Elastic member guide device and method of manufacturing disposable wearing article

A technology of elastic components and guiding devices, which is applied in the direction of textiles and papermaking, fabric elongation, clothing, etc., and can solve problems such as limited range, no specific reference to guides, widening of fixed position intervals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

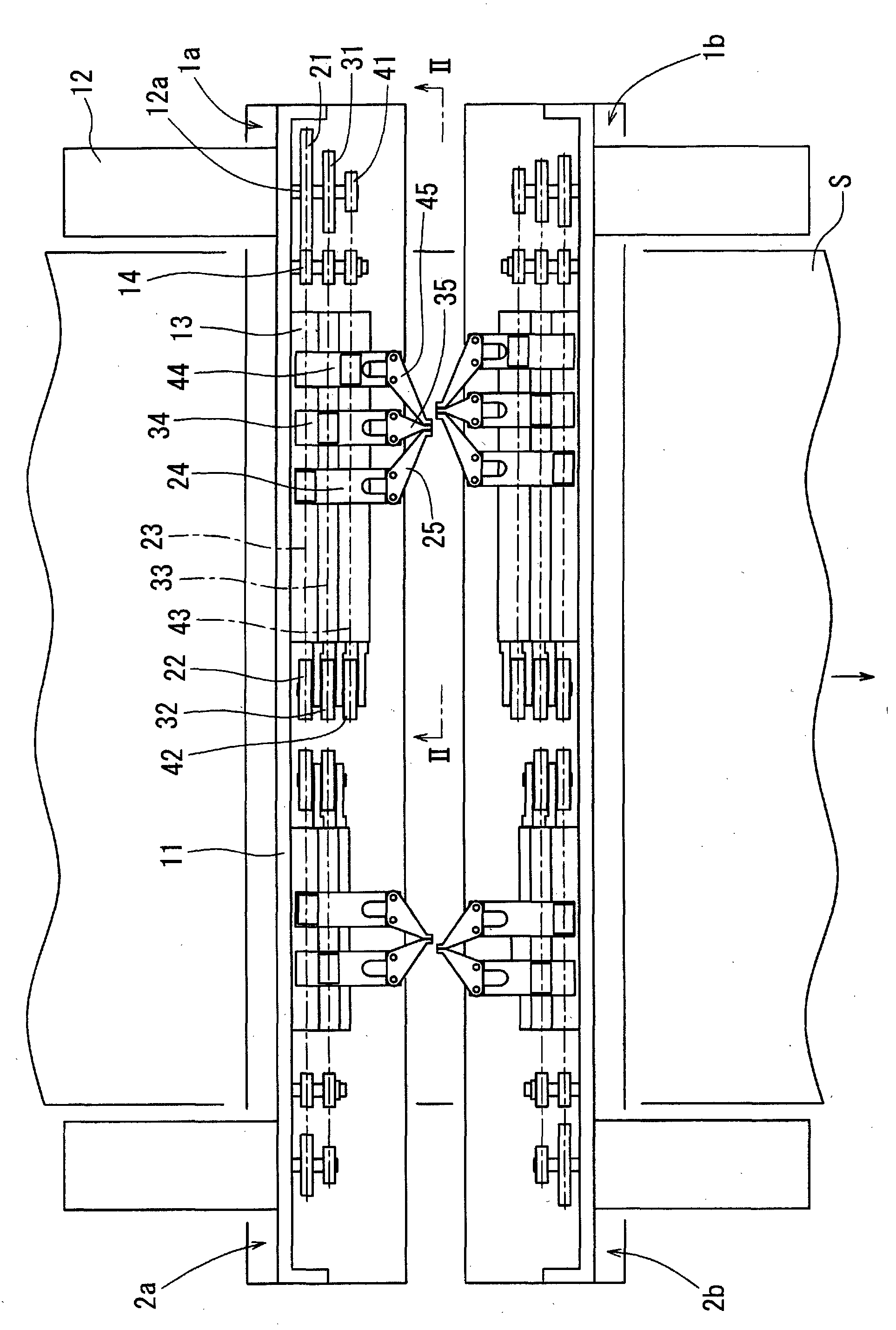

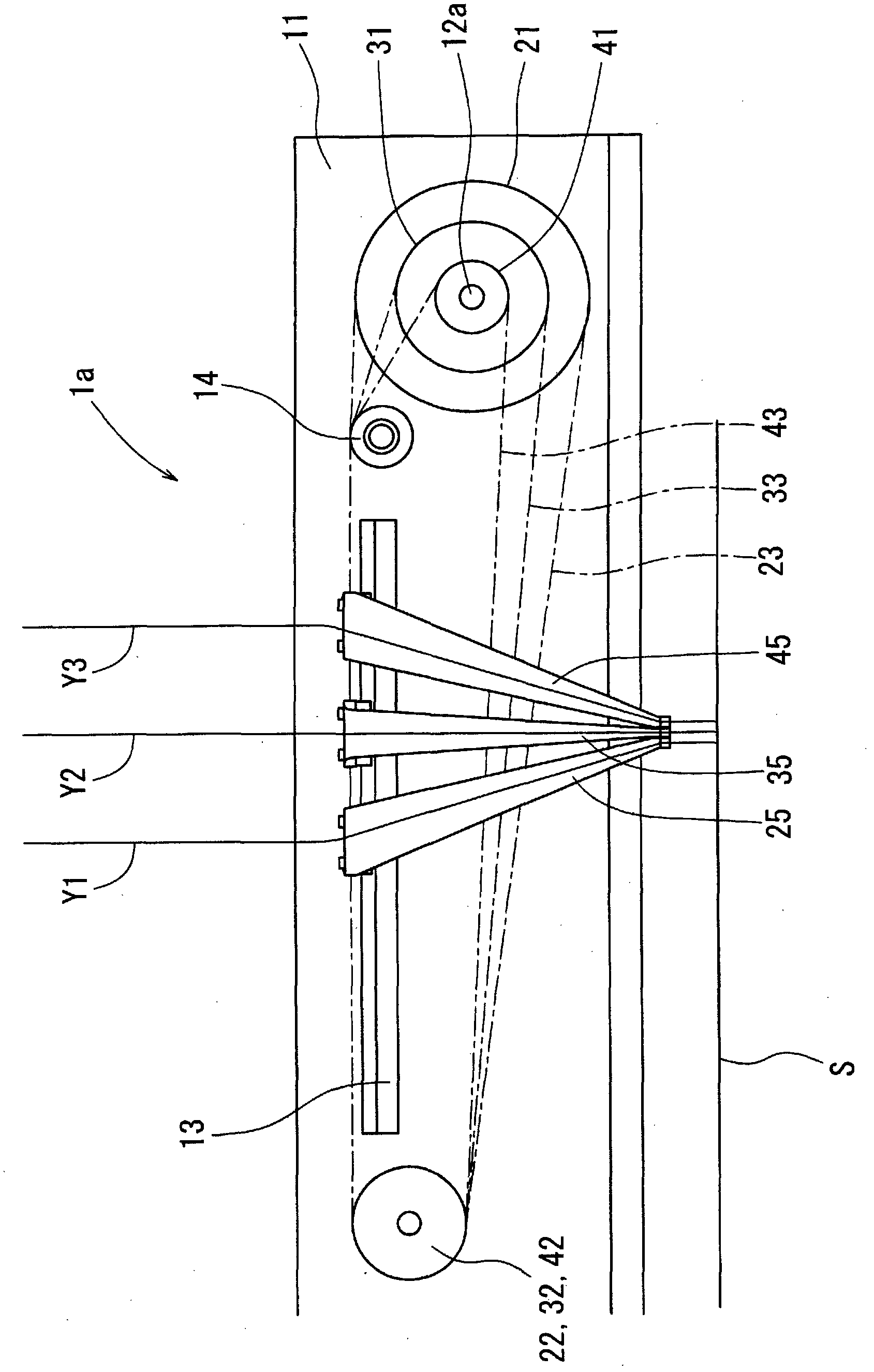

