Flattening machine

A technology of flat cars and racks, applied in the field of material sorting devices, which can solve problems such as low efficiency and high labor intensity of human flat cars, and achieve the effect of liberating productivity and improving the efficiency of flat cars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

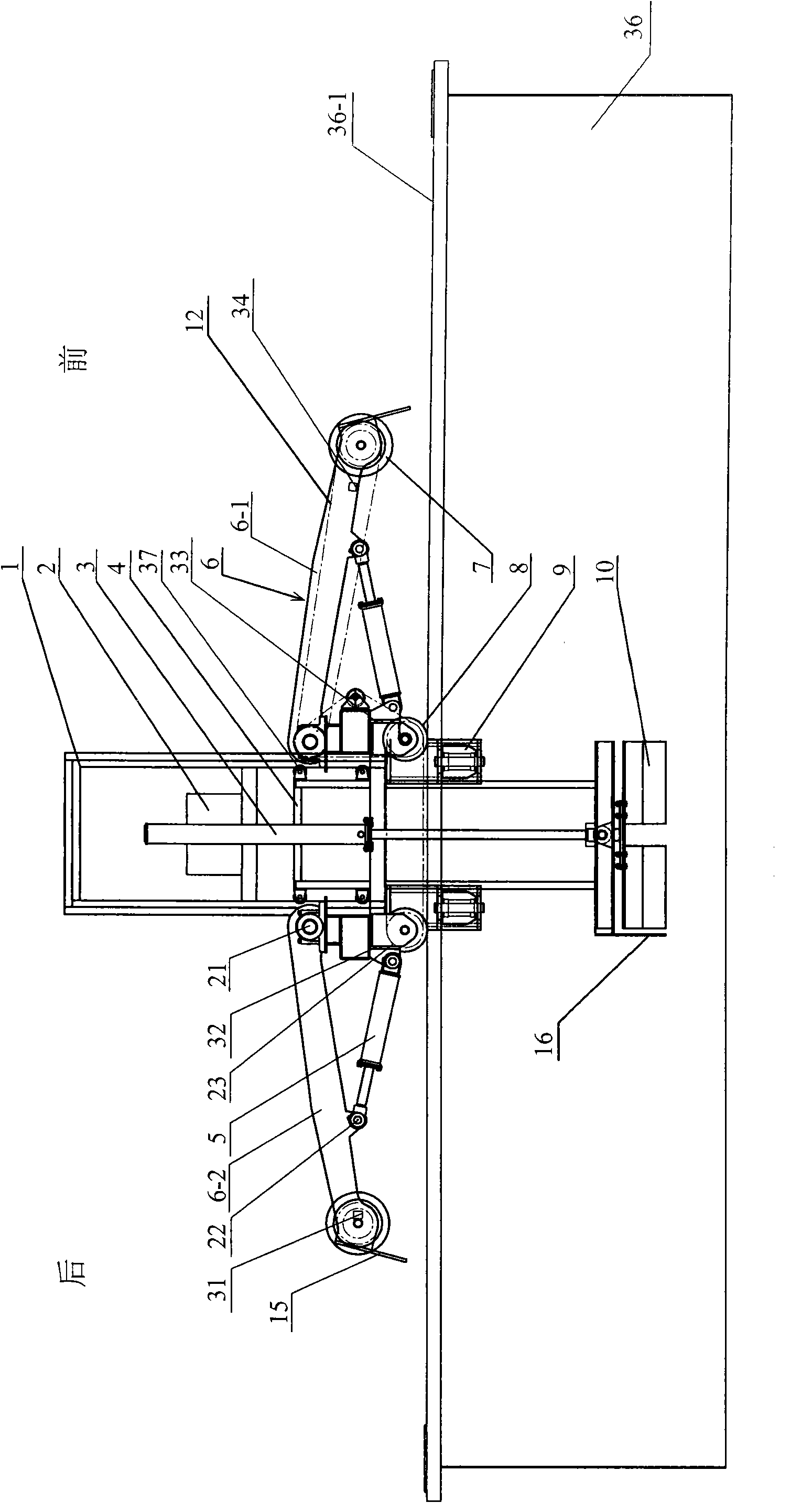

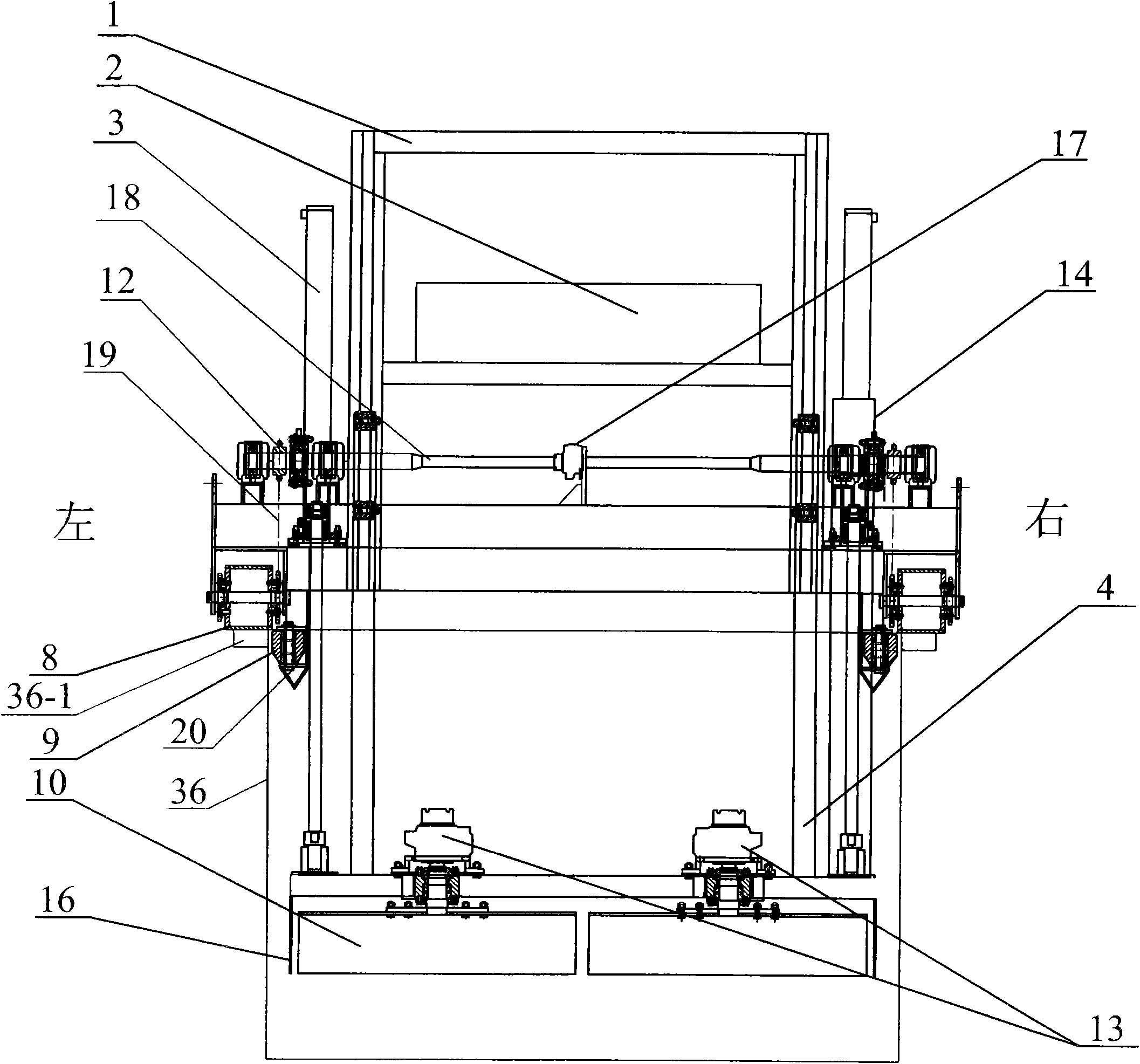

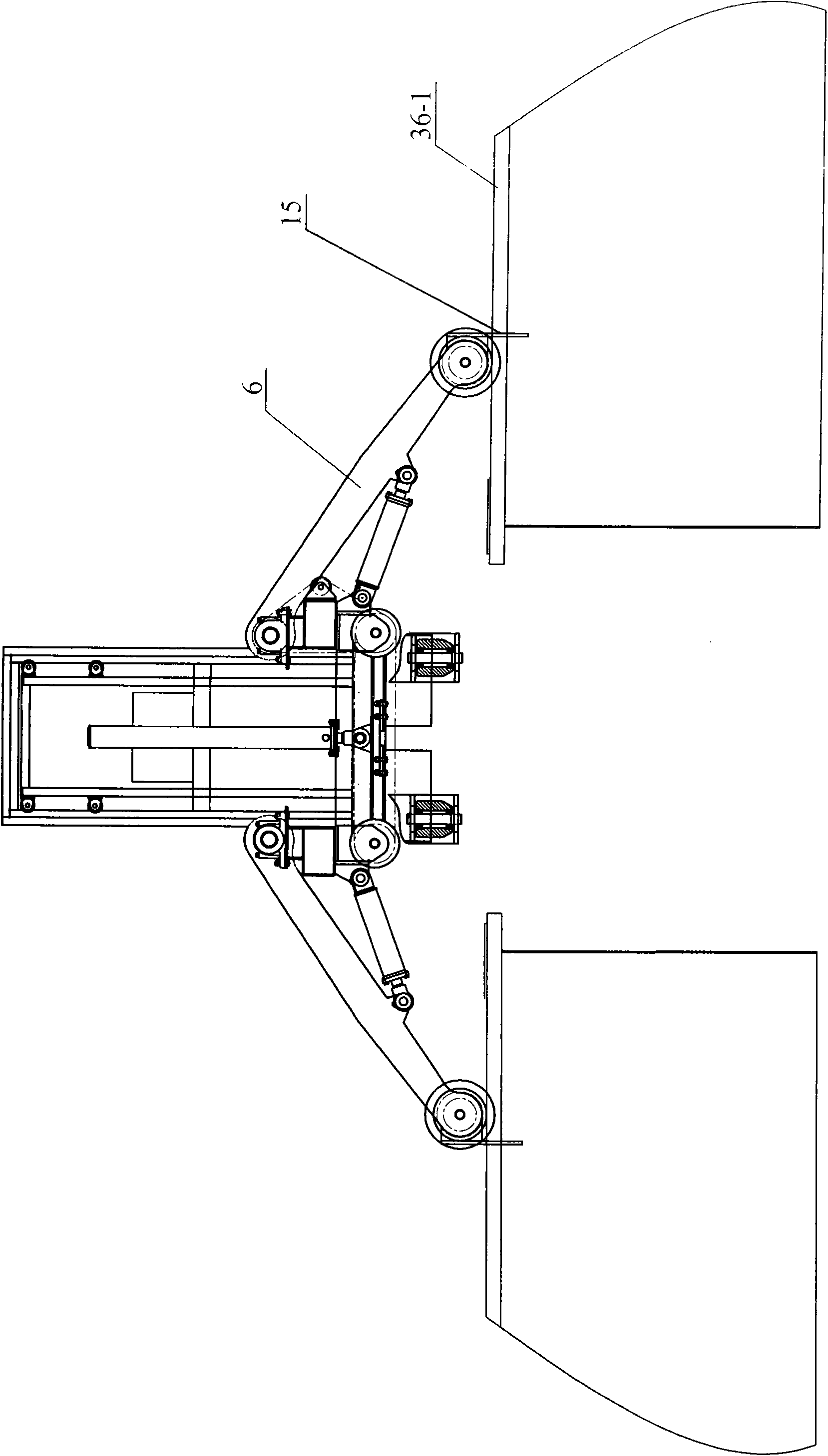

[0022] Embodiment one, see figure 1 As shown, the flat car machine of this embodiment is mainly composed of a frame 1, a flat car traveling mechanism, a horizontally rotating impeller 10 and a motor for driving the horizontally rotating impeller 10 to rotate. Wherein, the flat car running mechanism is installed on the frame 1, and can be composed of the flat car running wheels 8 installed on the bottom surface of the frame 1 and a driving mechanism for driving the flat car running wheels 8 to rotate. The flat car running wheels 8 are preferably provided with 4, two of which are installed on the front side of the frame 1, and the other two are installed on the rear side of the frame 1, and the front, rear, left and right sides are defined with the walking direction of the flat car machine four directions, such as figure 1 , figure 2 Notes shown (for clarity, figure 2 Some components in the straddle mechanism are omitted). The distance between the running wheels 8 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com