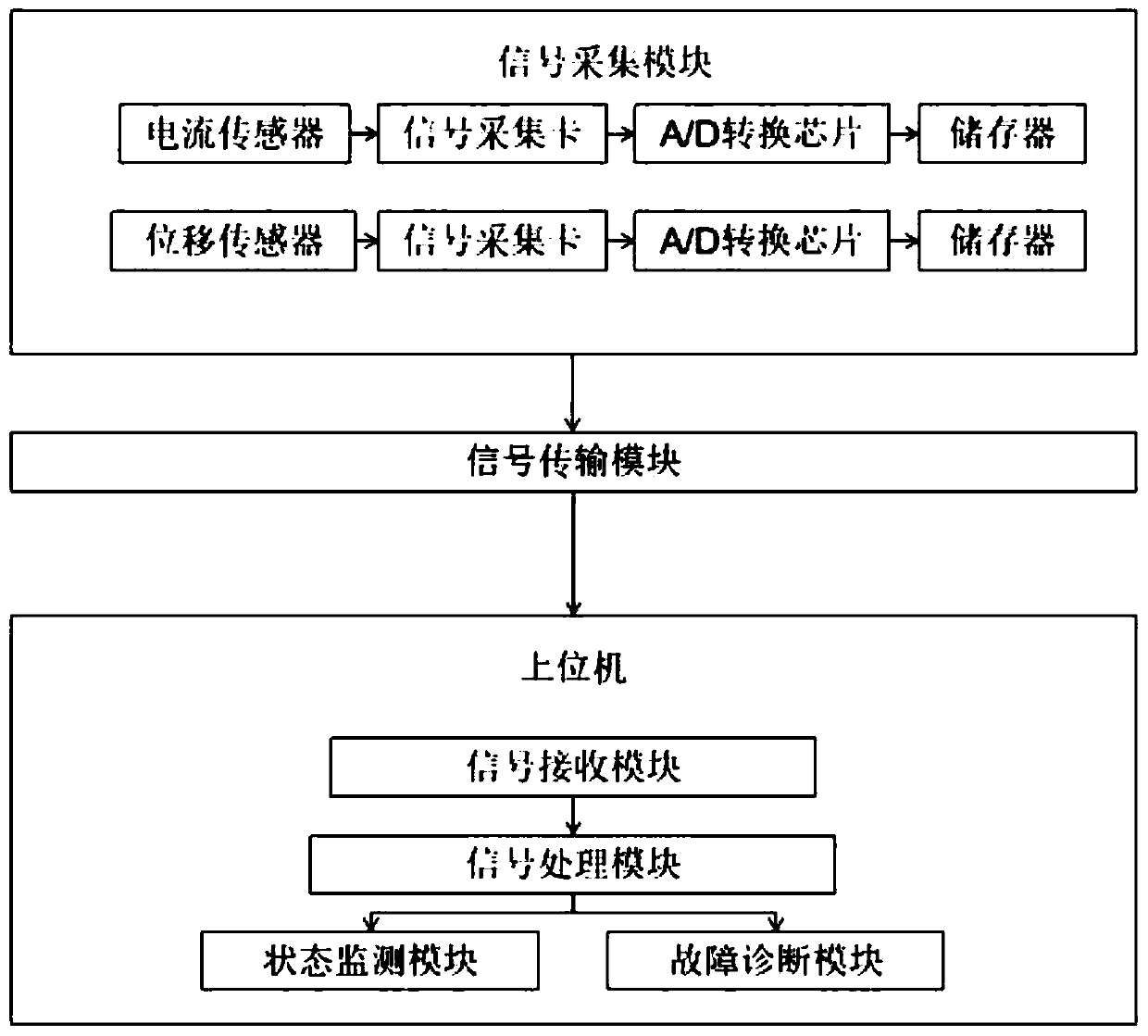

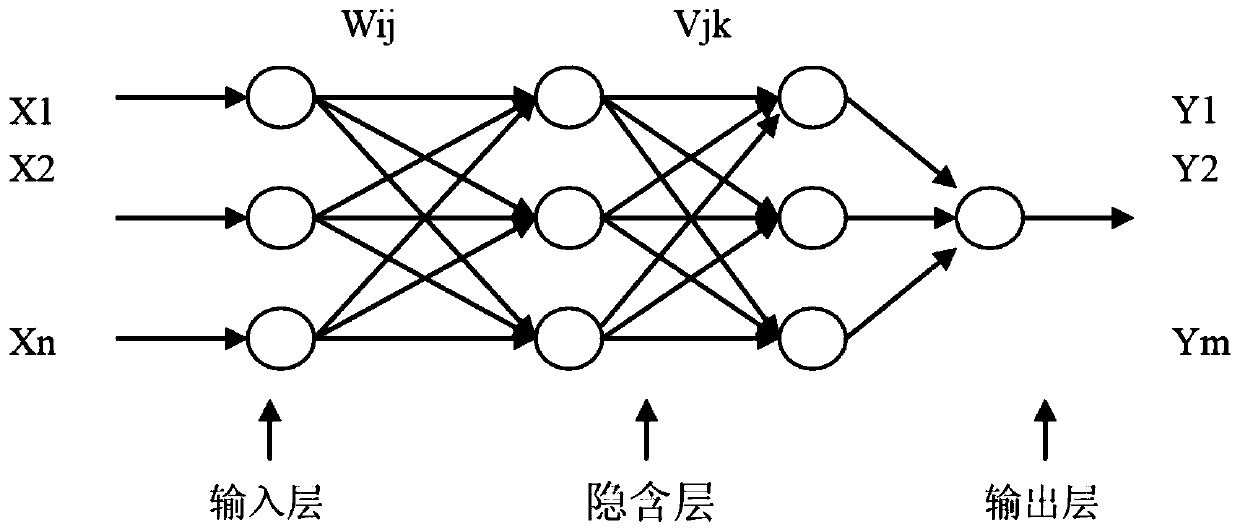

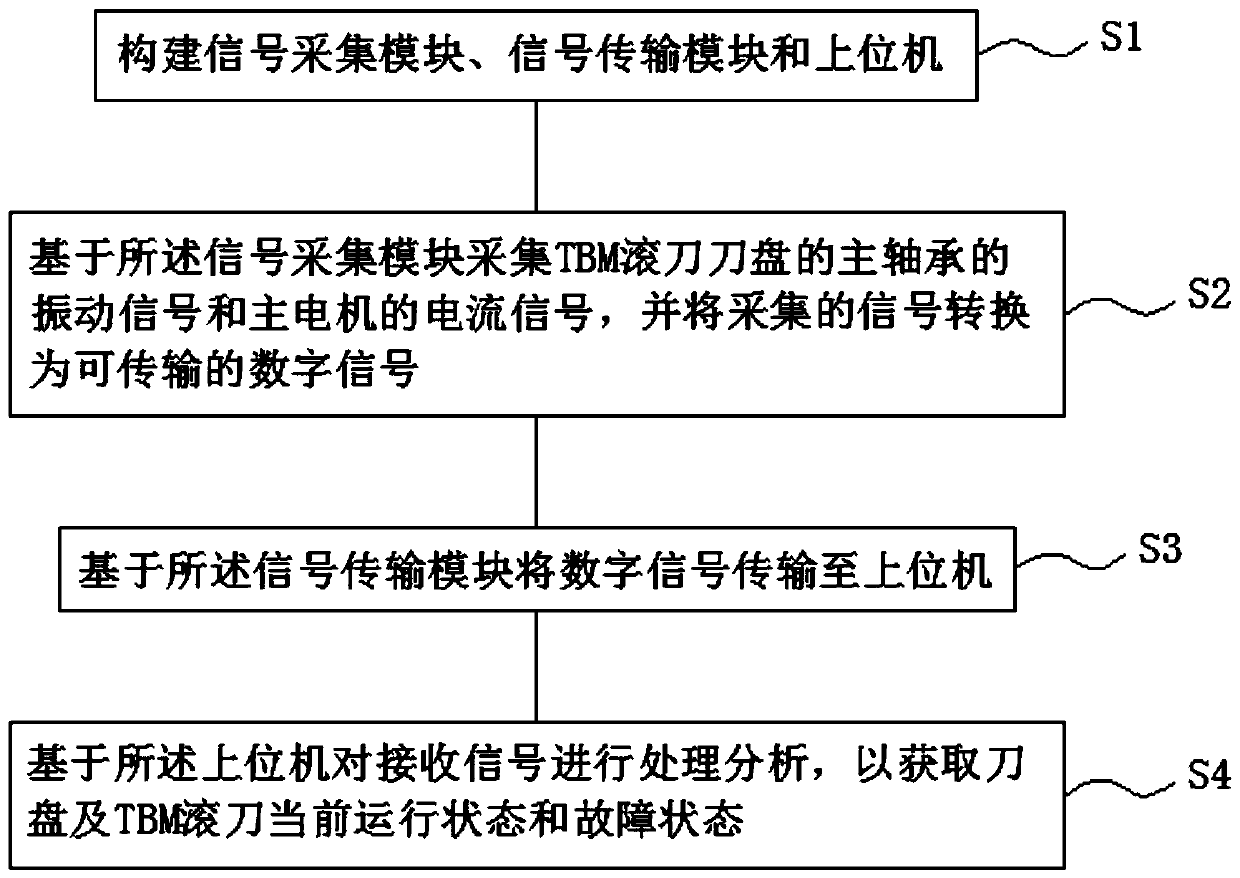

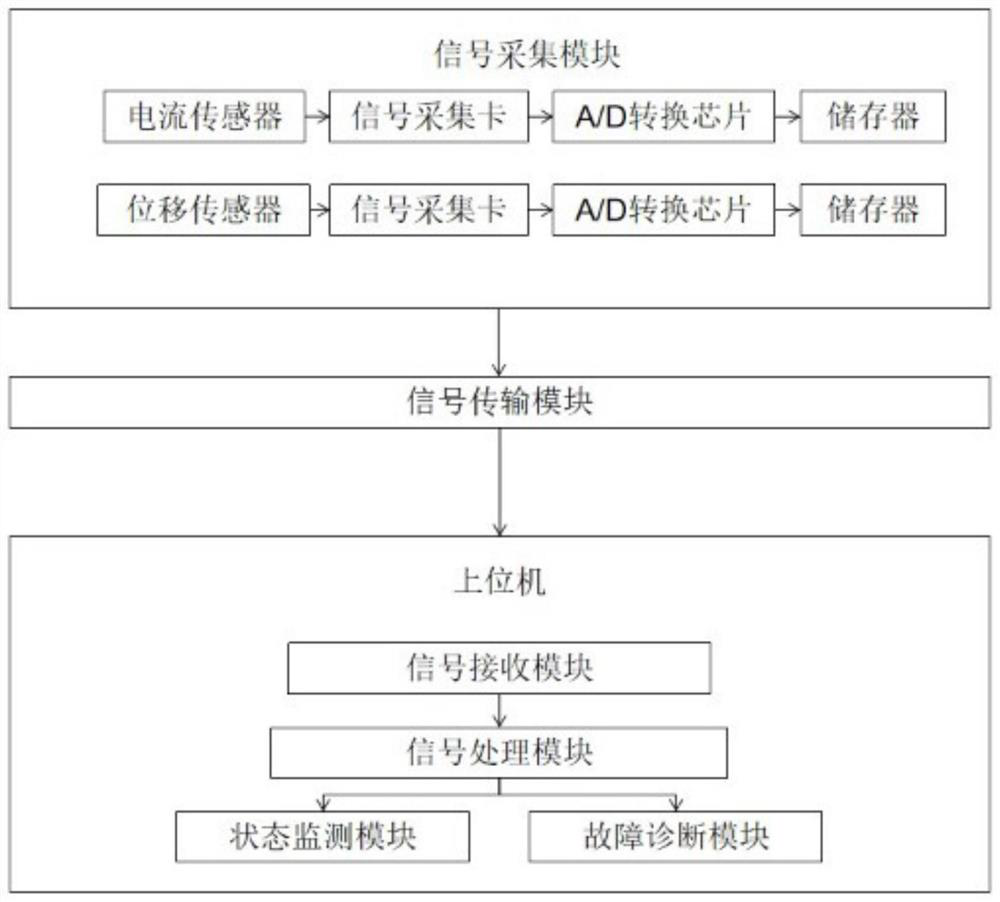

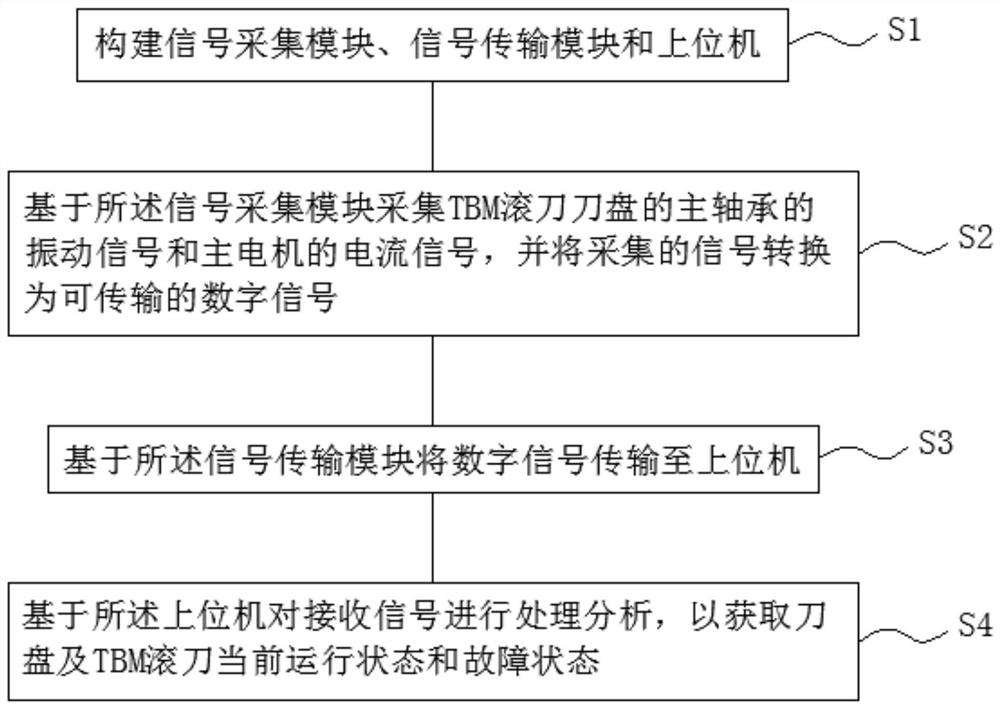

TBM hob state monitoring and fault diagnosis method and system

ActiveCN111322082ARealize online fault diagnosisGuaranteed timelinessMachine bearings testingTunnelsElectric machineryControl room

The invention belongs to the technical field of safe operation of TBM hobs, and discloses a TBM hob state monitoring and fault diagnosis method and system. The system comprises a signal acquisition module, a signal transmission module and an upper computer; the signal acquisition module is installed on a cutter head of a TBM hob and is used for acquiring vibration signals of a main bearing of thecutter head and current signals of a main motor and converting the acquired signals into transmittable digital signals; the signal transmission module is used for realizing communication transmissionbetween the signal acquisition module and the upper computer so as to transmit the digital signals to the upper computer; and the upper computer is arranged in a TBM main control room and used for receiving the signals transmitted by the signal transmission module and processing and analyzing the received signals so as to obtain the current operation state and fault state of the cutter head and the TBM hob. To sum up, the real-time monitoring and diagnosis of the TBM hob can be effectively realized, and the problems of distortion of collected signals and mixed signal backgrounds are effectively avoided, so that the monitoring and diagnosis accuracy is greatly improved.

