Steel structural concrete-based pre-cast bolt positioning device

A technology of pre-embedded bolts and positioning devices, applied in the field of machinery, can solve problems affecting construction quality, easy to deviate from the installation position, etc., and achieve the effects of improving installation quality, improving accurate positioning, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

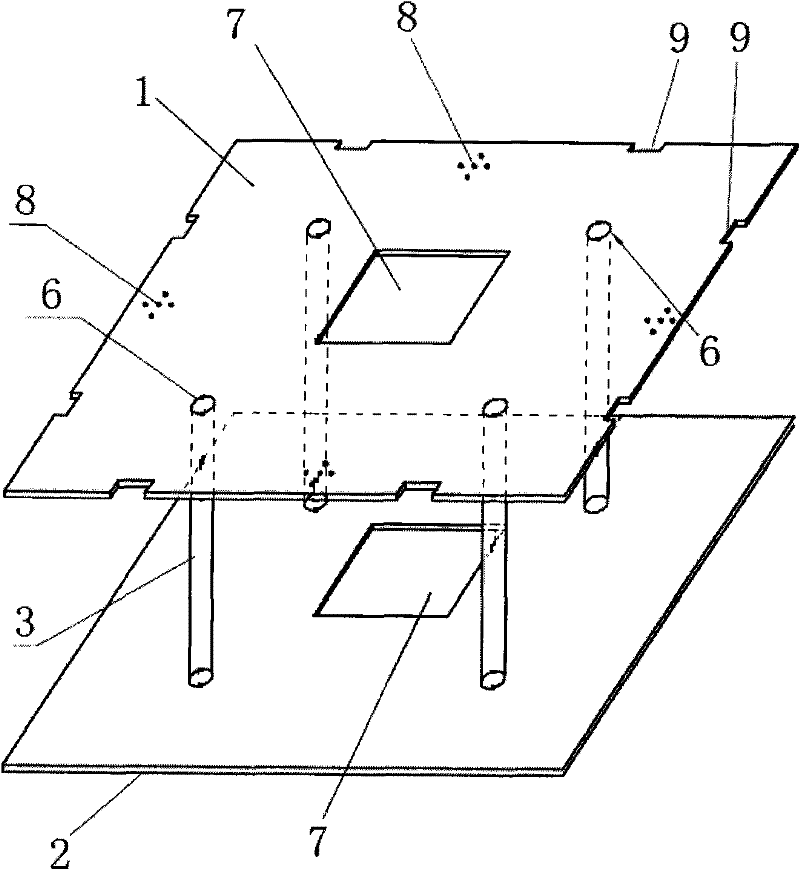

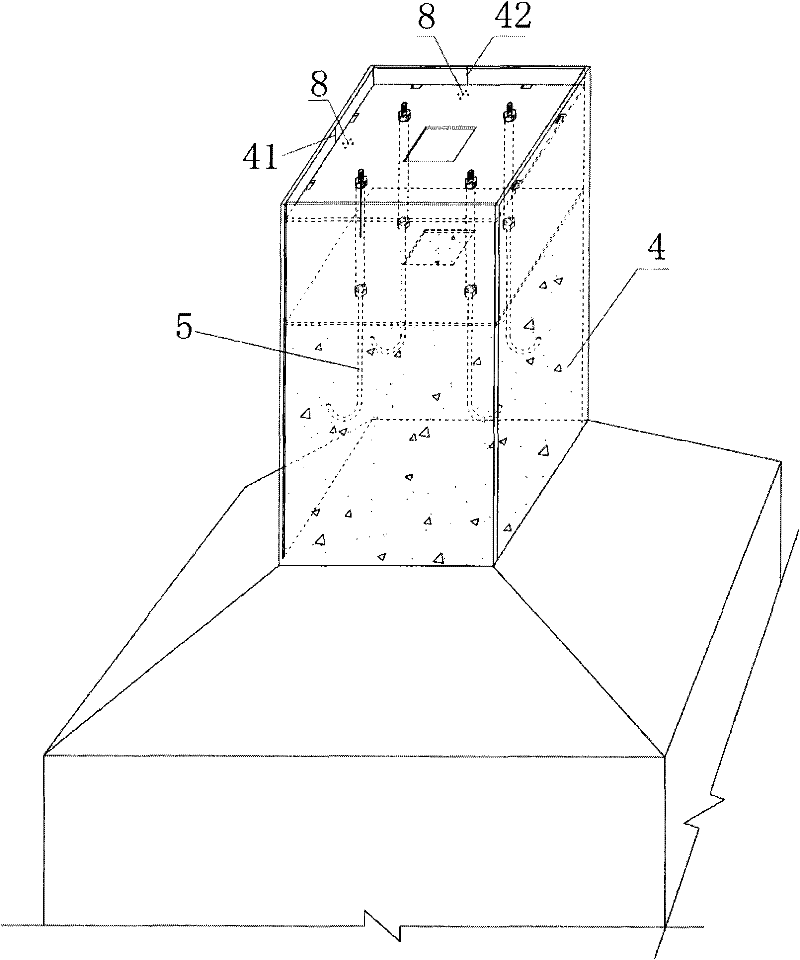

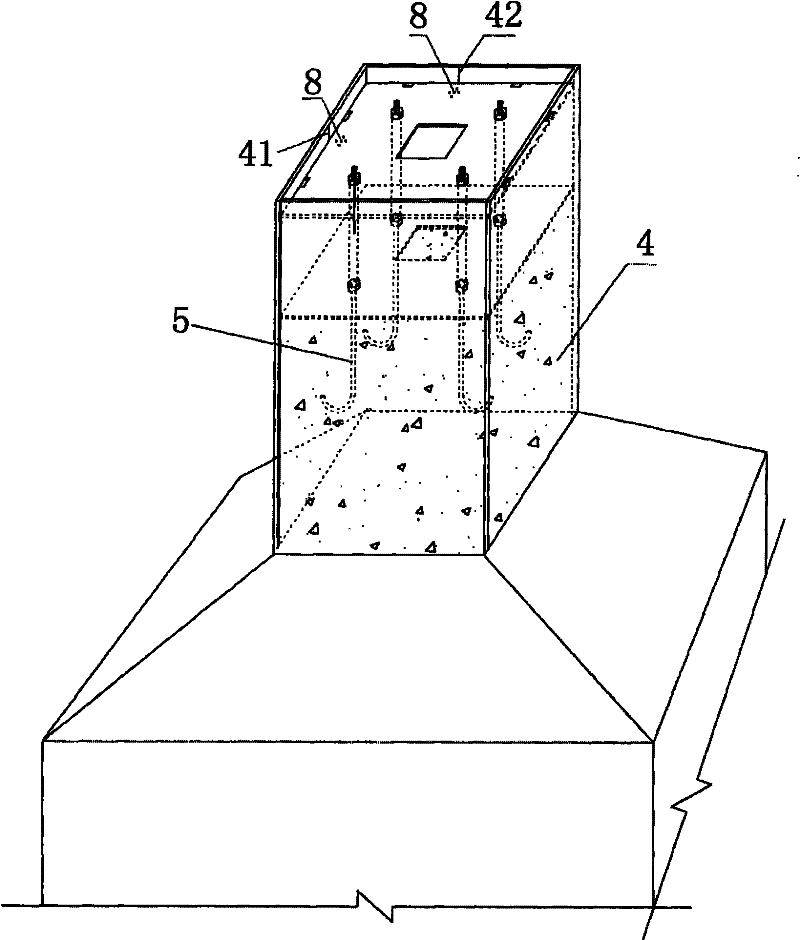

[0014] Such as figure 1 and figure 2 As shown, a steel structure concrete foundation embedded bolt positioning device of the present invention is composed of an upper formwork 1, a lower formwork 2 and a bolt casing 3, the upper formwork 1 and the lower formwork 2 are arranged in parallel up and down, and the upper formwork 1 and the lower formwork 2 is rectangular, and the corresponding side lengths are equal, the length of the upper formwork 1 and the lower formwork 2 is 10 mm smaller than the length of the cross-section of the concrete-based steel form 4 during pouring, and the width of the upper formwork 1 and the lower formwork 2 is less than that of the pouring The width of the cross-section of the concrete-based steel mold 4 is 10 mm, and the bolt sleeves 3 are welded on the upper formwork 1 and the lower formwork 2 respectively. The bolt sleeves 3 are perpendicular to the upper formwork 1 and the lower formwork 2, and the bolt sleeves 3 The inner diameter of the bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com