Rotor ground on-line monitoring device and method based on adaptive frequency square-wave voltage

A rotor grounding and monitoring device technology, which is applied in measuring devices, motor generator testing, measuring electricity, etc., can solve the problem that the gradual faults of system equipment cannot be displayed in time, cannot fully meet the condition maintenance of power plants, and cannot accurately determine the fault mechanism and other problems to achieve the effect of shortening the maintenance time, overcoming the excitation voltage and reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

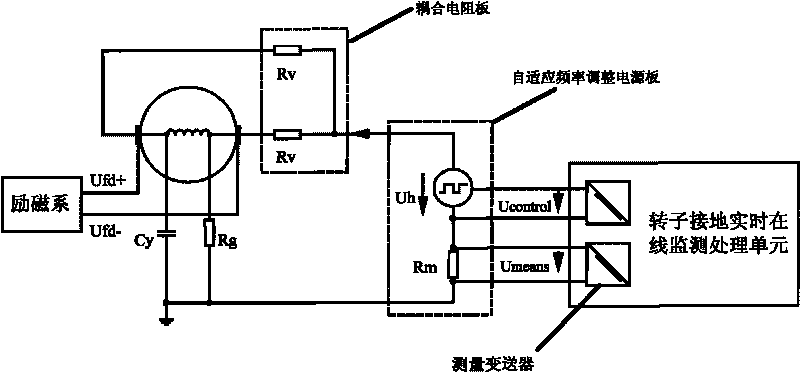

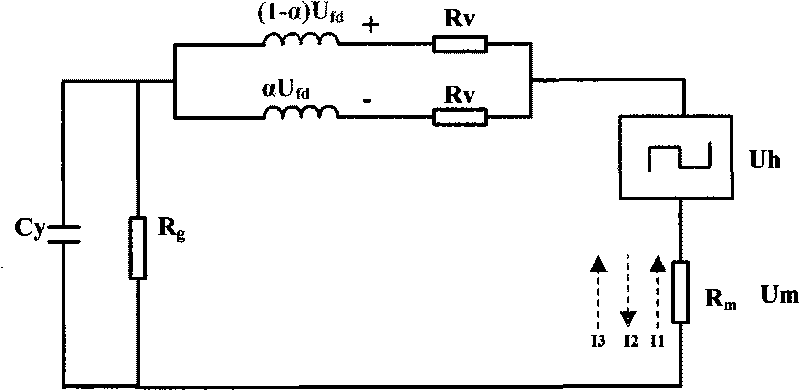

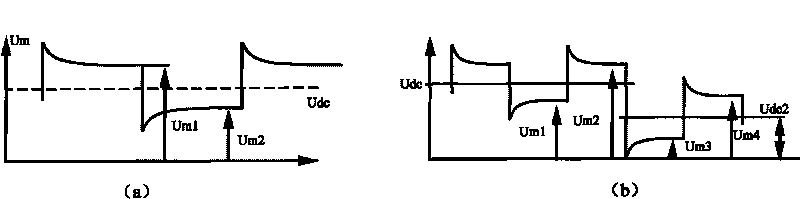

[0033] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

[0034] Such as figure 1 As shown, the rotor grounding online monitoring device based on the adaptive frequency square wave voltage of the present invention is characterized in that it includes a rotor grounding real-time online monitoring processing unit, an adaptive frequency adjustment square wave power supply board, a coupling resistance board, and first and second measurement Transmitter, in which the input ends of the coupling resistance board are respectively connected to the excitation voltage input end of the generator, the output end of the coupling resistance board is connected in series with the adaptive frequency adjustment square wave power board and then grounded, and the control of the adaptive frequency adjustment square wave power board The end is connected in series with the first measurement transmitter and then connected to the input end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com