Owner:HULUDAO LITIAN HEAVY IND MACHINERY

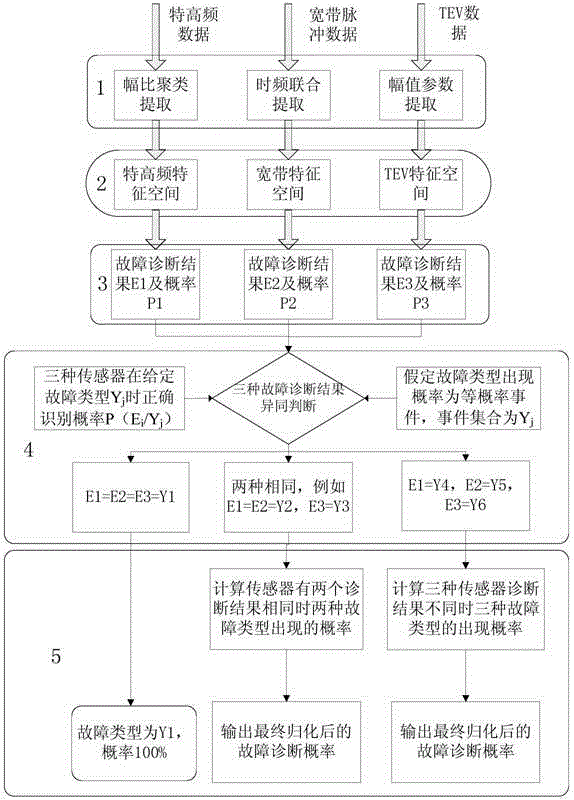

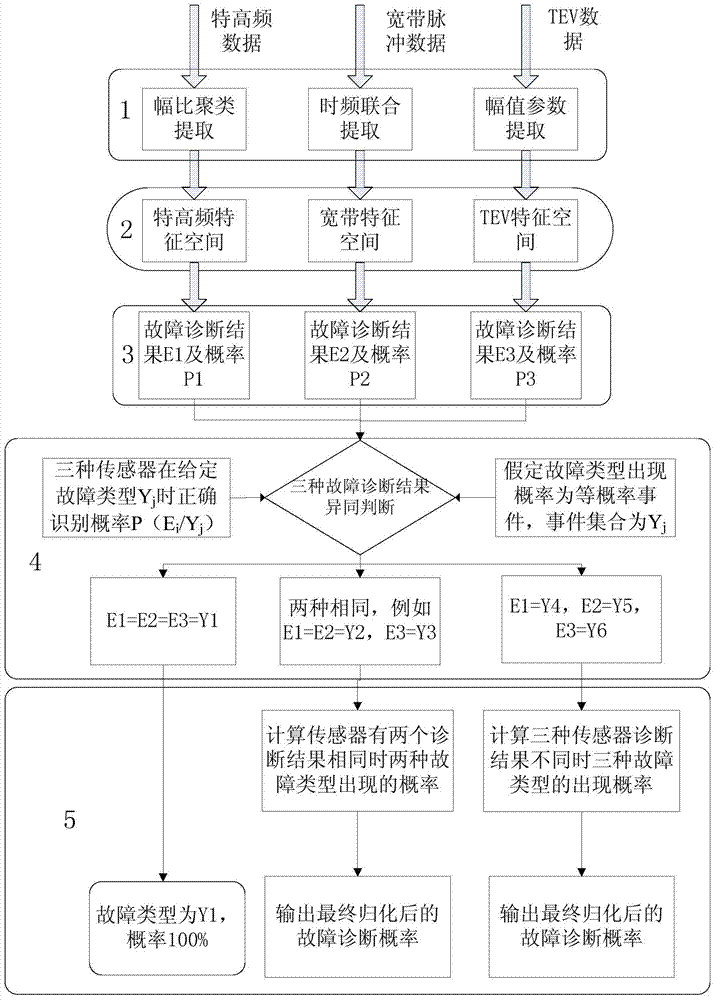

Converter transformer fault online diagnosis method based on three-sensor reasoning

ActiveCN104360190AImprove recognition accuracyRealize online fault diagnosisElectrical testingCharacteristic spaceEngineering

The intention discloses a converter transformer fault online diagnosis method based on three-sensor reasoning, and belongs to the technical field of ultra-high voltage direct-current power transmission device fault diagnosis. The method includes the steps of obtaining online data of a converter transformer by using online detection instruments, including the ultra-high frequency detection instrument, the broadband pulse detection instrument and the transient earth voltage (TEV) detection instrument, which can be obtained on projects at present as three sensors; calling the actually-measured online data of the converter transformer to achieve fault diagnosis, wherein effective discharging information is extracted from the actually-measured online data of the converter transformer, three types of sensor characteristic space are established, the fault diagnosis results of the three types of sensor characteristic space are obtained, the differences and similarities of the fault diagnosis results are judged, the diagnosis results are finally output, reasoning is conducted on data of the three sensors, and the final diagnosis results under the condition are obtained. By means of the method, the converter transformer fault diagnosis accuracy is effectively improved, and the online diagnosis of the transformer converter fault is achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

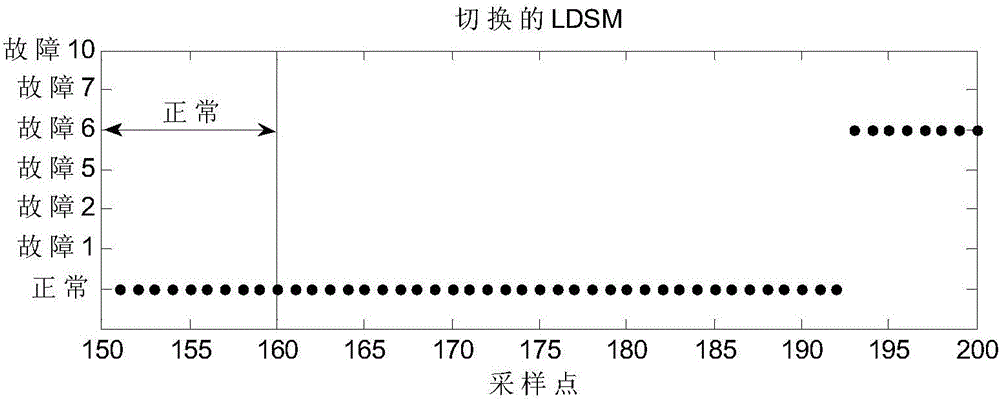

Fault diagnosis method based on switching supervised LDSM

InactiveCN105759787AEnhanced description abilityStrong modeling abilityElectric testing/monitoringDynamic system modelLinear dynamical system

The present invention discloses an industrial process fault diagnosis method based on a switching supervised LDSM (Linear Dynamic System Model), which is used for fault diagnosis on the condition that a key quality variable is obtainable in an industrial process. According to the fault diagnosis method, a supervised LDSM is expanded to a multi-modal form, and a switching supervised LDSM is established, thus dynamic characteristics and random characteristics of process data are considered, and important process operation information included in quality variables is also fully utilized. In comparison with the conventional method, the fault diagnosis method improves the capability of describing industrial process operation states by the model, improves a fault diagnosis effect, shortens delay time of diagnosis, enables fault processing to be more timely and effective, and is more beneficial to automatic enforcement of industrial process.

