Electric lifting stator inner cavity cyclometer

A technology of stator inner cavity and driving device, applied in mechanical counter/curvature measurement and other directions, can solve the problems of inability to guarantee the quality of motor stator assembly, time-consuming and laborious operation and low measurement accuracy, etc. Convenience and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

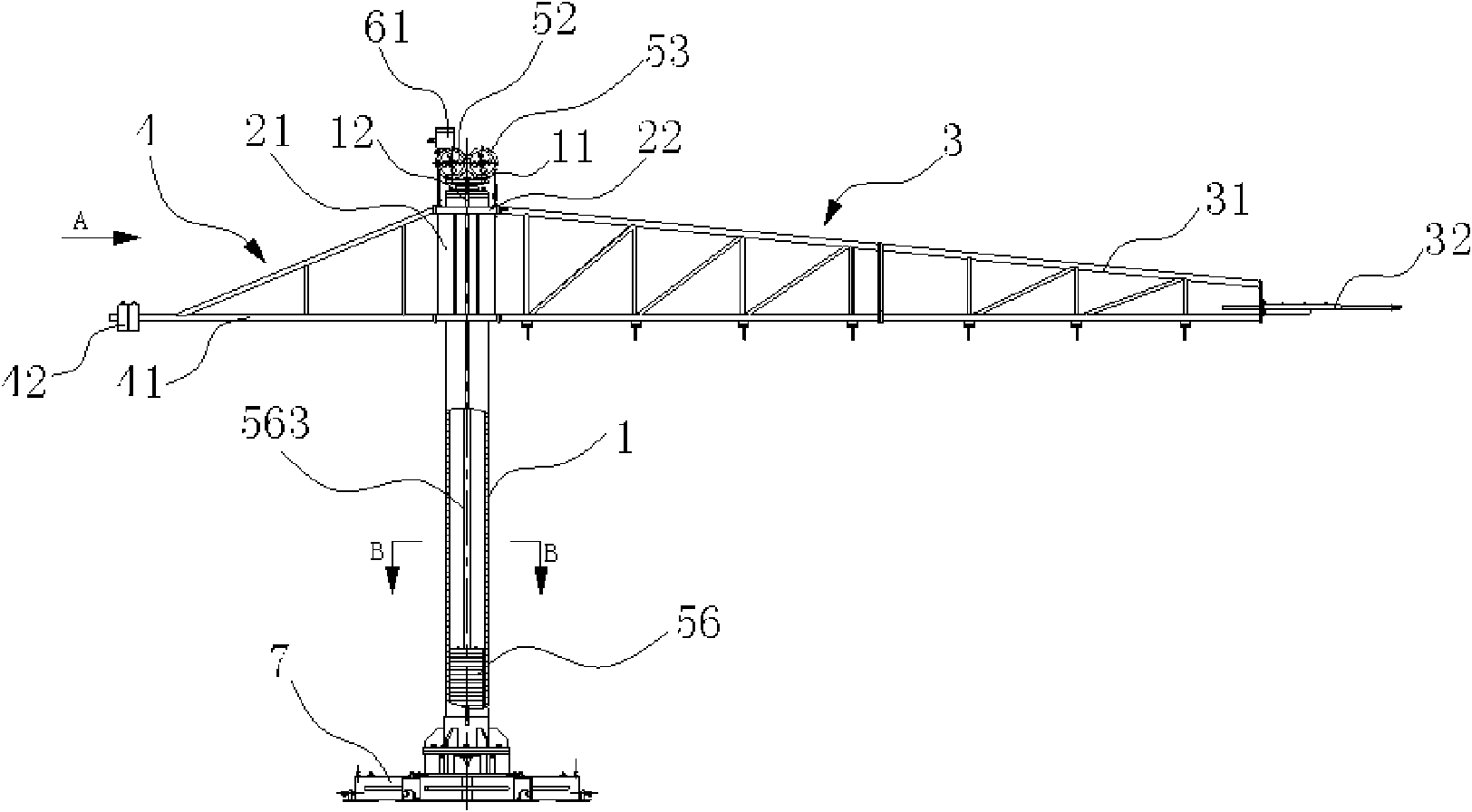

[0022] like figure 1 As shown, a stator inner cavity circle measuring device for electric lifting includes a base 7 and a central column 1 vertically fixed on the base 7 in a tubular structure. A sliding frame 2 is set on the central column 1, and a The measuring arm 3 and the balance arm 4 are respectively connected by bolts on both sides along the horizontal direction. The sliding frame 2 together with the measuring arm 3 and the balance arm 4 can rotate and slide up and down along the center column 1. The transmission mechanism connected to the device can drive the sliding frame 2 to slide up and down along the central column 1 under the drive of the driving device.