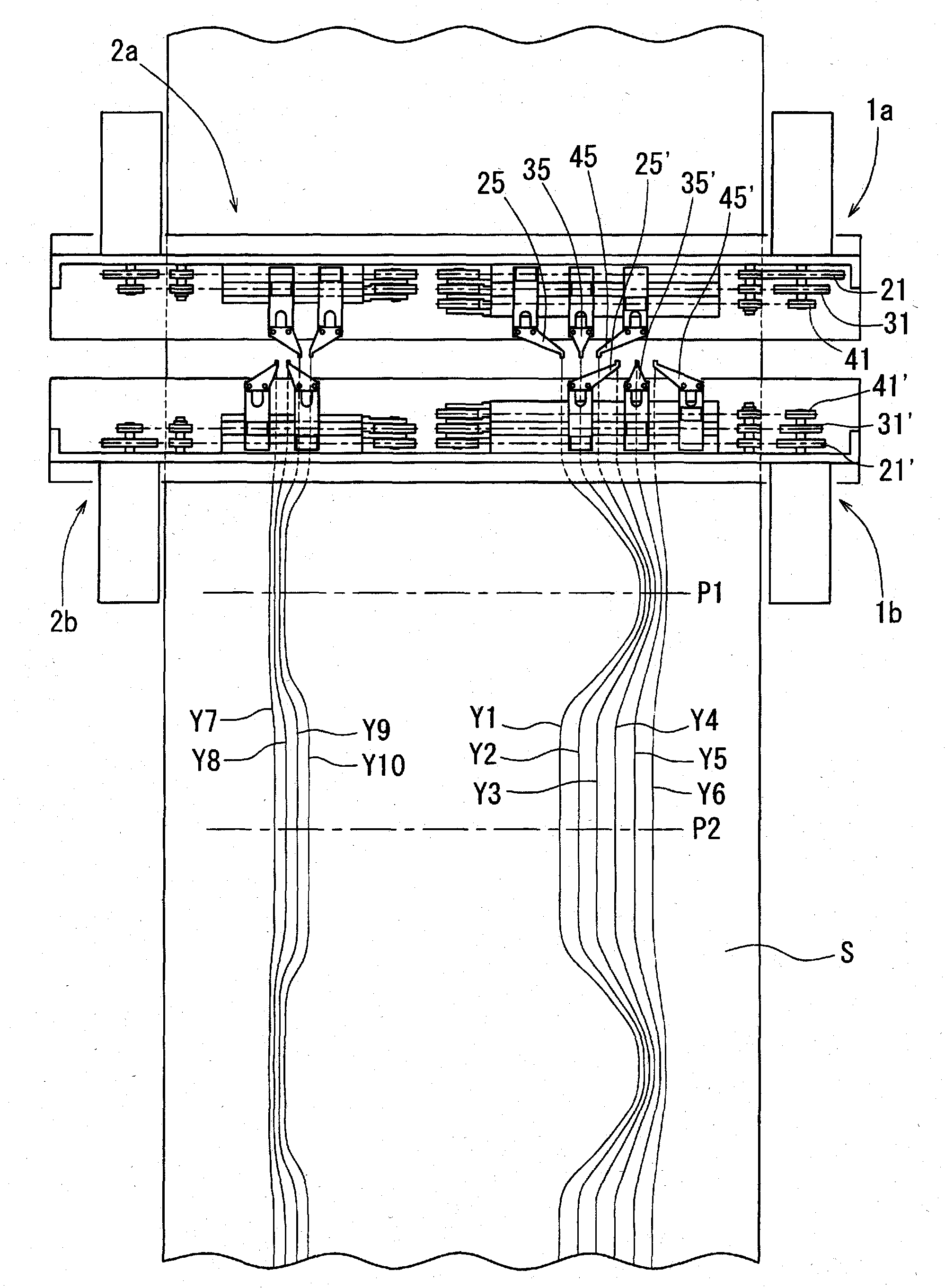

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0036] Such as figure 1 , figure 2 As shown, the elastic member guiding device 1a related to the embodiment includes: a machine frame 11 of a conveying production line spanning one side S of the fabric; a plurality of pulleys 21, 31, 41 are arranged concentrically in the direction of the central axis of rotation and are detachable. The driving shaft 12a of the drive shaft 12a; the driving part 12 that controls the positive and negative rotation of the driving shaft 12a; the driven pulleys 22, 32, 42 that are arranged in a one-to-one correspondence with the pulleys 21, 31, 41; The drive belt 23,33,43 on the pair; The guider detachable part 24,34,44 that is arranged on each drive belt 23,33,43; Guides 25, 35, 45. The conveying direction of the fabric is the direction in which the fabric moves from the upstream direction to the downstream direction. figure 1 Indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com