Owner:ZHEJIANG UNIV

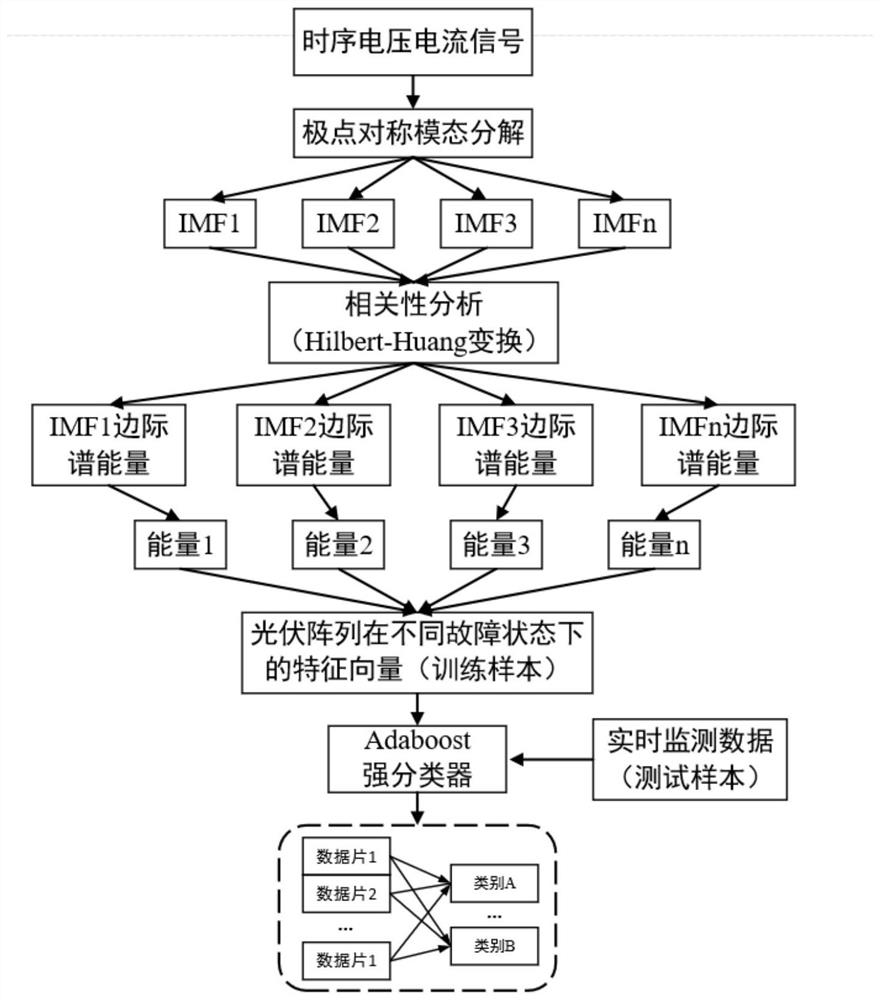

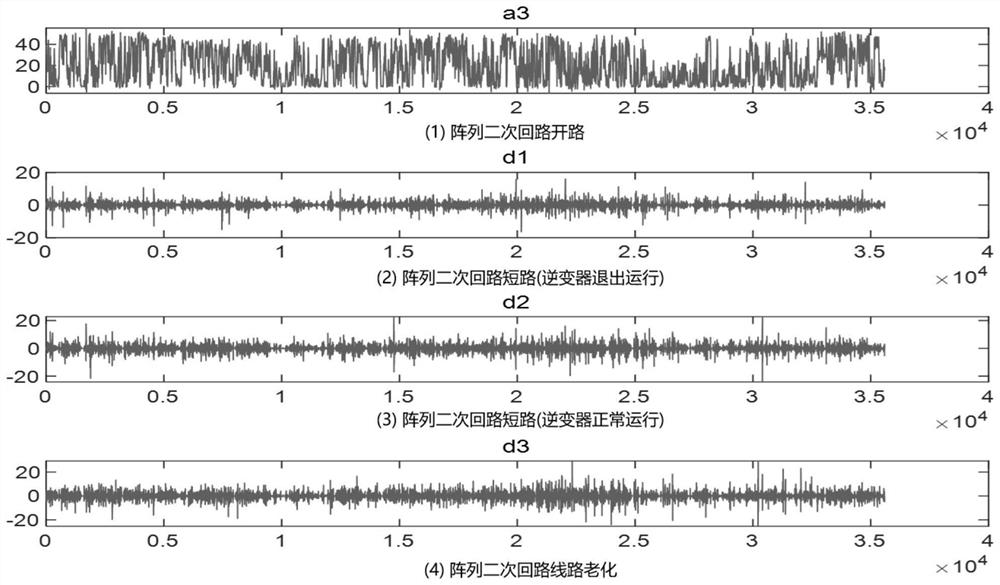

Photovoltaic array fault diagnosis method based on non-intrusive state detection

PendingCN114722895AAccurate fault diagnosisQuick TroubleshootingPhotovoltaic monitoringCharacter and pattern recognitionAlgorithmPrincipal component analysis

The invention belongs to the technical field of photovoltaic power generation, and particularly relates to a photovoltaic array fault diagnosis method based on non-intrusive state detection. On the basis of performing principal component analysis on original data, time sequence voltage and current data are subjected to pole symmetry mode decomposition, and mirror image continuation is adopted to repair breakpoint missing of an eigenmode function after mode decomposition. Hilbert-Huang transformation is carried out on the decomposed eigenmode function, Hilbert marginal spectrum energy is formed, actual waveforms of time sequence voltage and current are amplified, the influence of noise is reduced, and effective extraction of eigenvectors is achieved. A combined classifier formed by an Adaboost algorithm is utilized, a fuzzy clustering-mahalanobis distance model is adopted to calculate the vector similarity of a sample group, the weight coefficient of the combined classifier is effectively updated, and the perceptual ability of the classifier to errors is enhanced, so that effective mining of fault data is realized, and online fault diagnosis of a photovoltaic array system is realized.

