Punching tool facilitating installation of tunnel equipment

A technology for equipment installation and tunneling, applied in manufacturing tools, stone processing tools, stone processing equipment, etc., can solve problems such as poor stability, inaccurate drilling direction, and inability to complete precise drilling, and achieve the effect of improving precise positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

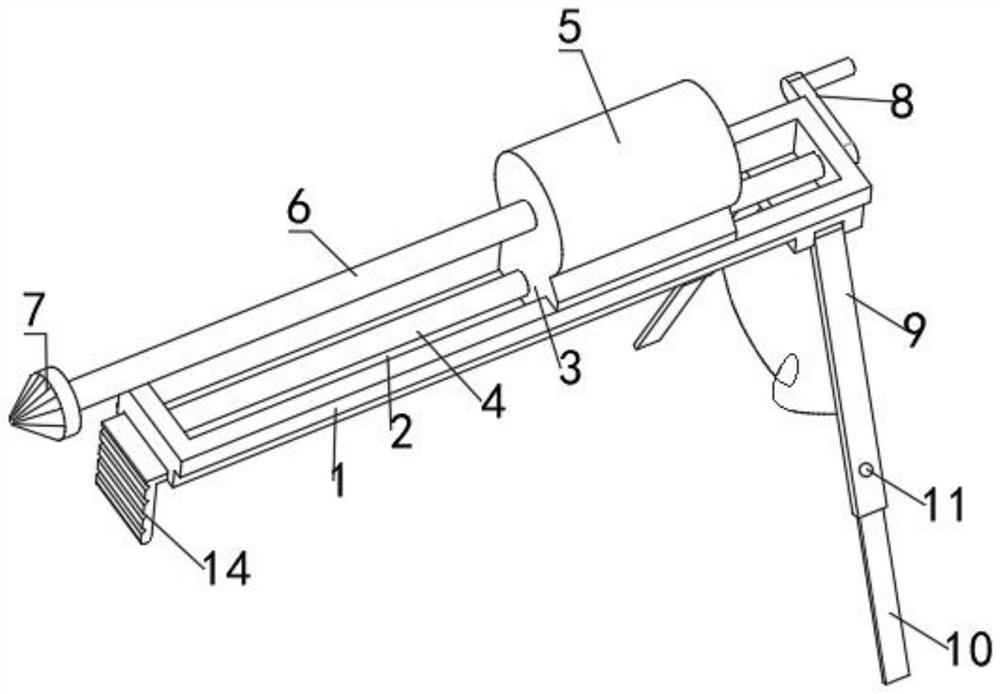

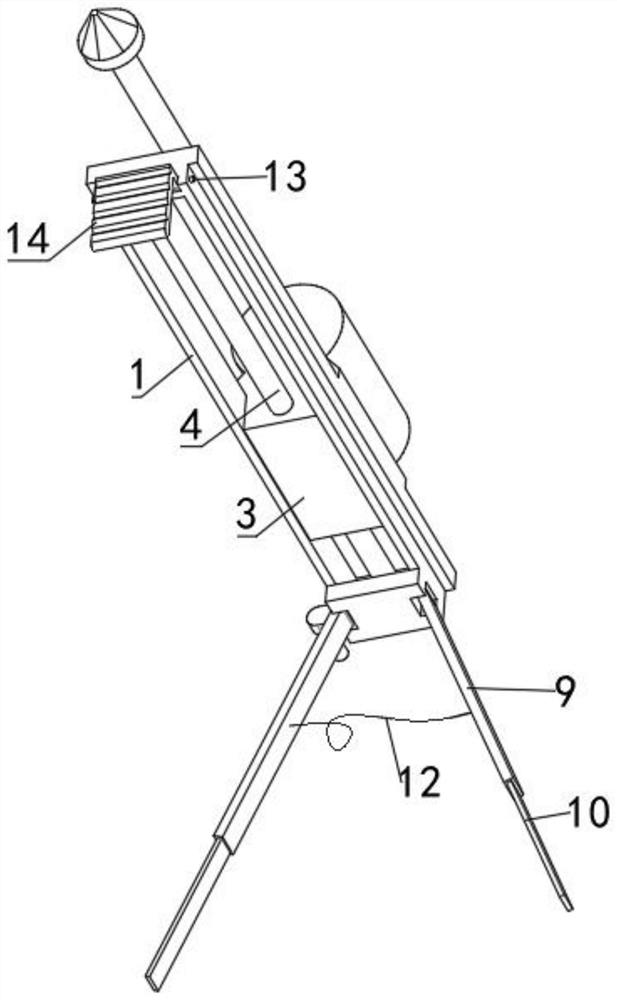

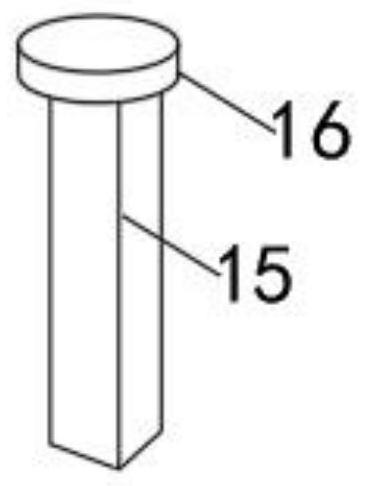

[0024] see Figure 1 to Figure 3 . The present invention provides a technical solution: a drilling tool that facilitates the installation of tunnel equipment, including a horizontally arranged motor mounting base 1, the upper surface of the motor mounting base 1 is provided with a chute 2, and the inner side of the chute 2 The wall is plugged with a motor base 3, the two sides of the motor base 3 are screwed with a screw 4 along the length direction of the chute 2, and the two ends of the screw 4 are screwed with the two ends of the chute 2, And one end of the screw mandrel 4 protrudes from the outside of the motor mount 1, a motor 5 is fixedly installed on the top of the motor mount 3, and a motor 5 parallel to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com