Fault diagnosing method of observing injection timing based on characteristic parameters of waveform of rail pressure

A technology of fuel injection timing and waveform characteristics, which is applied in the field of fault diagnosis of high-pressure common rail fuel injection systems of diesel engines, can solve rare and other problems, and achieve reliable fault diagnosis, high observation accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

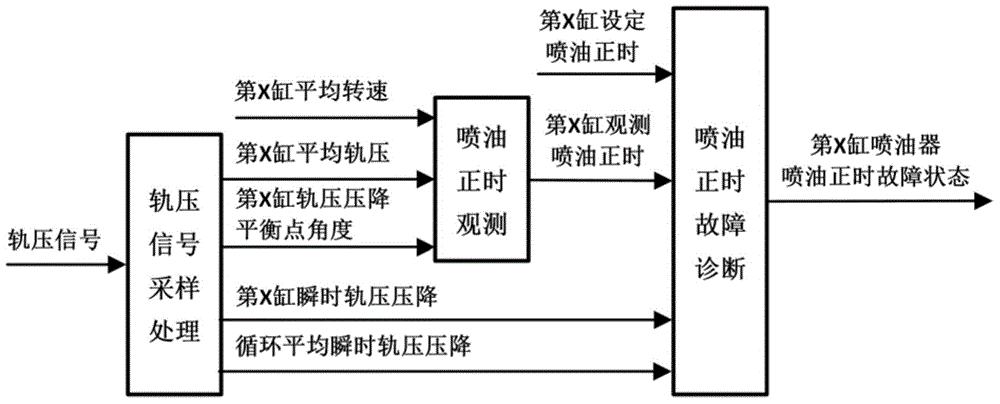

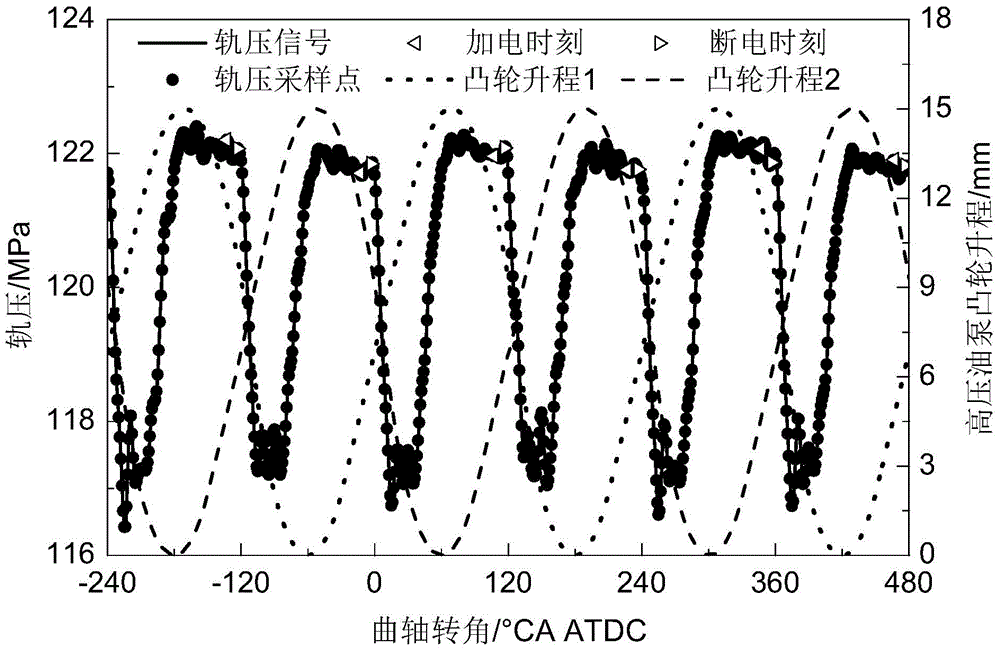

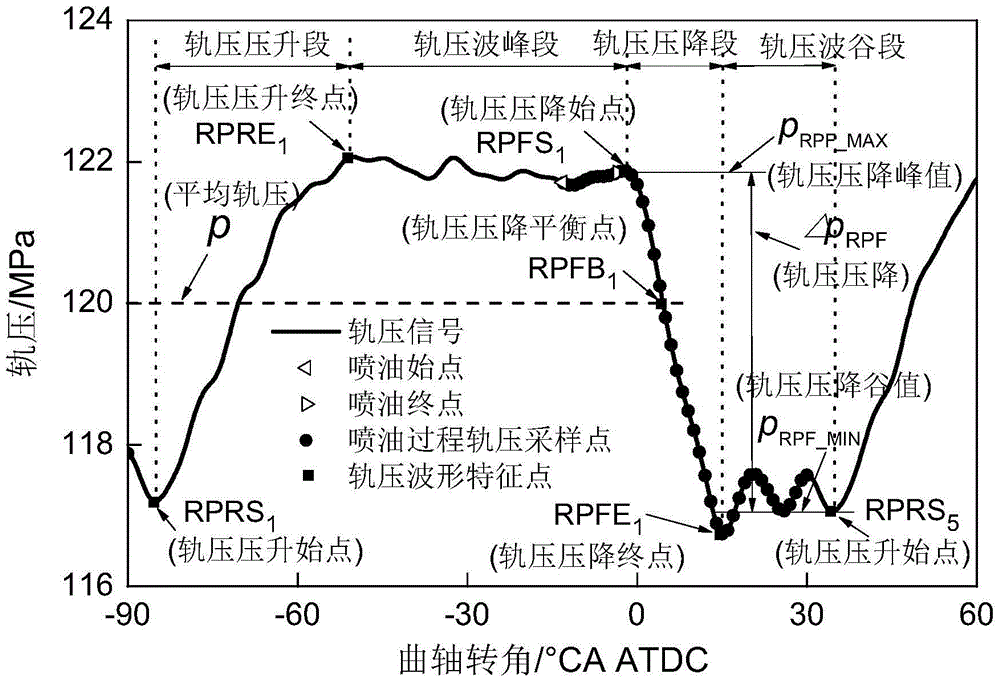

[0063] A fuel injection timing fault diagnosis method based on the observation of rail pressure waveform characteristic parameters of the present invention includes a rail pressure signal sampling processing step, a fuel injection timing observation step based on rail pressure waveform characteristic parameter observation, and a fuel injection timing based on the rail pressure waveform characteristic parameter observation step. Observed Injection Timing Troubleshooting Procedure. Firstly, the rail pressure drop balance point, average rail pressure, and average speed corresponding to each cylinder of the diesel engine are respectively obtained through rail pressure signal sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com