Owner:LIAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +3

On-line Diagnosis Method of Converter Transformer Fault Based on Three-sensor Reasoning

ActiveCN104360190BRealize online fault diagnosisImprove recognition accuracyElectrical testingBroadband pulseTransient state

The intention discloses a converter transformer fault online diagnosis method based on three-sensor reasoning, and belongs to the technical field of ultra-high voltage direct-current power transmission device fault diagnosis. The method includes the steps of obtaining online data of a converter transformer by using online detection instruments, including the ultra-high frequency detection instrument, the broadband pulse detection instrument and the transient earth voltage (TEV) detection instrument, which can be obtained on projects at present as three sensors; calling the actually-measured online data of the converter transformer to achieve fault diagnosis, wherein effective discharging information is extracted from the actually-measured online data of the converter transformer, three types of sensor characteristic space are established, the fault diagnosis results of the three types of sensor characteristic space are obtained, the differences and similarities of the fault diagnosis results are judged, the diagnosis results are finally output, reasoning is conducted on data of the three sensors, and the final diagnosis results under the condition are obtained. By means of the method, the converter transformer fault diagnosis accuracy is effectively improved, and the online diagnosis of the transformer converter fault is achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

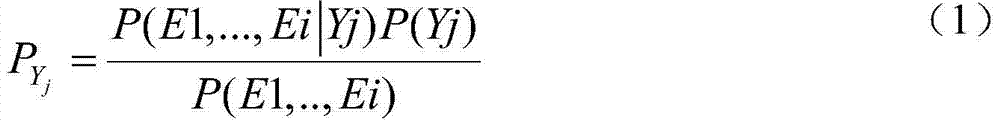

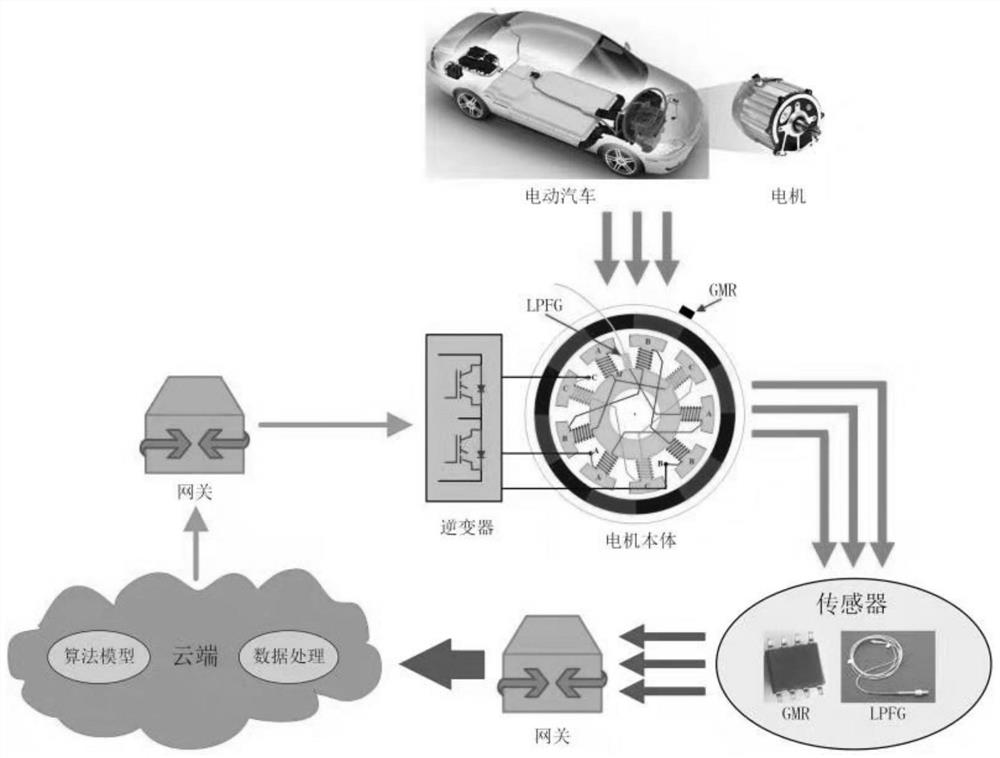

Fault diagnosis method and application of electric vehicle driving motor

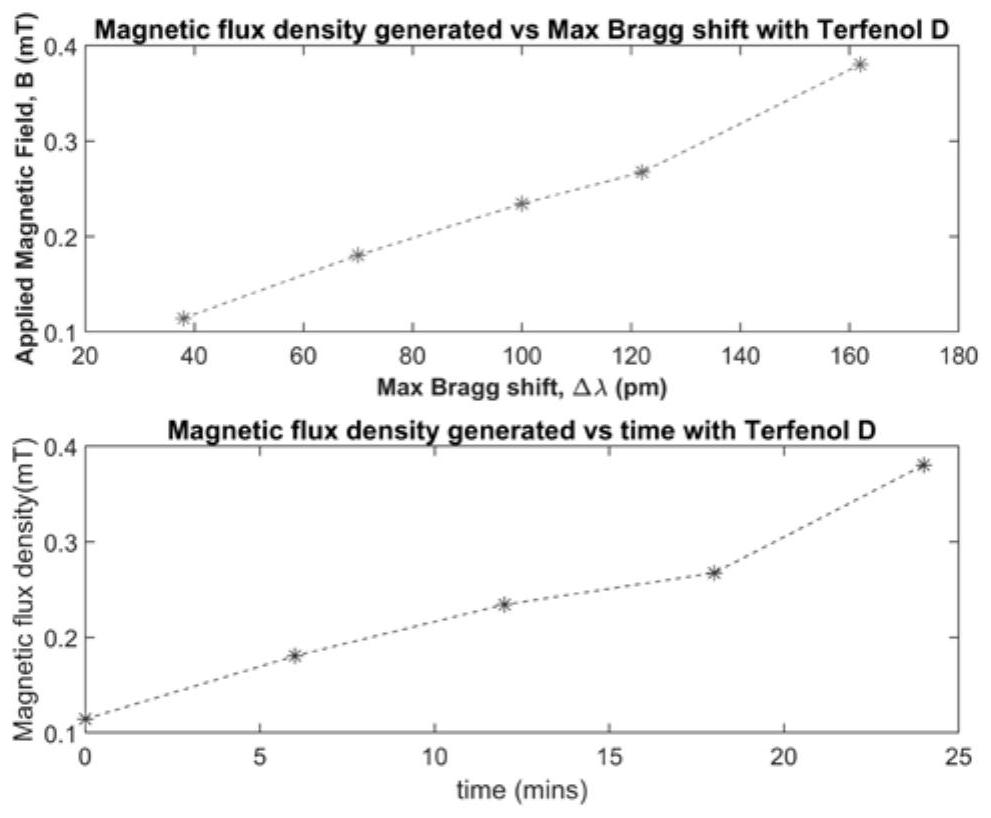

PendingCN113125954ARealize online fault diagnosisRealize functionTesting electric installations on transportDynamo-electric machine testingMathematical modelElectric machinery

The invention discloses a fault diagnosis method and application of an electric vehicle driving motor, and belongs to the technical field of vehicle monitoring. In order to solve the problem that prediction maintenance, online health detection and the like cannot be realized in the conventional electric vehicle motor driving, the invention provides a fault diagnosis method, which comprises the following steps: firstly, analyzing a fault formation mechanism of an electric vehicle driving motor; secondly, establishing a mathematical model and a fault mechanism theory, and establishing a relationship between the electric vehicle driving motor fault and a measurable signal and a calculation method; and then measuring the magnetic field and port parameters of the electric automobile in real time. And carrying out data analysis, and dynamically updating the built part health model to realize the detection of the state of the motor so as to provide a decision. Giant magnetoresistance and the long-period fiber grating sensing technology are combined for the first time and applied to fault diagnosis of the electric vehicle, full-life-cycle motor state monitoring is achieved, the operation and maintenance cost of the vehicle can be reduced, and the reliability and intelligence of an electric drive system of the electric vehicle are improved.

