Multi-tube bundling type vortex tube cold and hot separator device

A cold and hot separation, vortex tube technology, applied in the direction of refrigerators, refrigeration and liquefaction, machine operation, etc., can solve the problem that the cooling capacity is difficult to meet the use requirements, the cooling capacity of a single vortex tube is small, and the separation of cold and heat is not very good and other problems, to achieve the effect of improving cooling and heating efficiency, ensuring the matching accuracy, and simple and feasible structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

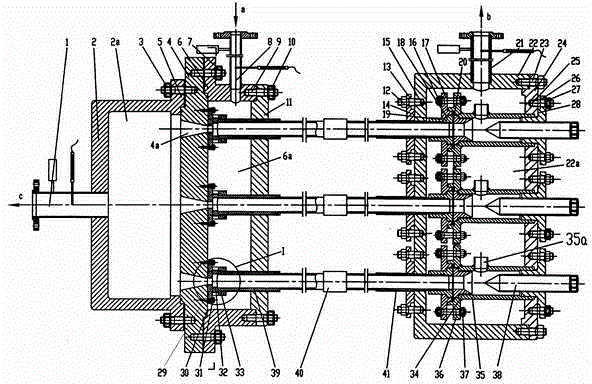

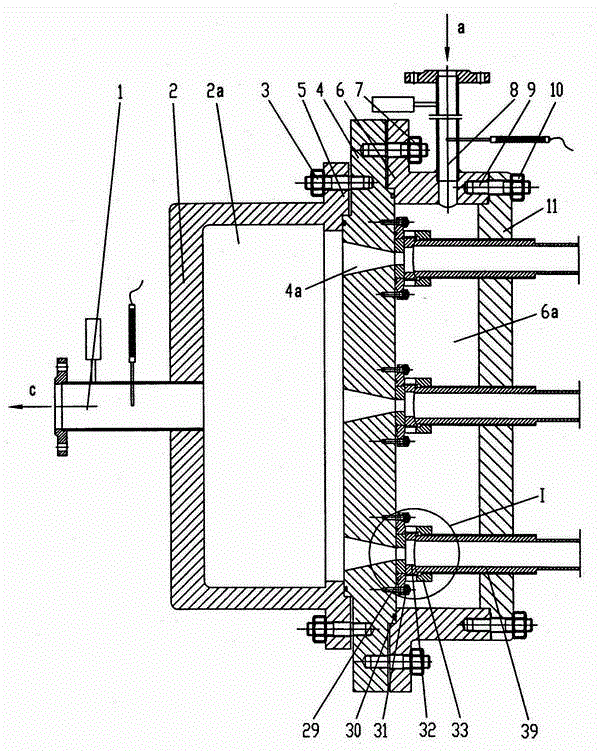

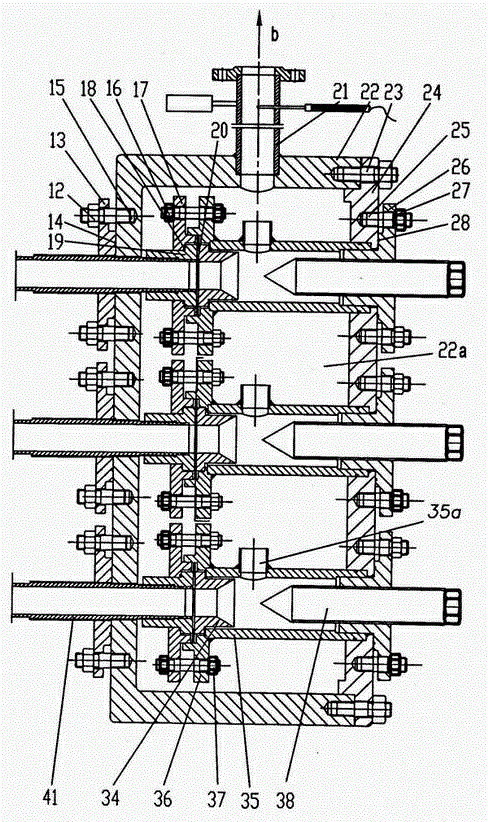

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

[0035] figure 1 , 2 , 3 shows the structure of a multi-tube bundled vortex tube cold and hot separation device. In the figure, a multi-tube bundled vortex tube cooling and heat separation device includes multiple single-tube vortex tube refrigerators, and it also includes a cold air collection chamber 2 , an air inlet chamber 6 and a hot end collection chamber 22 . The intake cavity 6 is fixedly connected with the diffuser plate 4 and the intake cavity cover 11 to form an intake cavity 6a, and the cold air collection cavity 2 is fixedly connected with the diffuser plate 4 to form a cold air collection cavity 2a. The hot end collection cavity 22 is fixedly connected with the hot end cover 24 to form a hot end collection cavity 22a.

[0036]The vortex tube cold and heat separation device adopts a multi-tube cluster structure. 2-50 vortex tube refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com