Steam burn prevention device of transverse exhaust pressure cooker

A pressure cooker, horizontal technology, applied in pressure cookers and other directions, can solve the problems of inconvenient scrubbing, inconvenient use, people burns, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

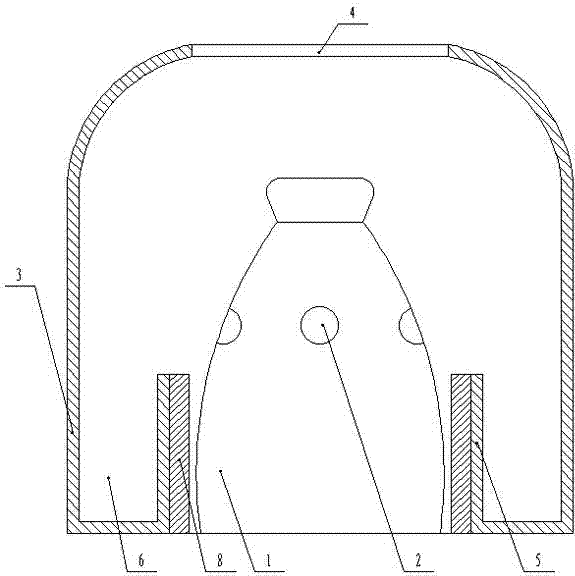

[0019] Such as figure 1 As shown, the horizontal exhaust pressure cooker anti-steam burner includes a splash guard 3, the height of the splash guard 3 is greater than the height of the pressure cooker nozzle 1, and the upper part of the splash guard 3 is in the shape of a truncated cone with a small upper part and a larger lower part. The top of the splash cover 3 is provided with an air outlet 4, and the bottom of the splash cover 3 is provided with an annular baffle 5, and the baffle 5 and the inner wall of the splash cover 3 form an annular water receiving tank 6, and the baffle 5 reaches the pot The distance of the cover is less than the distance of the horizontal air vent 2 on the pressure cooker from the pot cover.

[0020] Preferably, an annular elastic bushing 8 is also provided on the inner ring of the baffle plate 5 , and the diameter of the elastic bushing 8 is 2-3 mm larger than the maximum diameter of the nozzle 1 of the pressure cooker.

[0021] When in use, cov...

Embodiment 2

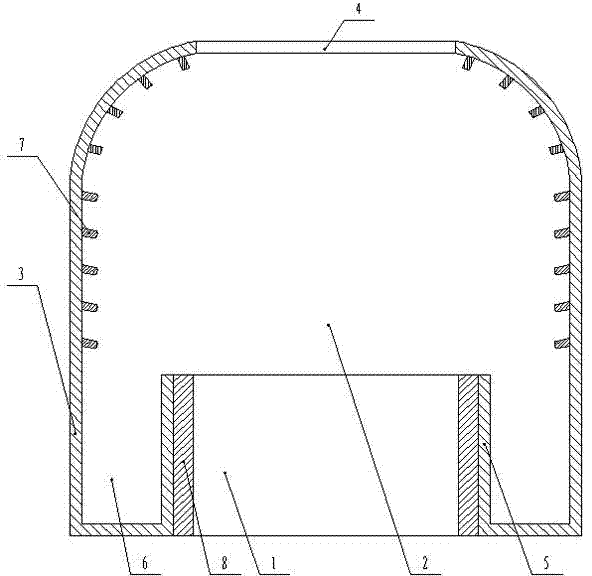

[0023] Such as figure 2 As shown, the horizontal exhaust pressure cooker anti-steam burner includes a splash guard 3, the height of the splash guard 3 is greater than the height of the pressure cooker nozzle 1, and the upper part of the splash guard 3 is in the shape of a truncated cone with a small upper part and a larger lower part. The top of the splash cover 3 is provided with an air outlet 4, and the bottom of the splash cover 3 is provided with an annular baffle 5, and the baffle 5 and the inner wall of the splash cover 3 form an annular water receiving tank 6, and the baffle 5 reaches the pot The distance of the cover is less than the distance of the horizontal air vent 2 on the pressure cooker from the pot cover.

[0024] Preferably, a plurality of condensation plates 7 are arranged at intervals on the inner wall of the splash guard 3 above the baffle plate 5, and the condensation plates 7 are arranged obliquely downward on the inner wall of the splash guard 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com