Owner:ANHUI UNIVERSITY

Online comprehensive service system for electric automobiles

InactiveCN105005815ARealize online fault diagnosisOvercome shortageData processing applicationsState of artComputer terminal

The invention discloses an online comprehensive service system for electric automobiles. The online comprehensive service system comprises a clustered repair control center, a plurality of repair control terminals and a plurality of electric automobile part manufacturing factory terminals. The repair control terminals and the electric automobile part manufacturing factory terminals are connected to the clustered repair control center through a communication network to exchange information. When electric automobiles need repairing at the repair control terminals, the clustered repair control center, based on the fault detection result of the electric automobiles, connects the repair control terminal to the electric automobile part manufacturing factory terminal with problem parts. Finally, the technicians at the electric automobile part manufacturing factory terminals guide the working staff at the repair control terminals to complete the repair work to the electric automobiles. The service system of the invention is capable of online detecting faults and remotely controlling repair robots and capable of integrating online repair guidance and skill training into one. Further, with such a service system, the problem of shortage of technicians can be overcome and online teaching can be given to electric automobile repairmen.

Owner:蔡乌力吉

A method and system for state monitoring and fault diagnosis of tbm hob

ActiveCN111322082BRealize online fault diagnosisGuaranteed timelinessData processing applicationsMachine bearings testingComputer hardwareControl room

The invention belongs to the technical field of safe operation of TBM hobs, and discloses a TBM hob state monitoring and fault diagnosis method and system. The system includes a signal acquisition module, a signal transmission module and a host computer; the signal acquisition module is installed on the TBM hob On the cutter head, it is used to collect the vibration signal of the main bearing of the cutter head and the current signal of the main motor, and convert the collected signal into a digital signal that can be transmitted; the signal transmission module is used to realize the communication between the signal acquisition module and the host computer Transmission to transmit digital signals to the host computer; the host computer is set up in the TBM main control room to receive the signal transmitted by the signal transmission module, and process and analyze the received signal to obtain the current operating status of the cutterhead and TBM hob and fault status; in summary, it can effectively realize the real-time monitoring and diagnosis of the TBM hob, and also effectively avoid the problems of acquisition signal distortion and mixed signal background, thus greatly improving the accuracy of monitoring and diagnosis.

Owner:HULUDAO LITIAN HEAVY IND MACHINERY

Distributed intelligent monitoring system for motor

InactiveCN100442063CRealize monitoringRealize local/remote synchronous monitoringDynamo-electric machine testingInformation processingDistributed intelligence

The invention relates to a distributed intelligent motor monitoring system. The system includes on-site low-level intelligent monitoring sub-stations, high-level intelligent monitoring general stations, and modular system application software for data collection and information processing to realize motor monitoring functions. Among them, the monitoring sub-station is connected to the motor at the corresponding position, and is composed of an intelligent monitoring module including monitoring instruments, meters, and data collectors. The intelligent monitoring general station is composed of a computer that realizes centralized processing of motor information and intelligent monitoring. interconnected by a data communication network. Through this system, the real-time collection and local / remote monitoring of various parameters of a single or multiple motors, motor operating status identification and fault diagnosis functions can be realized. Not only can it be used as special equipment for factory testing and type testing of motor manufacturers, but it can also be widely used in real-time monitoring or online fault monitoring of motors in metallurgy, chemical, petroleum, pharmaceutical and other industrial sectors.

Owner:杜玉晓

Electric automobile online comprehensive service system

InactiveCN105069510ARealize online fault diagnosisRealize remote operationData processing applicationsState of artEngineering

The present application discloses an electric automobile online comprehensive service system, wherein the comprehensive service system comprises a cluster maintenance control center and a plurality of maintenance control terminals. The maintenance control terminals are connected to the cluster maintenance control center by using a communication network. When an electric automobile needs to be maintained at a maintenance control terminal, the electric automobile is placed on a maintenance platform; an electric automobile fault detection device is connected to a diagnostic connector of the electric automobile, to detect a fault of the electric automobile; a detection result is sent to the cluster maintenance control center; and an electric automobile maintenance technician of the cluster maintenance control center operates online an electric automobile maintenance robot disposed at the maintenance control terminal, to finish maintenance on the electric automobile. According to the present application, not only on-line fault diagnosis of the electric automobile and remote operation of the maintenance robot are implemented; but also online maintenance instruction and skill training are integrated. Therefore, a problem of staff shortage in the prior art is overcome; and online teaching for electric automobile maintenance personnel may be performed.

