Distributed intelligent monitoring system for motor

A technology of intelligent motor and monitoring system, which is applied in the direction of motor generator testing, measuring electricity, and measuring devices, and can solve problems such as data analysis and processing, equipment safety and hidden dangers in industrial production, real-time identification of difficult motors, fault diagnosis and prediction, etc. Achieve the effect of equipment and personnel safety guarantee and ensure safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

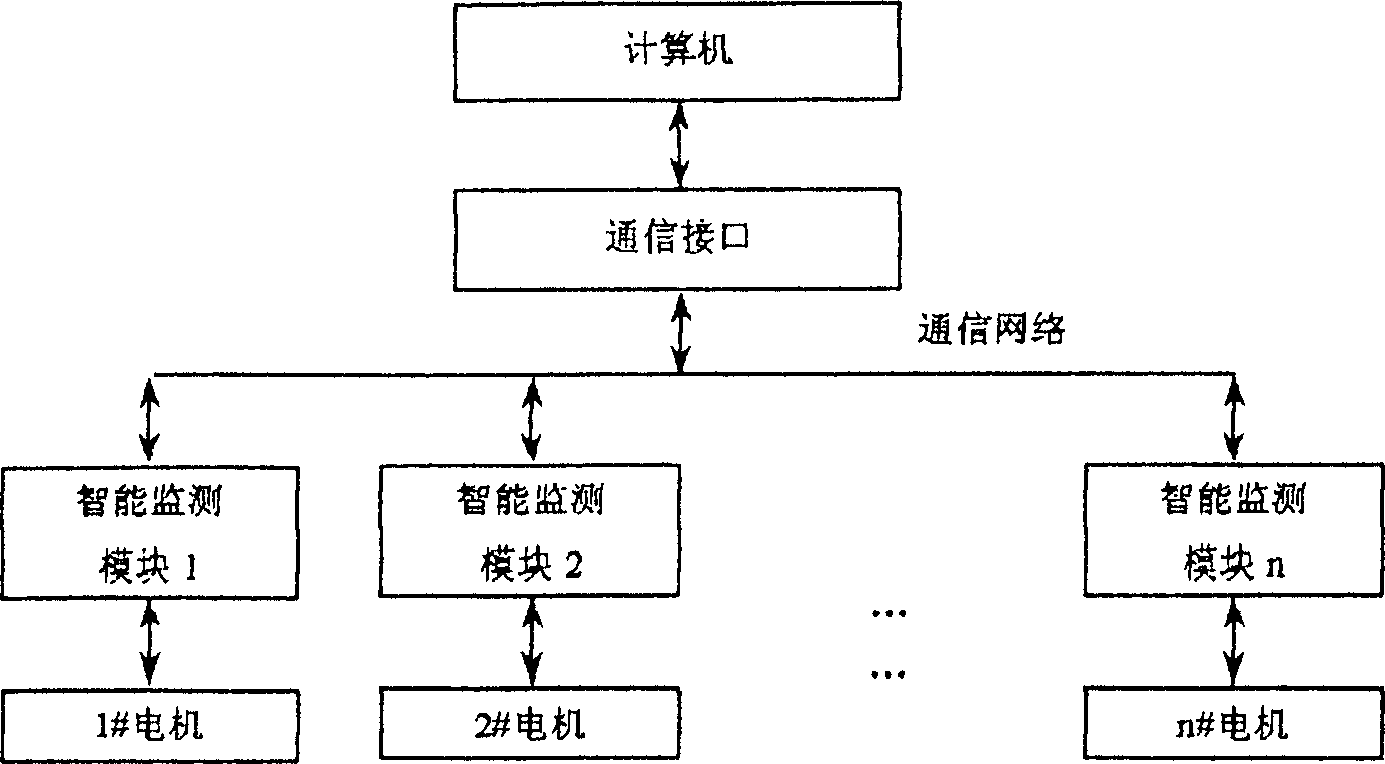

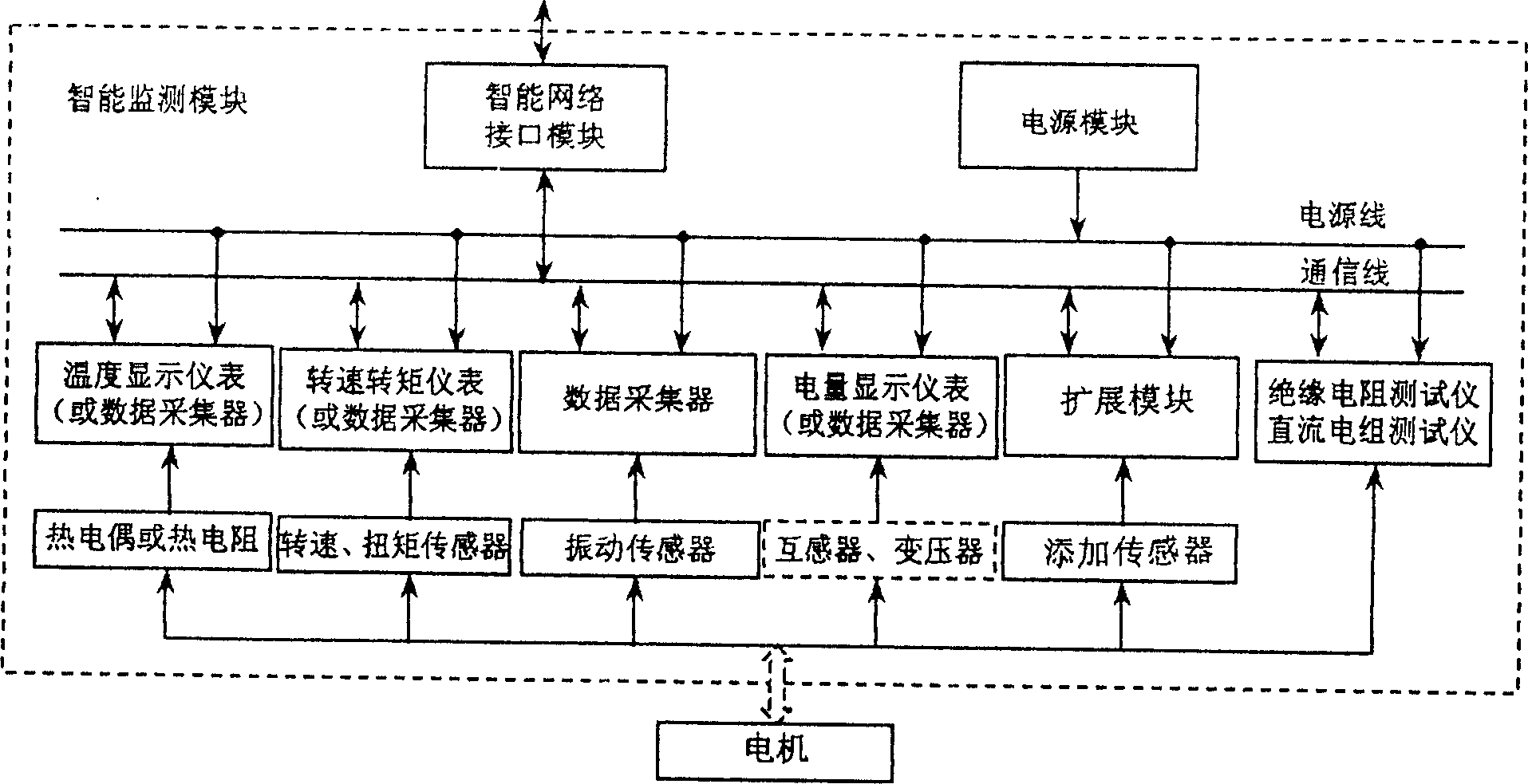

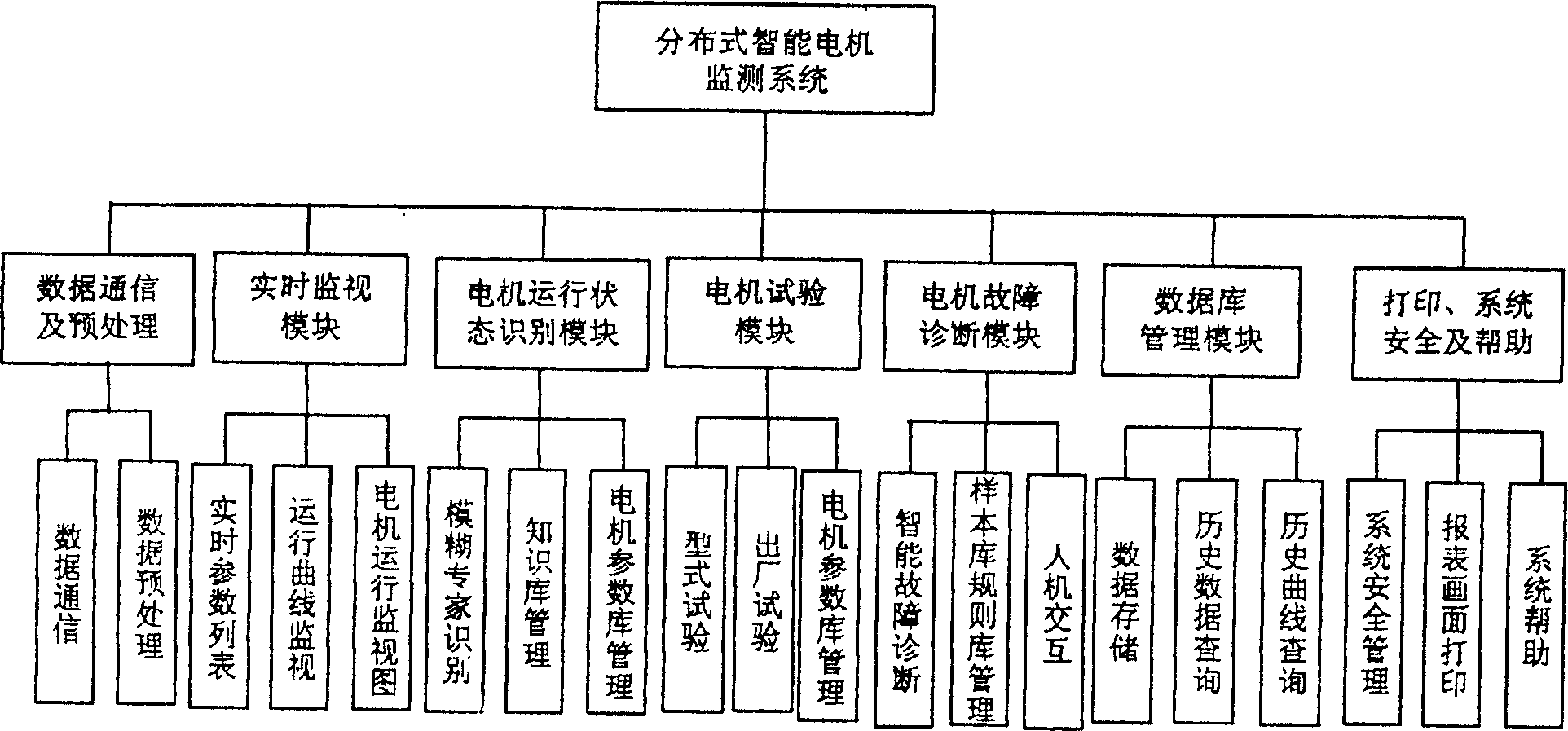

[0017] see figure 1 , the distributed intelligent motor monitoring system of the present invention comprises the bottom intelligent monitoring sub-station and the high-level intelligent monitoring general station (computer), wherein the monitoring sub-station is connected with the motor at the corresponding position, and is controlled by the intelligent monitoring system comprising monitoring instruments, meters, and data collectors. Composed of modules, the intelligent monitoring station is composed of a computer that realizes centralized processing of motor information and intelligent monitoring. The underlying monitoring sub-station determines the corresponding independent site number or IP address according to the model and location of the corresponding motor, and multiple indicators such as electric power parameters, speed, torque, temperature, noise, insulation, vibration, etc. of the motor are collected and analyzed by the corresponding underlying monitoring module. sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com