Fog lamp cover mounting structure

A technology for lampshades and fog lamps, which can be used in signal devices, transportation and packaging, bumpers, etc., and can solve problems such as poor aesthetics, and achieve the effect of improved appearance design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described below with reference to the drawings. In addition, left, right, front, and rear in the description represent orientations based on the driver seated in the vehicle. In addition, the drawings are viewed in the direction of the reference numerals.

[0031] (Example)

[0032] Examples of the present invention will be described.

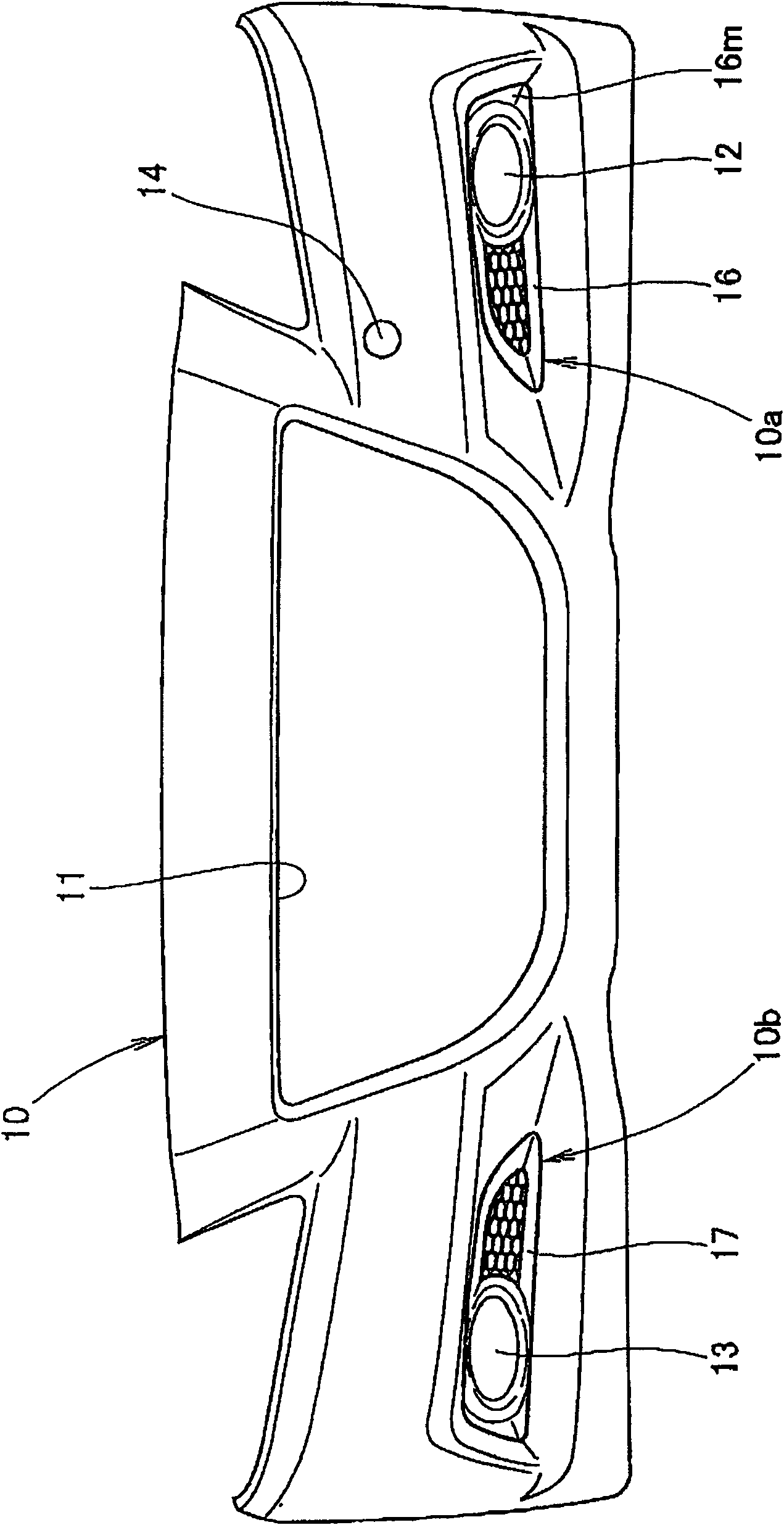

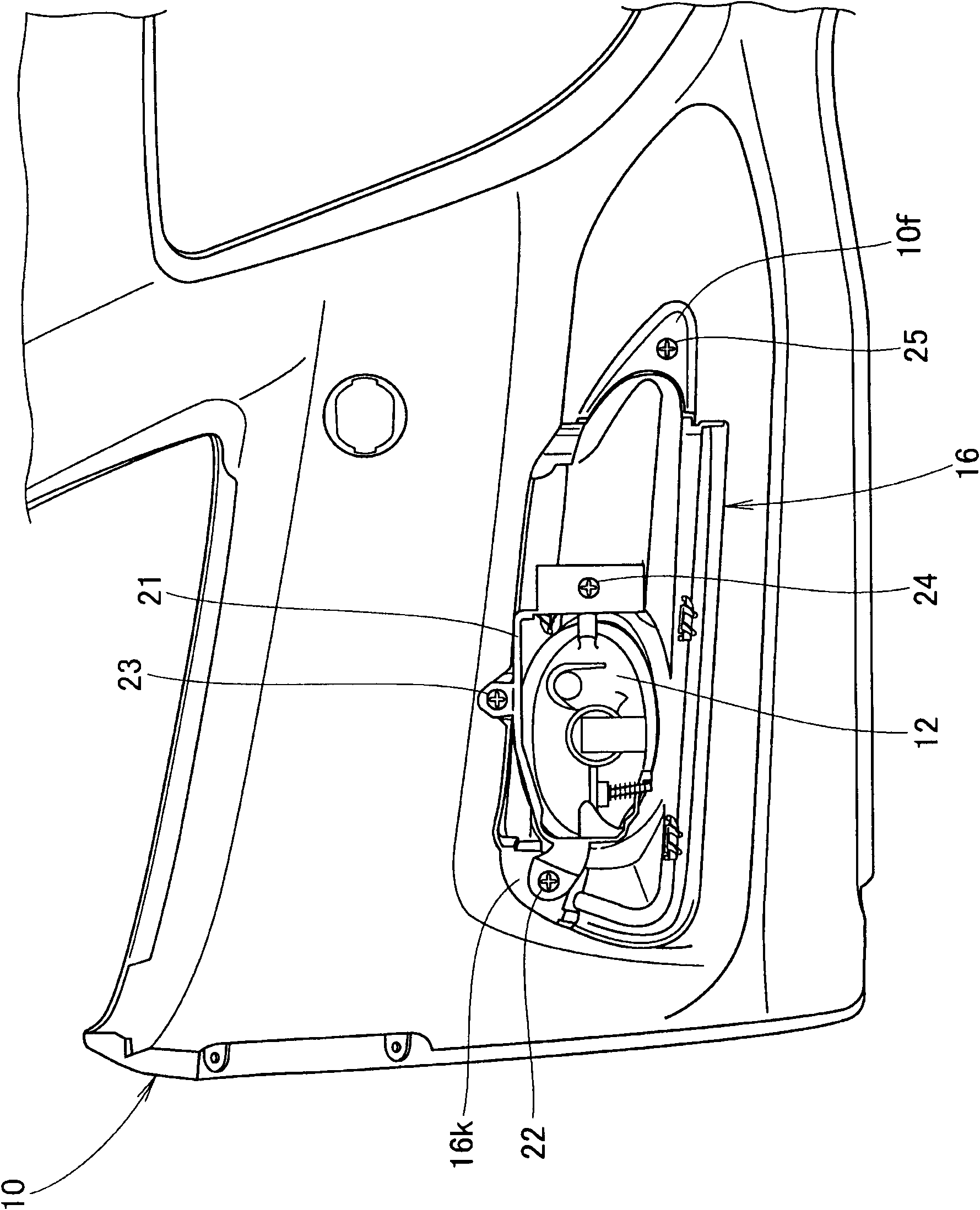

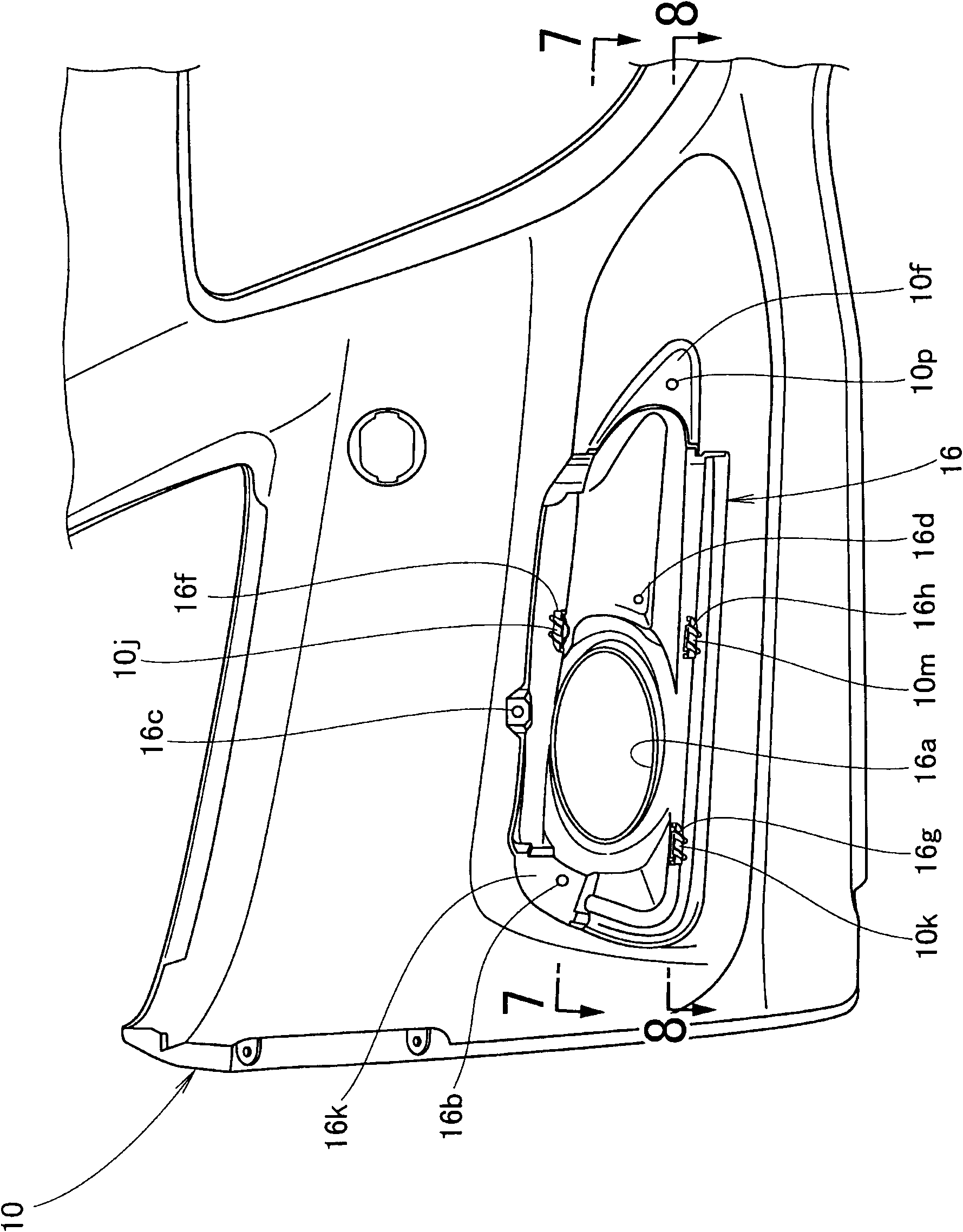

[0033] Such as figure 1 As shown, the bumper skin constituting the bumper together with energy absorbers, reinforcement members, etc., that is, the bumper surface 10 made of resin is attached to the left and right lower parts of the grille opening 11 provided in the center for attaching the front grille. There are a pair of fog lamps 12, 13, and an opening cover 14 is detachably attached to the left side of the opening 11 for the grille, and the opening cover 14 is used to plug the opening for the tow hook (not shown). ).

[0034] The fog lamps 12 and 13 are attached to edges of fog lamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com