Owner:蔡乌力吉

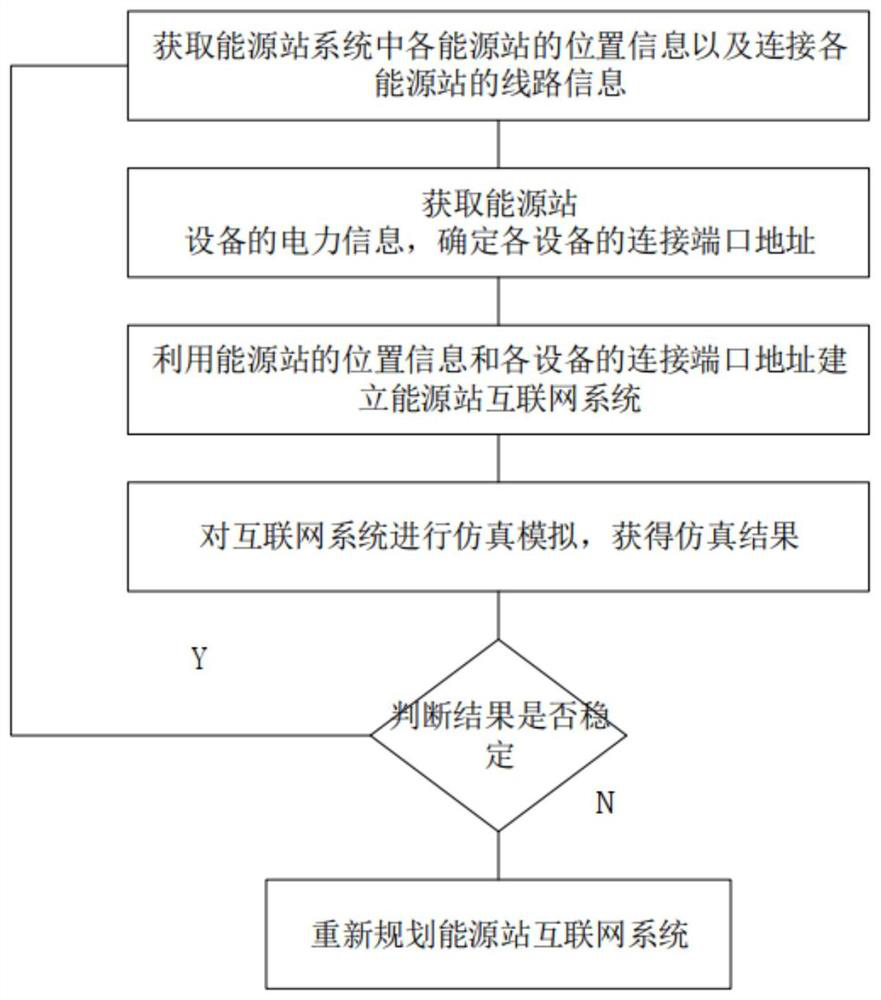

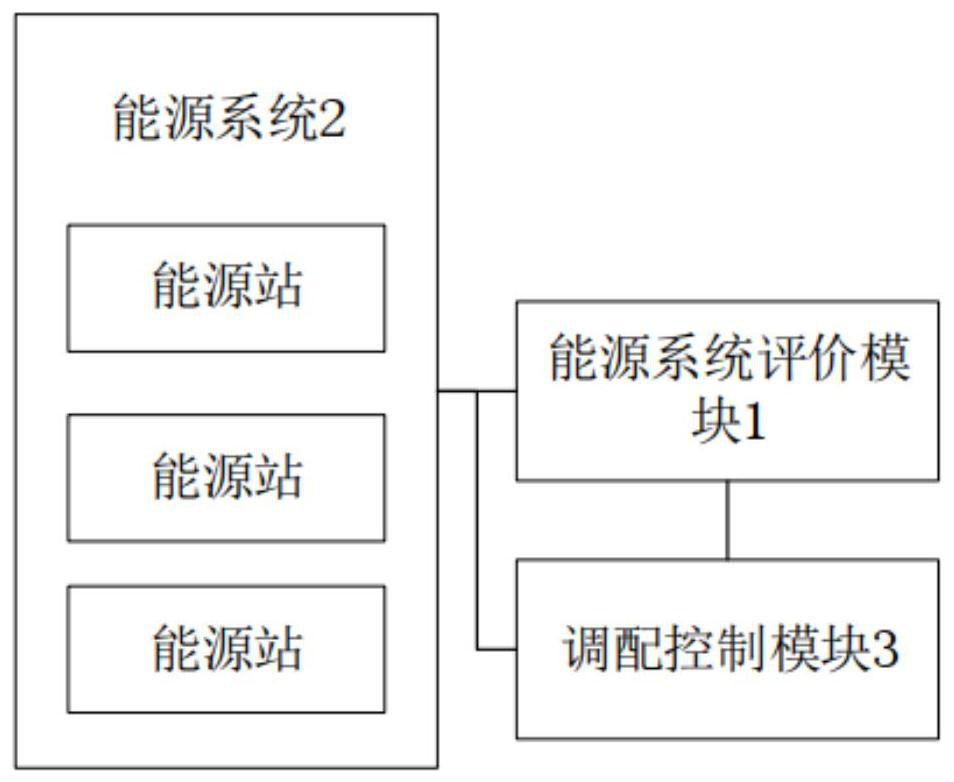

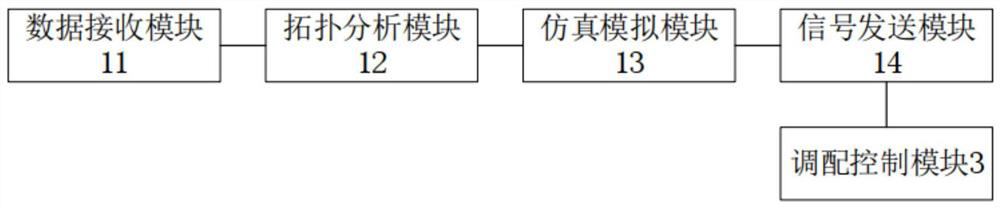

Regional integrated energy system evaluation method based on energy Internet layered architecture

PendingCN113837571AFacilitate power analysisRealize online fault diagnosis and early warningTechnology managementResourcesPower gridEngineering

The invention discloses a regional integrated energy system evaluation method based on an energy Internet layered architecture, and the method comprises the steps: taking the geographic position of equipment in an energy station system as an Internet system node, and marking a connection port address of the corresponding equipment at the Internet system node; using a power transmission line connected with equipment in an energy station system as an Internet system link, marking the power transmission line on the Internet system link as information, and it can be understood that a string of nodes and links between a signal sending node and a signal receiving node establish a power grid topological structure for a path of an Internet system; power analysis of power grid equipment is facilitated, the power analysis and application requirements of an energy station system are met, and online fault diagnosis and early warning of a power system are achieved.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

