Photoelectric conversion device

A photoelectric conversion element and electrode technology, which is applied in the direction of electrical components, photovoltaic power generation, and electric solid-state devices, can solve problems such as high practicability, safety issues, and inability to obtain performance, and achieve high practicability, improved design, and freedom. The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] [Production of Porous Metal Oxide Semiconductor]

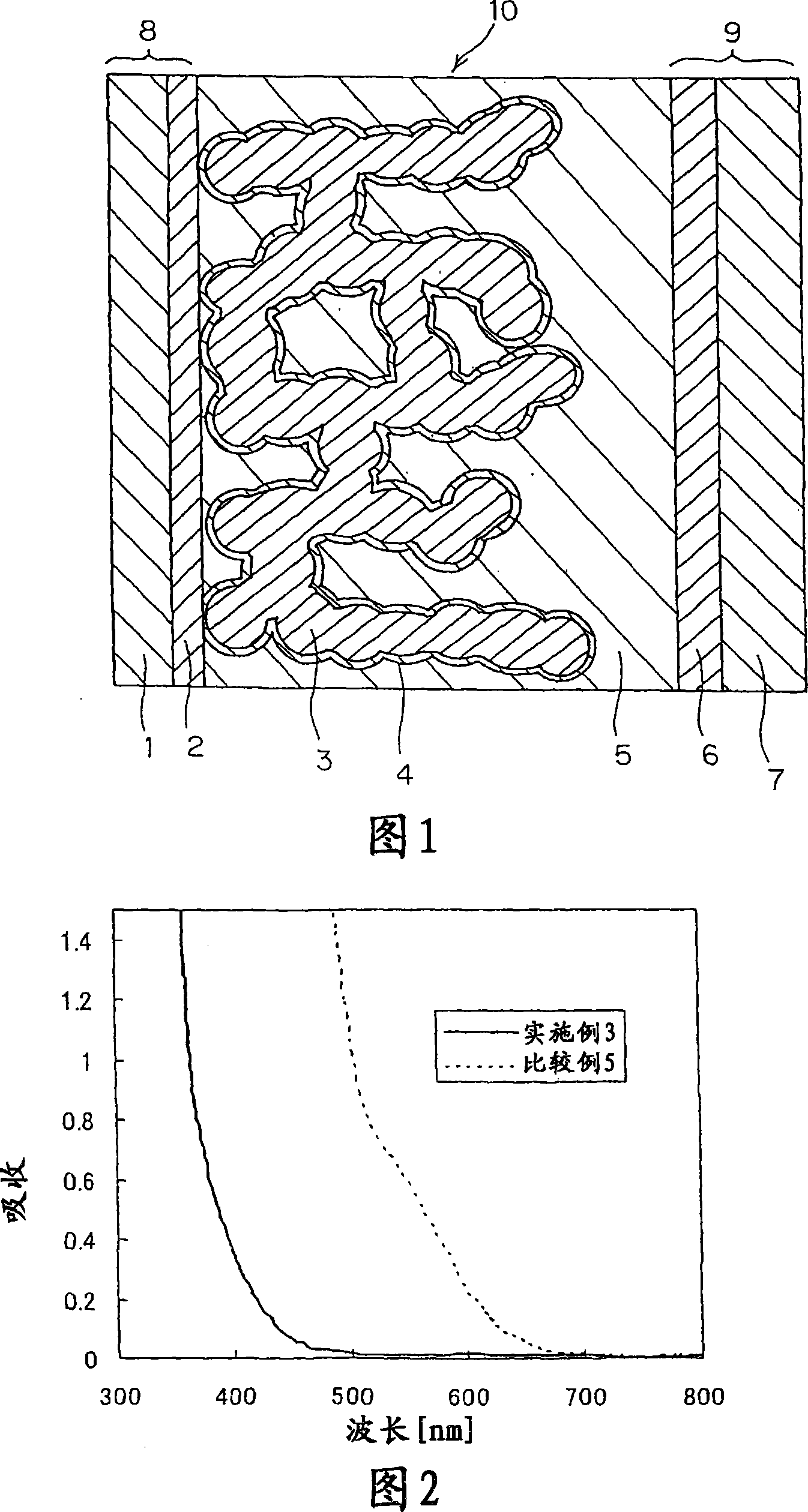

[0138] SnO doped with fluorine was formed by vacuum evaporation on a transparent substrate 1 made of glass. 2 To form the transparent conductive film, the porous metal oxide semiconductor layer 3 was formed on the transparent conductive film 2 by the following method.

[0139]As the electrode substrate 8 on which the transparent conductive film 2 is formed on the transparent substrate 1, FTO glass (manufactured by Nippon Sheet Glass Co., Ltd.) is used, and the film thickness of about 6 μm and the area of about 5 mm×10 mm are formed on the surface by the screen printing method. On the surface of the transparent conductive film 2 side, print a commercially available titanium oxide paste (manufactured by Catalyst Chemicals Co., Ltd., trade name: TSP-18NR, particle size 20nm), and then use the screen printing method on the same area, A commercially available titanium oxide paste (manufactured by Catalyst Kasei Co., Ltd.,...

Embodiment 2

[0149] A solar cell was produced in the same manner as in Example 1 except that 1-methyl-3-ethylimidazolium bis(trifluoromethanesulfonyl)imide was used as the solvent for the electrolyte layer 5 .

Synthetic example

[0171] A synthesis example of the redox couple of the present invention will be given below, but the synthesis method is not limited thereto, and known materials and synthesis methods can be used for production.

[0172] [Redox Pairs: Synthesis of Reductants]

[0173] Dissolve 1 molar equivalent of 5-methyl-2-mercapto-1,3,4-thiadiazole and 0.5 molar equivalent of potassium carbonate in methanol, and perform ultrasonic bath treatment while stirring until the potassium carbonate dissolves and disappears until (about 2.5 hours). Thereafter, the solid was removed using filter paper, the solvent was distilled off with a rotary evaporator, and the resulting white solid was washed with dichloromethane, followed by vacuum drying to synthesize 5-methyl-2-mercapto-1. 3,4-thiadiazole potassium salt. The reaction yield was 70%.

[0174]Next, 1 molar equivalent of the synthesized compound (concentration: 1M) was dissolved in acetone, and a solution (concentration: 1M) of 1 molar equival...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com