Automatical opening/closing type plating hanger

An electroplating rack, open-close technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of easy shaking of the circuit board and inconvenience of entering the circuit board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment:

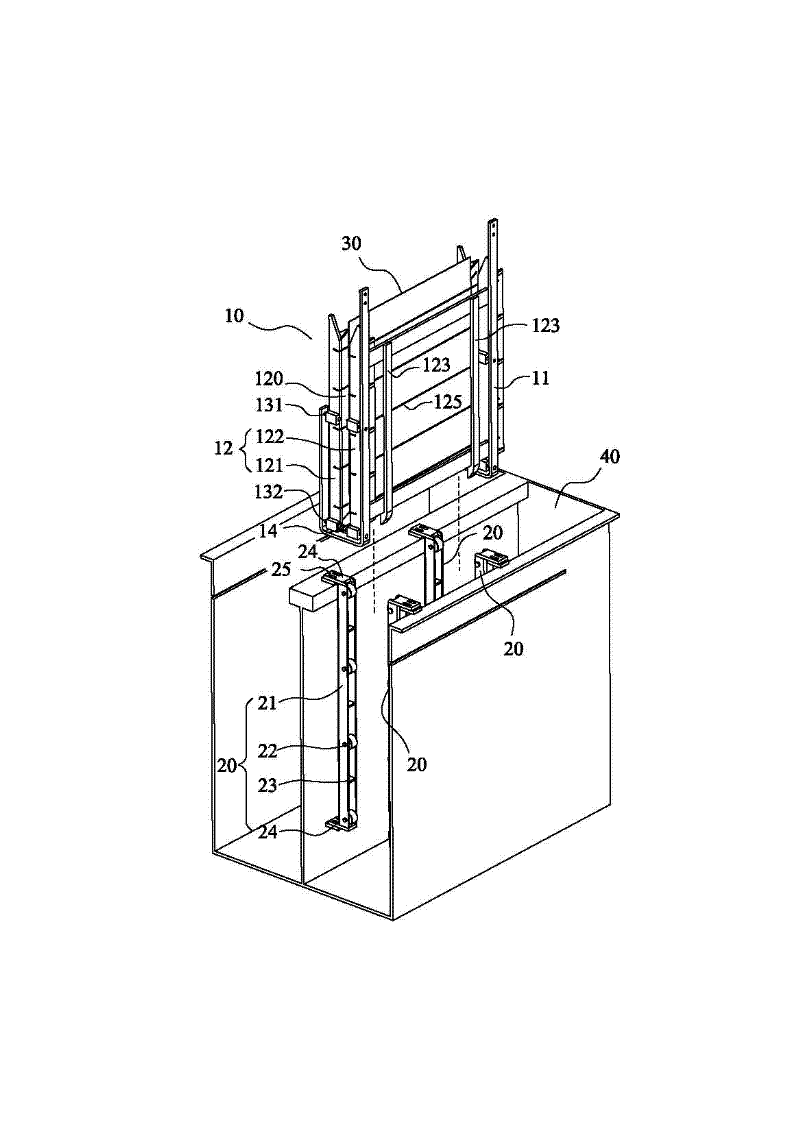

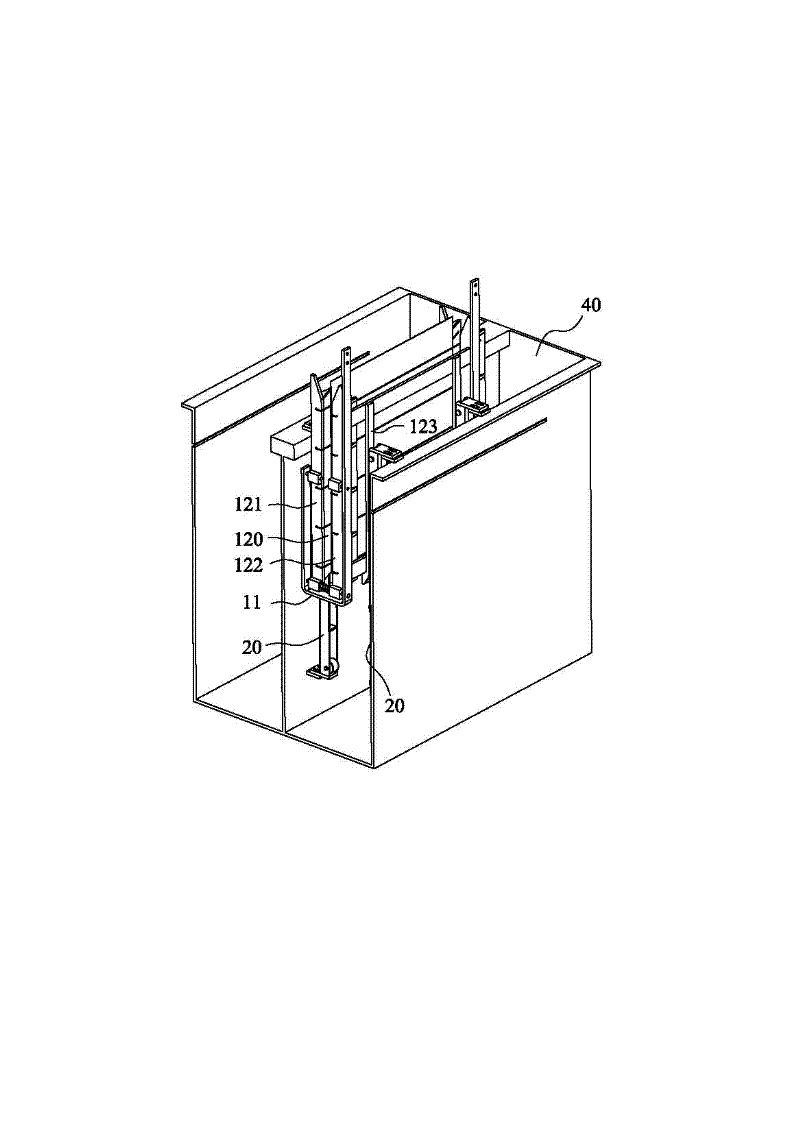

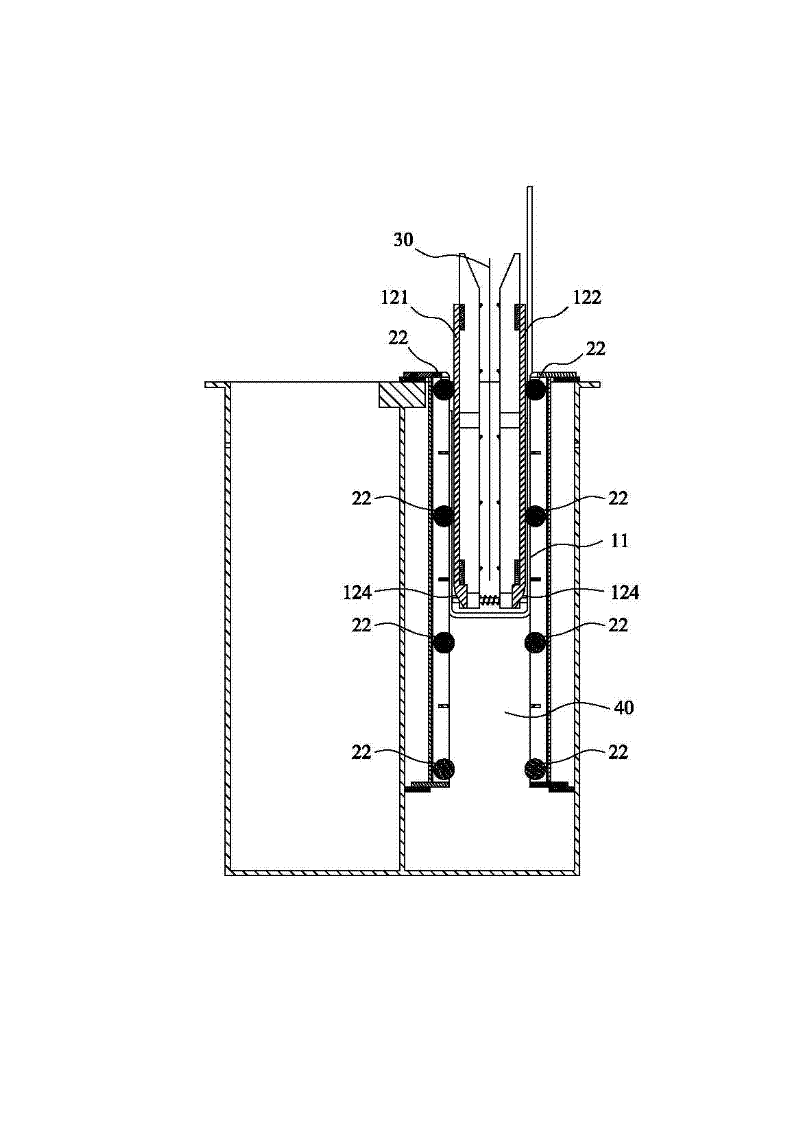

[0032] Please refer to Figure 1 to Figure 4 As shown, the specific structure of an automatic opening and closing type electroplating hanger of the present invention is shown, including a movable frame body 10 and a guide wheel mechanism 20, the movable frame body 10 can be lifted and lowered into the electroplating tank 40, and the guide wheel The mechanism 20 is installed on the tank walls on both sides of the electroplating tank 40 .

[0033] Specifically, the guide wheel mechanism 20 includes a vertical wheel seat 21 and a plurality of rollers 22. The vertical wheel seat 21 can be bent from PP board, and ribs 23 are preferably arranged in the bending groove. To play a strengthening role to ensure sufficient strength. The upper and lower ends of the vertical wheel base 21 are respectively provided with a fixed plate 24 for connecting with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com