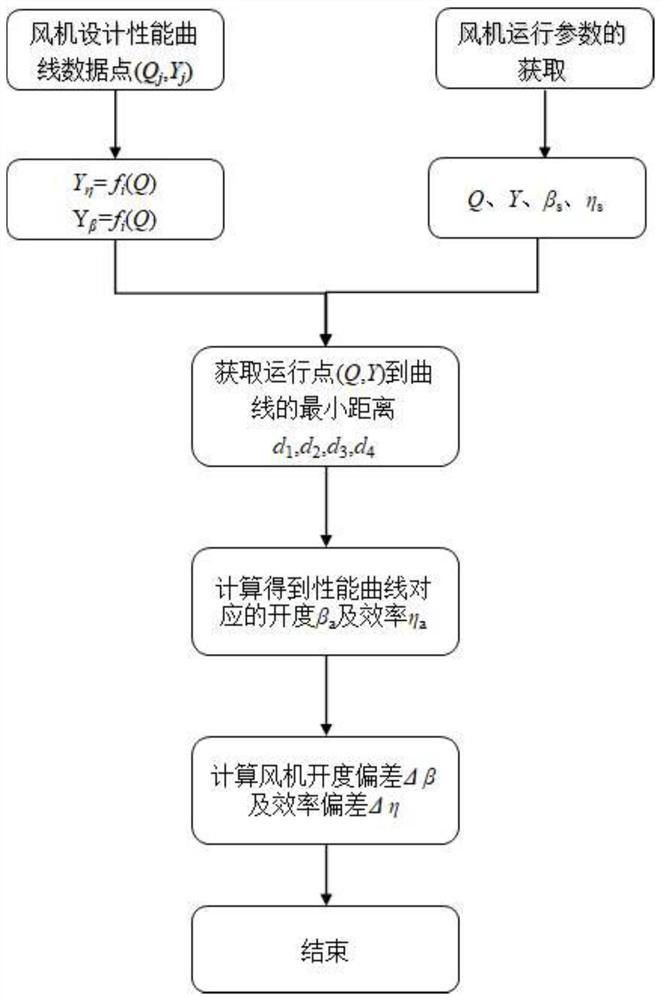

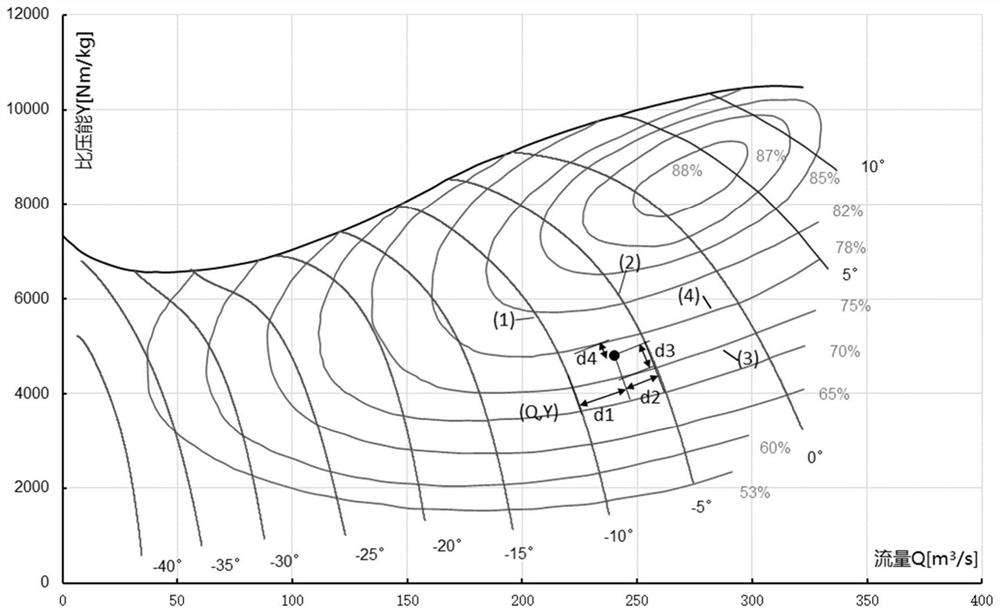

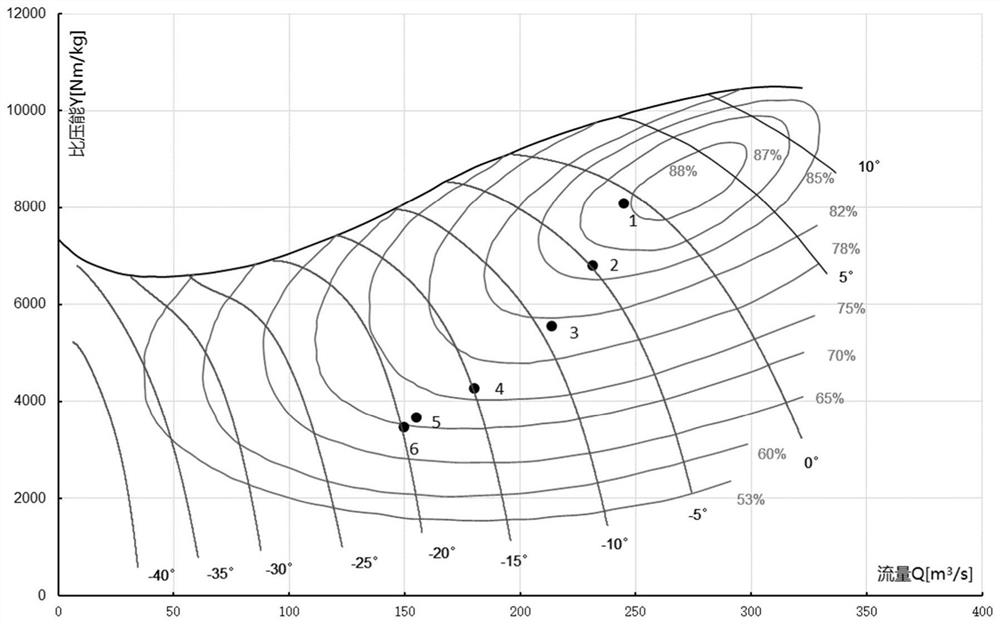

An online calculation method of fan opening and efficiency based on fan performance curve

ActiveCN113325700BImprove operational safetyRealize online fault diagnosisAdaptive controlMonitoring systemMechanical engineering

Owner:XIAN THERMAL POWER RES INST CO LTD +1

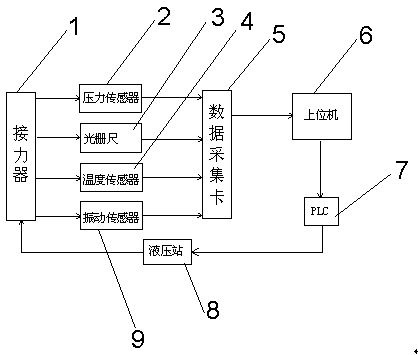

A hydraulic turbine servomotor intelligent leak detection system and method thereof

ActiveCN106762340BSolve online detectionGet rid of detection defectsEngine fuctionsHydro energy generationWater turbineData acquisition

The invention provides an intelligent leakage detection system of a servomotor of a water turbine and a method thereof and belongs to the technical field of the leakage detection of the servomotors of the water turbines. According to the technical scheme, the intelligent leakage detection system of the servomotor of the water turbine comprises a sensor set connected with the servomotor. The sensor set is connected with an upper computer with a fault diagnosis function through a data acquisition card to form a data transmission channel. The upper computer is connected with a hydraulic station through a PLC to form a control loop. The intelligent leakage detection system of the servomotor of the water turbine has the beneficial effects that the intelligent leakage detection system and method are adopted, the on-line detection of the servomotor on the spot is achieved, the defect that a hydraulic servomotor can only be dismounted to be subject to the leakage analysis is overcome. Meanwhile, the intelligent leakage detection system and method provides an intelligent computer detection method, thereby getting rid of the defect of traditional artificial and unaided eye detection.

Owner:STATE GRID CORP OF CHINA +2

Fault Diagnosis Method of Inverter Power Tube Open Circuit in Permanent Magnet Synchronous Motor Control System

ActiveCN110441643BRealize online fault diagnosisImprove anti-interference abilityElectric testing/monitoringContinuity testingMotor speedVoltage pulse

The invention relates to an inverter power tube open circuit fault diagnosis method in a permanent magnet synchronous motor control system. According to the method, a differential current state observer is designed based on a voltage balance equation to estimate the ideal differential current of the permanent magnet synchronous motor, and the distortion amount of the motor differential current isestimated by combination of the measured value of the differential current; and then a corresponding fault detection and positioning algorithm is designed according to the distortion rule of the motordifferential current caused by faults, so that the rapid and accurate on-line fault diagnosis of the circuit fault of the inverter switch tube is realized. The method has the advantages of being highin anti-jamming capability, strong in robustness, high in detection speed, high in detection accuracy and the like. In addition, the method can also be suitable for motor speed stabilization and speed change stages, and is suitable for two different modulation modes (a spatial voltage pulse width modulation mode or a carrier-based pulse width modulation mode). Therefore, the method is a universalvoltage source type inverter single switch tube open circuit fault diagnosis method.

Owner:BEIHANG UNIV

A method of testing the initial position angle of motor rotor

ActiveCN106787995BThere is no problem with the convergence of test resultsSimple on-site operationVector control systemsElectronic commutatorsElectric machineTerminal voltage

The invention discloses a method for testing the initial position angle of a motor rotor, which solves the technical problems of high requirements for testing conditions for the initial position angle of the motor rotor and difficult actual operation in the prior art. The method includes the following steps: Step 1, firstly, a current i is given to the motor to be tested to make the motor run; Step 2, after the motor runs, the current i is set to zero, that is, i d =0 and i q =0; Step 3, read the voltage u of the motor stator d-axis and q-axis in the converter at this time d , u q ; Step 4, according to u d , u q The trigonometric function relationship between the calculation obtains the initial position angle deviation θ of the motor rotor err . The invention uses the d-axis and q-axis voltages of the motor stator to directly calculate the initial position angle deviation of the motor rotor; the corresponding relationship between the motor terminal voltage and the initial rotor position angle in the motor controller is clarified; the method is simple and suitable for engineering field operations; Fault diagnosis and error correction control to improve system functional safety.

Owner:JING JIN ELECTRIC TECH HEZE CO LTD

A maglev train speed and distance measurement system

ActiveCN109318938BCompact structureReduce installation difficultyRailway signalling and safetyAnti jammingIn vehicle

Owner:TONGJI UNIV

An Automatic Fault Diagnosis System Triggered Based on Fault Model

ActiveCN106837707BRealize online fault diagnosisRealize automatic fault diagnosisMachines/enginesWind motor monitoringElectricityVibration acceleration

The invention discloses an automatic fault diagnosis system based on fault model trigger. The system comprises a sensor, a fault model, a fault classifier and a fault grade evaluation module. The sensor acquires vibration acceleration signals of all components of equipment to be detected; corresponding component types, component fault feature frequency and corresponding component fault codes including the component types and the component fault feature frequency are stored in the fault model, and when frequency components matched with the component fault feature frequency exist in the vibration acceleration signals, the component fault codes are sent to the fault classifier, and a start signal is sent to the fault grade evaluation module; the fault classifier is used for classifying the component fault codes, searching for corresponding fault type information and outputting the fault type information serving as a fault type diagnosis result; and the fault grade evaluation module is used for calculating vibration intensity according to the vibration acceleration signals after the start signal is received and evaluating the fault grade to obtain the fault grade diagnosis result. According to the automatic fault diagnosis system, the fault diagnosis efficiency of wind turbine generators and other equipment can be improved.

Owner:北京能高普康测控技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com