Method for manufacturing plane type stator and rotor and motor

A planar, stator technology, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of constructing stator and rotor, unable to use silicon steel punching structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention are described below with reference to the accompanying drawings.

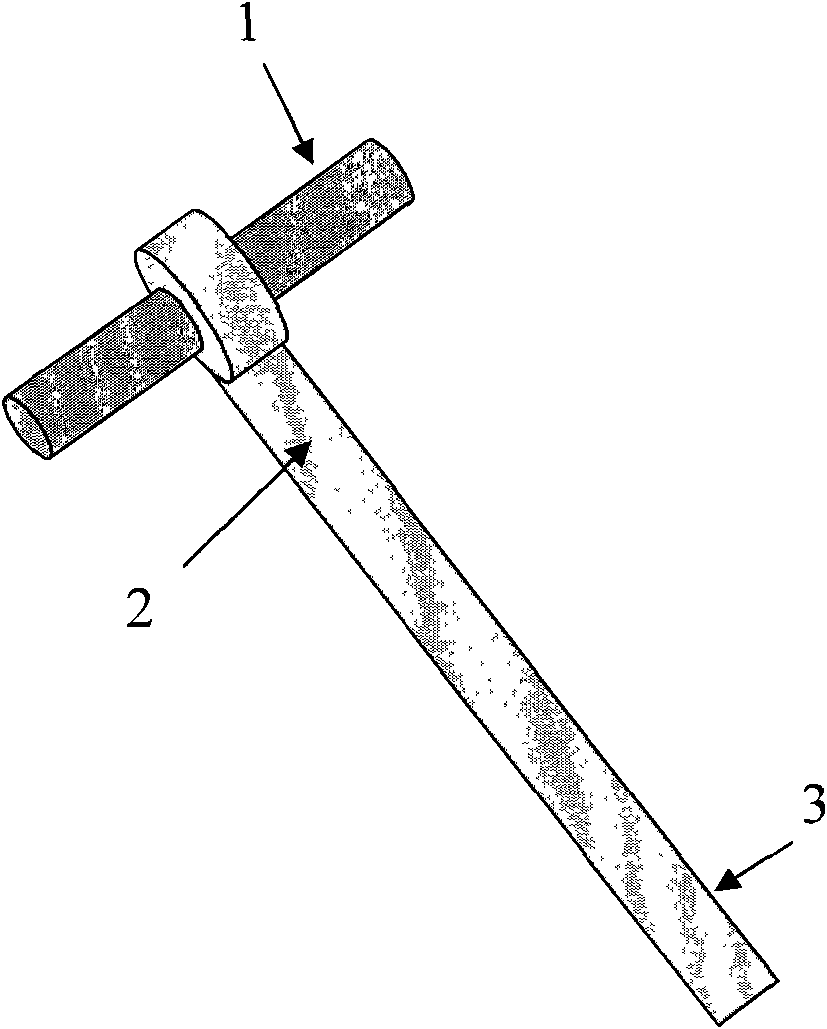

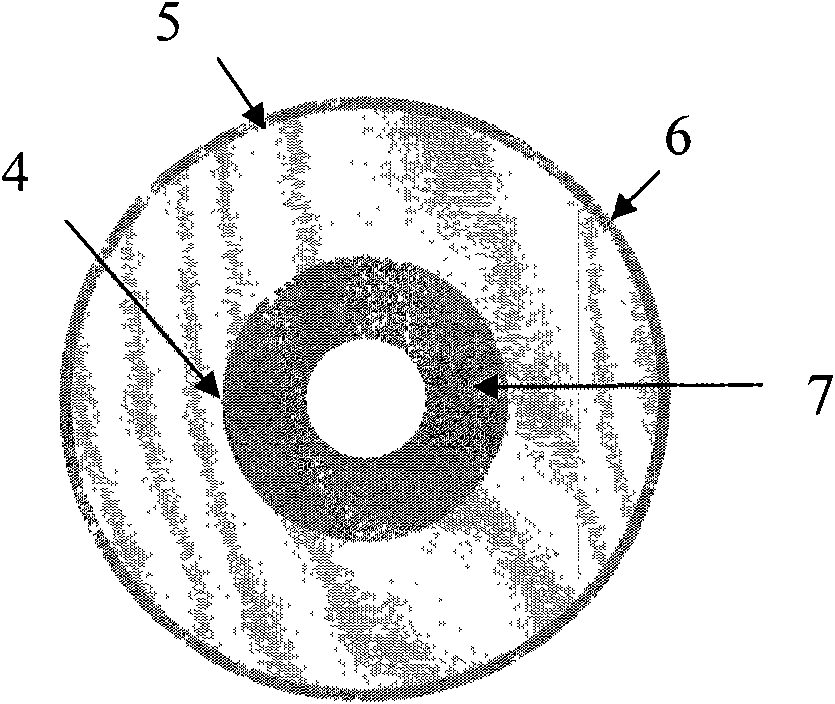

[0023] Such as figure 1 As shown, in the process of manufacturing the stator or rotor, firstly, the silicon steel plate (or other soft magnetic materials, such as pure iron, etc.) is cut into long strip-shaped materials, namely figure 1 Silicon steel strip 3 shown. One end of the silicon steel strip 3 is fixed on the cylindrical mold frame 1, and then it is tightly wound on the mold frame 1 layer by layer. The shape of the wound silicon steel strip is like a coiled spring. Preferably, the adhesive 2 is applied on the silicon steel strip 3 during the winding process to ensure effective bonding between the layers. Clamp it with a jig after winding, and remove the jig and the mold frame 1 in the middle after the adhesive is completely cured to obtain a hollow silicon steel disc. Then through mechanical processing methods such as grinding and cutting, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com