Side suction type range hood

A range hood and side-suction technology, applied in the field of side-suction range hoods, can solve problems such as shortening the service life of motors and return errors, and achieve the effects of increasing service life and improving precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

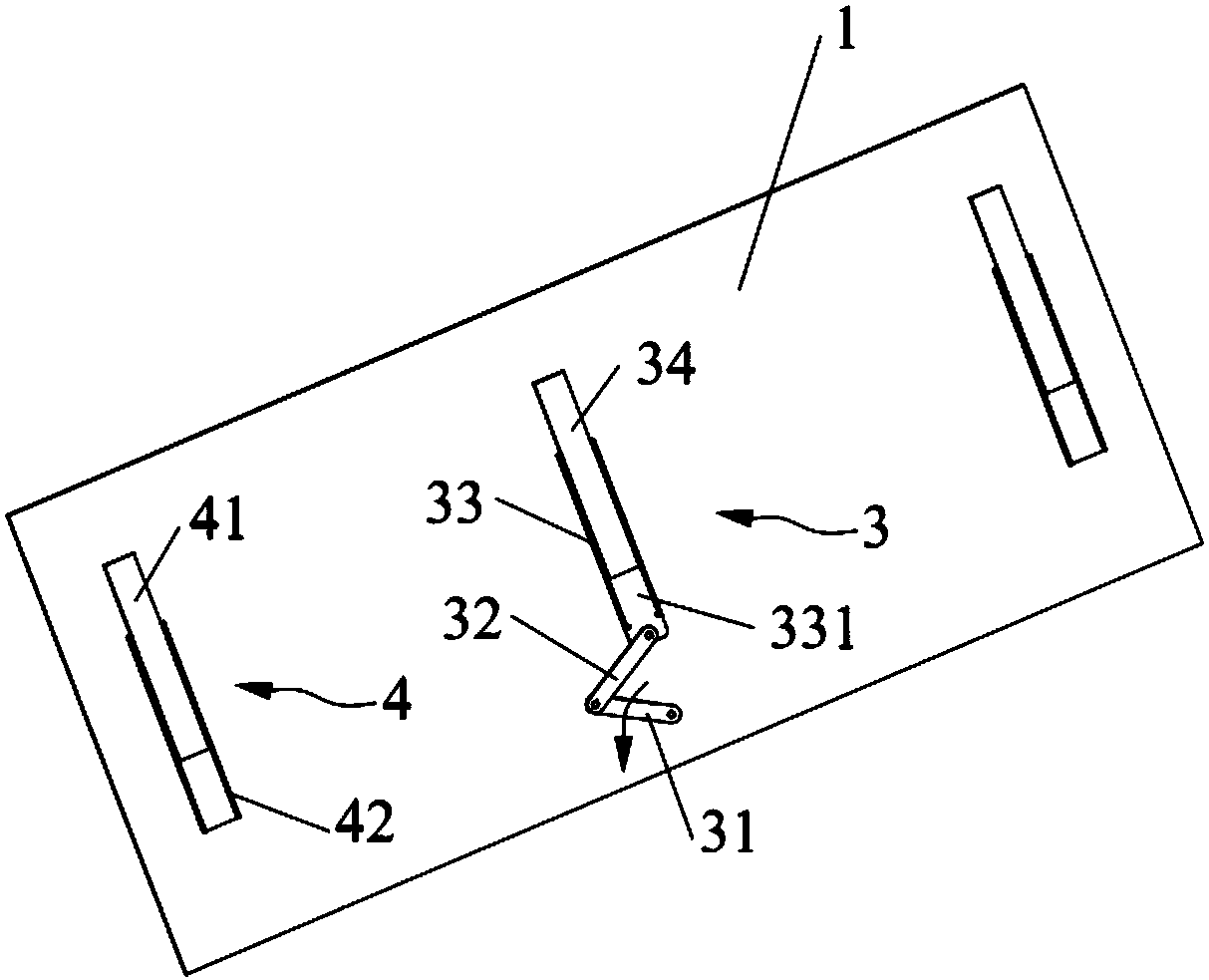

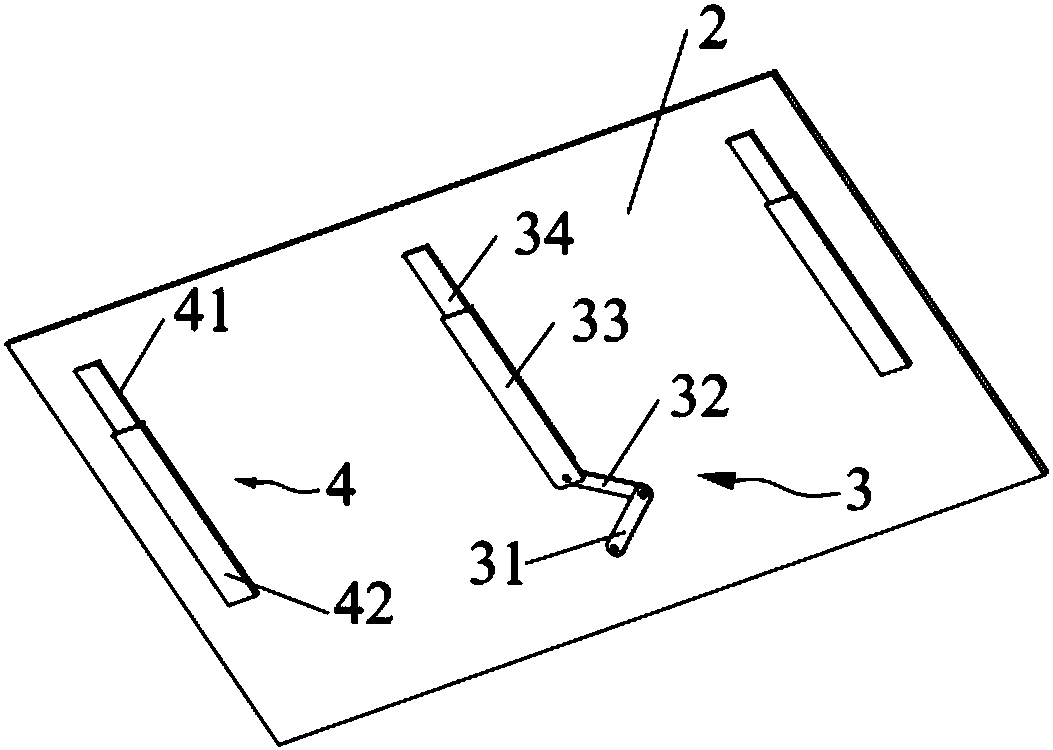

[0026] This embodiment provides a side suction range hood, the side suction range hood includes a box body and a panel 1, the air inlet of the box body is provided with a mesh plate 2, such as figure 1 and figure 2 As shown, the side suction range hood also includes a transmission mechanism 3 connected between the net plate 2 and the panel 1, the transmission mechanism 3 is connected with a driving mechanism, and the driving mechanism rotates in a direction to drive the The transmission mechanism 3 drives the panel 1 to reciprocate and periodically move linearly. Wherein, the driving mechanism is arranged in the box body.

[0027] In this embodiment, a transmission mechanism 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com