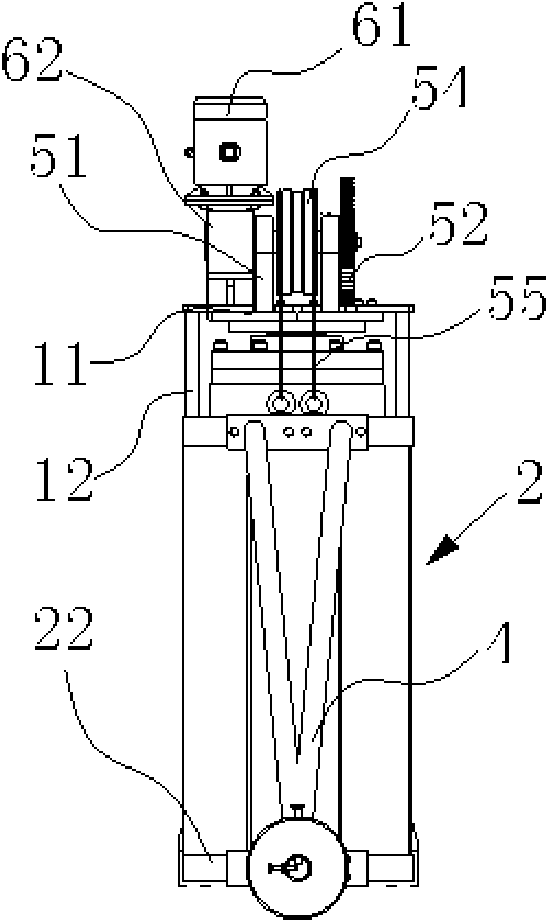

[0023] like figure 2 As shown, a top plate 11 is coaxially connected to the upper end of the central column 1 through an axial thrust bearing, and the driving device and transmission mechanism are installed on the top plate 11. The driving device includes a motor 61 and a reducer 62 connected with the motor ...

Embodiment 2

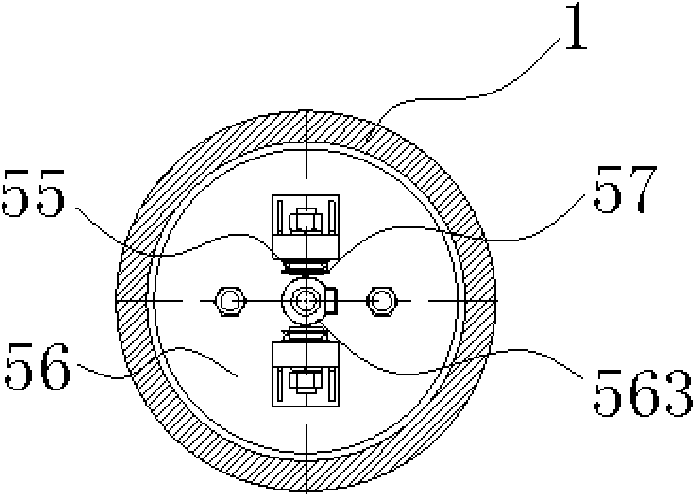

[0028] like Figure 4 As shown, a sprocket 58 is respectively set on the rotating shafts of the driving gear 52 and the driven gear 53 between the two support plates 51, and the two sprockets 58 are relatively arranged in the same vertical plane, corresponding between the two rotating shafts. A counterweight 56 is housed in the cavity of the tubular central column 1 below the sprocket 58. On both sides of the two rotating shafts, a sliding frame 2 is set on the tubular central column 1 corresponding to the sprocket 58 below. A chain 59 is respectively installed on the 58, and the inner end of the corresponding chain 59 is hingedly connected with the counterweight 56 end face downwards, and the outer end is hingedly connected with the sliding frame 2 downwards, and the counterweight 56 and the sliding frame 2 are suspended by the chain 59. On both sides of the sprocket 58, the chains 59 are symmetrically distributed on the end face of the sliding frame 2, and the remainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com